Patents

Literature

49results about How to "Guaranteed cross-sectional area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

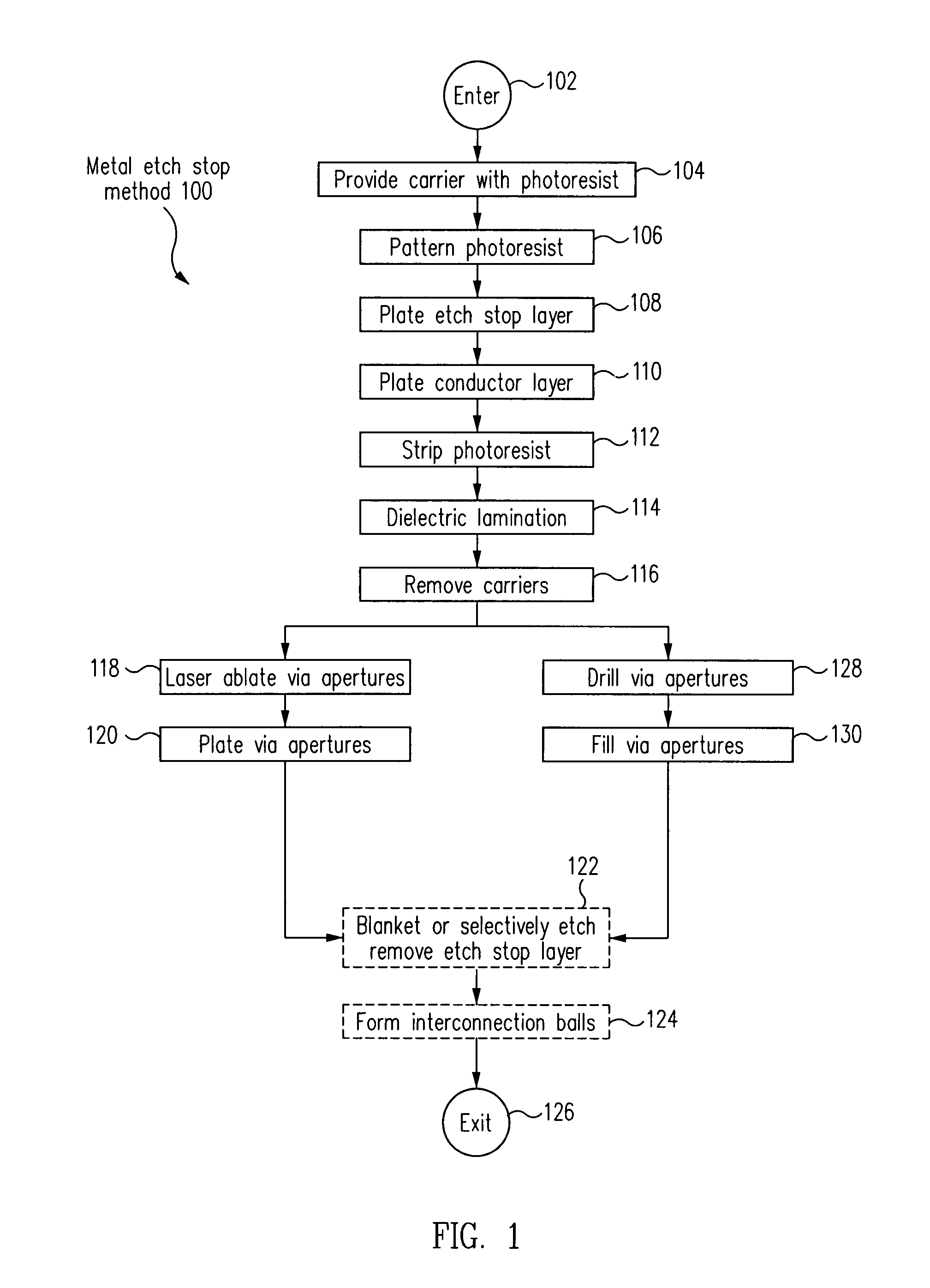

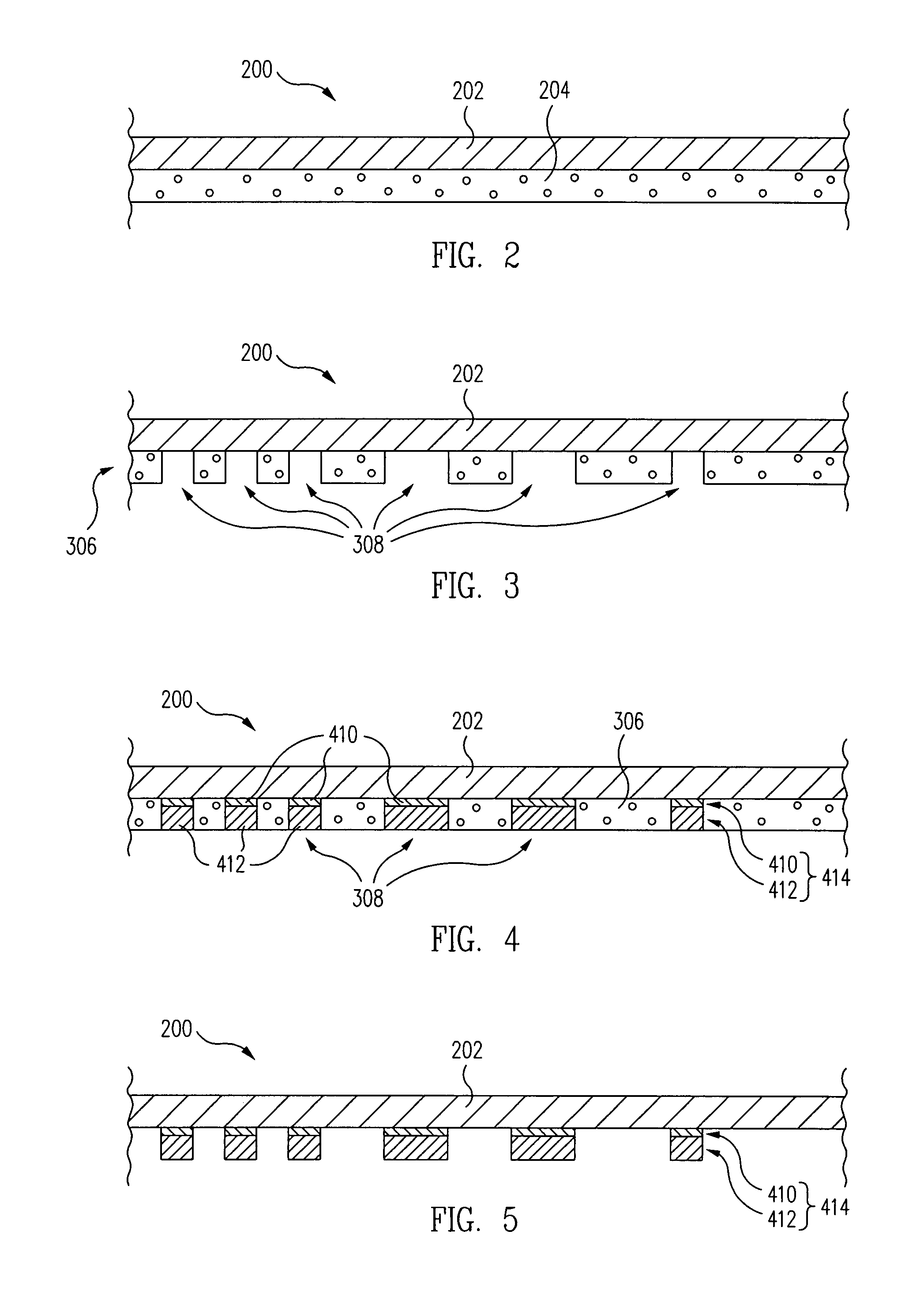

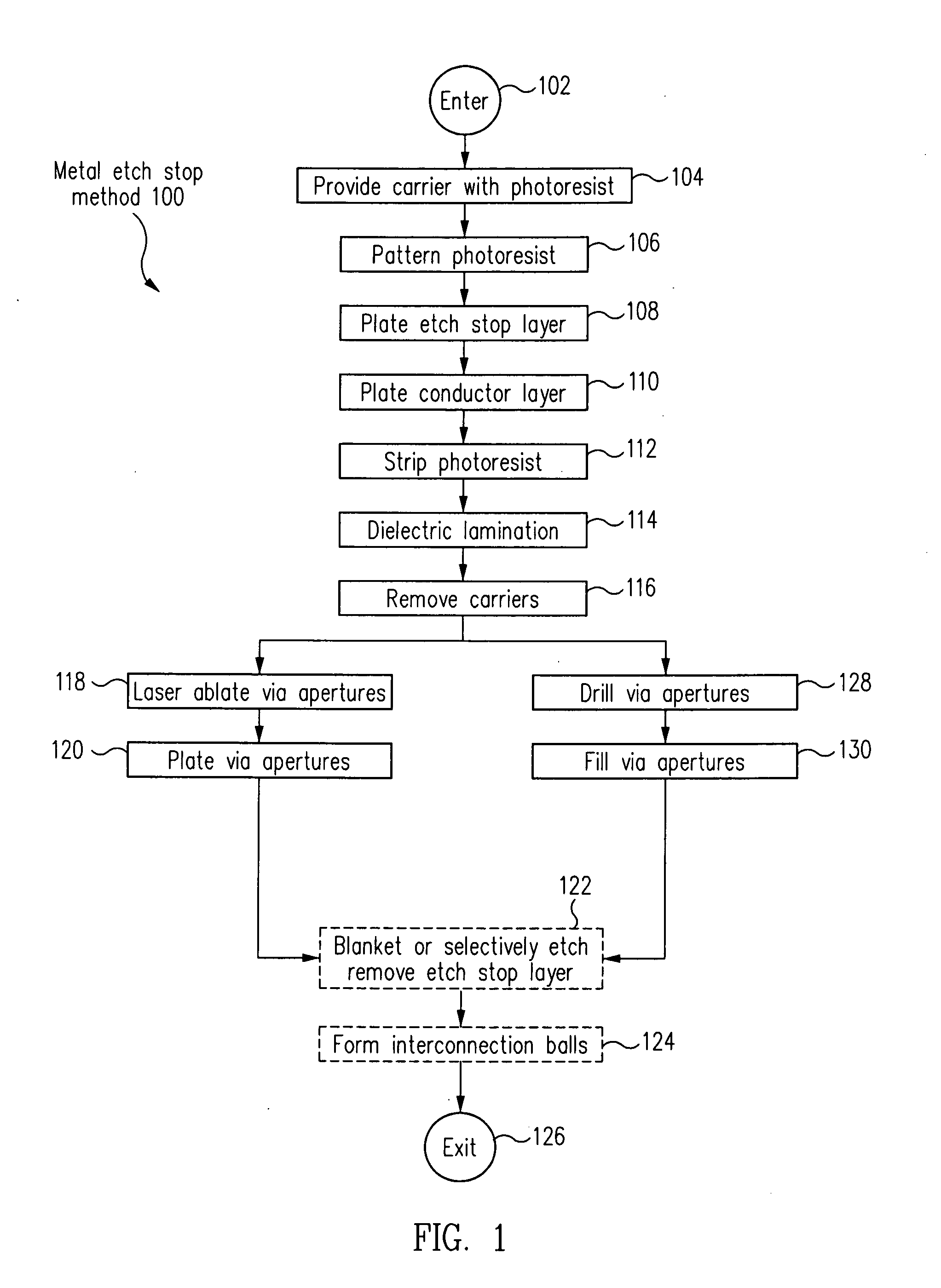

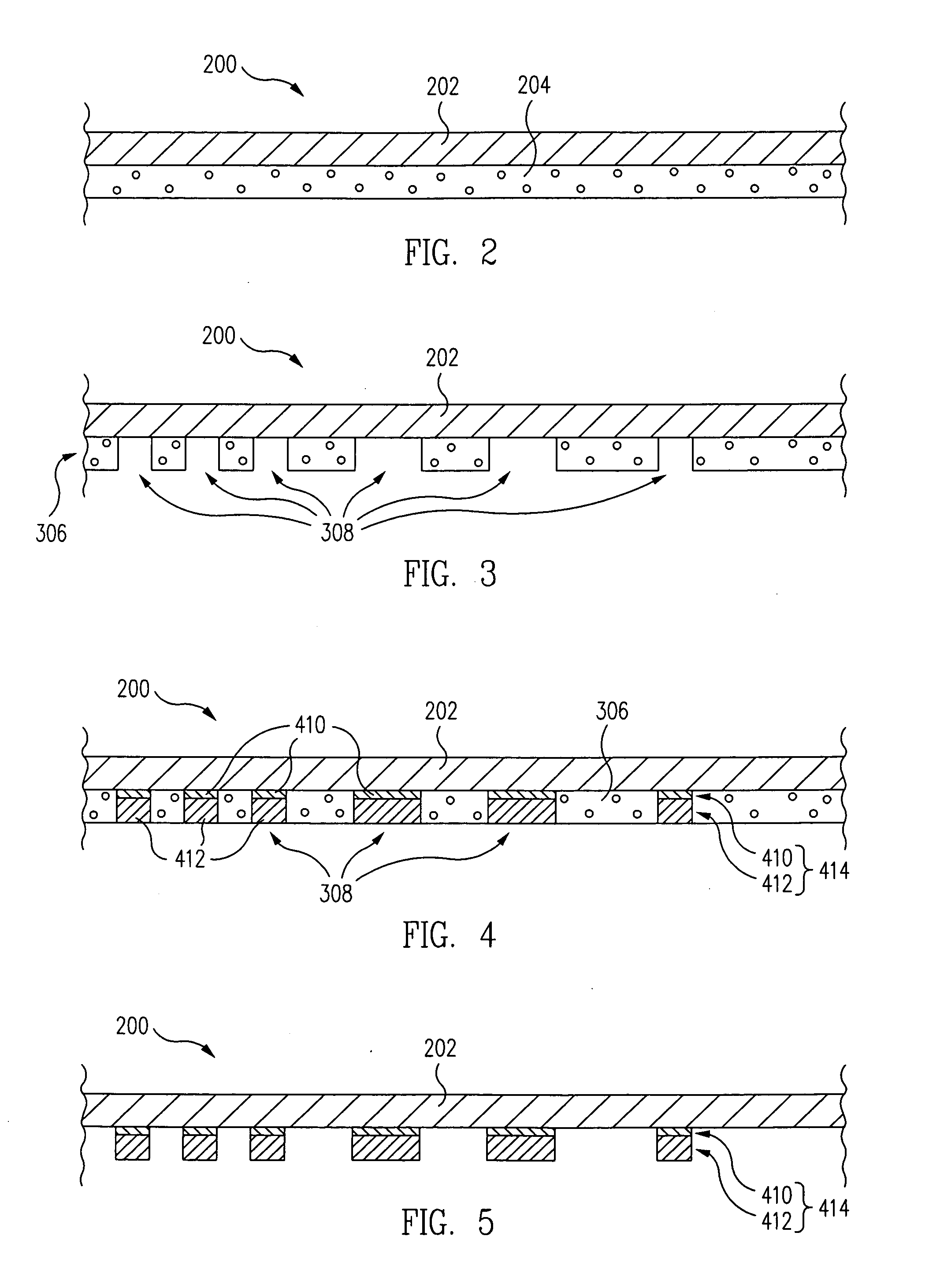

Metal etch stop fabrication method and structure

ActiveUS7923645B1Easy to manufactureReduce manufacturing costPrinted circuit assemblingSemiconductor/solid-state device detailsElectrical conductorEngineering

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

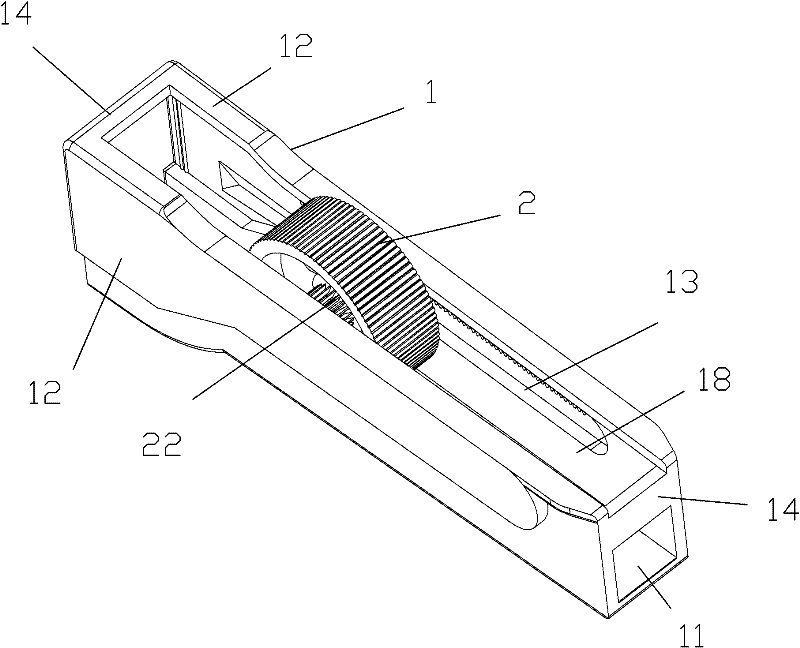

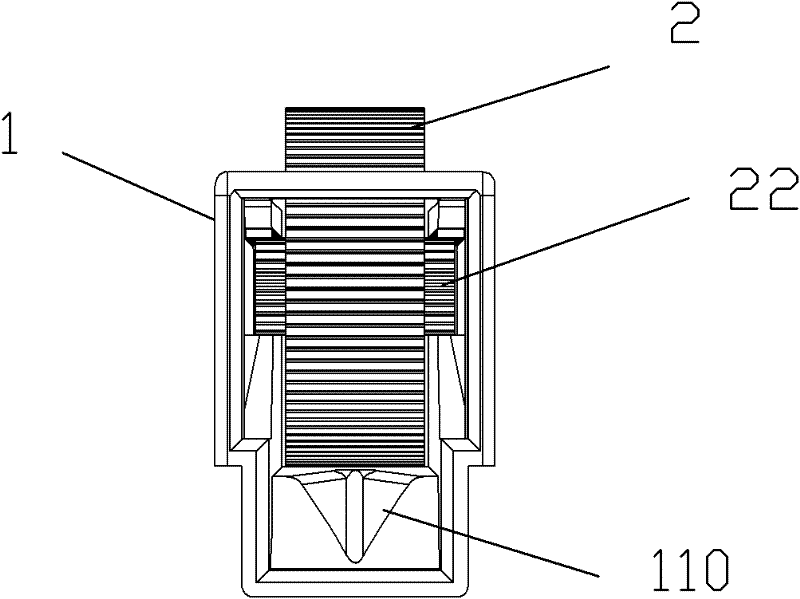

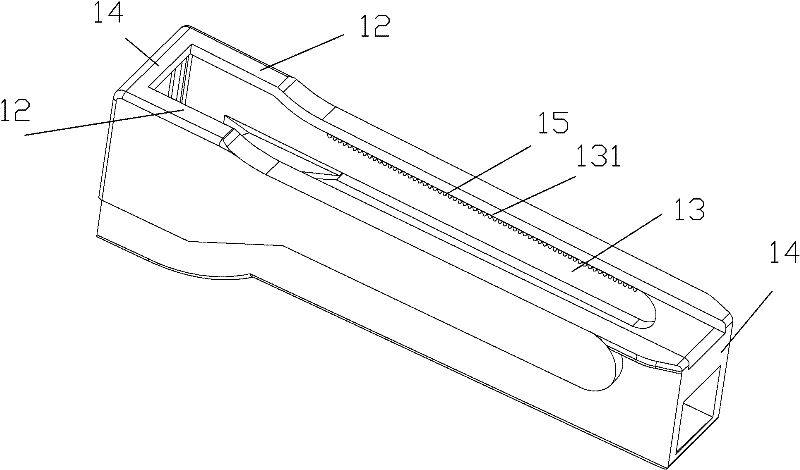

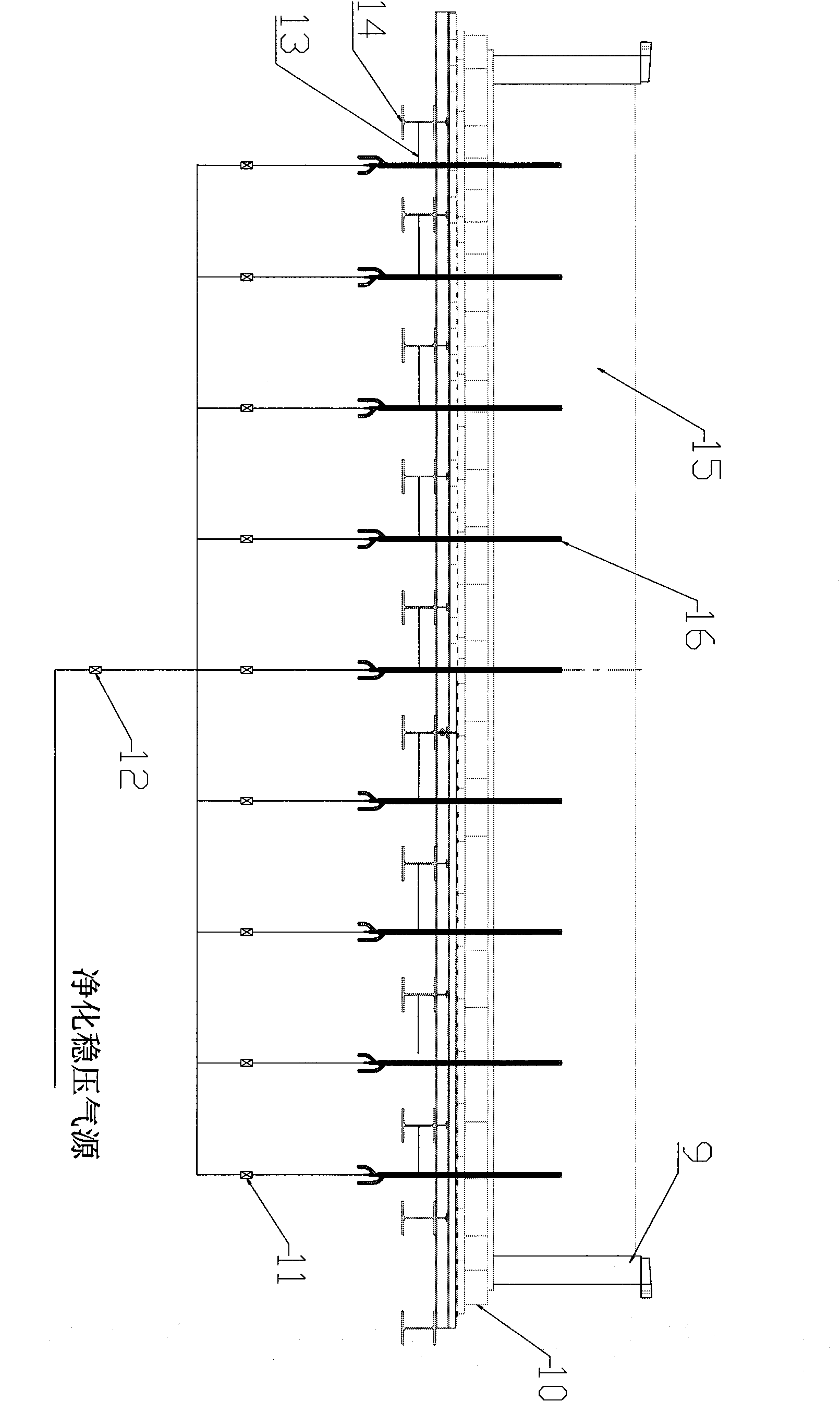

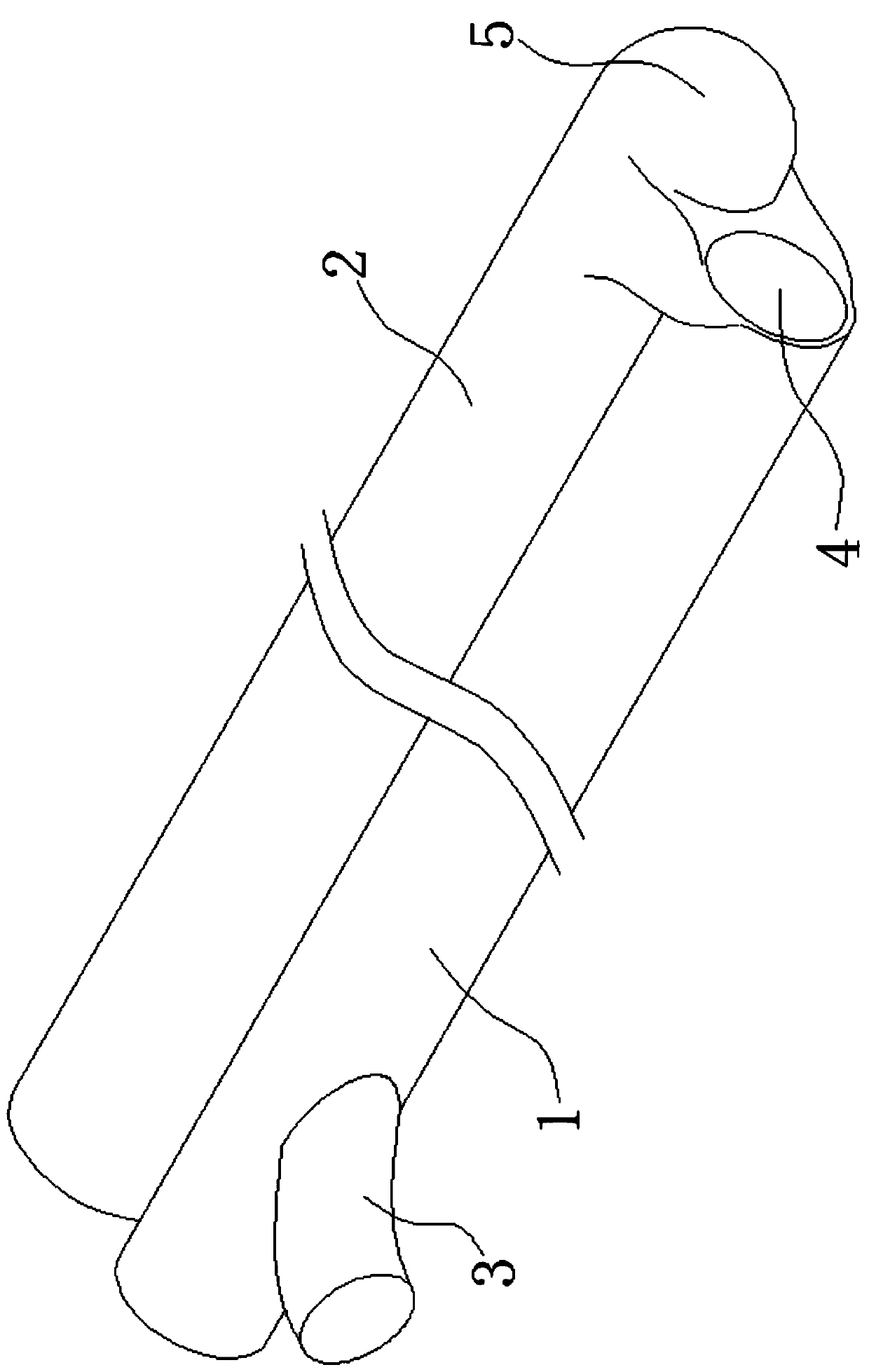

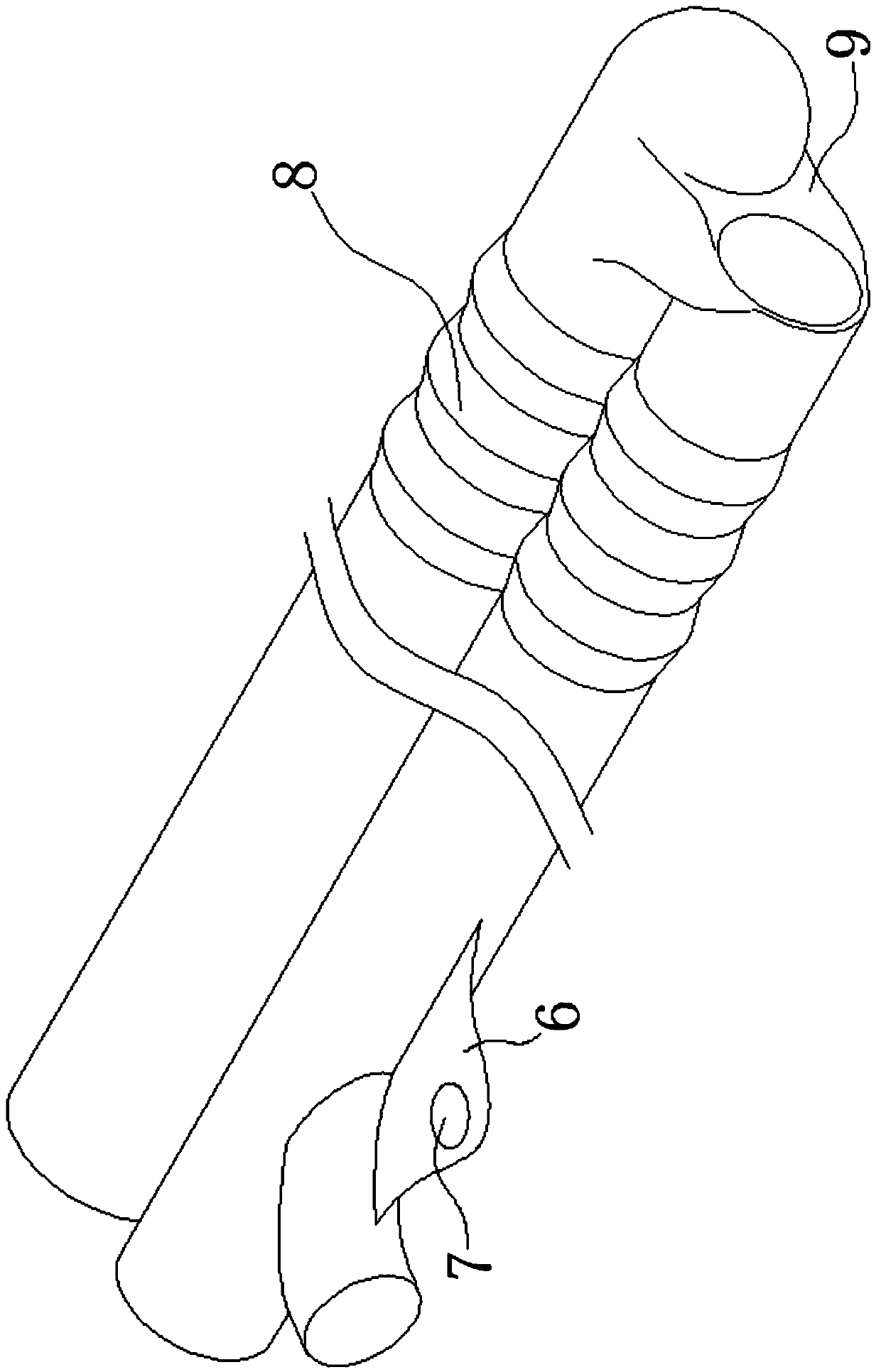

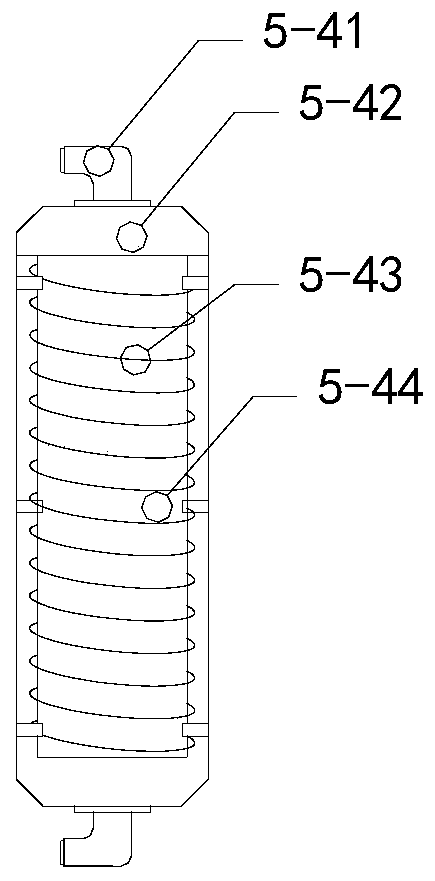

Infusion general flow velocity regulator

InactiveCN102451498AGuaranteed cross-sectional areaStable infusion speedIntravenous devicesEngineeringMechanical engineering

The invention discloses an infusion general flow velocity regulator. The regulator comprises a shell, a roller and an infusion conduit, wherein the shell comprises an inclined bottom wall and a pair of side walls; a pair of opposite sliding chutes is formed on the pair of side walls; the roller is provided with a roller shaft; the two ends of the roller shaft are arranged in the pair of sliding chutes respectively; and the infusion conduit passes through the shell and is positioned between the bottom wall of the shell and the roller. The regulator is characterized in that: the two ends of the roller shaft are provided with a gear respectively; racks are arranged on the side walls of the pair of sliding chutes; and the two gears are engaged with the racks in the pair of sliding chutes respectively. In the long-time infusion process, the gears are engaged with the racks in the sliding chutes, so that the roller cannot move without artificial factors, and the stability of infusion speeds is ensured.

