Hot-rolling perforation-cold-rolling forming method for hollow rock-drill steel

A technology of hot-rolled piercing and cold-rolled forming, which is applied in metal rolling and other directions, can solve the problems of low service life, out-of-round inner hole, and many processes, achieve accurate shape and size, ensure inner surface quality, and have a bright future in application broad effect

Inactive Publication Date: 2006-06-21

UNIV OF SCI & TECH BEIJING +1

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The main disadvantages of this process are: many procedures, long process, out-of-round inner hole and large mandrel consumption (one mandrel can only roll one hollow drill steel)

The main disadvantage of this process is that due to the absence of the mandrel to process the surface of the inner hole and the severe torsion of the pipe during the cross-rolling extension process, cracks, wrinkles and other defects often appear on the surface of the inner hole, resulting in low service life and instability.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1

[0056] Example 1: Rolling B28 and B32 pipes with a tube billet heating furnace, Φ50 two-roll piercer, and LD-30 three-roll cold rolling mill.

example 2

[0057] Example 2: Rolling D38 and B32 pipes with tube billet heating furnace, Φ50 two-roll piercer, and LD-30 three-roll cold rolling mill.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a hot-rolled perforation-cold-rolled forming method of hollow drill steel. It is characterized in that: the hot-rolled piercing-cold-rolled forming method is used to produce B and D-type hollow drill steels, and the hot-rolled piercing Φ50 two-roll cross-rolling piercing machine rolls the round solid tube blank of Φ50~Φ65mm in a hot state. Φ50~Φ65mm, hollow capillary tube with wall thickness of 6~17mm, after cooling, it is rolled and formed on a cold rolling mill. The invention starts from the geometric characteristics of the hollow steel and realizes a specific deformation process through tool design. Compared with the existing production method, the main advantages of the present invention are: few working procedures, short flow process, good quality of inner hole, high precision of shape and size.

