Special-shaped wire sheath for optical fiber unit in special optical cable

An optical fiber unit and optical cable technology, applied in the field of special-shaped wire sheath, can solve the problems of deformation of the protective tube of the optical fiber unit, increased optical fiber transmission loss, large diameter of the optical cable cross-section, etc. Powerful, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

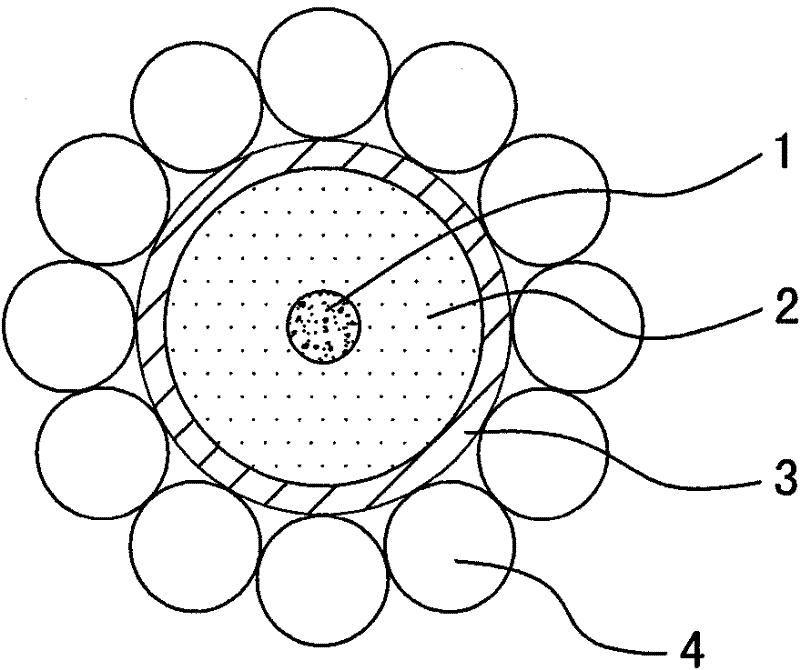

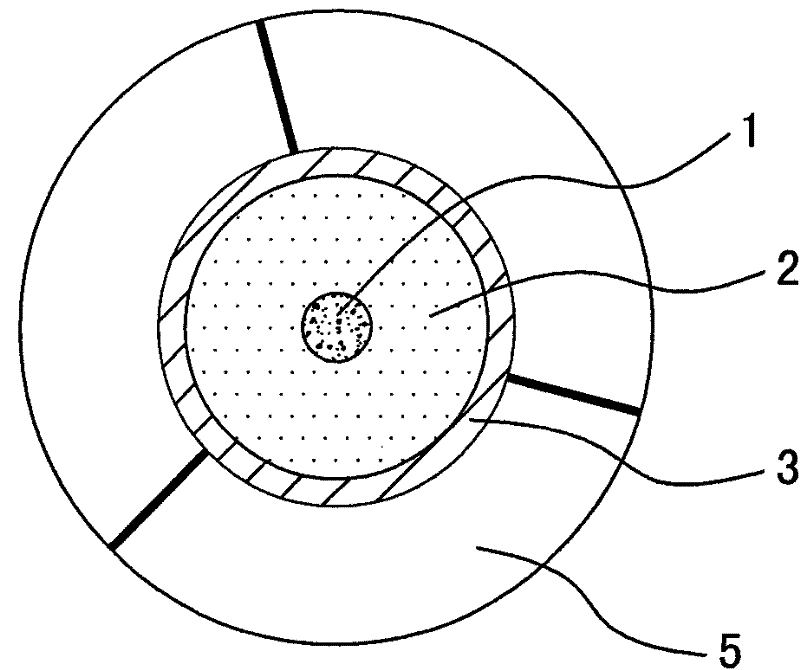

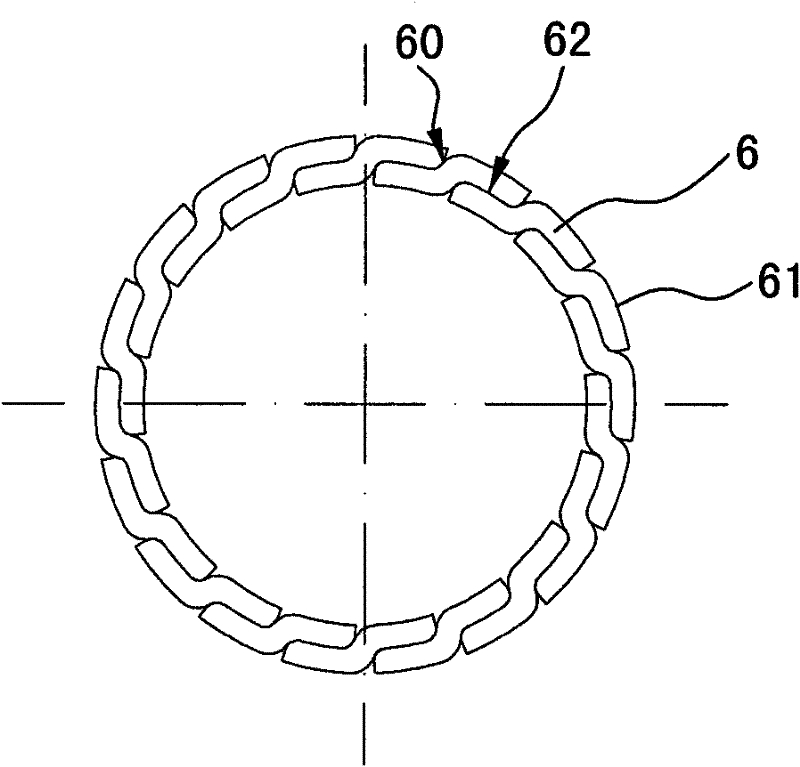

[0015] The invention relates to a special-shaped wire sheath of an optical fiber unit in a special optical cable, such as Figure 3-Figure 6 As shown, it includes special-shaped wires made of metal materials, and the special-shaped wires are arranged into a circular sheath, and the optical fiber unit is protected in the circular sheath. The optical fiber unit is as follows figure 1 , figure 2 As shown, it consists of an optical fiber 1, a water-blocking ointment 2 and a protective tube 3, and is characterized in that the special-shaped wire is a metal sheet 6, and there is an overlapping part between the former metal sheet and the latter metal sheet through mutual The cross section is overlapped to form a circular tube, and it is twisted in a helical shape. Each metal sheet material 6 of this scheme has partial overlapping overlapping arrangement, and the gap between each other is small, and the lateral pressure resistance strength is high, and at the same time compared with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com