Owner:美舒医疗器械贸易(上海)有限公司

Bubbling device for molten glass

InactiveCN102153269AManual replacementImprove securityGlass furnace apparatusShielding gasDepth direction

The invention discloses a porous bubbling device with a cooling structure, and belongs to the field of tank furnace melting for glass production. The bubbling device consists of a porous gas pipeline and a cooling pipeline for protecting the gas pipeline; the bubbling device can be positioned at any position in the depth direction of molten glass by cooling and can be adjusted according to different produced glass; and the cross section area of a single gas pipe outlet of a bubbling port (7) can be reduced through multiple pores, and the purposes of preventing the molten glass from flowing backward and controlling bubble frequency and bubble diameter are fulfilled by combining a one-way valve (or check valve) and a pressure adjusting valve of an upstream air supply pipeline of an air inlet (4).

Owner:QINHUANGDAO KAIWEI SCI & TECH +1

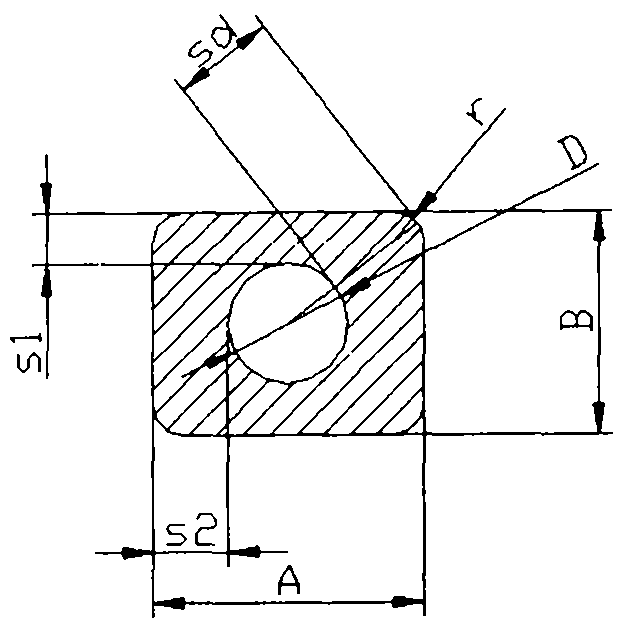

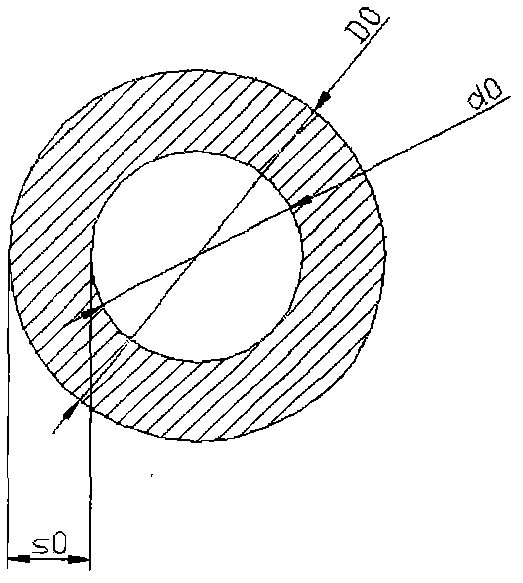

Method for processing rectangular round-hole wire copper pipe of dual water internal cooling generator

The invention discloses a method for processing a rectangular round-hole wire copper pipe of a dual water internal cooling generator, which comprises the steps of: selecting a pipe blank, casting, extruding and stretching the selected pipe blank to form a circular pipe blank; rolling the formed pipe blank; annealing the rolled pipe blank; carrying out transitional stretching on the annealed pipe blank; and then, stretching the pipe blank after transitional stretching to form a finished product. The processing method solves the problems of large material consumption of a coil, large volume of a unit, poor cooling effect of the coil and finally short unit use life because the material of the coil is solid or has a rectangular inner hole adopted in the prior art. The processing method has the advantages of material saving, long service life and the like.