Description

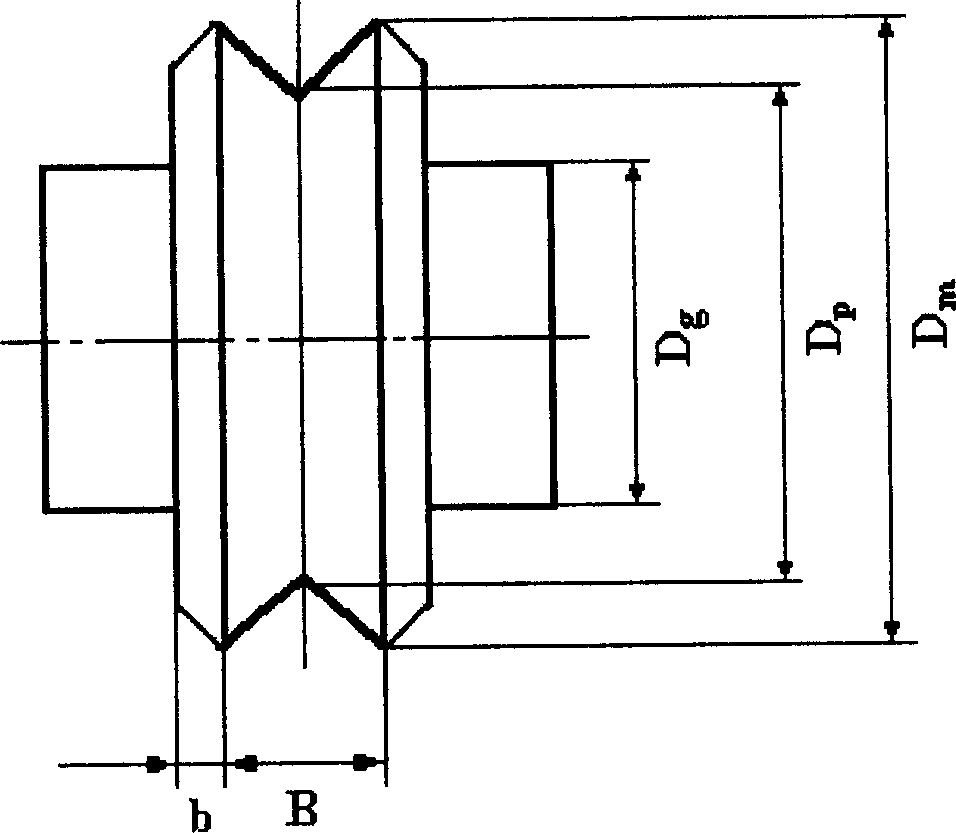

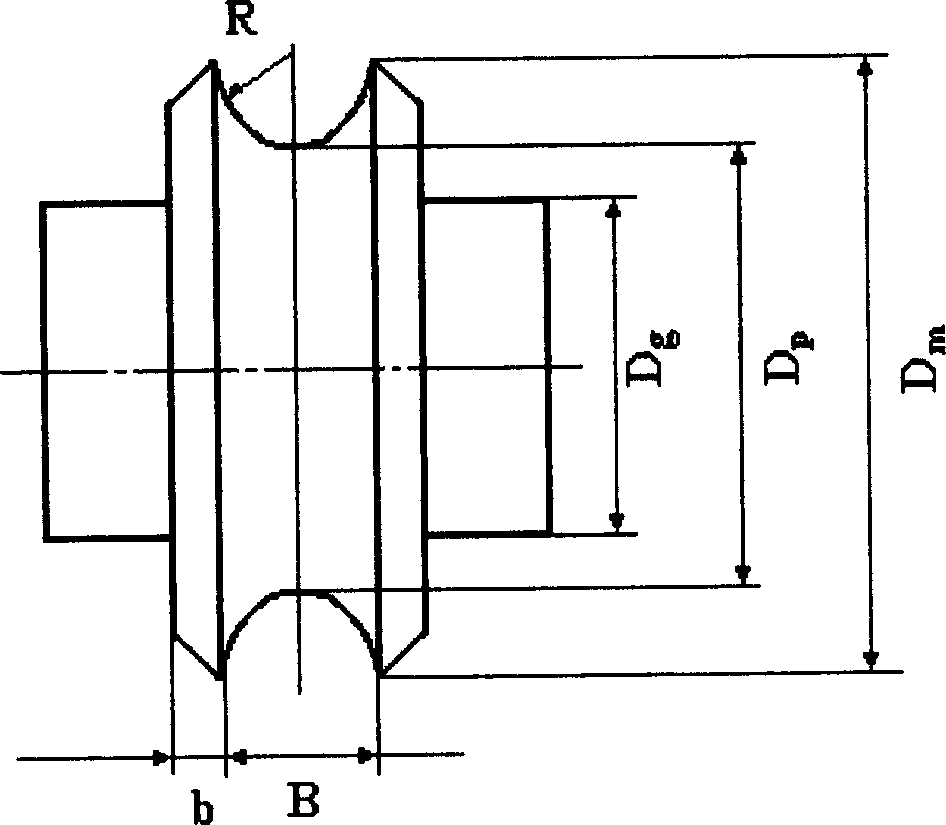

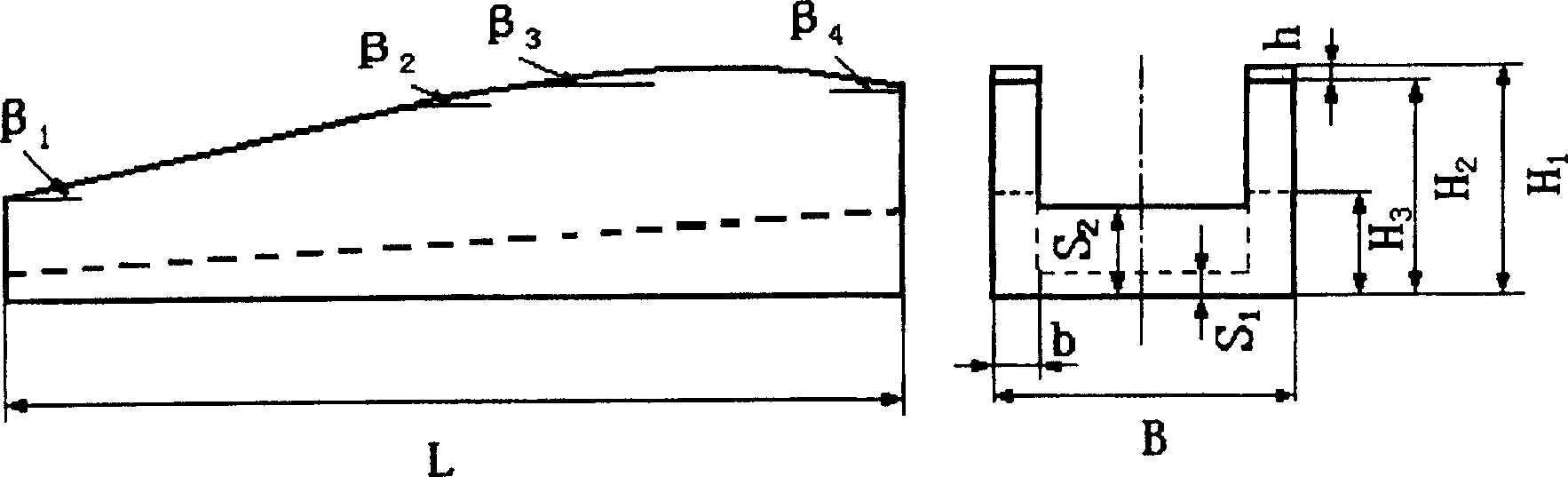

technical field [0001] The invention belongs to the technical field of metal material processing, and in particular provides a hot-rolled piercing-cold-rolled forming method for hollow drill tool steel. Background technique [0002] Hollow drill steel is the main tool used for rock drilling and drilling in mining. Commonly used specifications are hexagonal B19~B45 (the number indicates the distance between opposite sides in mm) and circular D32~D51 (the number indicates the diameter in mm), and its cross section is as follows: figure 1 As shown, the water injection hole in the center is used for water, dust removal and cooling. [0003] The geometric characteristics of hollow drill steel are: wall thickness (the ratio of wall thickness to outer diameter S / D is 1 / 3.2~1 / 3.5), small inner hole (minimum is only 5.5mm), long length (up to 6mm ). In view of the above-mentioned geometric characteristics of "like (steel) pipe but not (steel) pipe", this product can neither comple...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B21B23/00

Inventor 陈恩义付晨光石兆镛朱景清

Owner UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com