Cladding device used for multilayer composite braided fiber ringlike bands

A woven fiber, multi-layer composite technology, applied in the field of machinery, can solve the problems of no product thickness adjustment function, unreasonable structural design, and wrinkles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing.

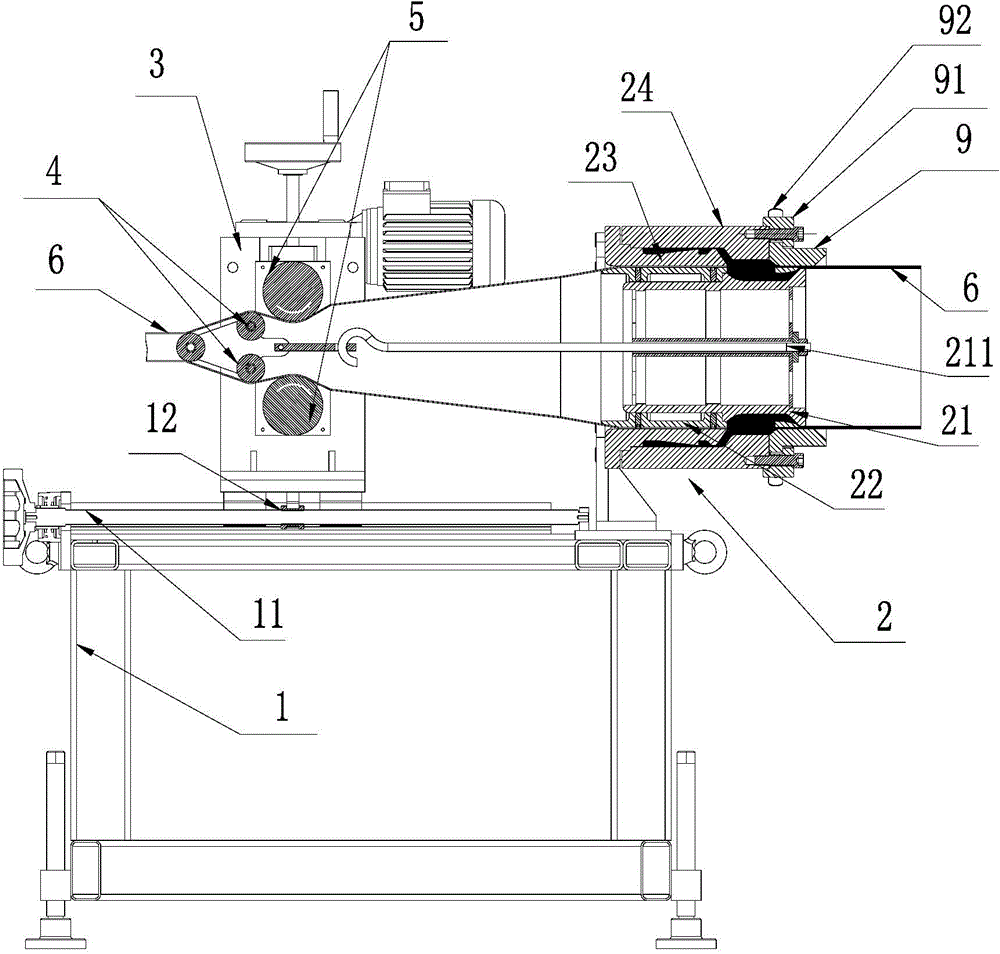

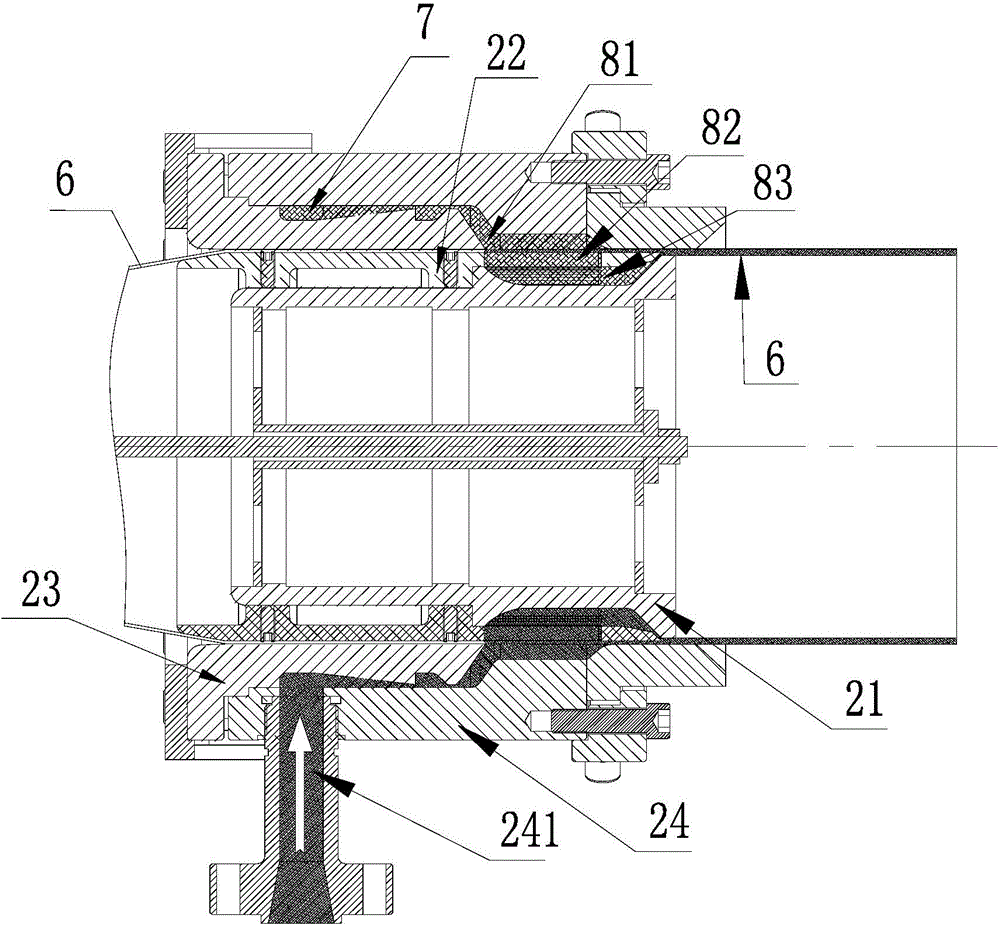

[0037] see figure 1 and figure 2 , the present invention is used for the cladding device of multi-layer composite braided fiber endless belt, comprises frame 1, cladding mold 2, tension dragging frame 3, torpedo head shunting shuttle 4 and a pair of dragging and conveying rollers 5. The cladding mold 2 includes an inner molten pool mandrel 21 , an inner and outer shunt sleeve 22 , an outer mandrel 23 and a cladding mold body 24 .

[0038] Overmold 2 is fixed on one side of machine frame 1 . The tension drag frame 3 is slidably arranged on the frame 1 facing the covering mold 2 . Specifically, the frame 1 is provided with a longitudinal adjustment screw 11 facing the covering mold 2, and the longitudinal adjustment screw 11 is provided with a sliding nut 12 that moves longitudinally with the rotation of the screw, and the tension drag frame 3 is fixed on the On the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com