Owner:上海飞轮有色新材料股份有限公司 +1

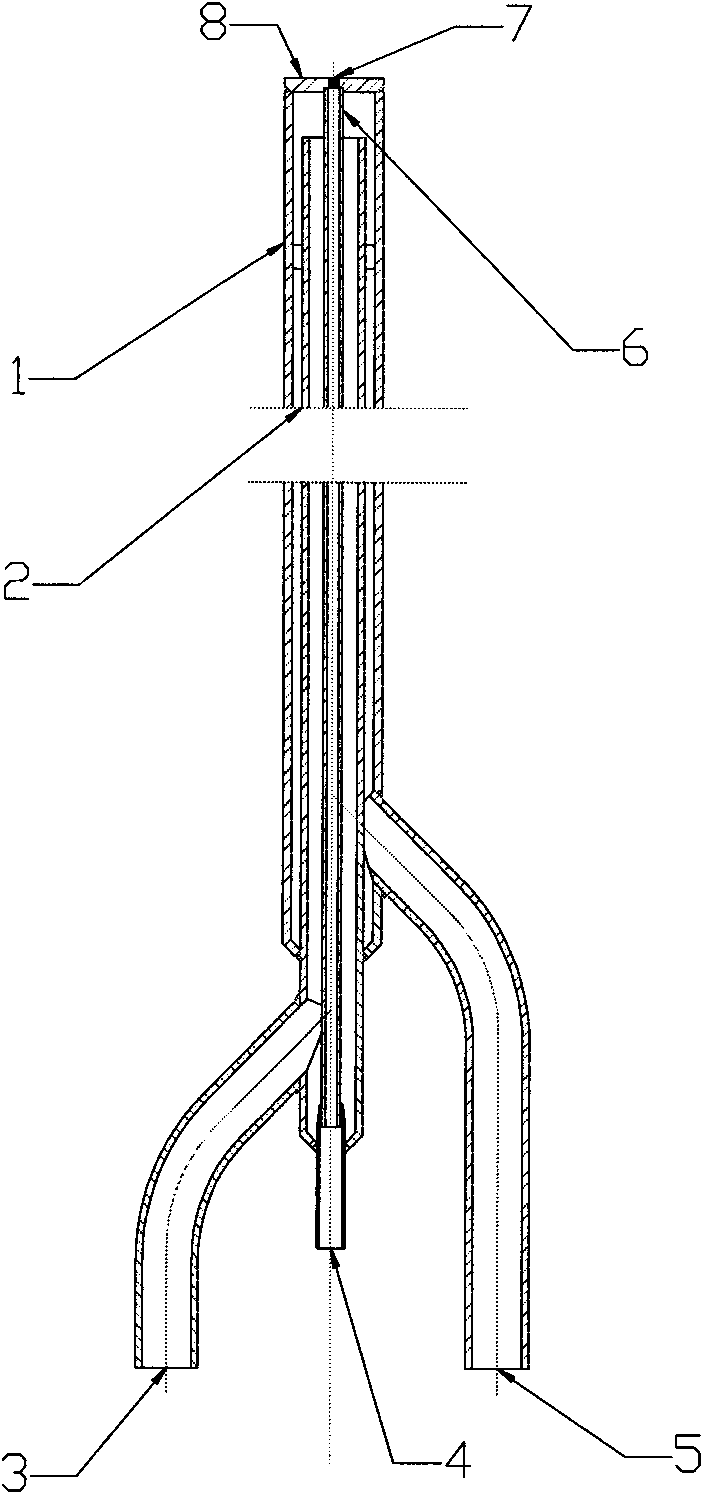

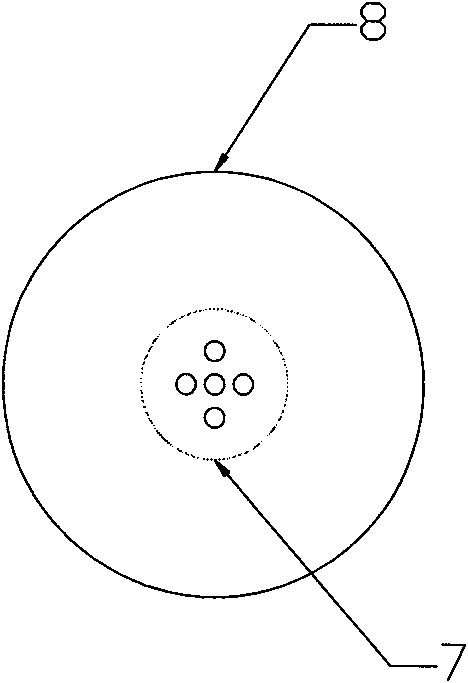

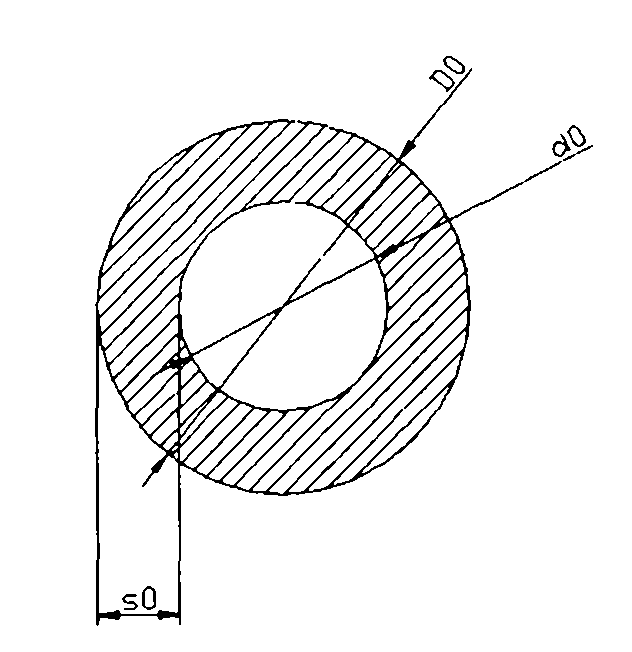

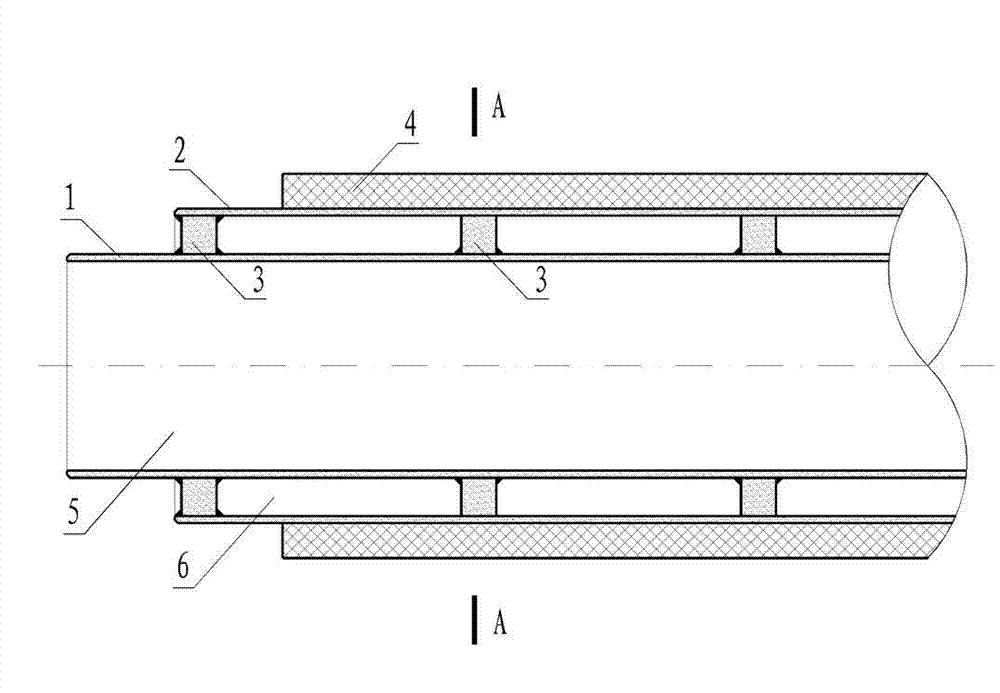

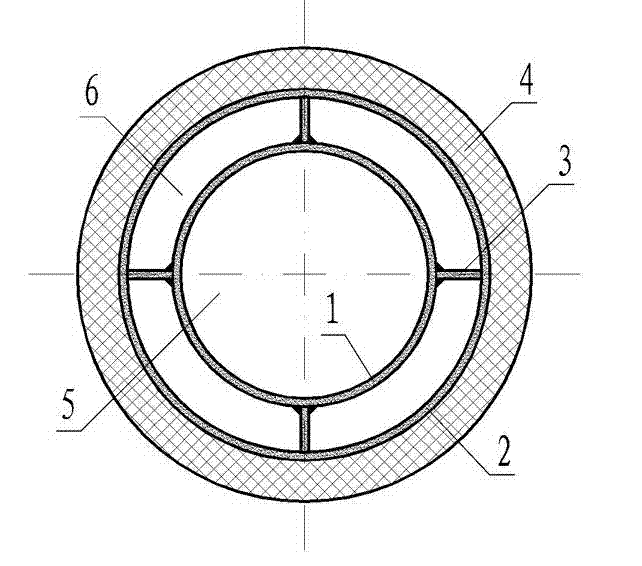

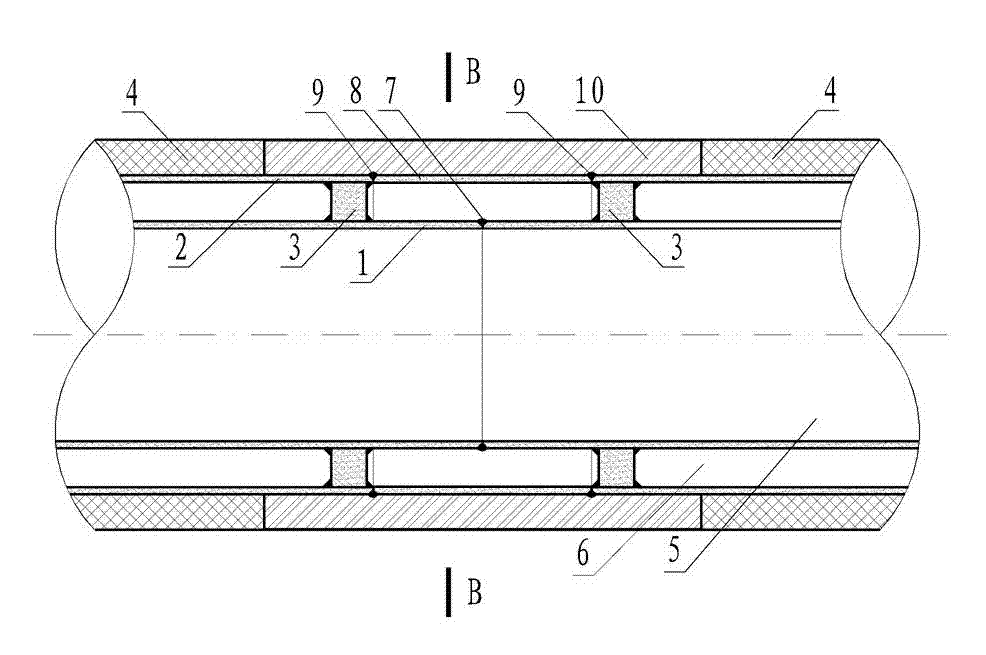

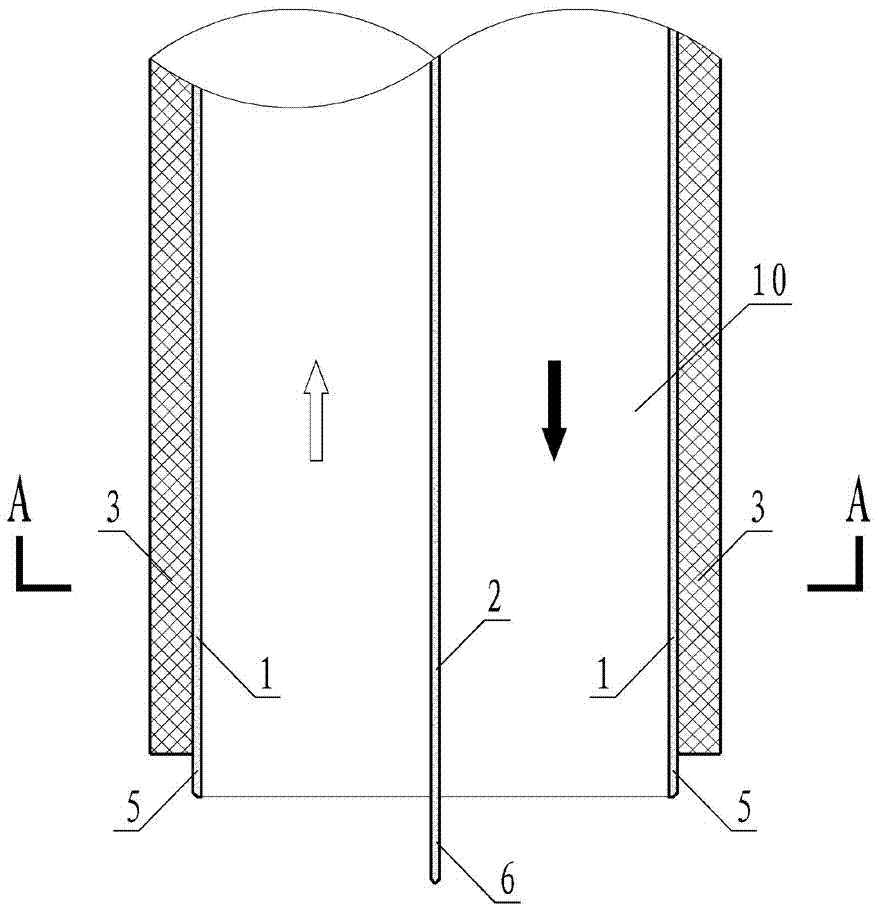

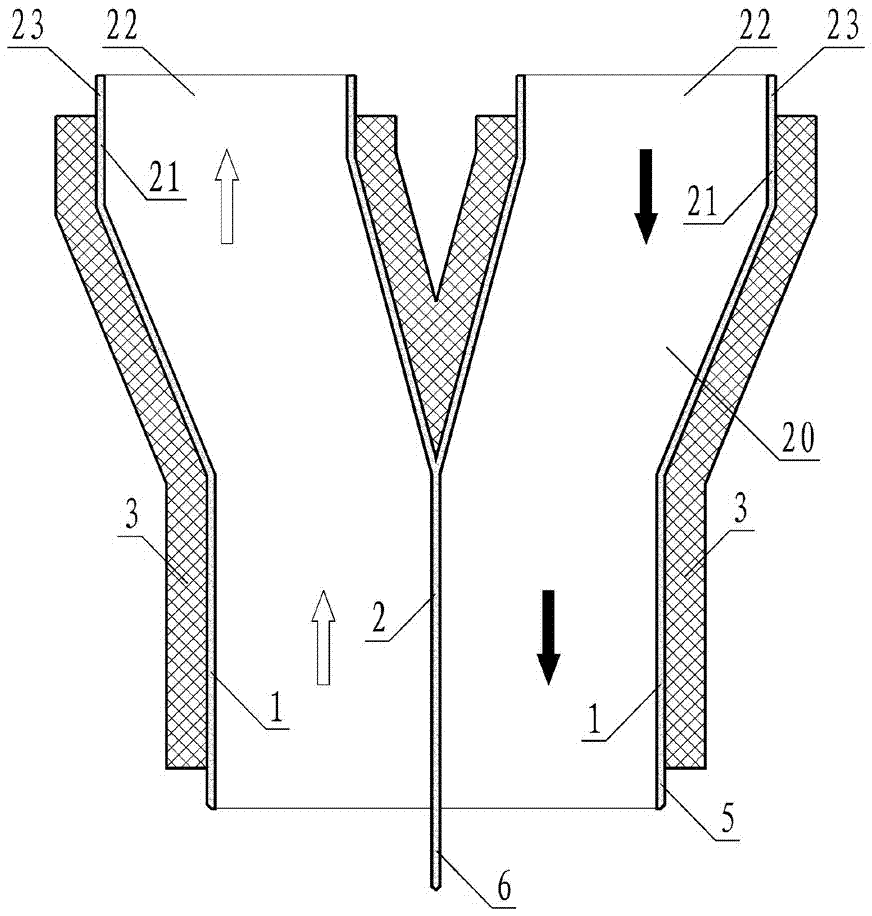

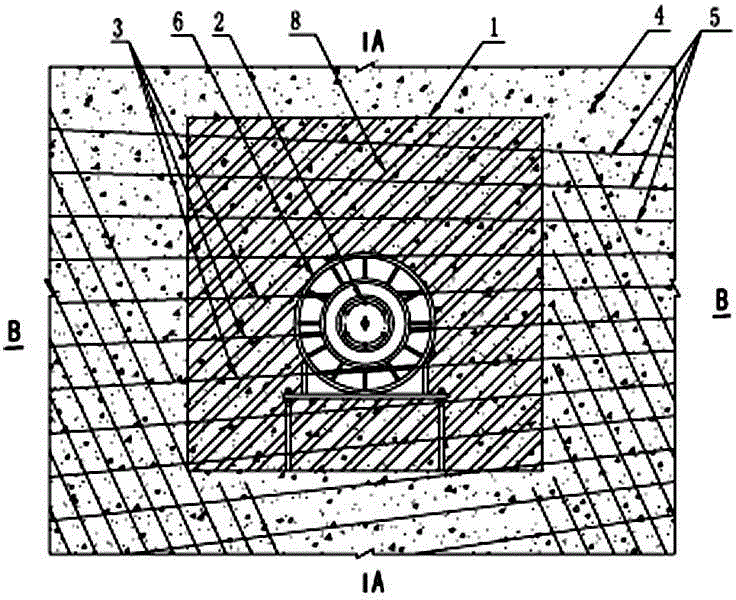

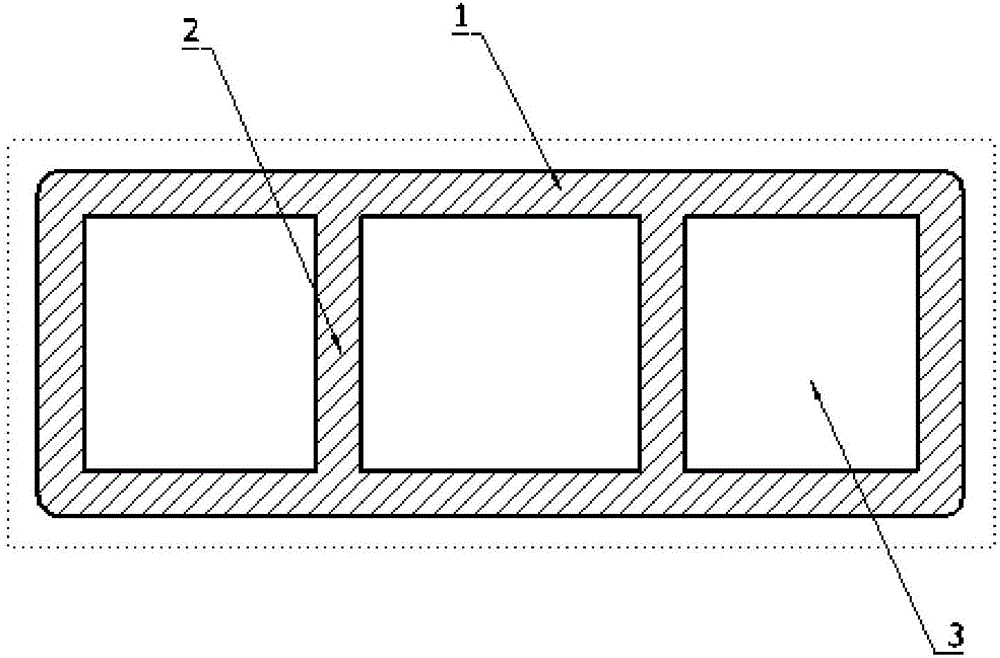

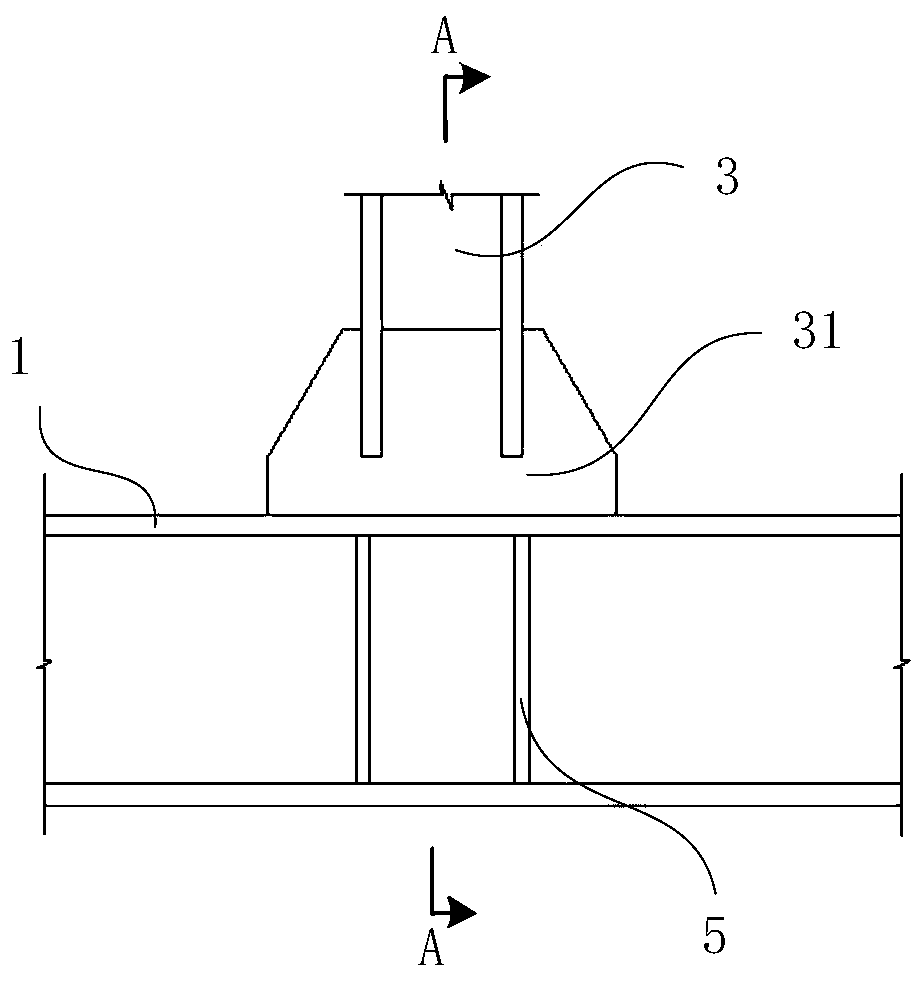

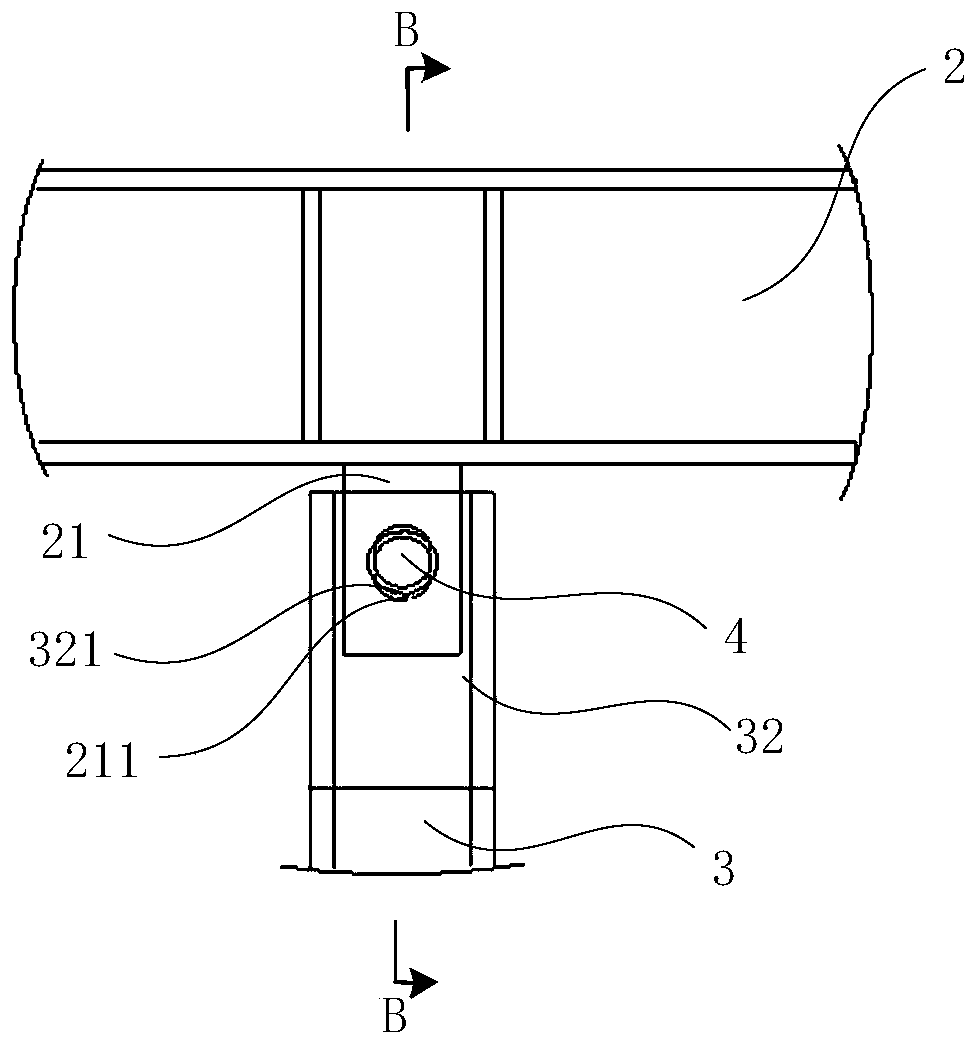

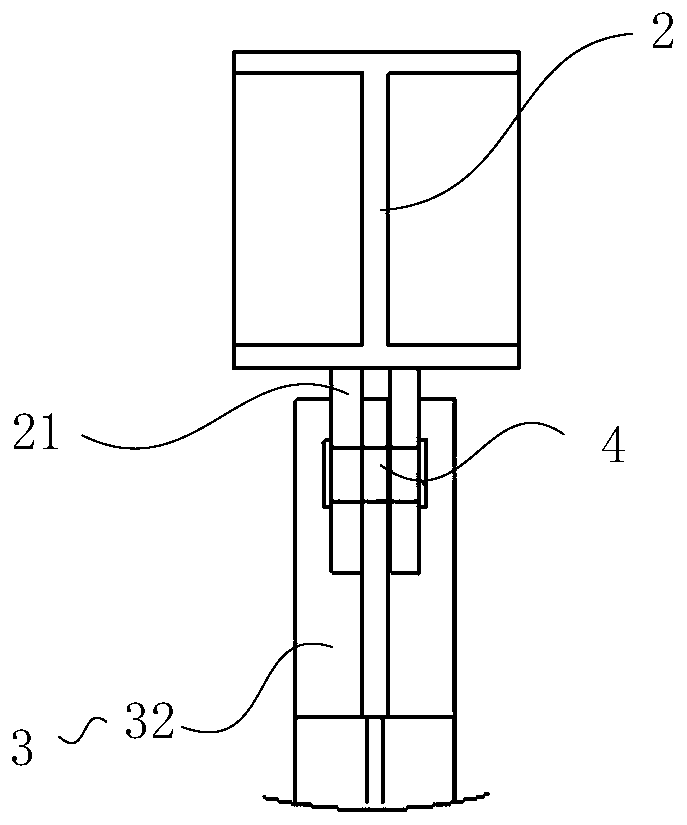

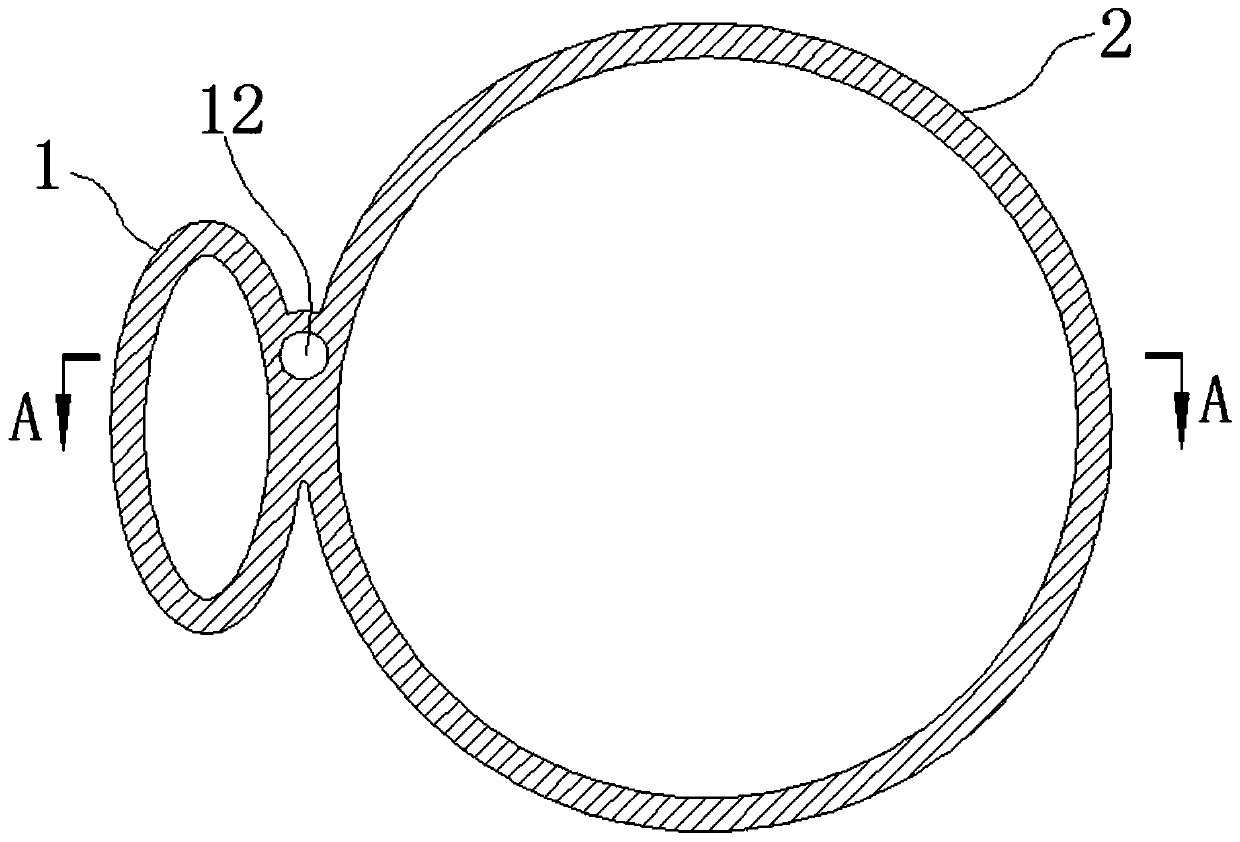

Double-hole concentric heat tube

InactiveCN103047487AGuaranteed cross-sectional areaReduce laying widthPipe elementsBranching pipesDouble tubeEngineering

The invention discloses a double-hole concentric heat tube. The double-hole concentric heat tube mainly comprises an inner tube 1, an outer tube 2, positioning tenons 3 and a heat preserving layer 4. The inner tube 1 is supported by the positioning tenons 3 and fixed inside the outer tube 2, and the inner tube 1 and the outer tube 2 form a concentric circle and the single double-hole tube. The positioning tenons 3 are arranged at intervals, and every four tenons are evenly welded and distributed on the outer side of the inner tube 1 at 90 degrees. An annular channel between the inner tube 1 and the outer tube 2 forms an outer hole 6, and the outer hole 6 and an inner hole 5 jointly form the double-hole concentric heat tube and are equal in area. Compared with heat tubes paved in a double-tube paralleling mode in the prior art, the occupied width can be decreased, and a smallest net safety distance of underground pipelines is ensured. Earth volume required ditch excavation is decreased through direct burying pavement. The superficial area is smaller than that in the double-tube paralleling mode, heat energy consumption can be reduced, and energy is saved.

Owner:刘建华

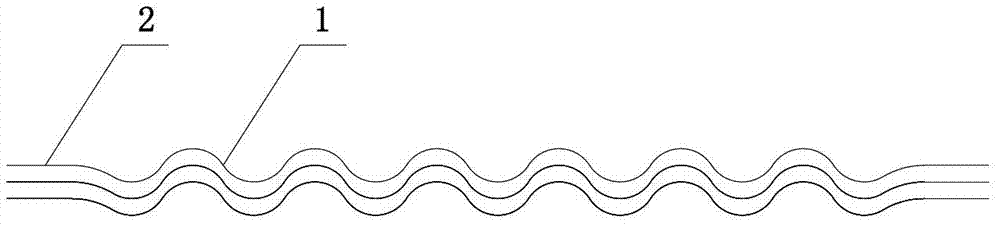

Structure and method for conductive connection between copper materials or between copper material and other components

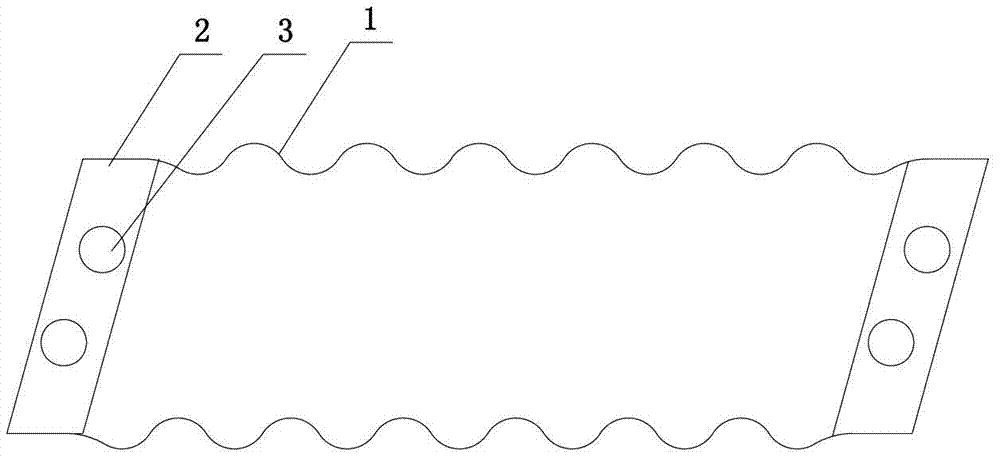

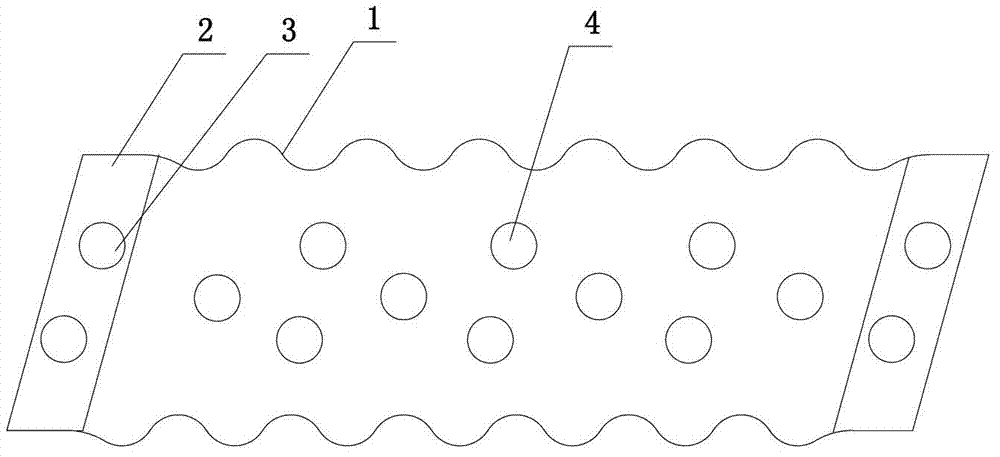

InactiveCN102738600AFully contactedClosely connectedLine/current collector detailsClamped/spring connectionsState of artWave shape

The invention relates to a connection technology between copper materials or between a copper material and other components, in particular to a structure and method for conductive connection between copper materials or between a copper material and other components. A multi-layer copper foil flexible connection structure is connected between the copper materials or between the copper material and other components, the copper foil flexible connection structure is a multi-layer structure formed by superposing wave-shaped or snake-shaped or unfolded spiral copper foil strips, the middle wave-shaped or snake-shaped or unfolded spiral copper foil strips are in a free layering state, and two ends of the wave-shaped or snake-shaped or unfolded spiral copper foil strips of the multi-layer structure are directly connected to the copper materials or other components. The structure and method for conductive connection disclosed by the invention solve the problems of unsatisfactory conductive performance, low reliability and the like of the prior art, the copper foil flexible connection which has a simple structure and high reliability and is convenient to maintain is adopted, and the conductive connection structure not only has a good conductive performance, but also has good heat compensation ability and a vibration isolation effect.

Owner:江西九星铜业有限公司

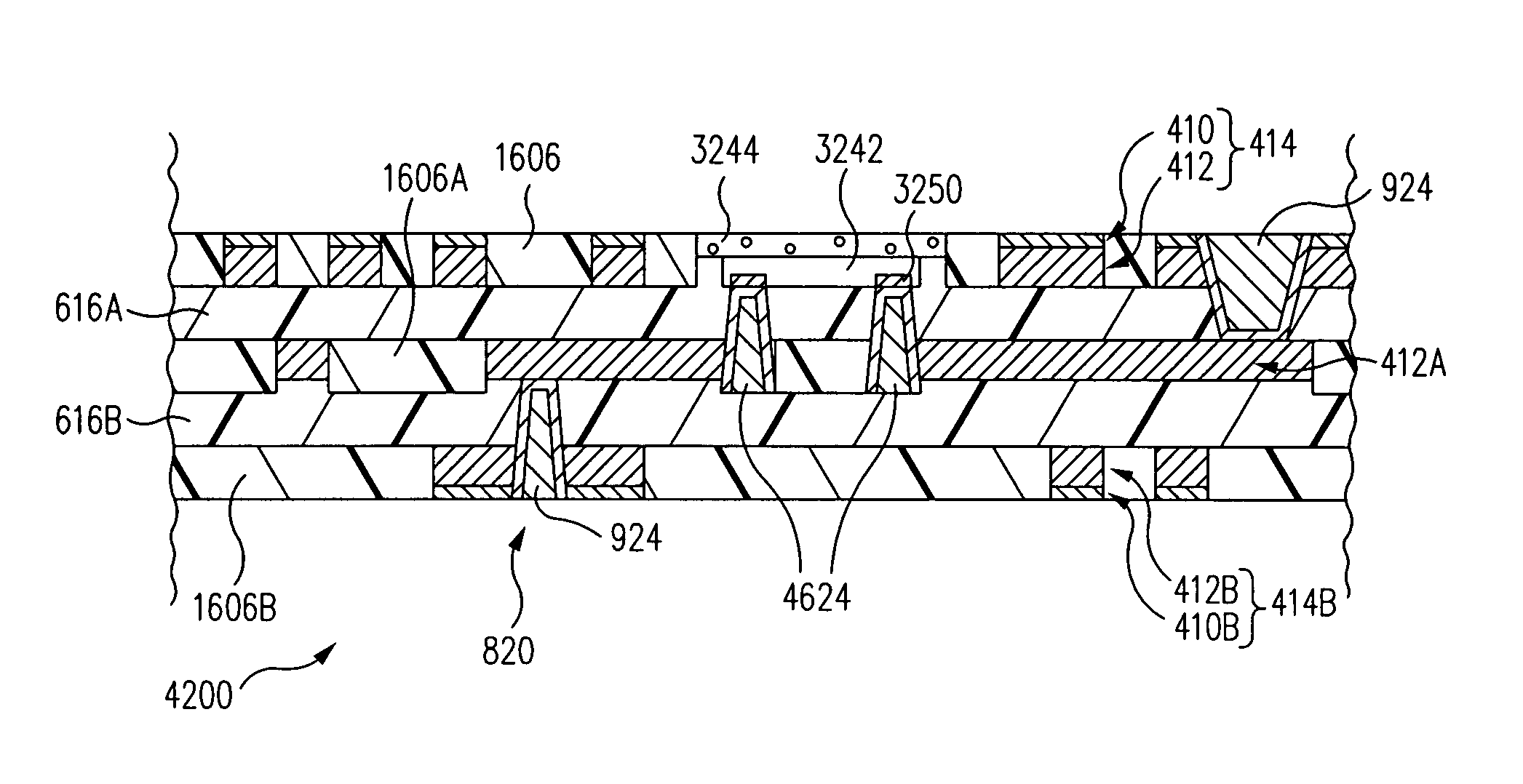

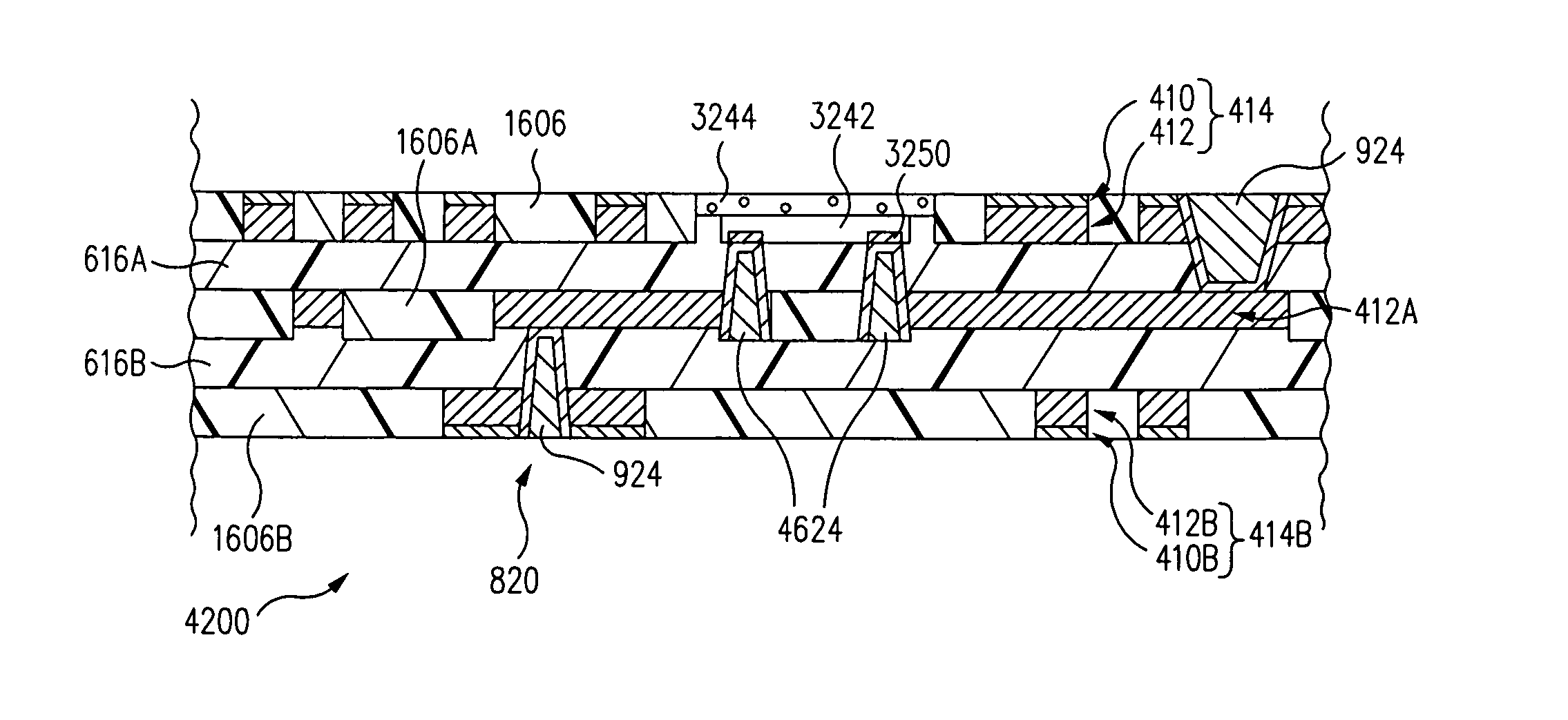

Metal etch stop fabrication method and structure

ActiveUS8383950B1Easy to manufactureReduce manufacturing costContact member manufacturingSolid-state devicesElectrical conductor

A first patterned etch stop layer and a first patterned conductor layer are laminated by a dielectric material to a second patterned etch stop layer and a second patterned conductor layer. As the etch stop metal of the first and second patterned etch stop layers is selectively etchable compared to a conductor metal of the first and second patterned conductor layers, the first and second patterned etch stop layers provide an etch stop for substrate formation etch processes. In this manner, etching of the first and second patterned conductor layers is avoided insuring that impedance is controlled to within tight tolerance.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

