Process for preparing pipe by punching high temperature alloy bar

A technology for superalloys and pipes, applied in temperature control, metal rolling, etc., can solve problems such as low production efficiency and material waste, and achieve the effects of high work efficiency, wide application range and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A GH4145 superalloy pipe with an outer diameter of 30 mm and a wall thickness of 4 mm was prepared.

[0041] (1) Forging to produce billet: the GH4145 superalloy ingot prepared by vacuum melting method is forged and opened at 900°C to make a billet with a diameter of Φ40mm and the surface is polished;

[0042] (2) On-line induction heating of the billet: induction heating of the GH4145 superalloy billet with a diameter of Φ40mm, the heating temperature is 1000°C, and the heating time is 10 minutes;

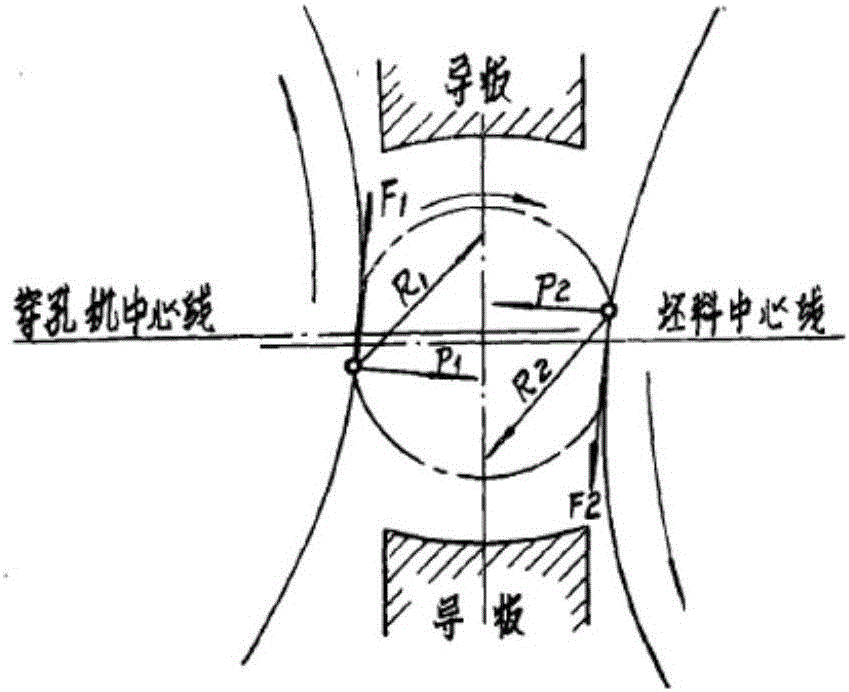

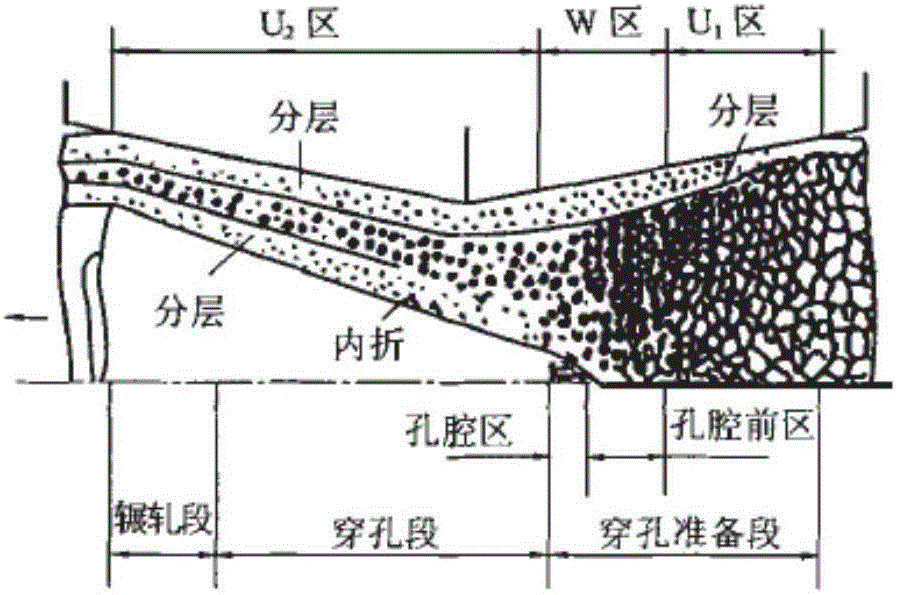

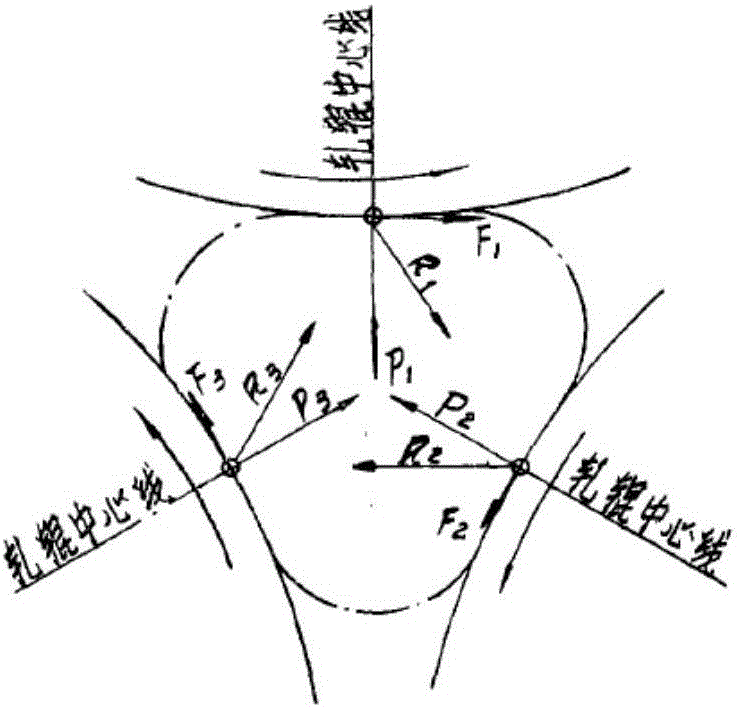

[0043] (3) The front end of the three-roll planetary rolling mill is equipped with a perforated plug for billet rolling and piercing: the three-roll planetary rolling mill is used to roll the billet after induction heating, and the perforated plug is arranged at the front end of the planetary rolling mill roll to directly pass the GH4145 superalloy rod The billet is pierced into a pipe during rolling, the diameter of the piercing plug is 20mm, and the length of the piercing...

Embodiment 2

[0045] A GH5188 superalloy pipe with an outer diameter of 45 mm and a wall thickness of 7 mm was prepared.

[0046] (1) Forging to produce billet: the GH5188 superalloy ingot prepared by vacuum melting method is forged and opened at 1150°C to make a billet with a diameter of Φ60mm and the surface is polished;

