Corner terminal of storage battery

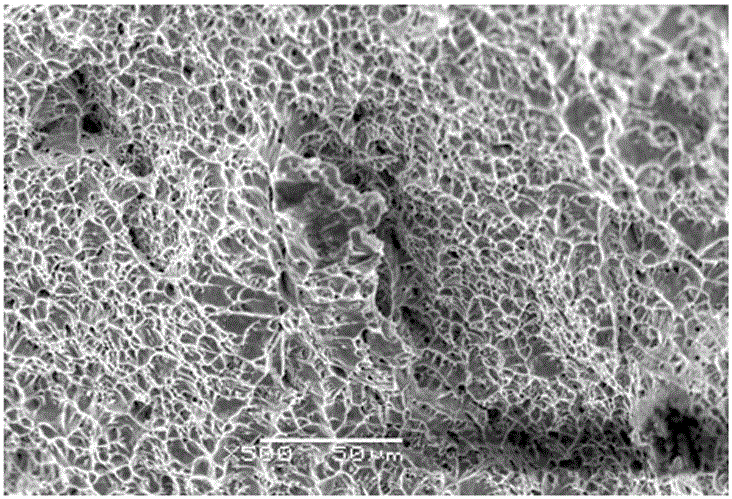

A technology of angle terminals and storage batteries, which is applied to battery pack components, battery boxes/coats, small-sized batteries/battery packs, etc., can solve problems such as difficult one-time molding, poor fluidity of lead blanks, and insufficient density, and achieve The internal section has no air bubbles, the structure of the parts is dense, and the inner and outer surfaces are smooth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

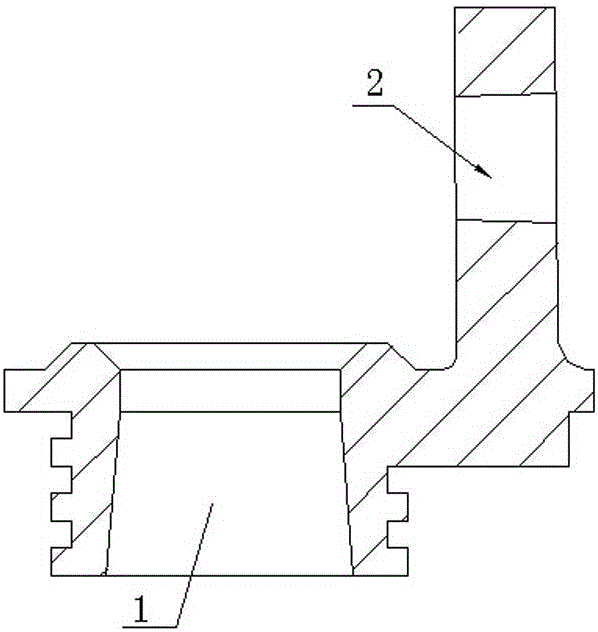

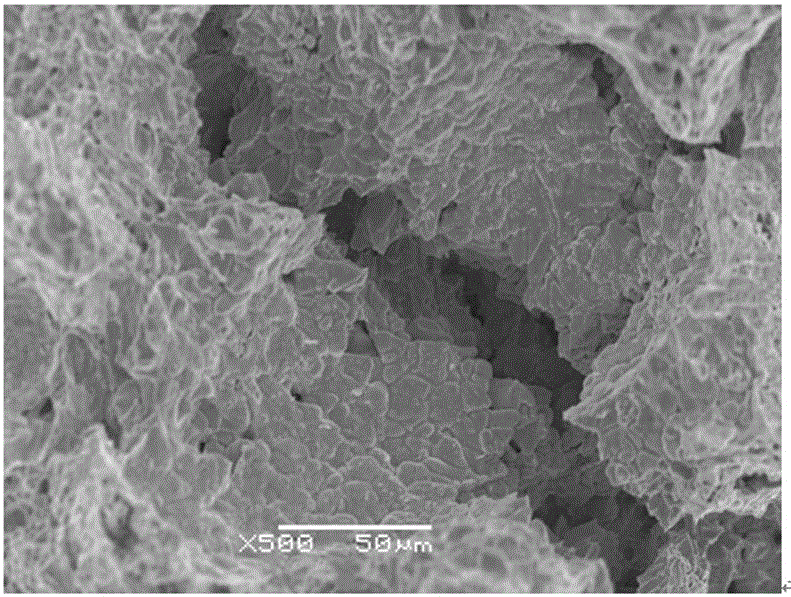

[0014] The present invention as figure 1 , 3 As shown, the schematic diagram of metallographic structure analysis after cold extrusion of extrusion die.

[0015] First the lead alloy is melted in a melting furnace.

[0016] 2 Match the shape and size of the blank according to the amount of extrusion, make a mold and pour it into a blank.

[0017] 3. Put the blank into the extrusion die, and extrude the product by cold pressing at one time. The pressure of the extrusion die is 63T-100T.

[0018] 4 Make tooling, trim product extrusion burrs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com