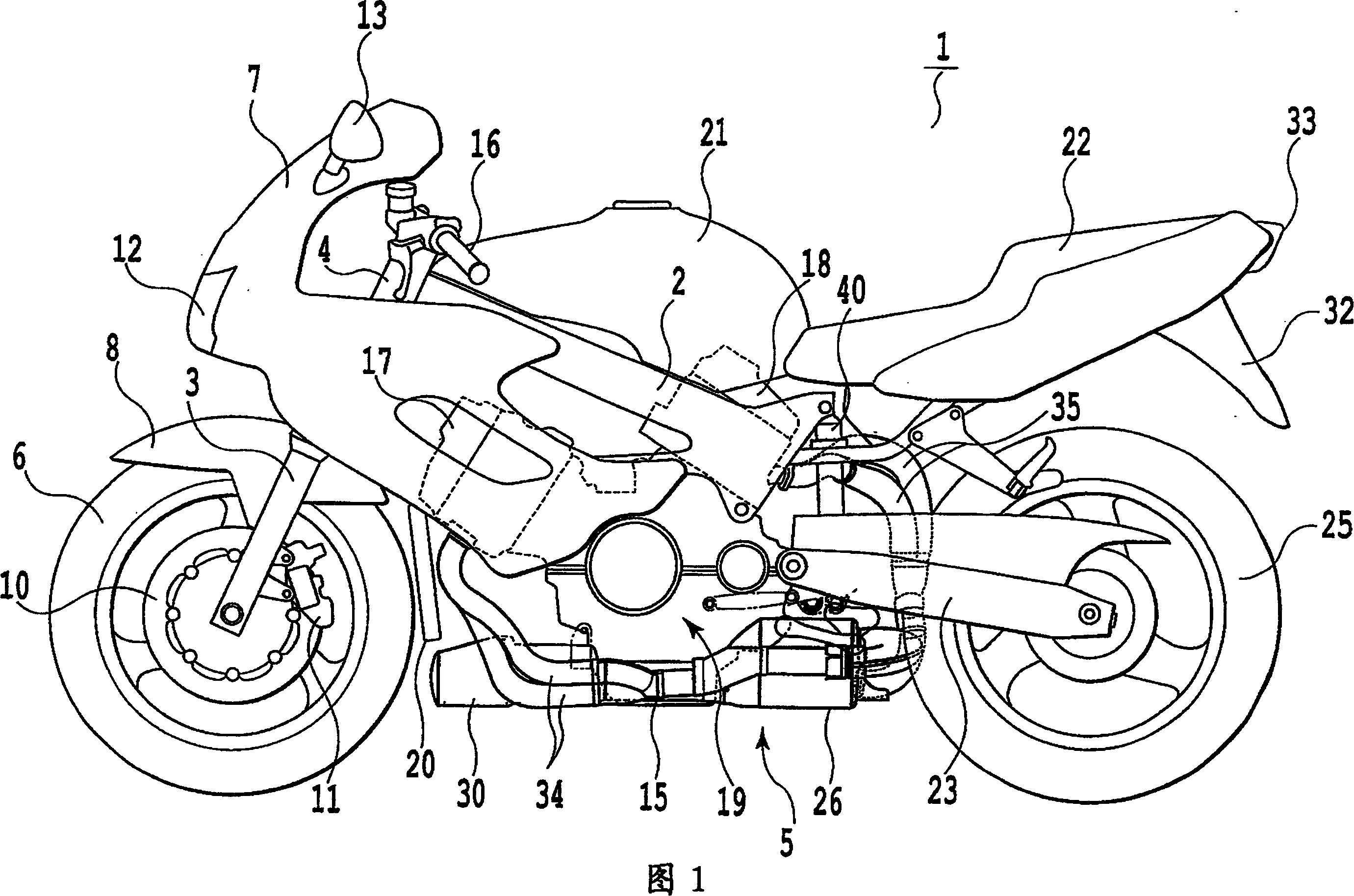

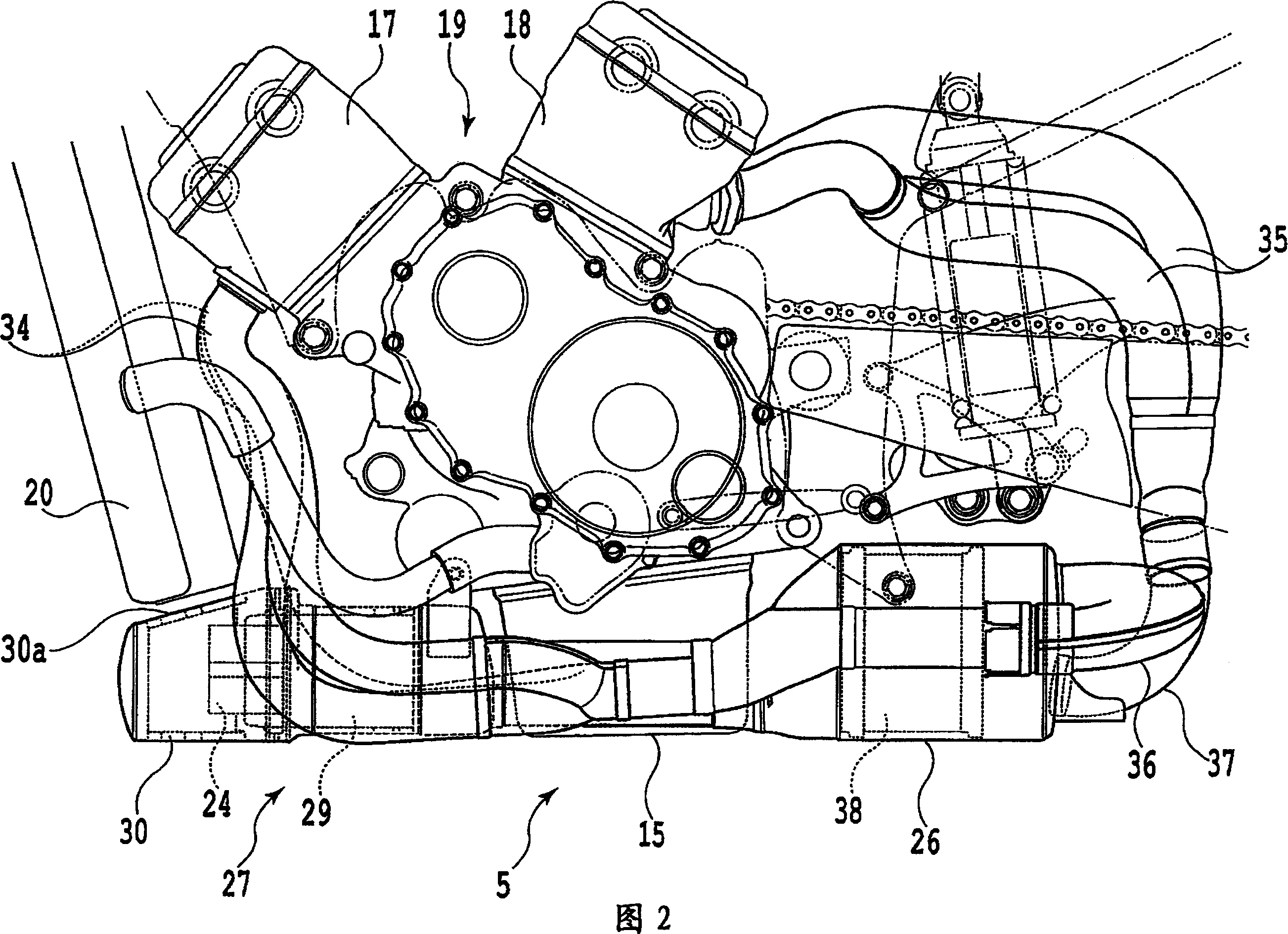

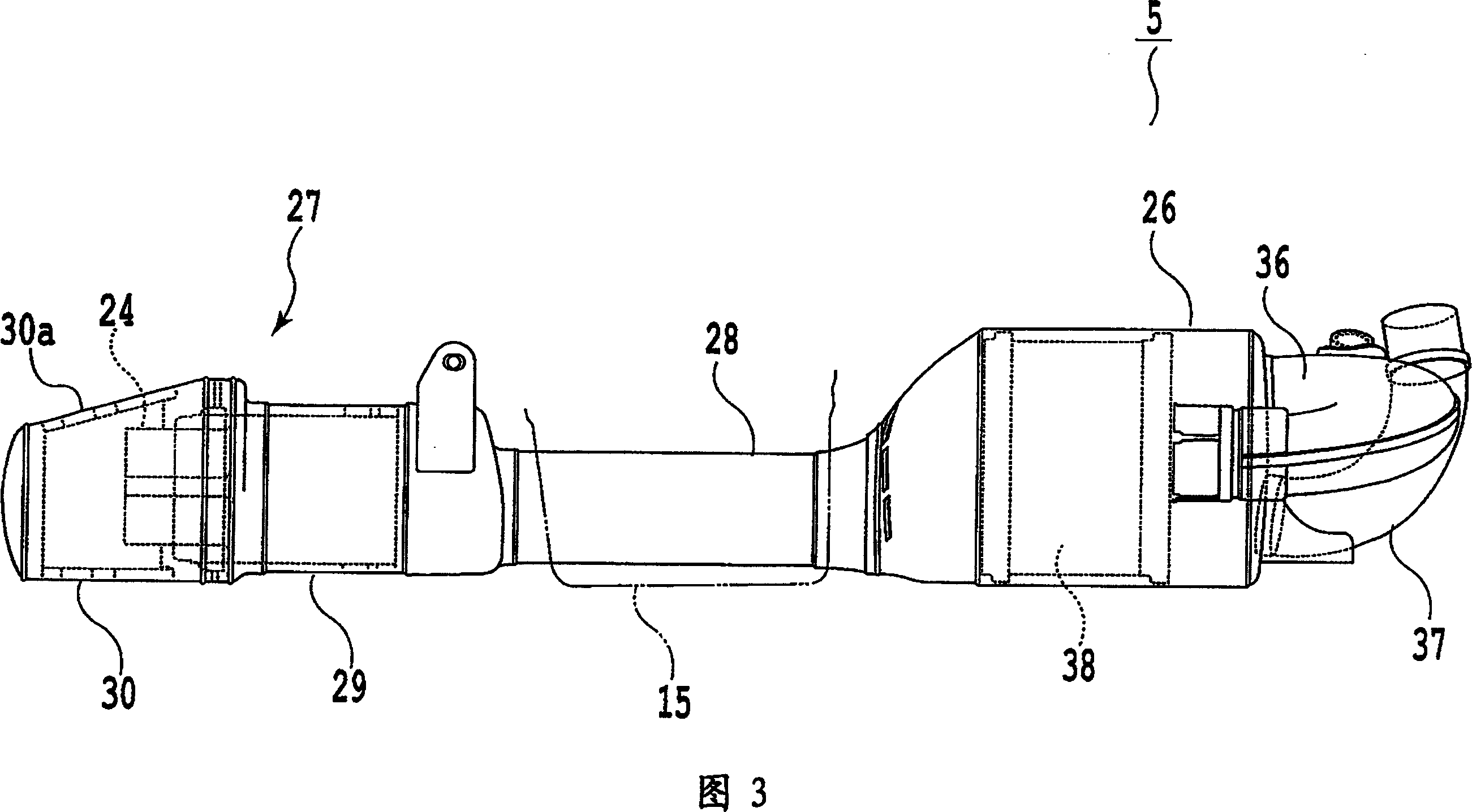

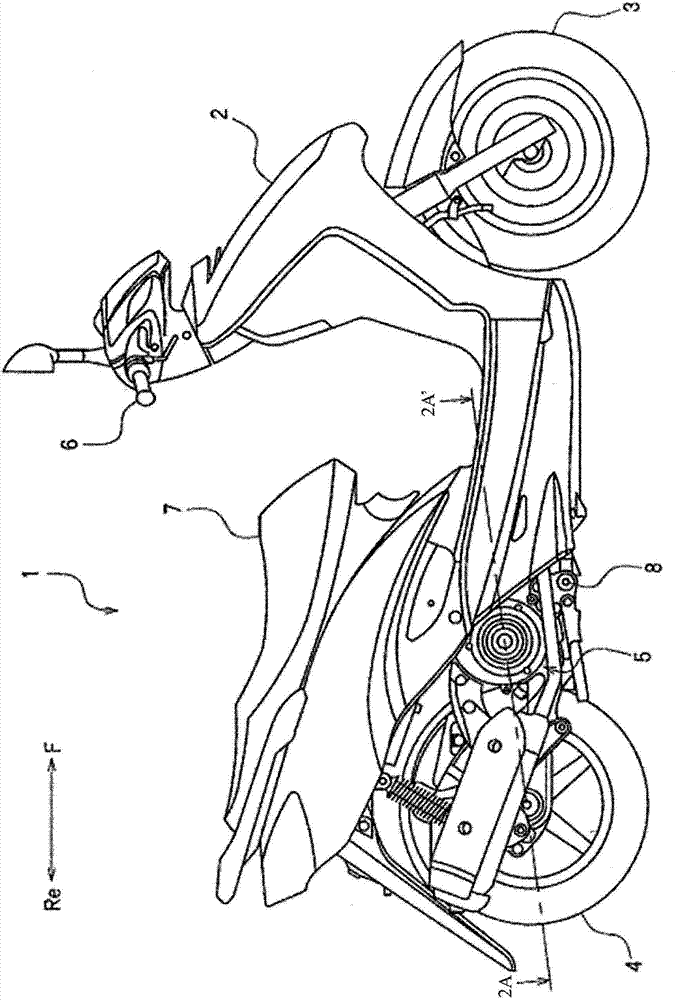

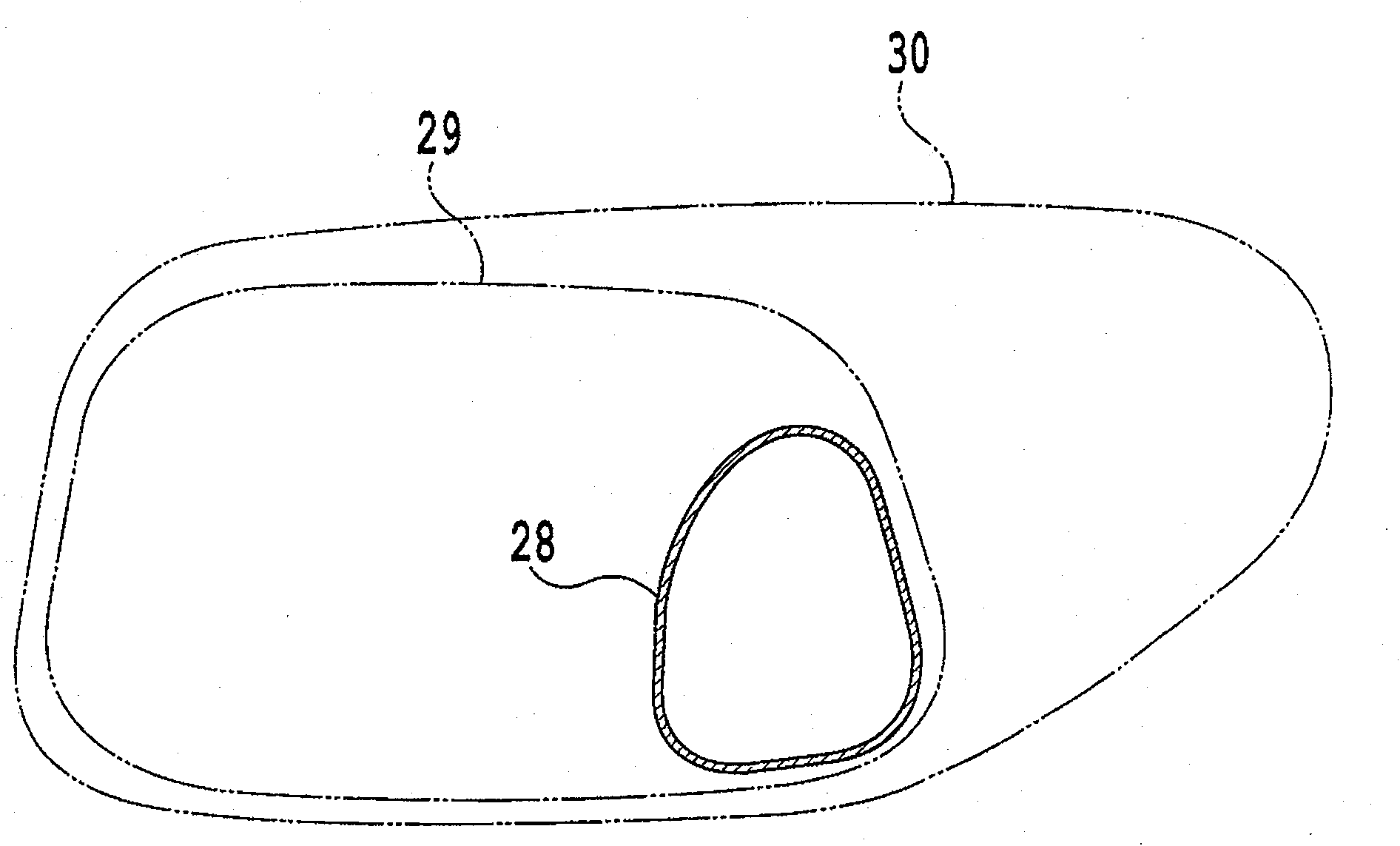

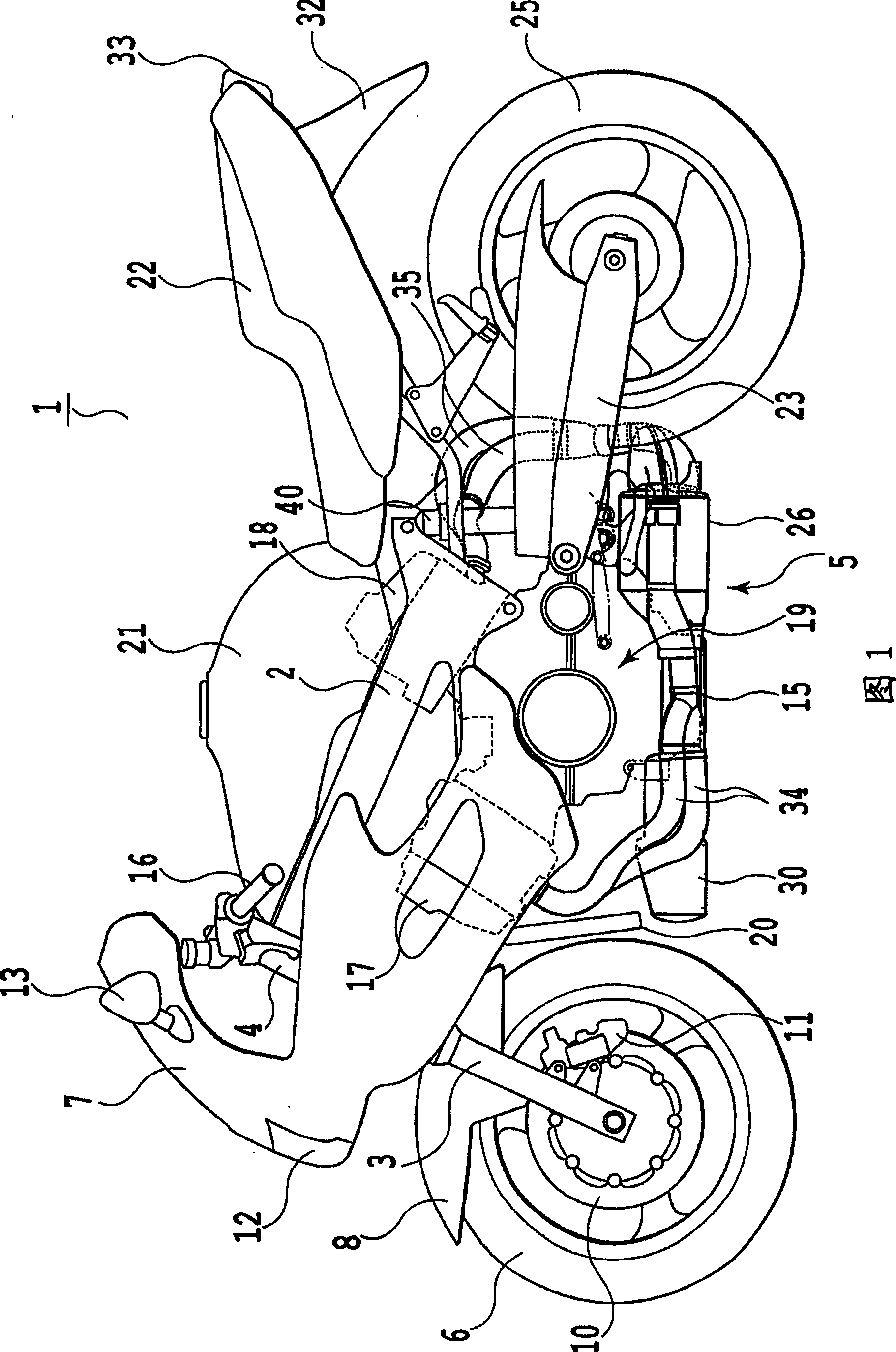

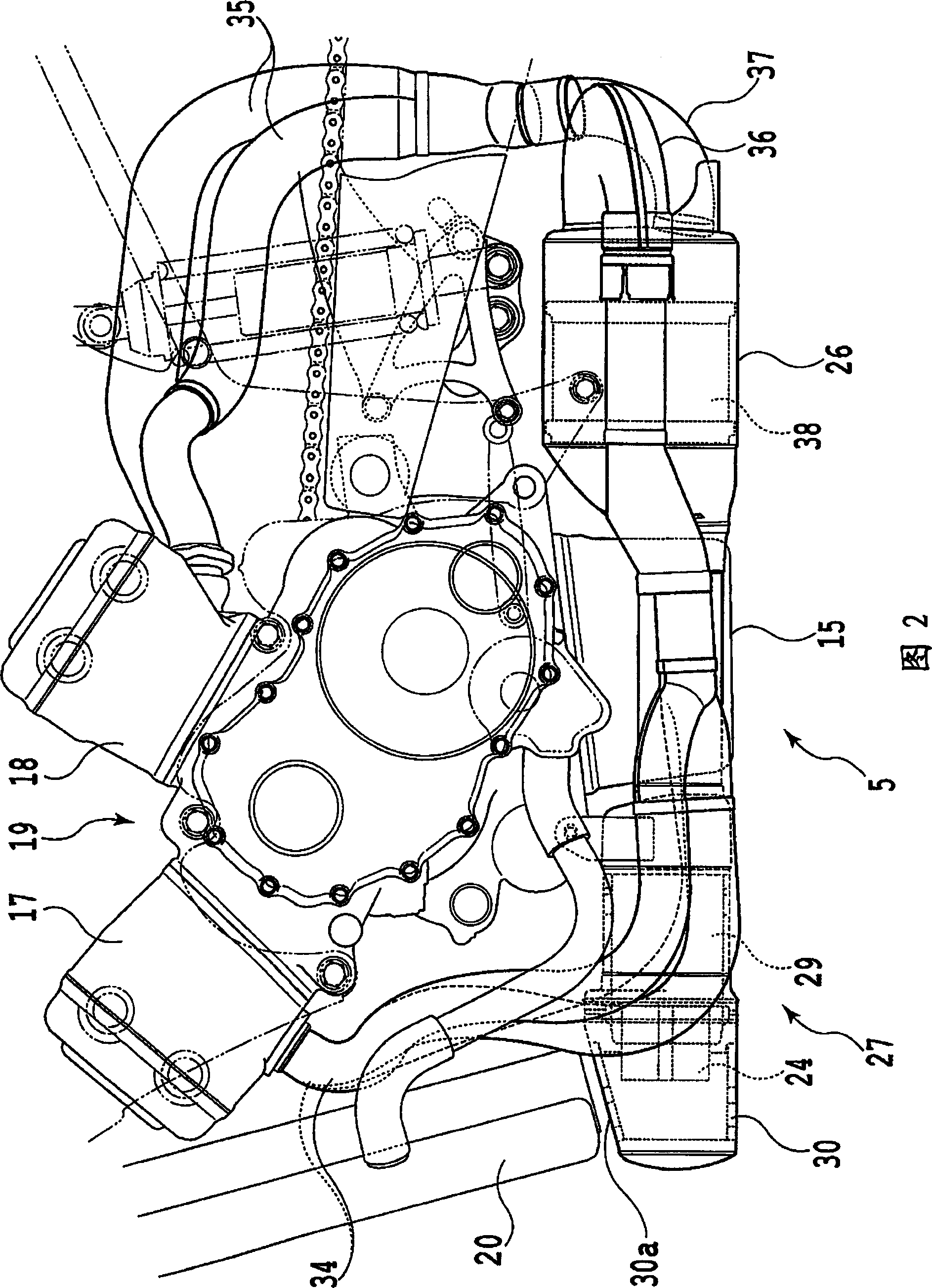

Exhaust device for two-wheel motorcycle

InactiveCN1959074AImprove space utilizationGuaranteed volumeExhaust apparatusSilencing apparatusEngineeringExpansion chamber

Disclosed is an exhaust apparatus for two-wheeled motorcycle. The space utilization of exhaust apparatus arranged under the motor can be further improved in a two-wheeled motorcycle attached with a transverse V-shape motor. At the front and rear of an oil disc (15) respectively provides a front expansion chamber (27) and a rear expansion chamber (26) which are connected with each other via connecting pipe (28). Wherein, the connecting pipe (28) is arranged at right side of the motorcycle body. In the space formed with the front expansion chamber (27) and the rear expansion chamber (26) respectively provided at front and rear and the connecting pipe (28) provided at side, the oil disc (15) can be arranged to protrude downward. Thus, the oil disc (15) volume can be sufficiently ensured, andthe space utilization of exhaust apparatus (5) can be further improved.

Owner:HONDA MOTOR CO LTD

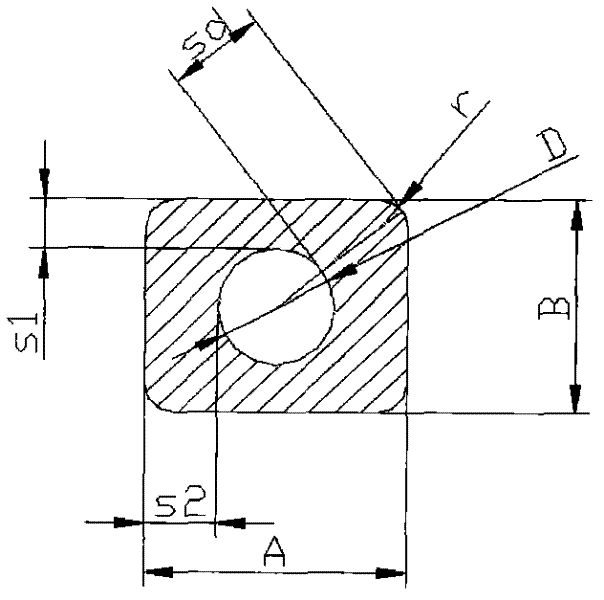

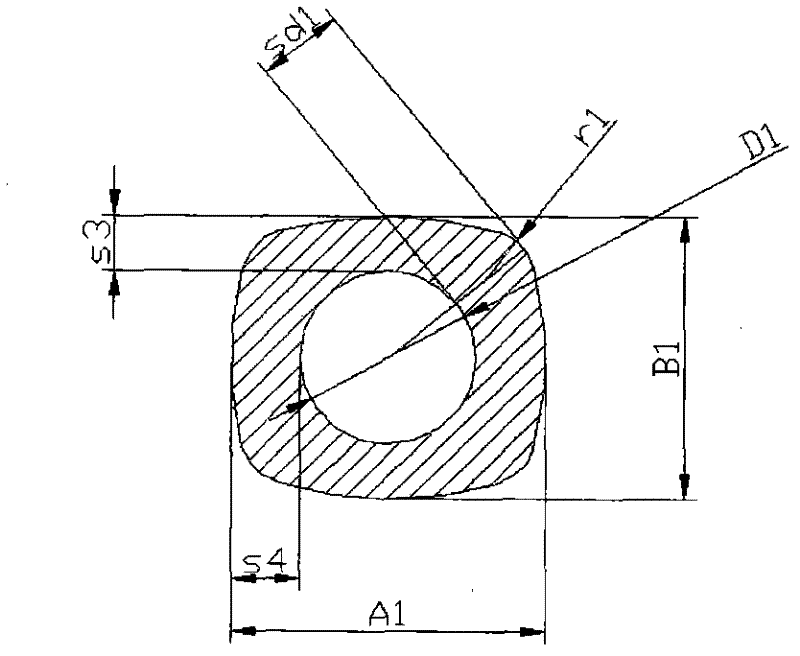

Insert, holder, and cutting tool using said insert and holder

ActiveCN102387883APrevent rotationHigh repeatabilityLathesTurning toolsEngineeringMechanical engineering

Owner:KYOCERA CORP

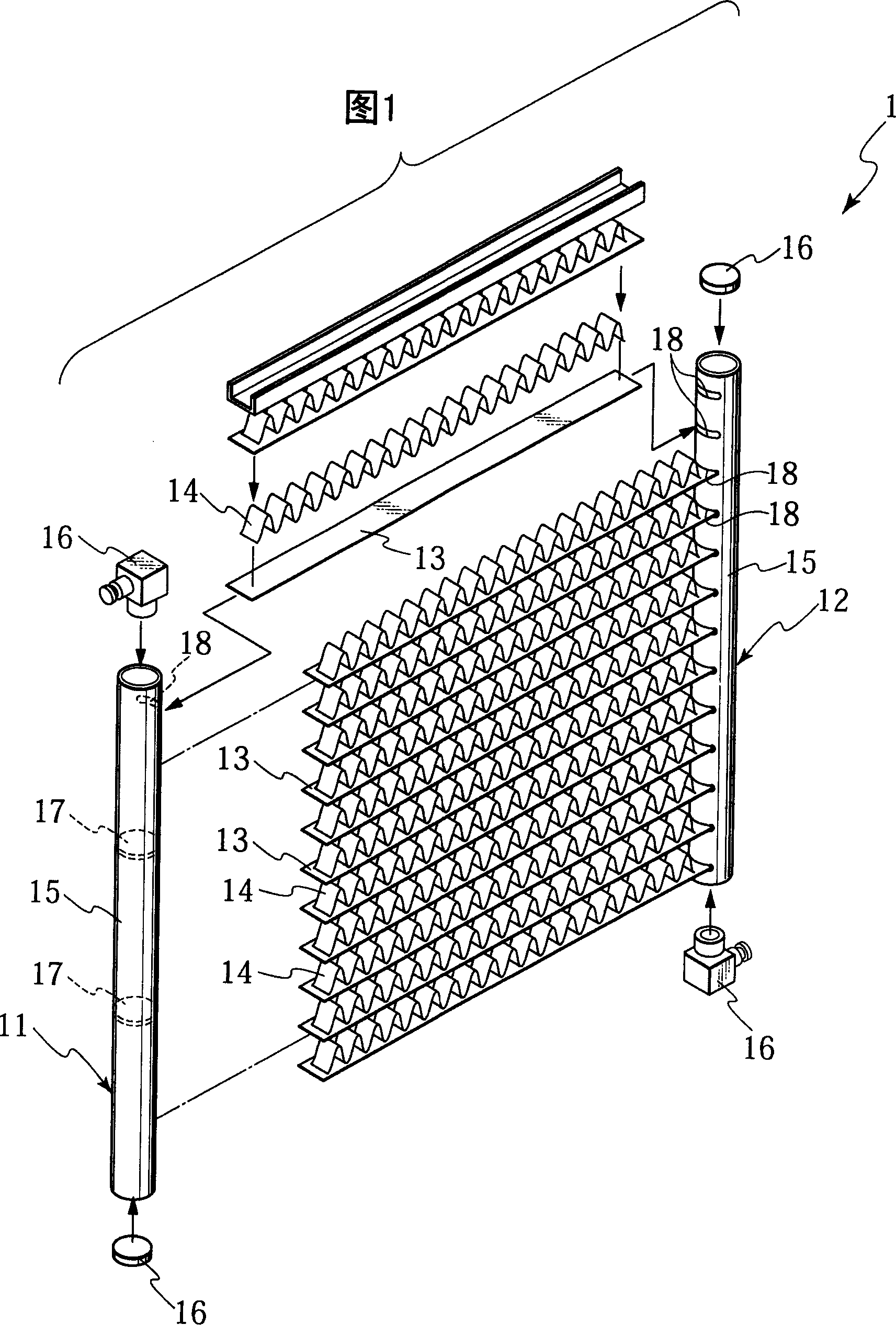

Water supply tank for heat exchanger

InactiveCN1534267AGuaranteed cross-sectional areaAir-treating devicesEvaporators/condensersPlate heat exchangerEngineering

A pipe of a header pipe is formed by combining two separated bodies separated along a longitudinal direction. The first separated body has a tube holding wall portion including an insertion hole inserting a flat tube thereto, and a pair of straight portions protruded from the tube holding wall portion in an approximately orthogonal direction and set along both sides in a width direction of the tube, and is formed in a C-shaped cross sectional shape.

Owner:CALSONIC KANSEI CORP

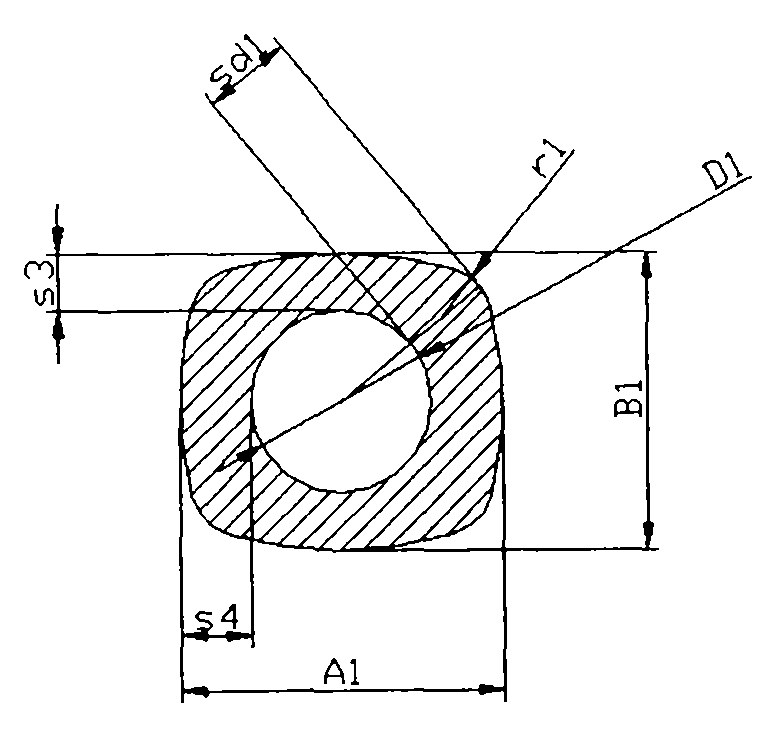

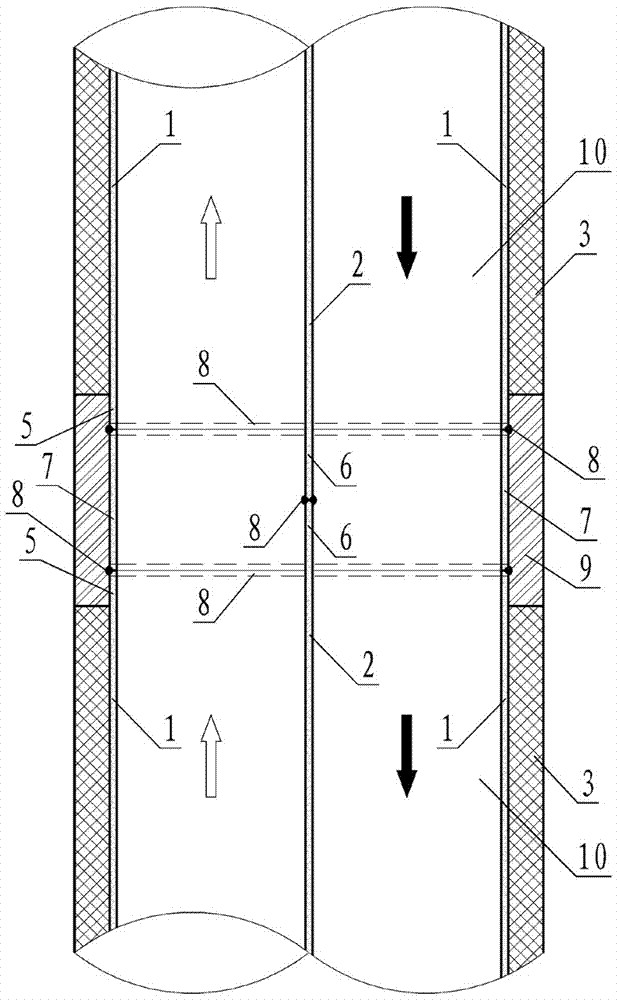

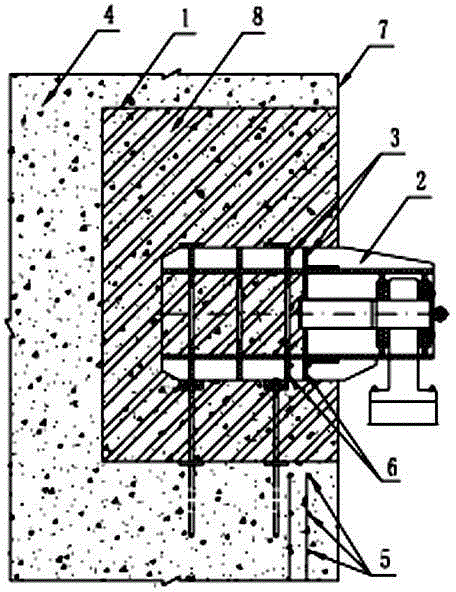

Double-hole parallel thermal power tube

ActiveCN107420652AGuaranteed cross-sectional areaReduce laying widthBranching pipesRigid pipesThermal energyLine tubing

The invention relates to a double-hole parallel thermal power tube, relates to thermal power tube network projects, and in particular relates to a tube and fittings of a thermal power tube network. According to the double-hole parallel thermal power tube, a partition plate is arranged in the middle of an elliptic tube wall of the cross section of the double-hole parallel thermal power tube, and then two horizontally parallel tube holes are formed; a heat-preservation layer is arranged on the outer side of the double-hole parallel thermal power tube; the cross section areas of the two tube holes are identical; the two tube holes are respectively used as a water supply tube and a water return tube of a thermal power tube network. On premise that the cross section areas of the tube holes are identical to those of round tubes of a same nominal diameter and the cross section areas of the water supply tube and the water return tube are ensured, the pipeline laying width is reduced, the underground space is saved, underground pipelines can be laid conveniently, the volume of earthwork of troughs is reduced, and the workload of pipeline hoisting and positioning is also reduced when being compared with that of the prior art; the outer surface area of the tube wall is smaller than those of two tubes of the prior art, so that thermal energy consumption can be effectively reduced, and the energy can be saved; the steel consumption of steel tube sections and outer heat-preservation layers is less than that of double tubes of the prior art, and materials can be saved.