[0047] (2) On-line induction heating of the billet: induction heating of the GH5188 superalloy billet with a diameter of Φ60mm, the heating temperature is 1200°C, and the heating time is 30 minutes;

[0048] (3) The front end of the three-roll planetary rolling mill is equipped with a perforated plug for billet rolling and piercing: the three-roll planetary rolling mill is used to roll the billet after induction heating, and the perforated plug is arranged at the front end of the planetary rolling mill roll to directly pass the GH5188 superalloy rod The billet is pierced into a pipe during rolling, the diameter of the piercing plug is 30mm, and the length of the piercin...

Embodiment 3

[0050] A Hastelloy C-276 superalloy pipe with an outer diameter of 60 mm and a wall thickness of 10 mm was prepared.

[0051] (1) Forging to produce billet: the Hastelloy C-276 superalloy ingot prepared by vacuum melting method is forged and opened at 1200°C to make a billet with a diameter of Φ80mm and the surface is polished;

[0052] (2) On-line induction heating of billets: induction heating of Hastelloy C-276 superalloy billets with a diameter of Φ80mm, the heating temperature is 1300°C, and the heating time is 60 minutes;

[0053] (3) The front end of the three-roll planetary rolling mill is equipped with a perforated plug for billet rolling and piercing: the three-roll planetary rolling mill is used to roll the billet after induction heating, and the perforated plug is arranged at the front end of the planetary rolling mill roll, and the Hastelloy C-276 The high-temperature alloy billet is pierced into a pipe during rolling. The diameter of the piercing plug is 40mm, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com