Process for preparing GH4145 alloy pipes

A technology of GH4145 and preparation process, applied in the field of preparation process of GH4145 alloy pipe, can solve the problems of cracking, low performance level and reliability, unstable quality, etc., and achieve the effect of smooth inner and outer surfaces, saving raw materials, and high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

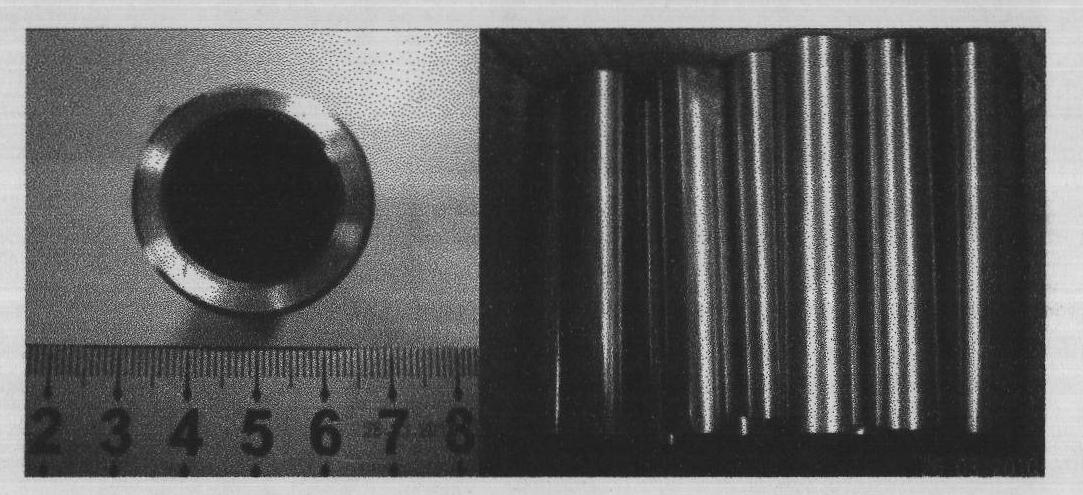

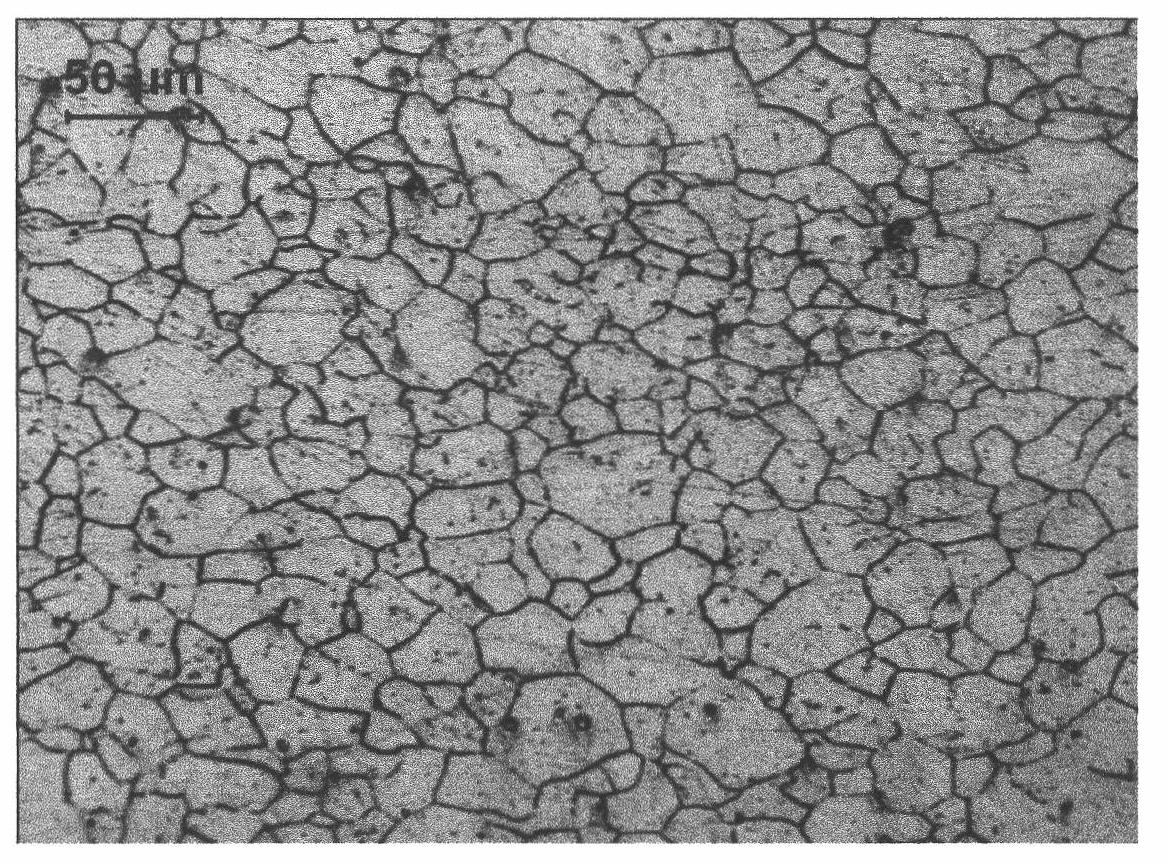

[0030] The GH4145 alloy ingot is smelted by vacuum induction and electroslag, forged at 1180℃ to form a Φ40mm round bar with a deformation of 80%, and then solution heat treated at 1020℃×30 minutes, and processed into a Φ41mm×7mm tube by machined drilling The billet is cold-rolled and annealed 5 times repeatedly, and rolled into a Φ29mm×2.5mm pipe. Finished product organization see image 3 , The rolling process parameters are shown in Table 1.

[0031] Table 1 Example 1 Rolling process parameters

[0032]

Embodiment 2

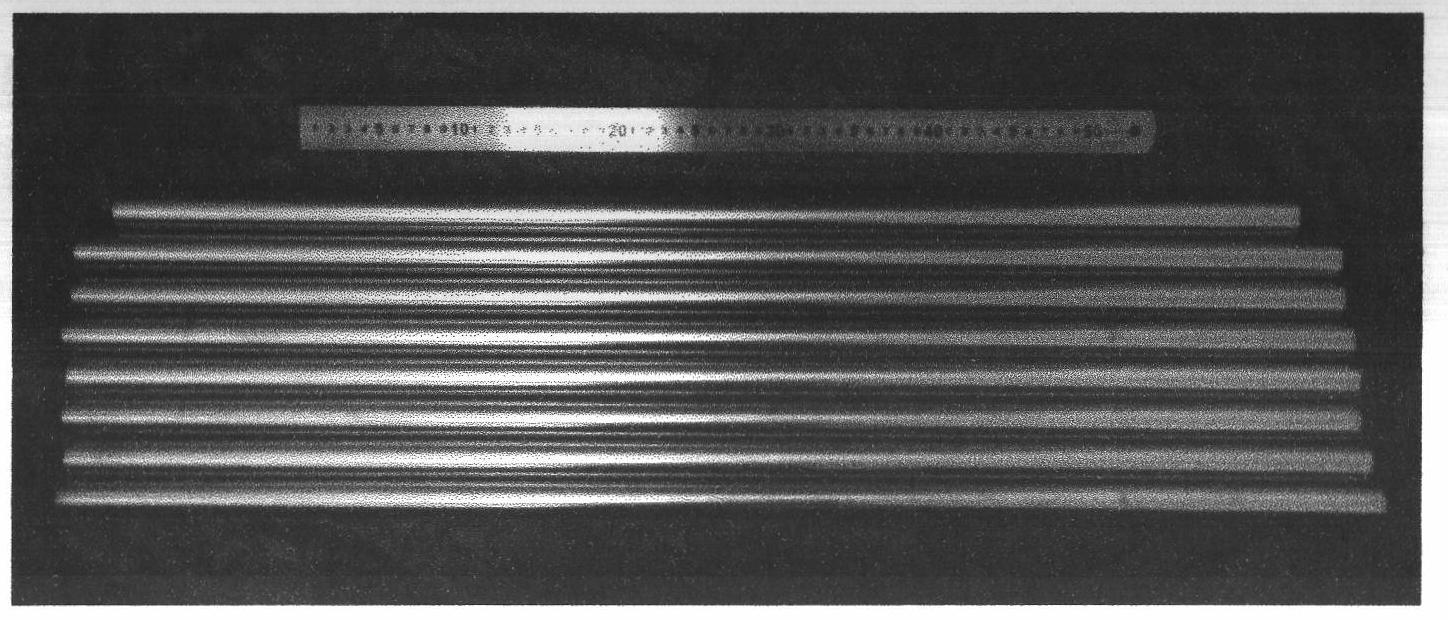

[0034] The GH4145 alloy ingot is smelted by vacuum induction and electroslag, forged at 1120℃ to form a Φ40mm round bar with a deformation of 37%, and then solution heat treated at 1000℃×30 minutes, and processed into a Φ41mm×6.5mm tube by machined drilling The tube is cold-rolled and annealed repeatedly 8 times to form a tube of Φ25mm×0.6mm. The structure is shown in Figure 4 , The rolling process parameters are shown in Table 2.

[0035] Table 2 Example 2 Rolling process parameters

[0036]

[0037]

Embodiment 3

[0039] The GH4145 alloy ingot is smelted by vacuum induction and electroslag, and forged at 1120℃ to form a Φ40mm round bar with a deformation of 37%. After solution heat treatment at 1000℃×30 minutes, it is processed into a Φ41mm×6mm tube billet by machining and drilling. , This pipe is cold-rolled and annealed repeatedly 8 times, and rolled into a Φ25.8mm×0.4mm pipe. The structure is shown in Figure 5 , The rolling process parameters are shown in Table 3.

[0040] Table 3 Example 3 Rolling process parameters

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com