Owner:广东智铭设计有限公司

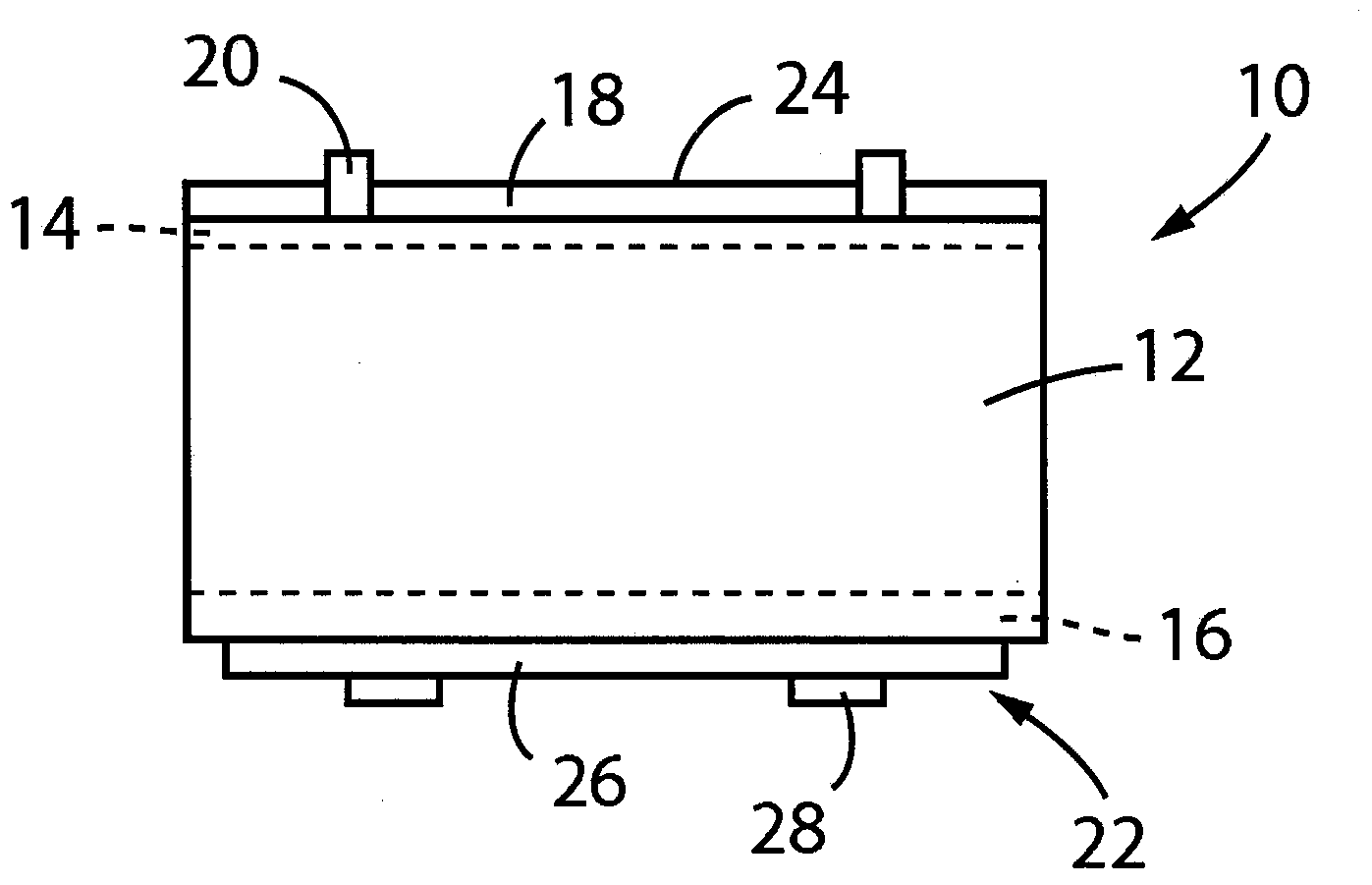

Conductive paste composition for solar cells

InactiveCN103797584AGuaranteed cross-sectional areaReduce tensionNon-conductive material with dispersed conductive materialPhotovoltaic energy generationConductive pasteSilver paste

Provided is a conductive paste composition for solar cells that makes it possible to simplify control of the penetration amount of an electrode material during the fire-through process, and to easily obtain an ohmic contact. The solar cell (10) has a light-receiving surface electrode (20) formed by the fire-through method, and the light-receiving surface electrode (20) is configured from a thick-film silver containing glass that contains SO2 in the amount of 0.05-5.0 mol%; hence, the thick-film silver paste reduces viscosity when the glass softens while maintaining favorable corrosion resistance, without adding alkali metals such as Li, Na and K, or changing the composition. Therefore, a thin, uniform glass layer is formed at the interface between the light-receiving surface electrode (20) and an n-layer (14); hence, it is possible to obtain a solar cell having excellent electrical properties.

Owner:NORITAKE CO LTD

Construction method for articulated gate shoe of pull rod of fan-shaped reinforcing steel bar penetrating arc door of gate pier

ActiveCN104099907AGuaranteed cross-sectional areaReduce construction difficultyBarrages/weirsRebarBuilding construction

The invention discloses a construction method for an articulated gate shoe of a pull rod of a fan-shaped reinforcing steel bar penetrating arc door of a gate pier. The construction method comprises the following steps that (1) when fan-shaped reinforcing steel bars are connected to one another, the fan-shaped reinforcing steel bars which penetrate in second-stage concrete grooves of the articulated gate shoe and are blocked by the articulated gate shoe extend out of first-stage concrete and extend to second-stage concrete grooves of the articulated gate shoe by a certain overlapping length, and the overlapping length is determined according to standard requirements and does not affect installation of the articulated gate shoe; and the rest fan-shaped reinforcing steel bars which penetrate in the second-stage concrete grooves of the articulated gate shoe and are not blocked by the articulated gate shoe are directly connected to one another, and then first-stage concrete of the gate pier is poured; (2) a plurality of circular steel plates are welded on the articulated gate shoe in a sleeving manner at intervals along the axial direction of the articulated gate shoe at first, and the number of the circular steel plates is determined according to the number of rows of the fan-shaped reinforcing steel bars which are blocked by the articulated gate shoe; and (3) the fan-shaped reinforcing steel bars which extend out of the first-stage concrete and extend to the second-stage concrete grooves of the articulated gate shoe by the certain overlapping length in the first step are welded with the corresponding circular steel plates, and then second-stage concrete of the articulated gate shoe is poured. The construction method for the articulated gate shoe of the pull rod of the fan-shaped reinforcing steel bar penetrating arc door of the gate pier has the advantages that the construction difficulty is reduced, and the engineering investment is saved.

Owner:YELLOW RIVER ENG CONSULTING

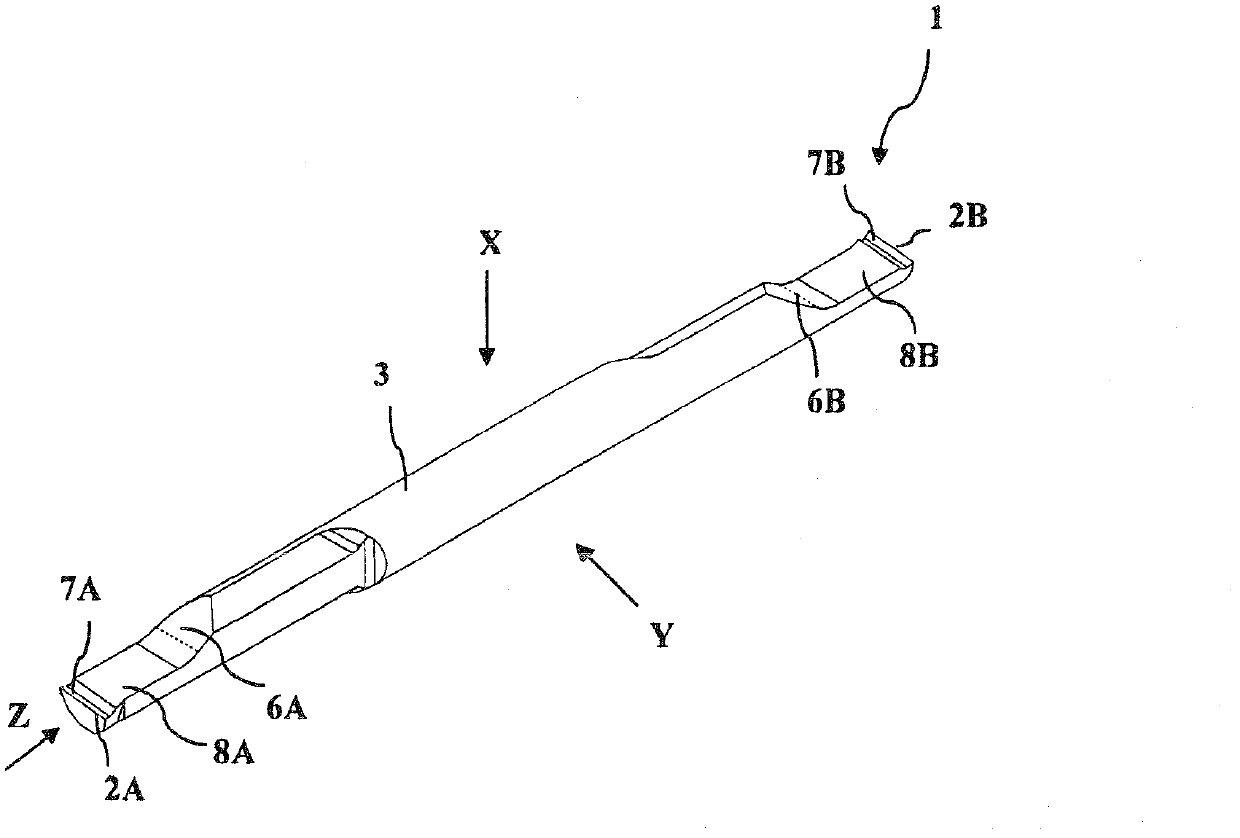

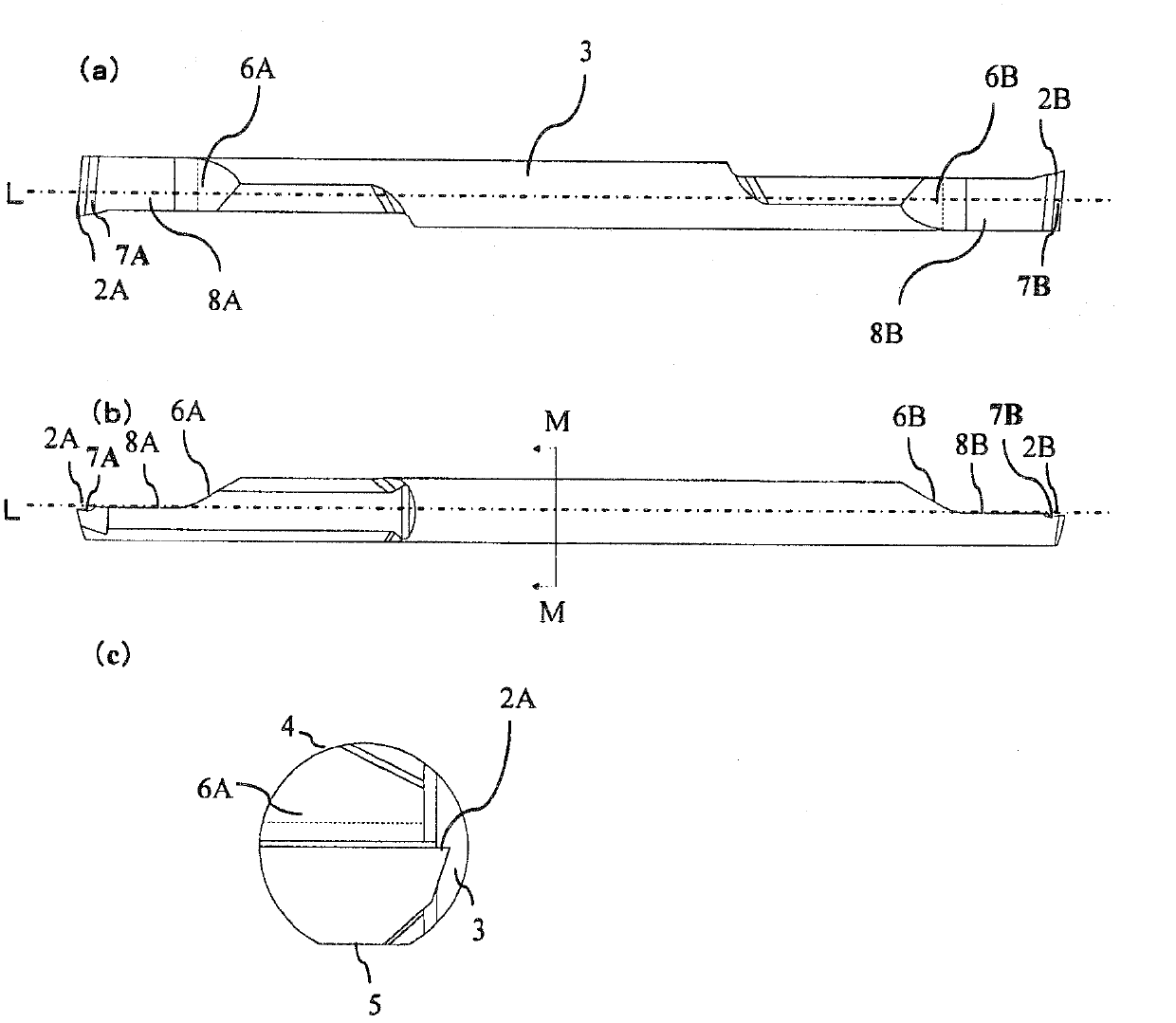

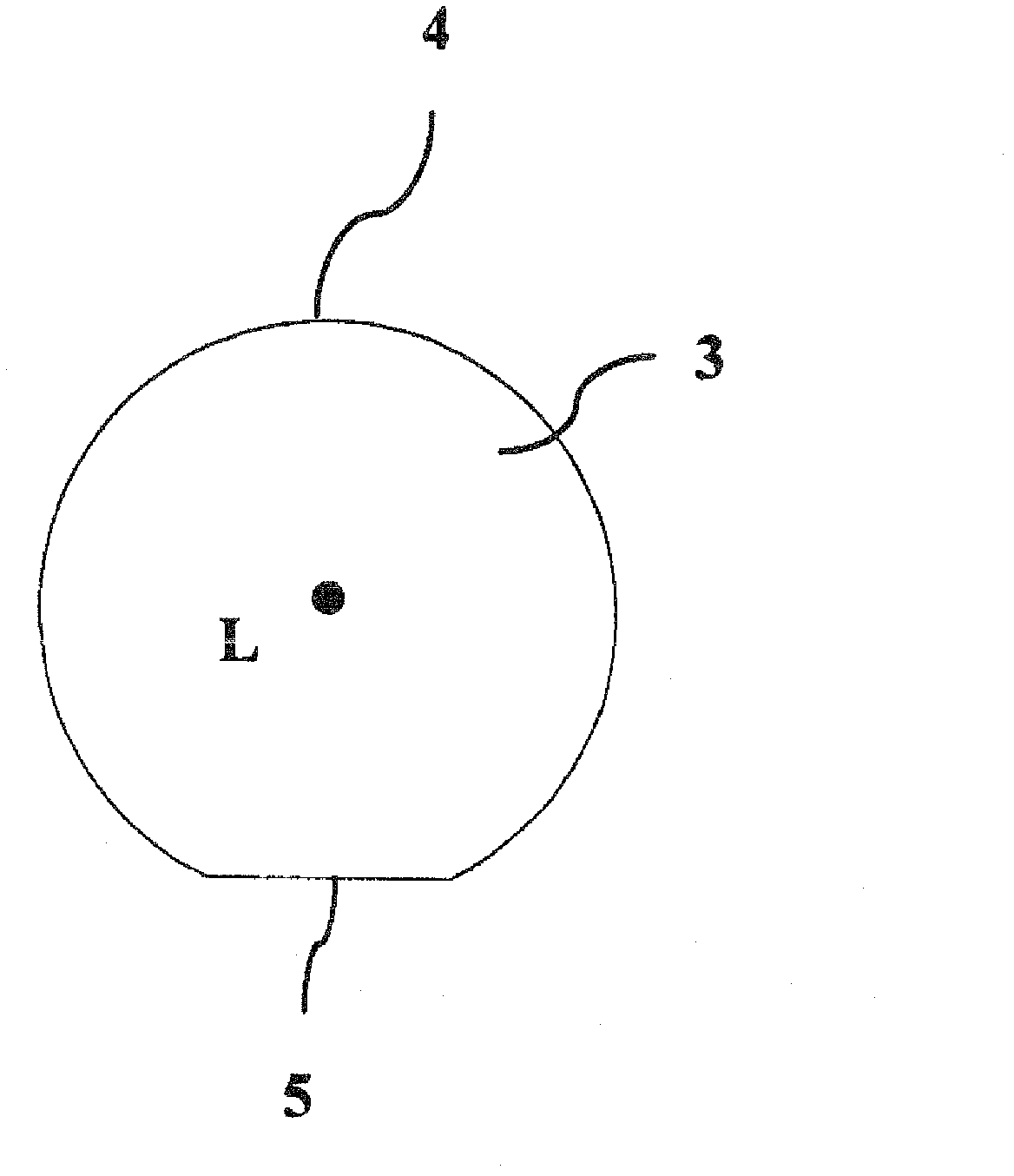

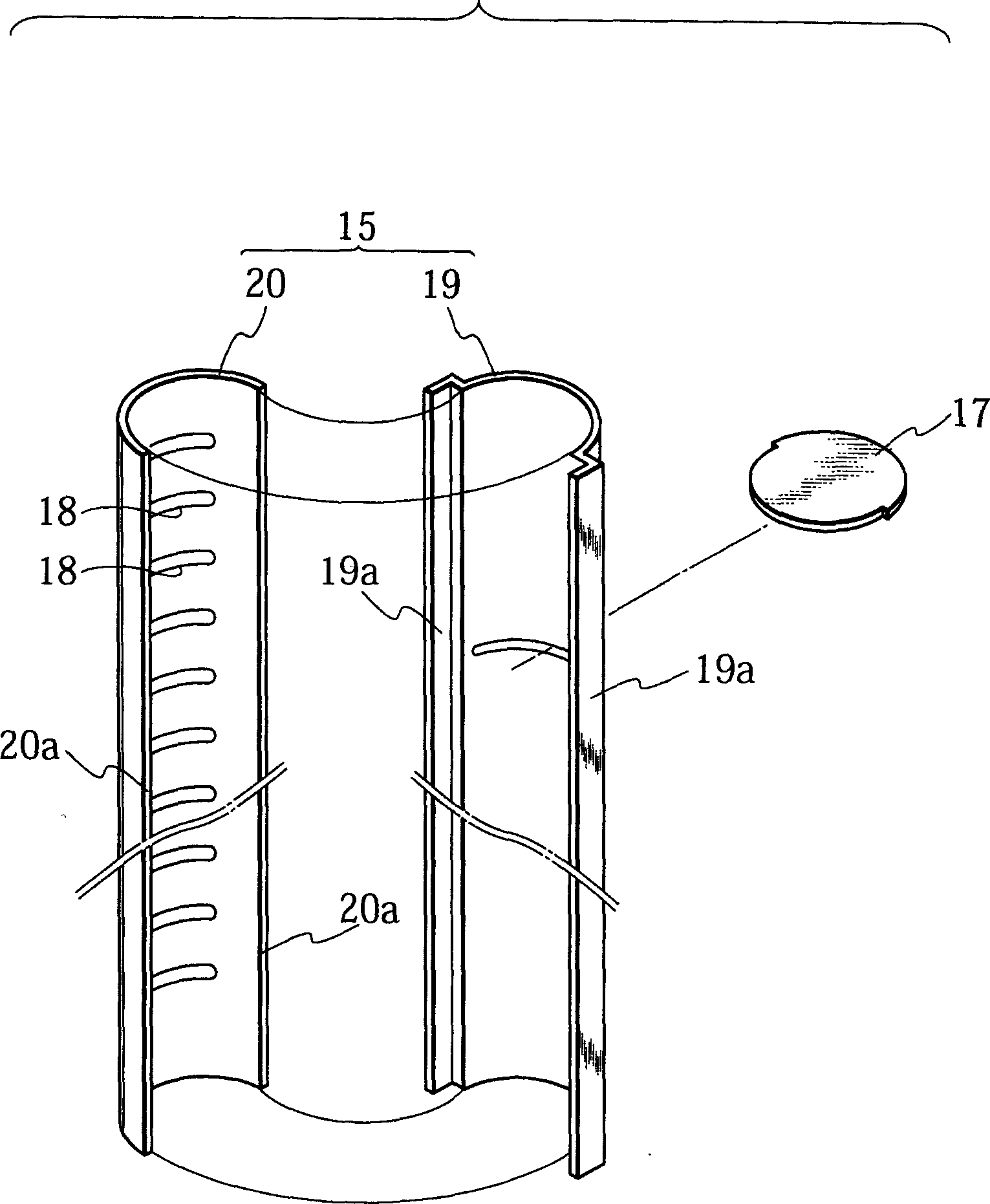

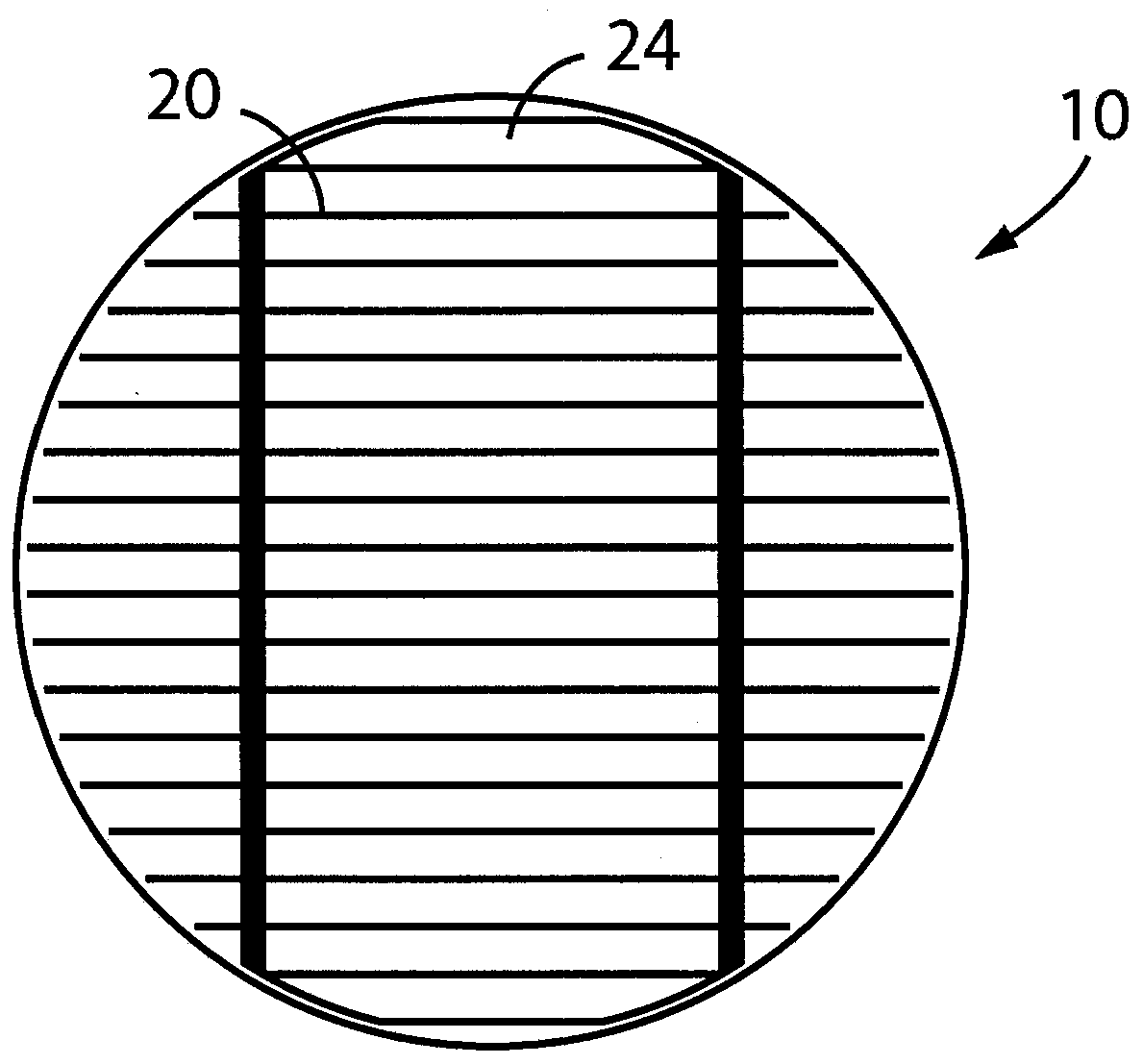

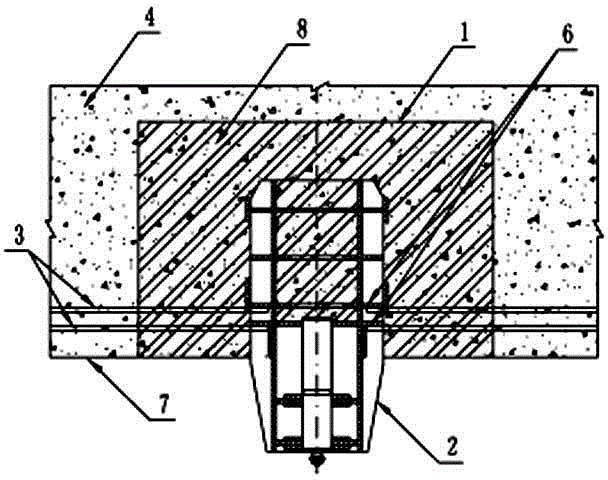

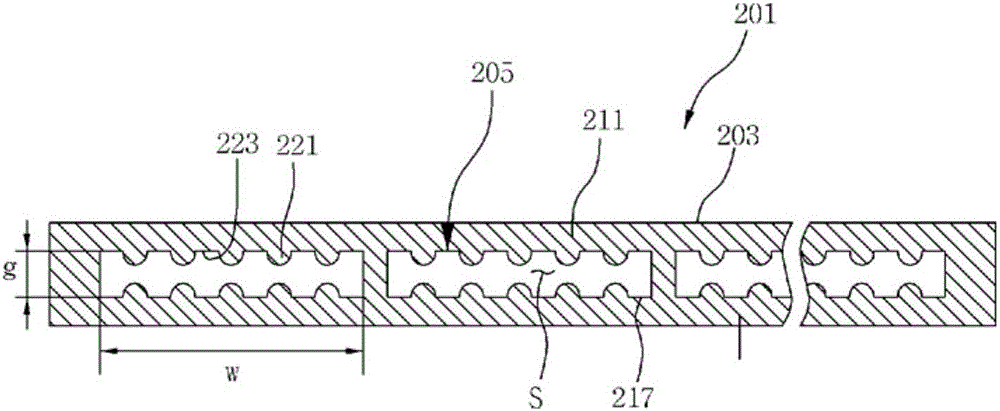

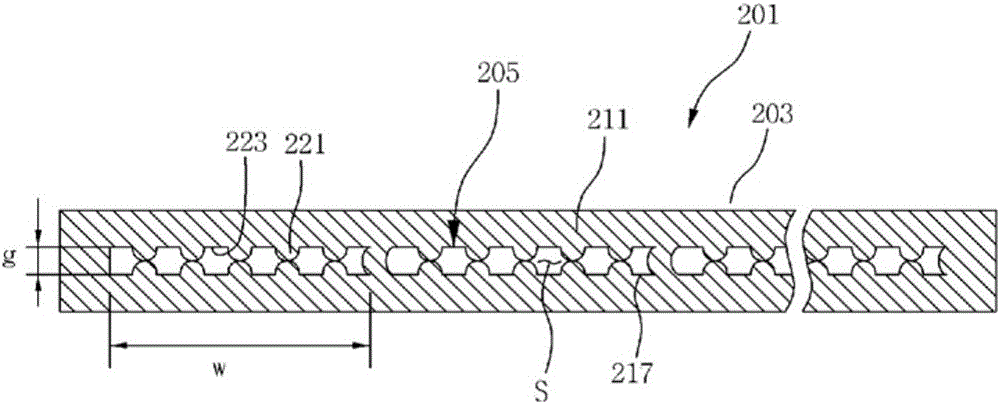

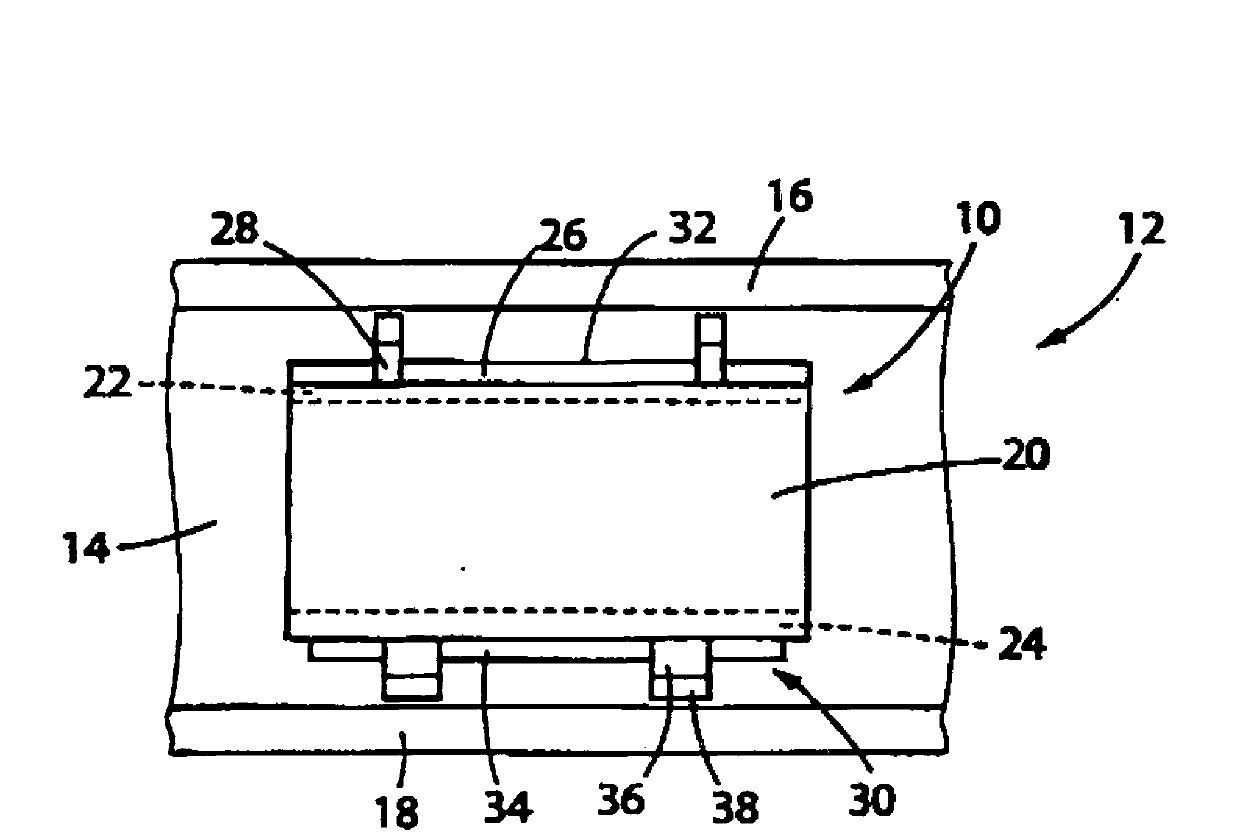

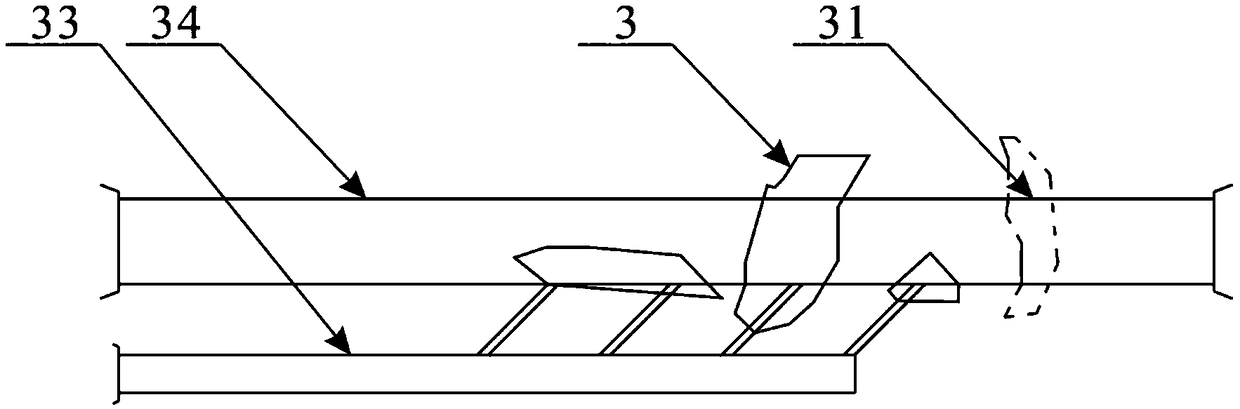

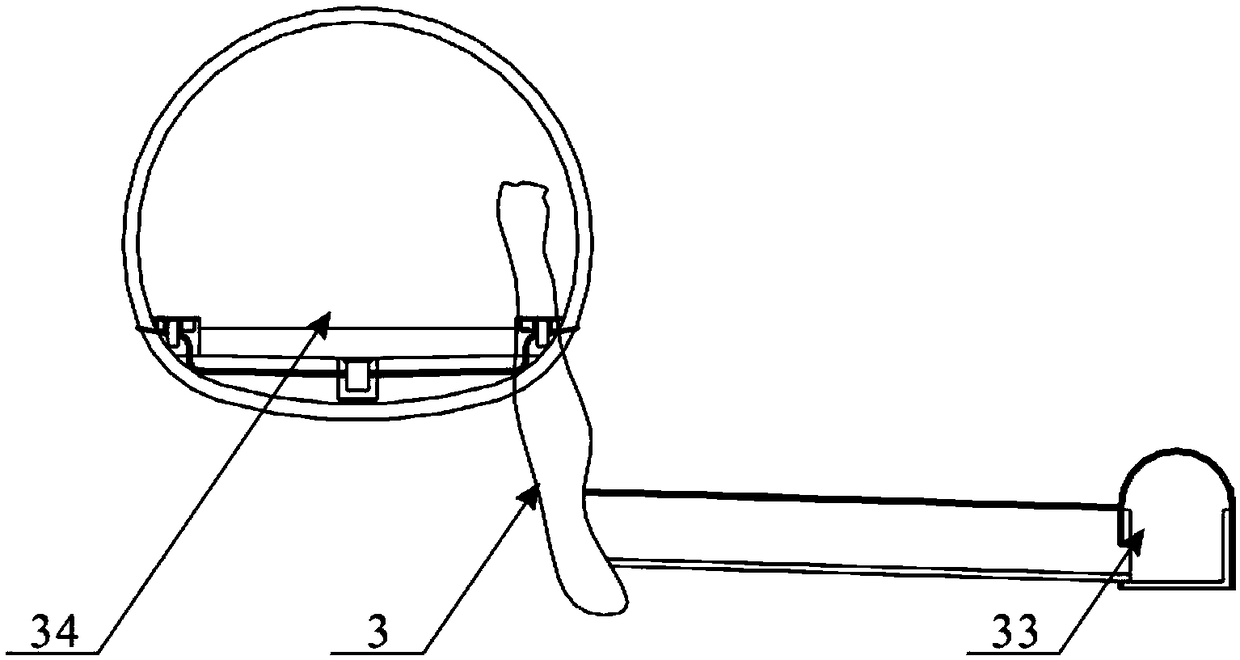

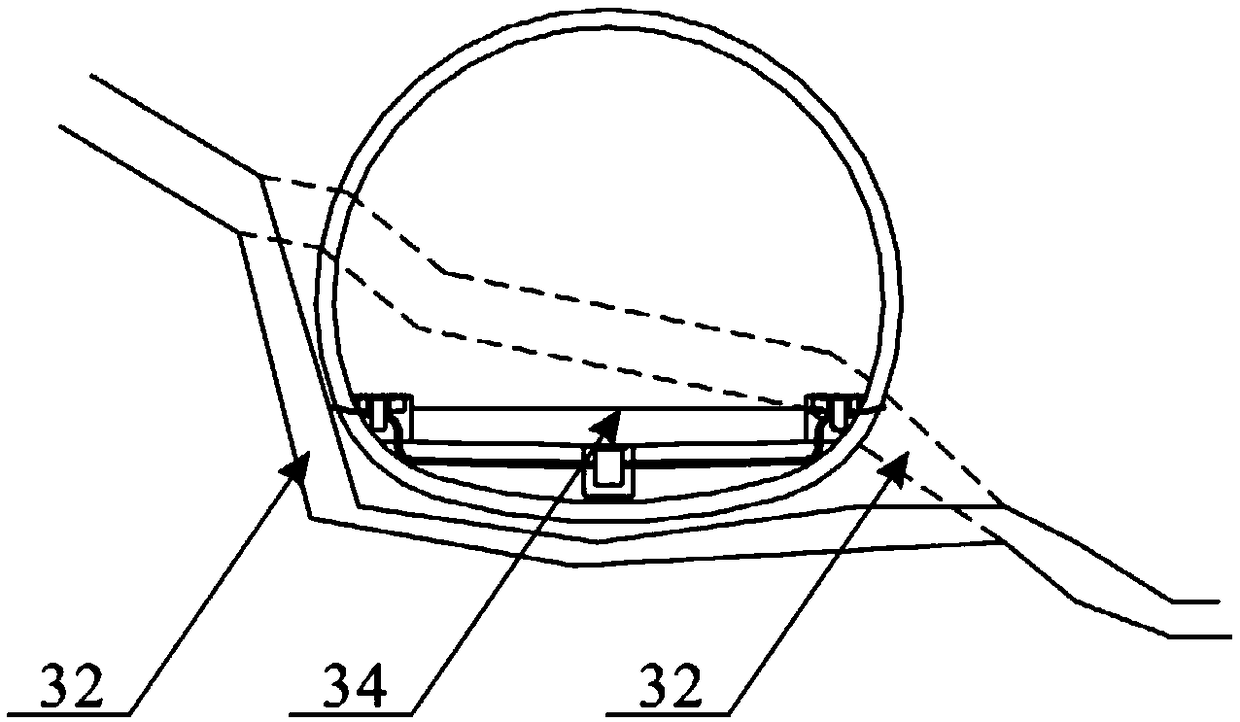

Thin heat pipe having wicks of crisscross structure

InactiveCN105793660ALow flow resistanceImprove discharge efficiencyIndirect heat exchangersHeat exchanger casingsWorking fluidEngineering

The present invention relates to a thin heat pipe having wicks of a crisscross structure, the thin heat pipe comprising: a housing (3) constituting a plate-shaped outer body having a thickness smaller than the length or width thereof; an operating fluid evaporated at an evaporation portion on one side of the housing (3) and then condensed at a condensation portion on the other side thereof, thereby transferring heat from the evaporation portion to the condensation portion; and wicks (5) extending in the longitudinal direction such that the operating fluid, which has been condensed at the condensation portion, returns to the evaporation portion, wherein the wicks (5) are arranged on inner peripheral surfaces of respective flat plate bodies (11) so as to crisscross each other in the transverse direction such that the flow sectional area of an operating space (S) is maintained to be constant in the transverse direction; as a result, a sufficient sectional area of an injection opening for degassing is secured, and the boiling operating fluid is prevented from being discharged in a liquid lump state, thereby enabling expectation of improving the heat pipe quality and production efficiency.

Owner:TTM

Method for processing rectangular round hole conductor copper pipe of double-water internal cooling generator

The invention discloses a method for processing the rectangular round hole conductor copper pipe of a double-water internal cooling generator, comprising the following steps: selecting a pipe blank; casting, extruding and stretching the selected pipe blank to form a round pipe blank; rolling the shaped pipe blank; annealing the rolled pipe blank; transiting and stretching the annealed pipe blank; and stretching the transited and stretched pipe blank to form a finished product. With the method, the technical problems of large coil consumable amount, large unit volume, poor coil cooling effect and short service life of the unit because the coil material adopted in the prior art is solid or has a rectangular bore can be solved, and the method has the advantages of material conservation, long service life and the like.

Owner:徐宗保

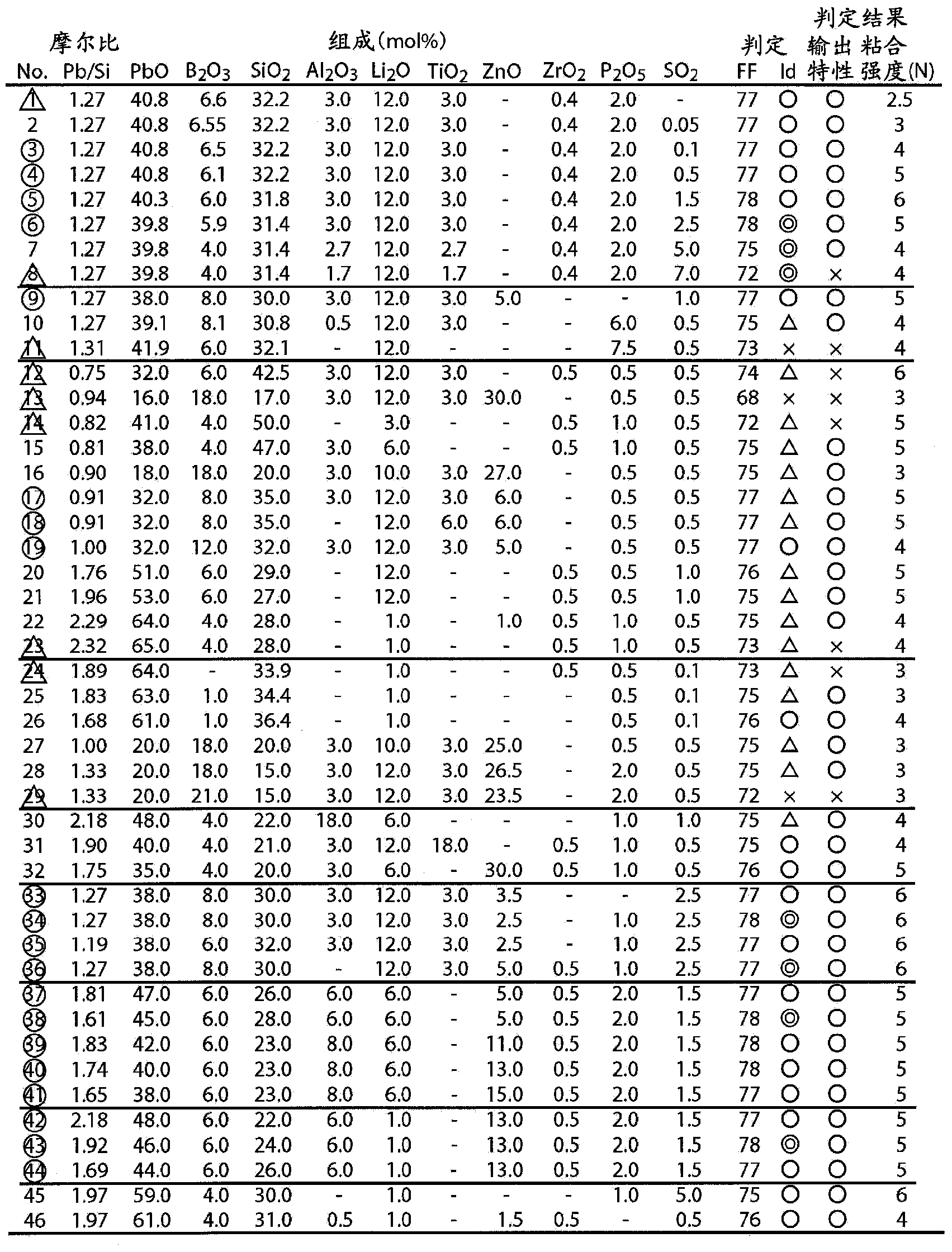

A paste composition for a solar cell electrode

InactiveCN103151093AIncreasing the thicknessReduce tensionMetal/alloy conductorsPhotovoltaic energy generationOhmic contactLead glass

The invention provides a paste composition for a solar cell electrode. According to the invention, the intrusion amount of electrode material can be easily controlled even when electrodes are formed in n layers of thin solar cells of a shallow emitter structure with a firing holing method and high-efficiency solar cells with high FF value and less current leakage can be obtained. An illuminated surface electrode is formed by thick film silver comprising, by weight, 1-10 parts of lead glass with respect to 100 parts of silver. The lead glass contains 6-62 mole% of PbO, 1-18 mole% of B2O3, 8-49 mole% of SiO2, 0-30 mole% of A12O3, 1-30 mole% of Li2O, 1-30 mole% of TiO2, 0-30 mole% of ZnO, 0-1.0 mole% of ZrO2 and 0-6 mole% of P2O5 and thus the intrusion quantity is controlled to be 80-90nm. Therefore, even the line width is reduced to be 100 microns, favorable ohmic contact can be obtained and photoelectric conversion efficiency of the solar cells can be improved.

Owner:NORITAKE CO LTD

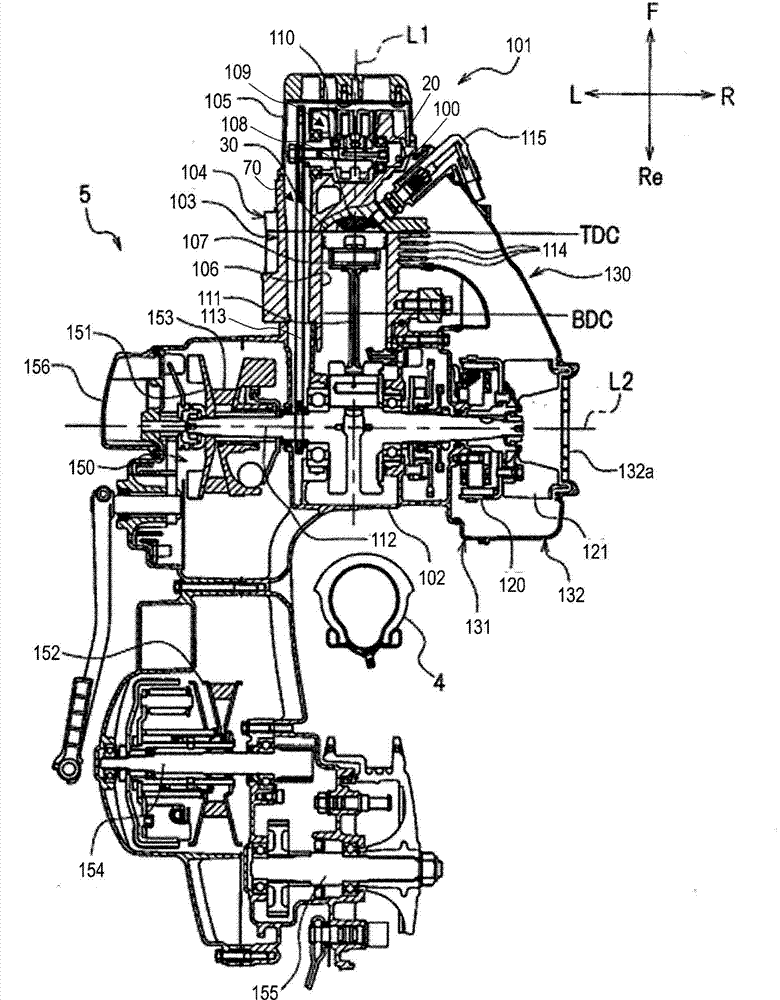

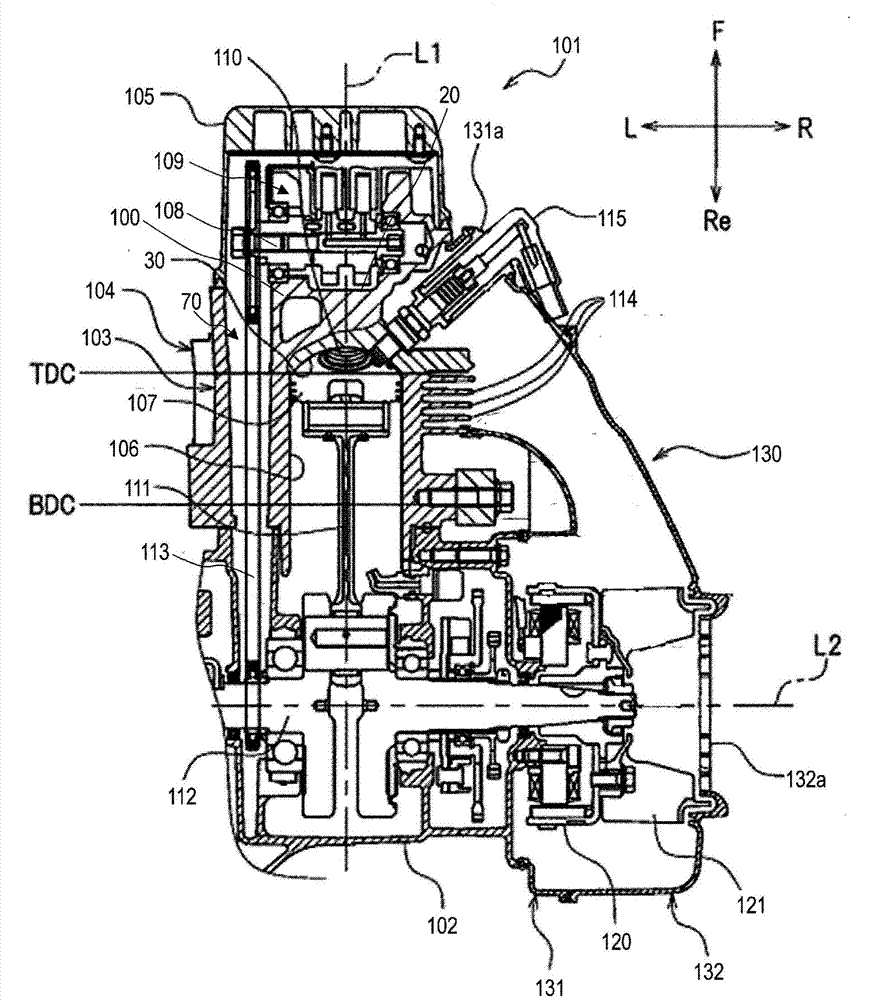

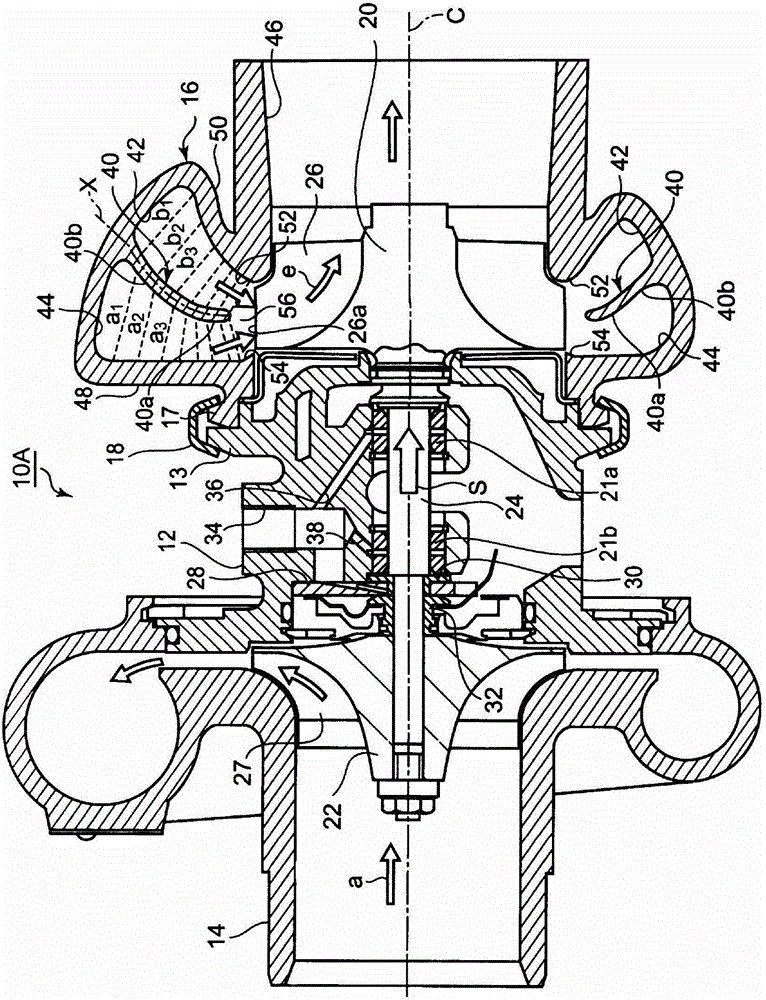

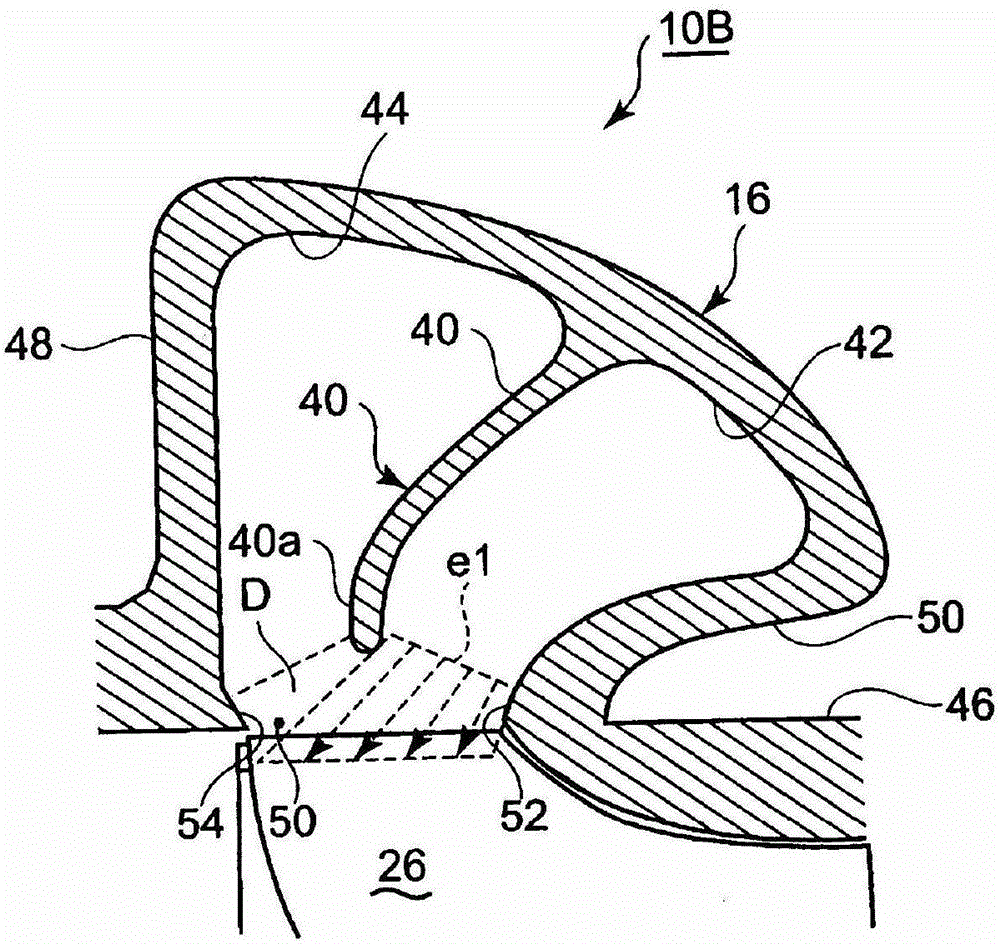

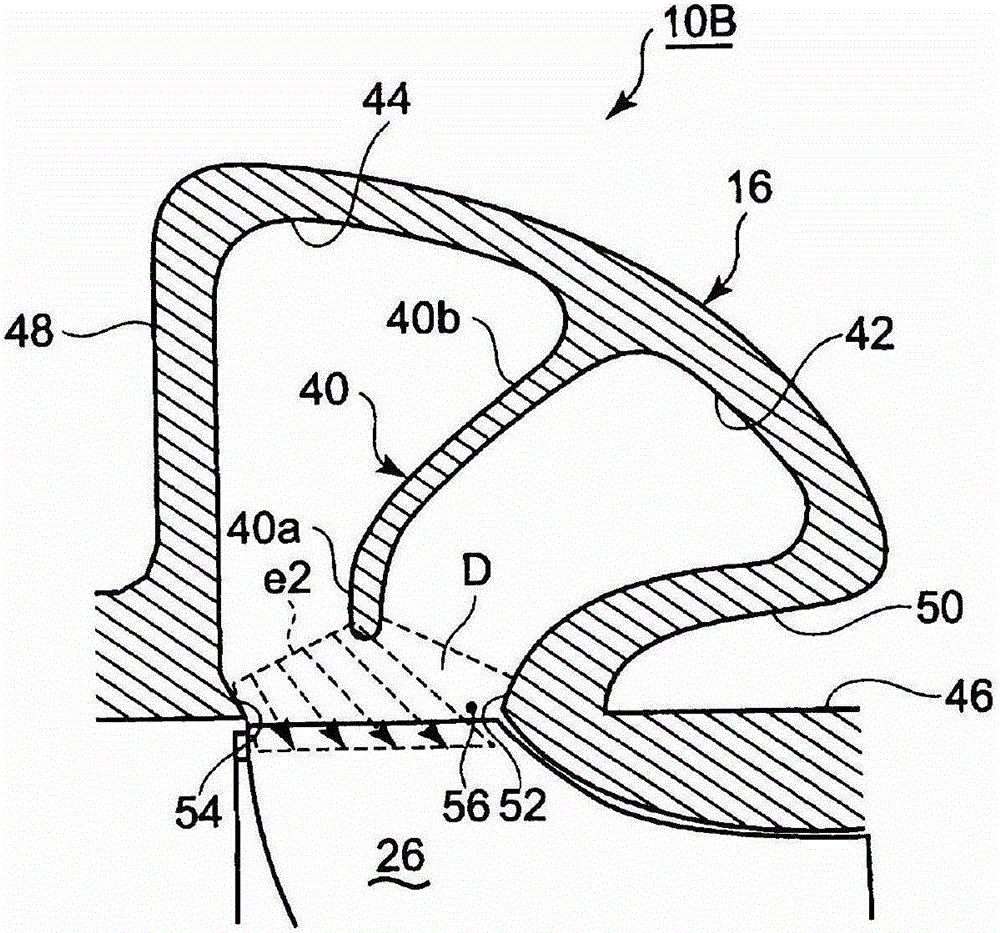

Air-cooling type internal combustion engine and saddled vehicle having the same

ActiveCN103711560ABig spaceGuaranteed cross-sectional areaAir coolingCylinder headsCylinder headExternal combustion engine

The present invention relates to an air-cooling type internal combustion engine and a saddled vehicle having the same. The air-cooling type internal combustion engine includes a cylinder head body (100), the cylinder head body (100) including: a plurality of cooling fins (10); a cam chamber wall (20) defining a cam chamber (109); a combustion chamber wall (30) defining a combustion chamber (110); an intake duct (40) through which air intake into the combustion chamber (110) is to occur; an exhaust duct (50) through which exhaust from the combustion chamber (110) is to occur; and a cooling air duct (60) for allowing cooling air to pass through the cam chamber wall (20) and the combustion chamber wall (30). The cylinder head body (100) is integrally molded from an aluminum alloy by die casting. The cylinder head body (100) further includes a cam chain chamber (70) for accommodating a cam chain (113). When viewed in the cylinder axis direction (D1), the exhaust duct (50) extends in such a manner that the exhaust duct (50) becomes more distant from the cam chain chamber (70) when going from the inlet side toward the outlet side, and the exhaust duct (50) is formed so that an axis (50x) of the exhaust duct (50) is linear.

Owner:YAMAHA MOTOR CO LTD

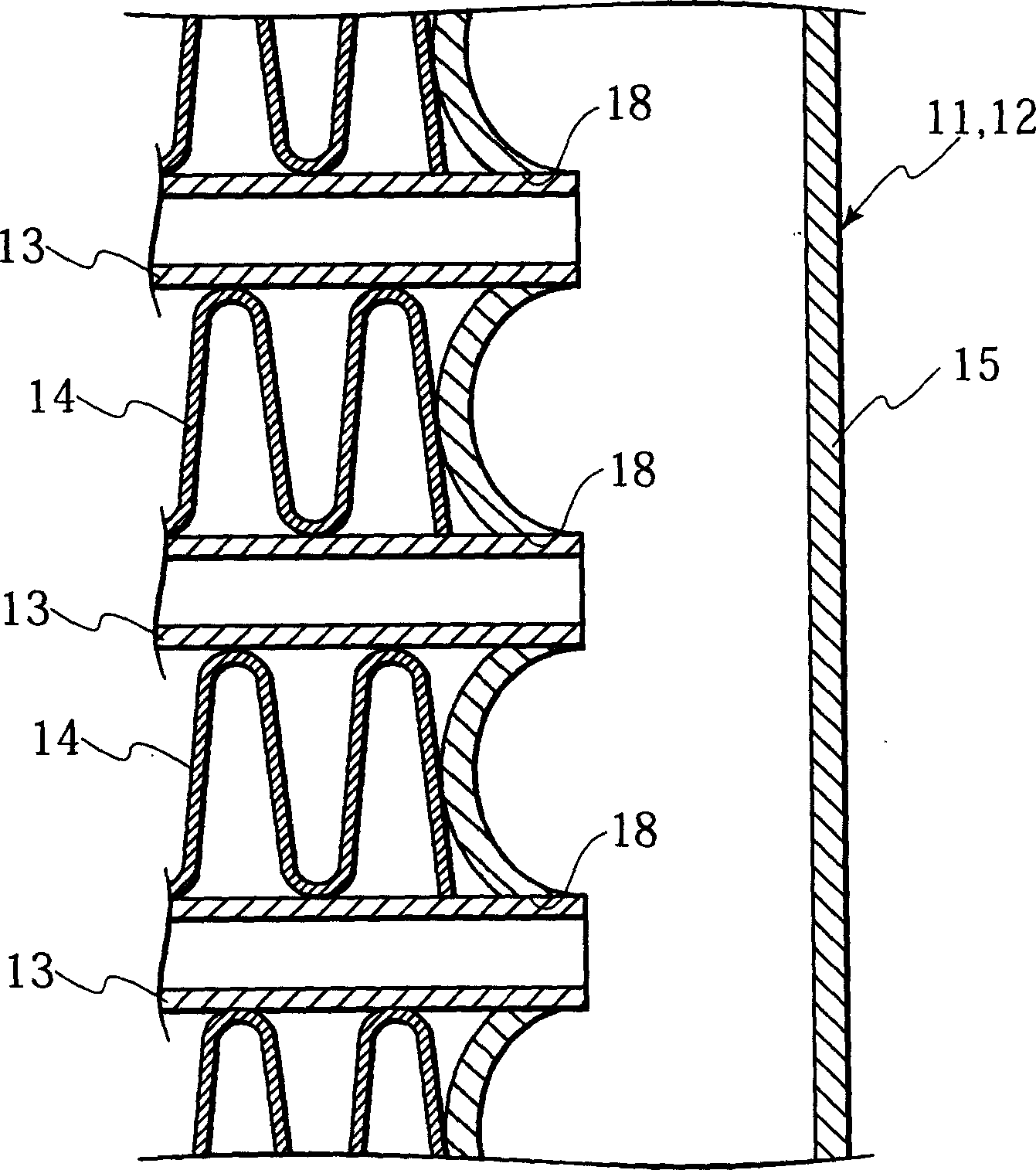

Hollow conductor with reinforcing ribs

InactiveCN104464896AGuaranteed cooling effectAvoid section reductionSingle tube conductorsTransformers/inductances coils/windings/connectionsWater channelTransformer

The invention relates to a hollow conductor with reinforcing ribs for a water-cooled transformer and a water-cooled electric reactor. The conductor comprises a conductor wall and at least one reinforcing rib arranged in the conductor wall, and a hollow cavity defined by the conductor wall is divided into a plurality of flow water channels by the reinforcing ribs. The hollow conductor with the reinforcing ribs can effectively avoid the phenomenon that the sections of the hollow-out channels are reduced due to inwards recessing of the hollow conductor caused by bending deformation in the process that the hollow conductor is wound into a coil, and ensure the sectional area of the water flow channels and the cooling effect of the water-cooled transformer and the water-cooled electric reactor.

Owner:JINPAN ELECTRIC GRP SHANGHAI

Building steel structure

PendingCN110185144AReduce the cross-sectional areaGuaranteed cross-sectional areaBuilding constructionsEngineeringGravitation

Owner:CCDI INT SHENZHEN DESIGN CONSULTANTS

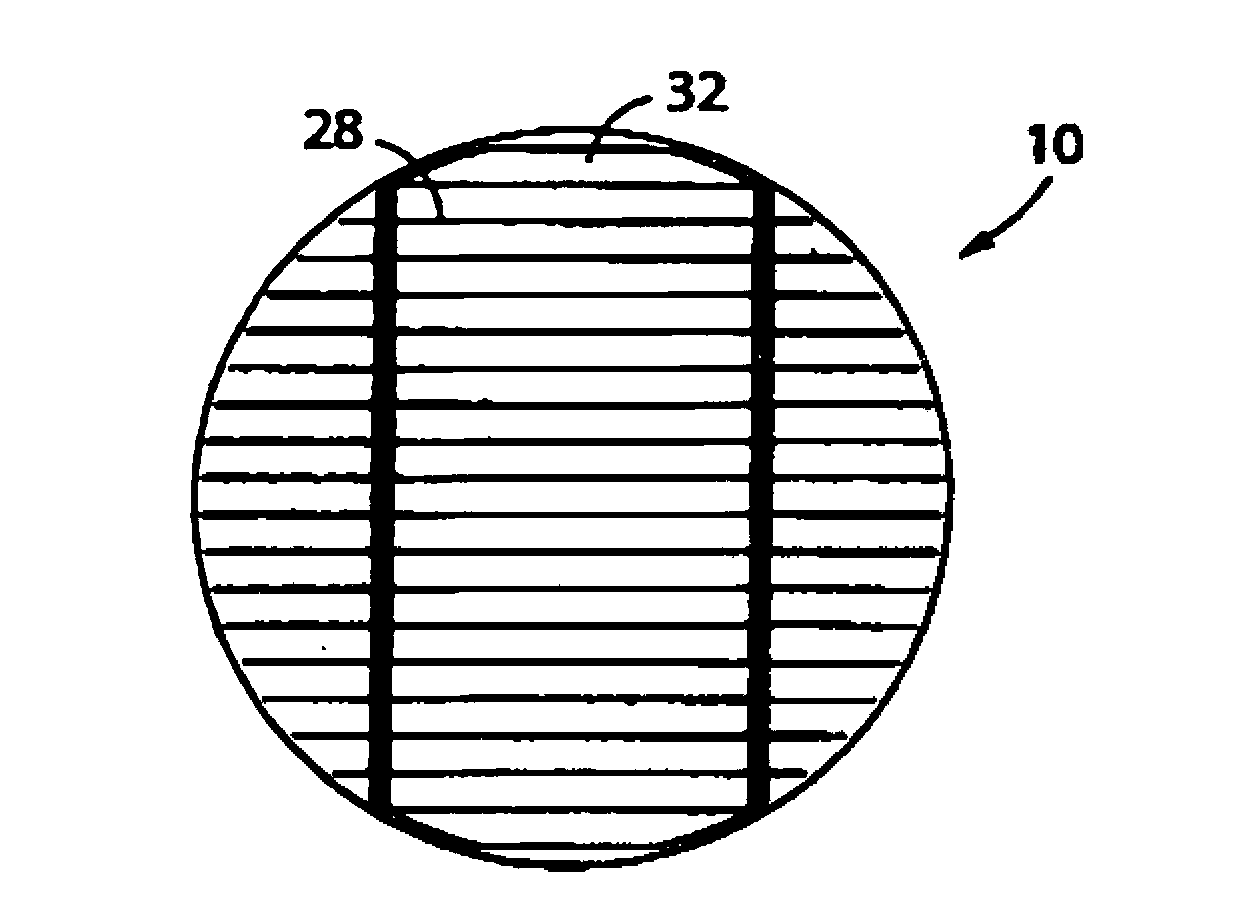

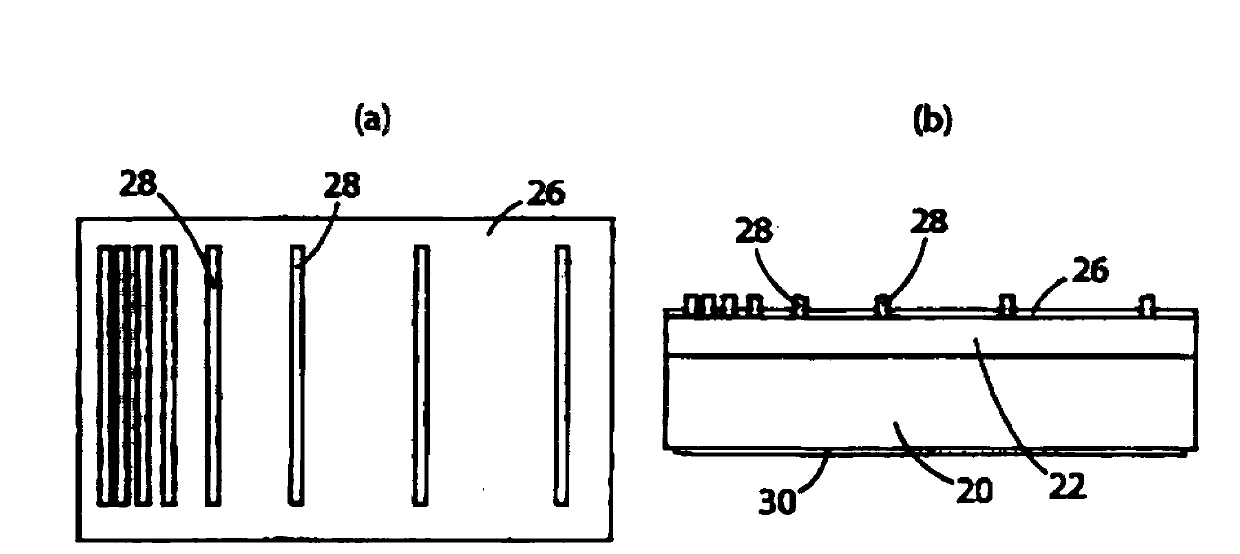

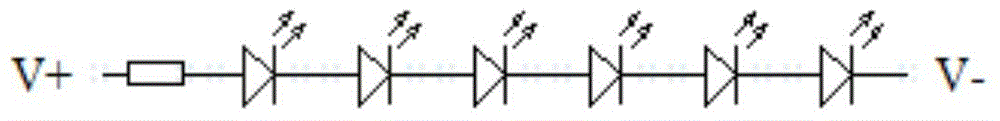

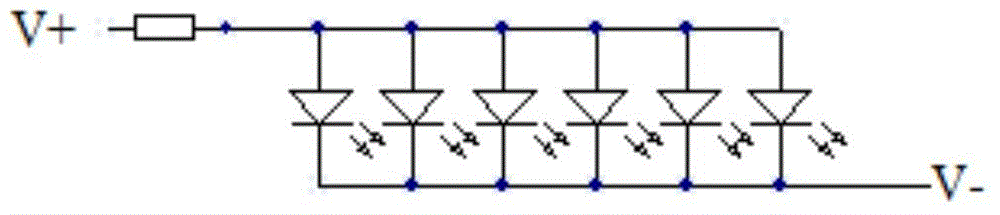

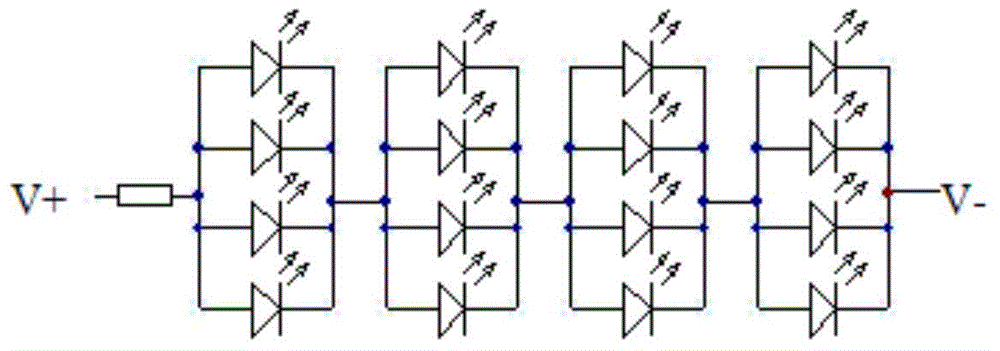

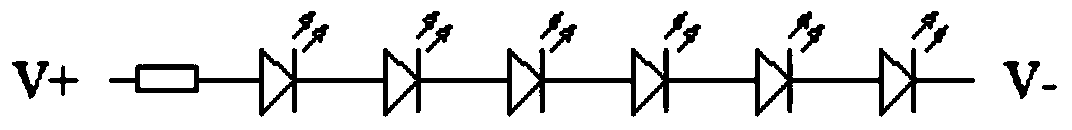

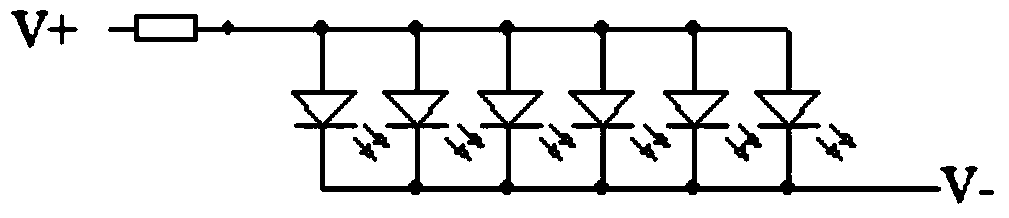

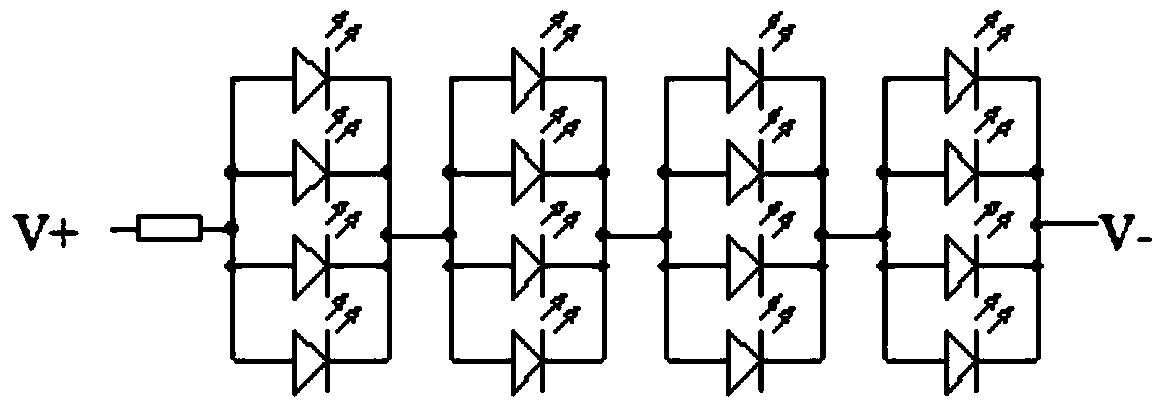

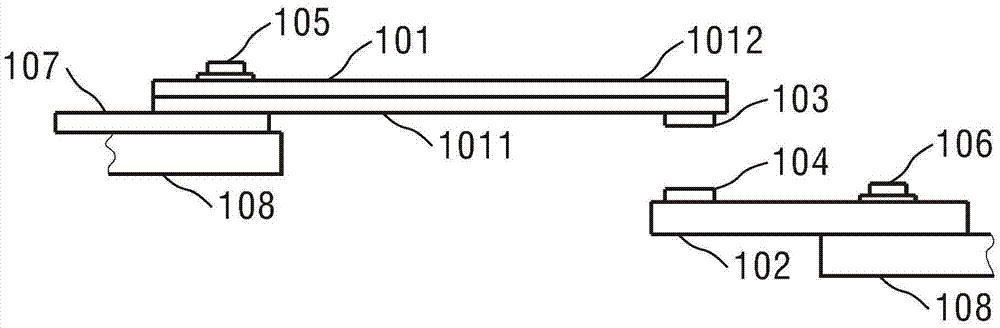

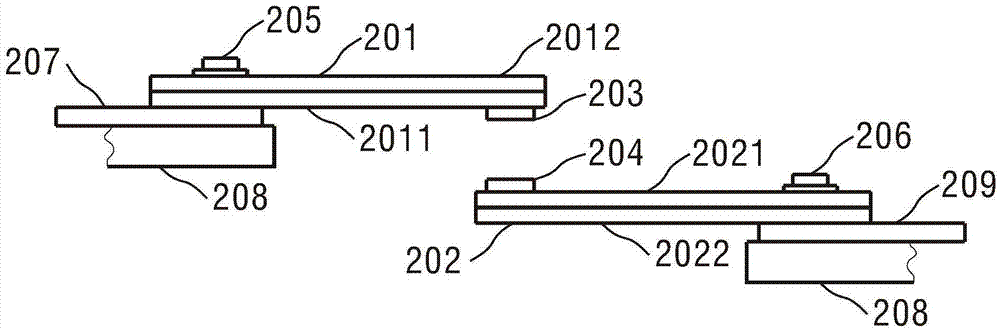

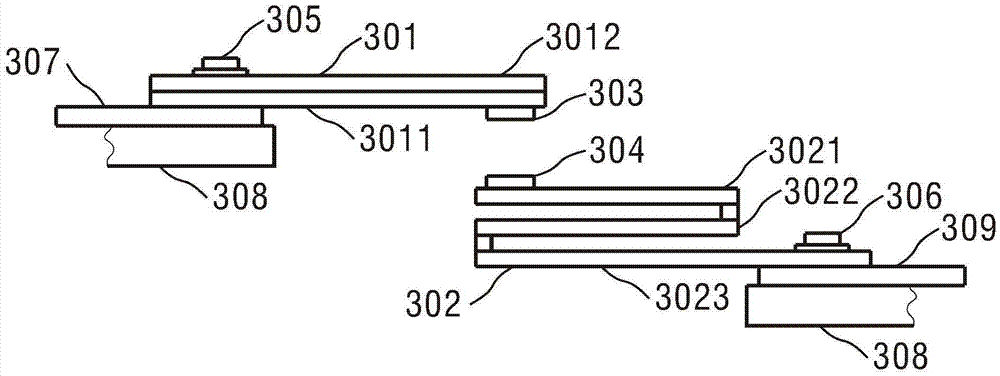

LED module with temperature signal output and detection current signal output and application circuit thereof

ActiveCN105067035AConvenient series and parallel connectionGuaranteed cross-sectional areaMeasurement devicesBuck converterElectrical polarity

The present invention discloses an LED module with a temperature signal output and a detection current signal output and an application circuit thereof. The LED module at least comprises an LED substrate, an LED chip group, a current detection device and a temperature detection device. The current detection device and the chip group are connected in series and then are packaged in the LED substrate. The temperature detection device is installed on the LED substrate. The upper and lower sides of the LED substrate are provided with positive and negative electrodes, the polarity of the electrodes at the same side are the same, and the leading-out end of each electrode is provided with a conductive pad. The application circuit comprises multiple groups of LED modules and an external control conversion circuit which comprises an A / D converter, a controller MCU and a D / A converter. The output ends of the current detection device and the temperature detection device of each group of LED modules are connected to the input end of the A / D converter, and the A / D converter is connected to a D / A converter through a controller. According to the LED module and the application circuit, the series and parallel connection between the LED modules is facilitated, the replacement is convenient, the working current and temperature of a single LED module are monitored at any time according to needs, and the normal working of an LED light source is ensured.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Endoscopic cannula and endoscope

InactiveCN109602379ALow costSimplify sanitation requirementsSurgeryEndoscopesEndoscopeGeneral surgery

The invention discloses an endoscopic cannula and an endoscope. The endoscopic cannula includes an endoscope tube, a forcep channel and an aspirator connecting end, wherein one end of the endoscope tube is open and the other end is closed and has good light transmittance; a forcep channel is parallel to the endoscope tube, the outer walls of the endoscope tube and the forcep channel are mutually adhered, and the forcep channel is provided with a suction opening at the same end of the closed end; the aspirator connecting end is connected with the non-two ends of the forcep channel at a certainincluded angle. The endoscope tube, the forcep channel and the aspirator connecting end are made of a flexible transparent material. The endoscope tube is used for inserting an endoscope, the endoscope includes a light source and a camera system, and the forcep channel can be connected with an external inspiratory device or a matched endoscope forcep. The endoscopic cannula can sleeve the endoscope to be used, it is easy for the suction opening to absorb the liquid in the patient's body, and the endoscope is always in the package of the endoscope tube and is not polluted. After the use, the cannula is discarded directly, thus eliminating the disinfection operation of the endoscope, improving the efficiency of the use of the endoscope and reducing the cost of the department.

Owner:杭州市儿童医院

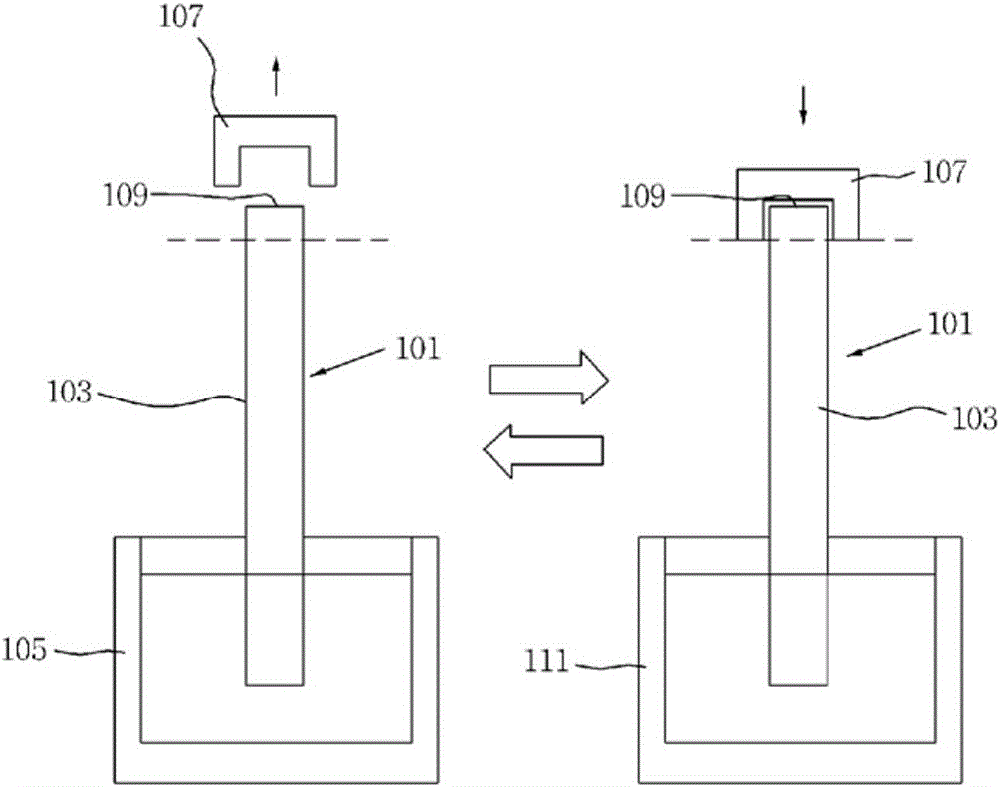

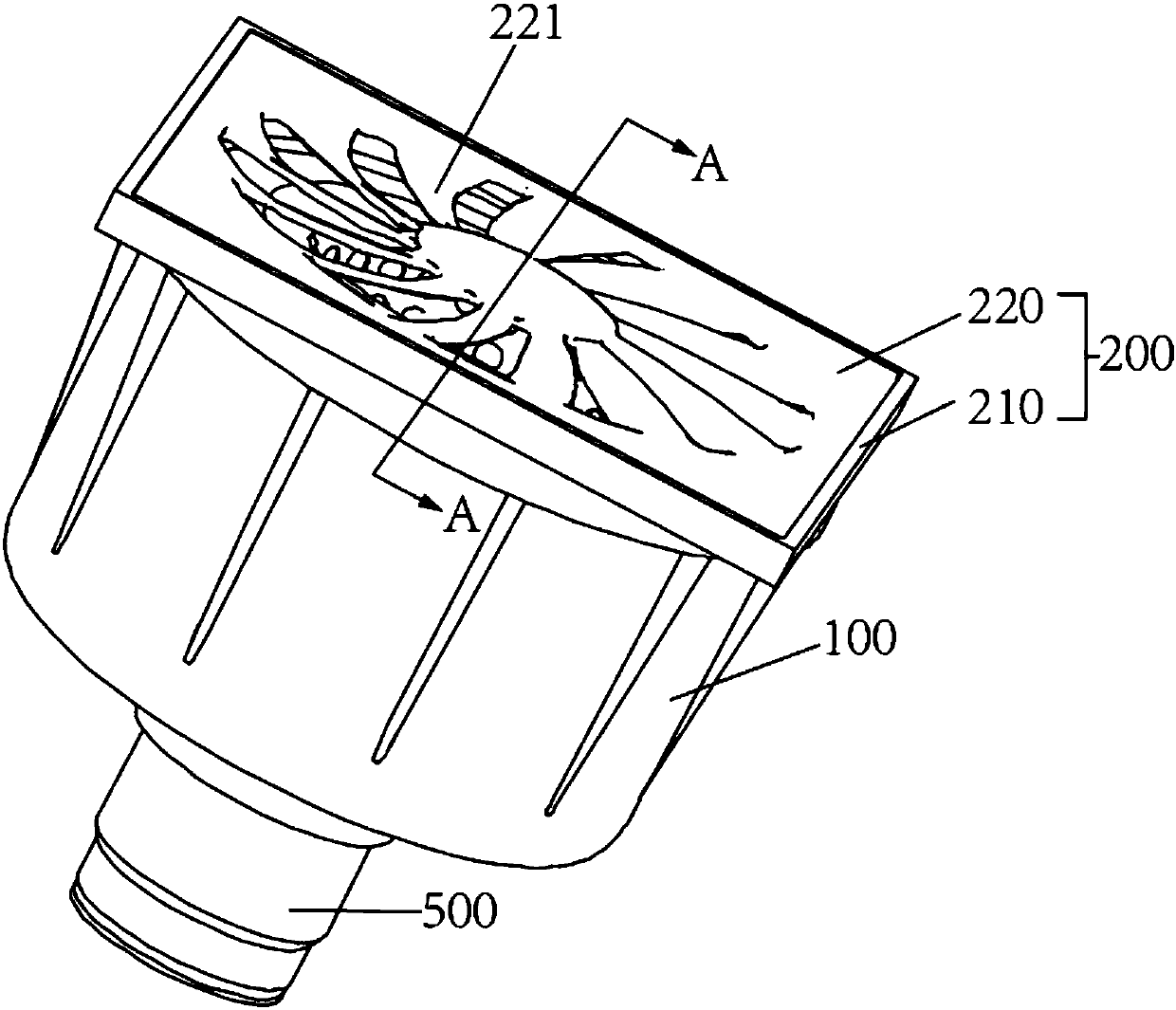

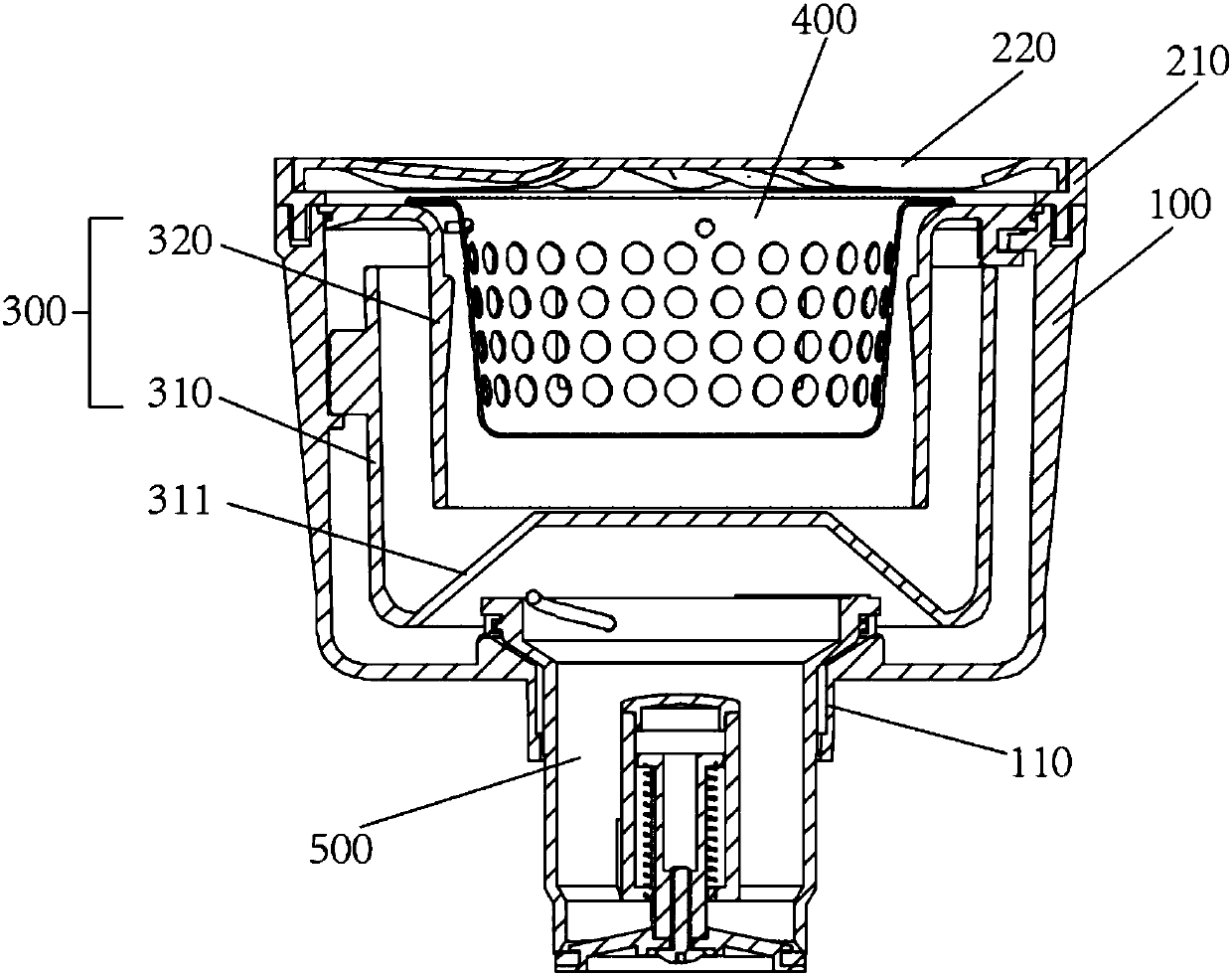

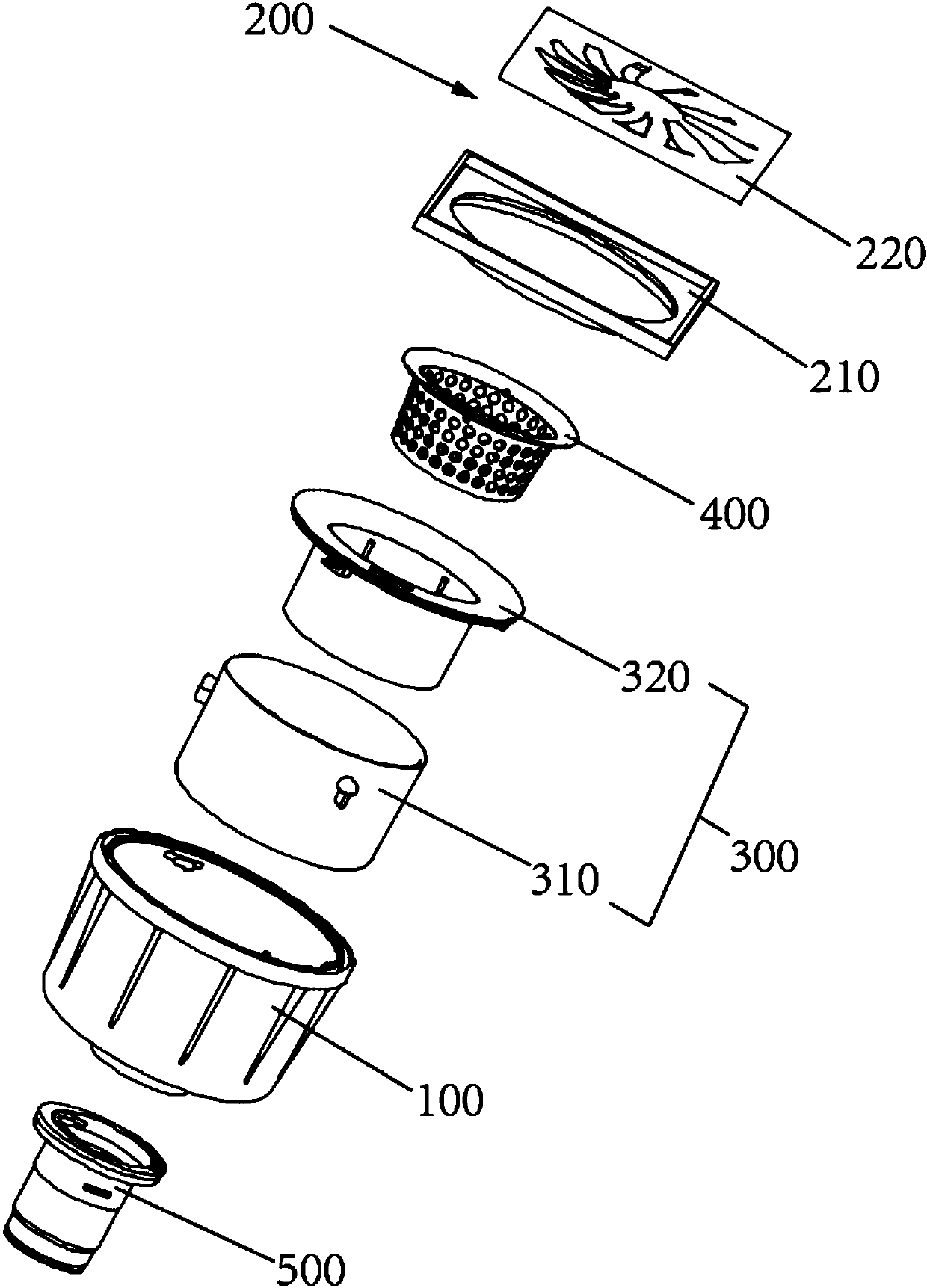

Reverse siphoning type great-discharge-volume floor drain

The invention provides a reverse siphoning type great-discharge-volume floor drain, which comprises a case and a sealing cover, wherein the sealing cover is covered above the case so as to form a cavity; a siphoning assembly is arranged in the cavity, and comprises a water sealing core and an inner core; an opening of the water sealing core is upward and is arranged inside the cavity; the inner core is in a tubular shape with openings at two ends and is arranged inside the water sealing core; a flanging edge outwards extends from the upper edge of the inner core; the flanging edge is in abut joint with the inner wall of the case; the bottom of the water sealing core is provided with a flow guide table; the flow guide table upwards projects and extends. A plurality of water discharging passages are formed among the water sealing core, the inner core and the case; the cross area of each passage is smaller than the cross area of the upper passage. The plurality of water discharge passagesare formed; the cross section ratio of the two adjacent passages are controlled; the siphoning water discharging effect is good; the water discharging quantity is great.

Owner:XIAMEN JINGYICHENG METAL PROD

Tunnel combined-type lining structure with maintainable drainage passage

InactiveCN109236321AImprove reliability and durabilityGuaranteed cross-sectional areaUnderground chambersDrainageStructural engineering

Owner:SOUTHWEST JIAOTONG UNIV

Exhaust device for two-wheel motorcycle

InactiveCN1959074BImprove space utilizationGuaranteed volumeExhaust apparatusSilencing apparatusEngineeringExpansion chamber

Disclosed is an exhaust apparatus for two-wheeled motorcycle. The space utilization of exhaust apparatus arranged under the motor can be further improved in a two-wheeled motorcycle attached with a transverse V-shape motor. At the front and rear of an oil disc (15) respectively provides a front expansion chamber (27) and a rear expansion chamber (26) which are connected with each other via connecting pipe (28). Wherein, the connecting pipe (28) is arranged at right side of the motorcycle body. In the space formed with the front expansion chamber (27) and the rear expansion chamber (26) respectively provided at front and rear and the connecting pipe (28) provided at side, the oil disc (15) can be arranged to protrude downward. Thus, the oil disc (15) volume can be sufficiently ensured, andthe space utilization of exhaust apparatus (5) can be further improved.

Owner:HONDA MOTOR CO LTD

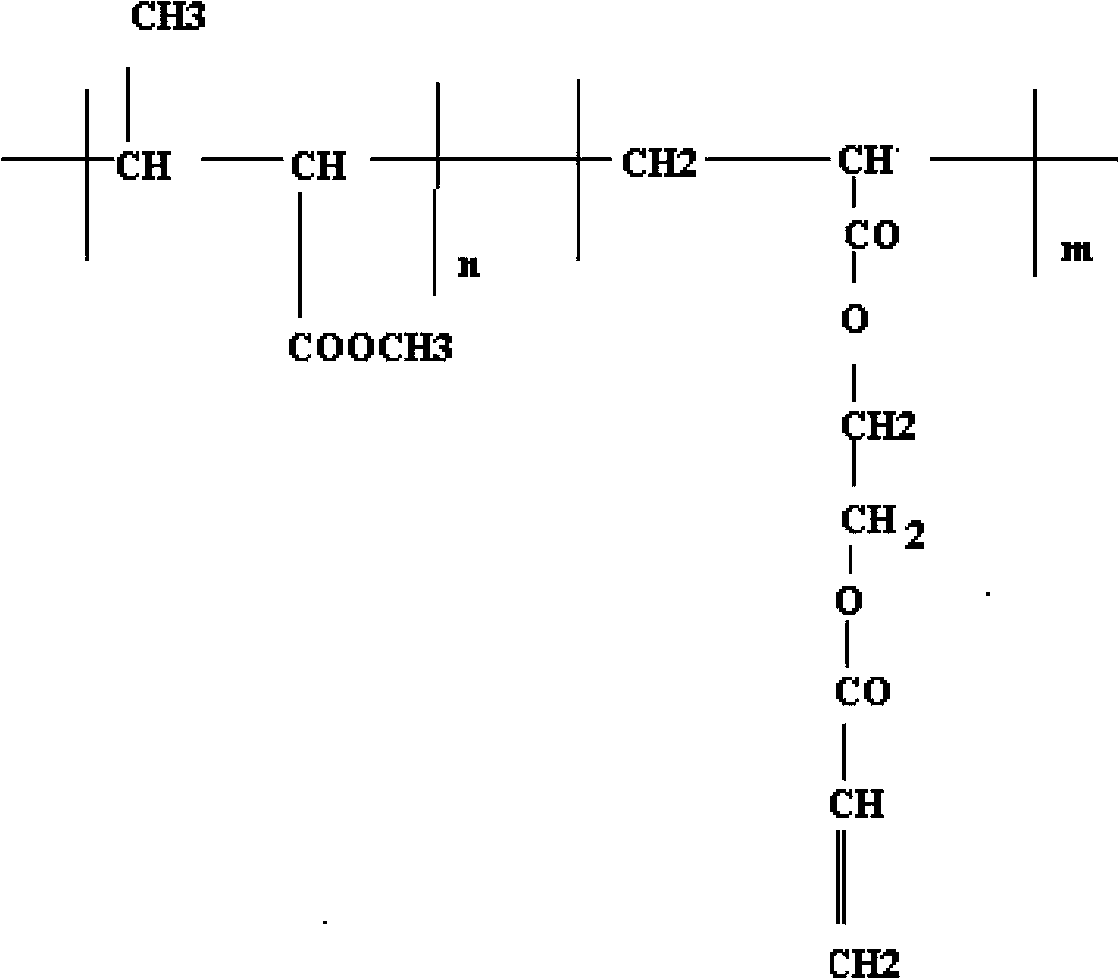

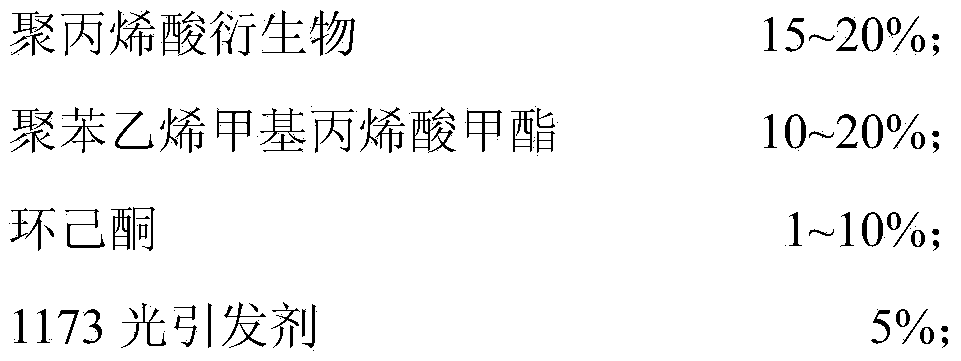

Silver conductive composition without screen printing and used for line manufacturing

InactiveCN102800379BGuaranteed cross-sectional areaImprove conductivityNon-conductive material with dispersed conductive materialCable/conductor manufactureCyclohexanonePolystyrene

The invention discloses a silver conductive composition without screen printing and used for line manufacturing. The silver conductive composition comprises components with the following weight percentages: 15-20% of polyacrylic acid derivative, 10-20% of polystyrene methyl methacrylate, 1-10% cyclohexanone, 5% 1173photoinitiator, 1-10% triphenylamine, and 40-60% of silver. The invention also discloses a method for preparing the silver conductive composition without screen printing and used for line manufacturing, and application thereof in preparation of electronic circuits of color plasma flat-panel displays. With the method, electronic circuits lower than 20-50[mu]m can be produced. Height of the circuits can be adjusted, thereby ensuring sectional areas of the circuits, improving conductivity. Compared with screen printing, the method improves production efficiency.

Owner:JIANGSU UNIV OF SCI & TECH

Turbine housing for twin-scroll turbocharger

ActiveCN103038479BSmall outer diameterEliminate flow differencesCombustion enginesStatorsTurbochargerEngineering

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

A LED module with temperature signal output and detection current signal output and its application circuit

ActiveCN105067035BConvenient series and parallel connectionGuaranteed cross-sectional areaMeasurement devicesBuck converterĆuk converter

The present invention discloses an LED module with a temperature signal output and a detection current signal output and an application circuit thereof. The LED module at least comprises an LED substrate, an LED chip group, a current detection device and a temperature detection device. The current detection device and the chip group are connected in series and then are packaged in the LED substrate. The temperature detection device is installed on the LED substrate. The upper and lower sides of the LED substrate are provided with positive and negative electrodes, the polarity of the electrodes at the same side are the same, and the leading-out end of each electrode is provided with a conductive pad. The application circuit comprises multiple groups of LED modules and an external control conversion circuit which comprises an A / D converter, a controller MCU and a D / A converter. The output ends of the current detection device and the temperature detection device of each group of LED modules are connected to the input end of the A / D converter, and the A / D converter is connected to a D / A converter through a controller. According to the LED module and the application circuit, the series and parallel connection between the LED modules is facilitated, the replacement is convenient, the working current and temperature of a single LED module are monitored at any time according to needs, and the normal working of an LED light source is ensured.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

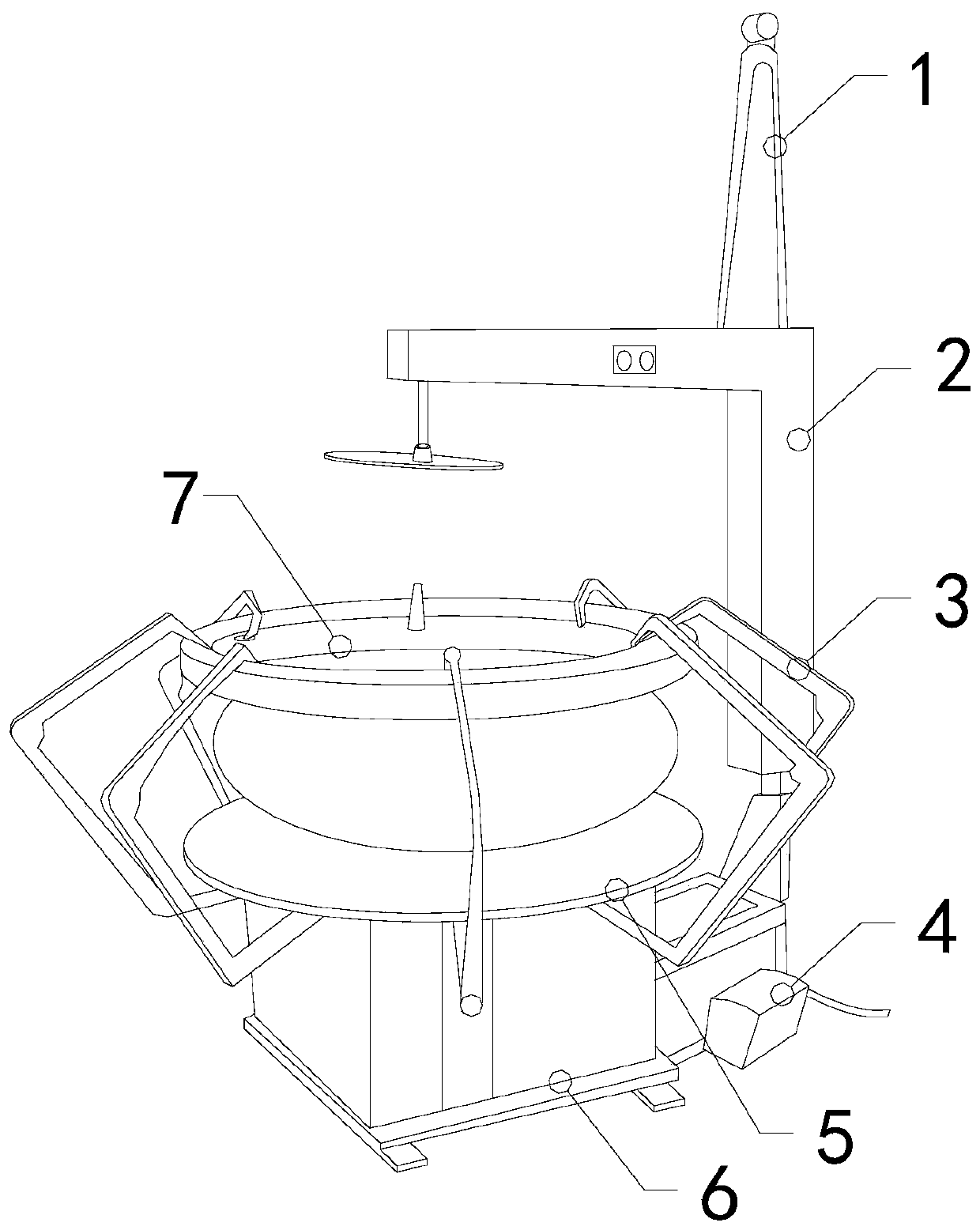

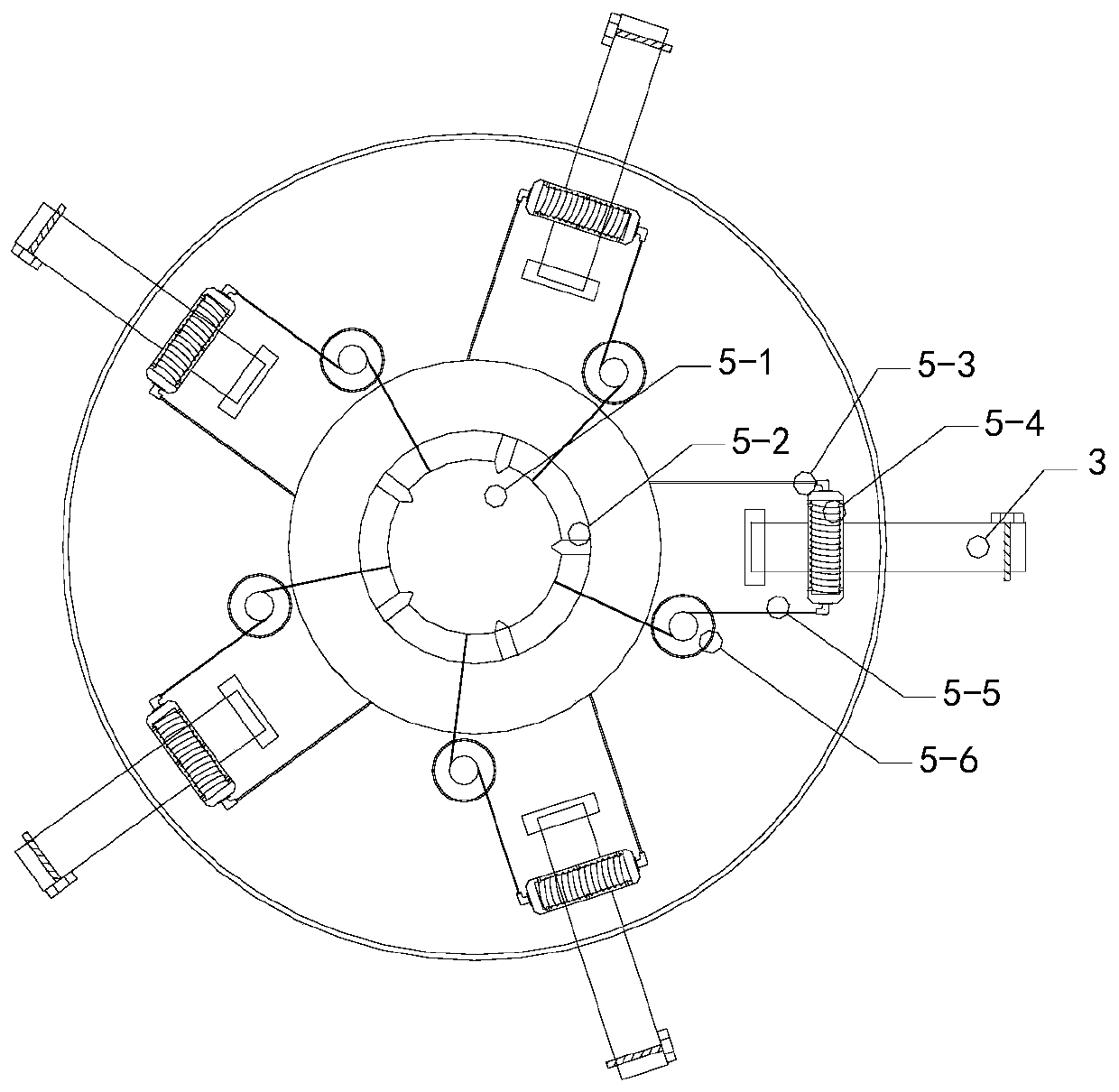

Vertical envelope feeding machine

The invention discloses a vertical envelope feeding machine. The vertical envelope feeding machine structurally comprises a supporting column, a supporting frame, two or more fixing jaws, an electriccontrol cabinet, a repulsive structure, a base and a contactor. The fixing jaws are mounted at the upper top of the base and are uniformly distributed at equal intervals. The supporting frame is mounted on one side of the base. The electric control cabinet is arranged on the front end face of the supporting frame and movably makes contact with the supporting frame. According to the vertical envelope feeding machine, an electromagnet is arranged at the bottom of each fixing jaw, and the two horizontal ends of each electromagnet are perpendicular to the corresponding fixing jaw, so that the magnetic fields of the electromagnets on every two fixing jaws are repulsive to separating the fixing jaws, and every two fixing jaws are prevented from crossing when used for fixing a tire tread; and theelastic contact area between the contactor and a tire can be automatically adjusted by means of a roller which is arranged on a circular body and can be elastically adjusted through a spring, so thatit is guaranteed that the sectional area is enlarged, the contactor is completely attached and fixed to the tire tread, and fixing is more stable.

Owner:绍兴市雨芸机械有限公司

Contact structure and switch apparatus

InactiveCN107240531AImprove elastic deformation abilityGuaranteed cross-sectional areaContact materialsElectromagnetic relay detailsManipulatorEngineering

The invention provides a contact structure and a switch apparatus. The contact structure includes: a first contact point, a second contact point, a first contact manipulator and a second contact manipulator. The first contact manipulator includes at least two elastic sheets which are each in staggered arrangement, and one end of respective elastic sheets are in mutual fixed arrangement. The second contact point is arranged on the second contact manipulator. The first contact point is disposed on the first contact manipulator near the elastic sheet which is on one side of the second contact manipulator. The at least two elastic sheets of the first contact manipulator develop flexible deformation which make the first contact point and the second contact point to be in contact under the driving force. The switch apparatus includes at least one driver and the aforementioned contact structure. The technical solution can reduce the number of contact points of the contact structure.

Owner:SIEMENS AG

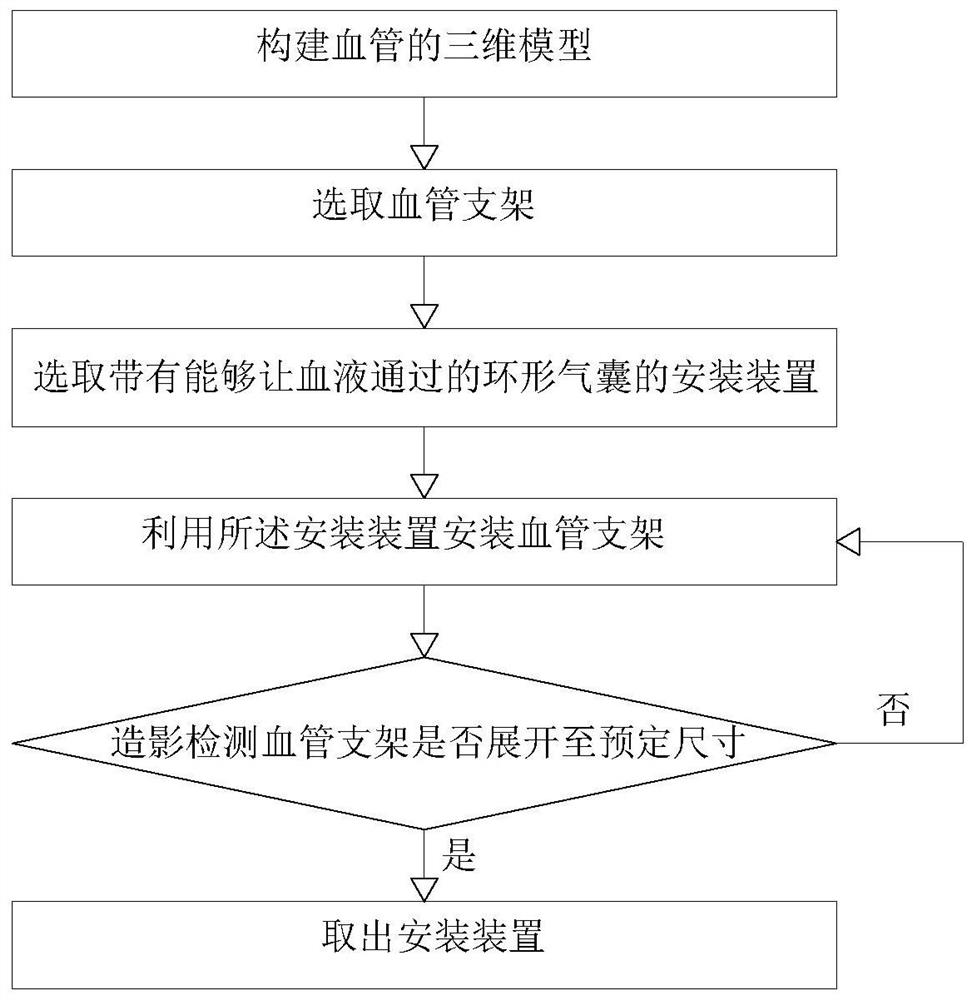

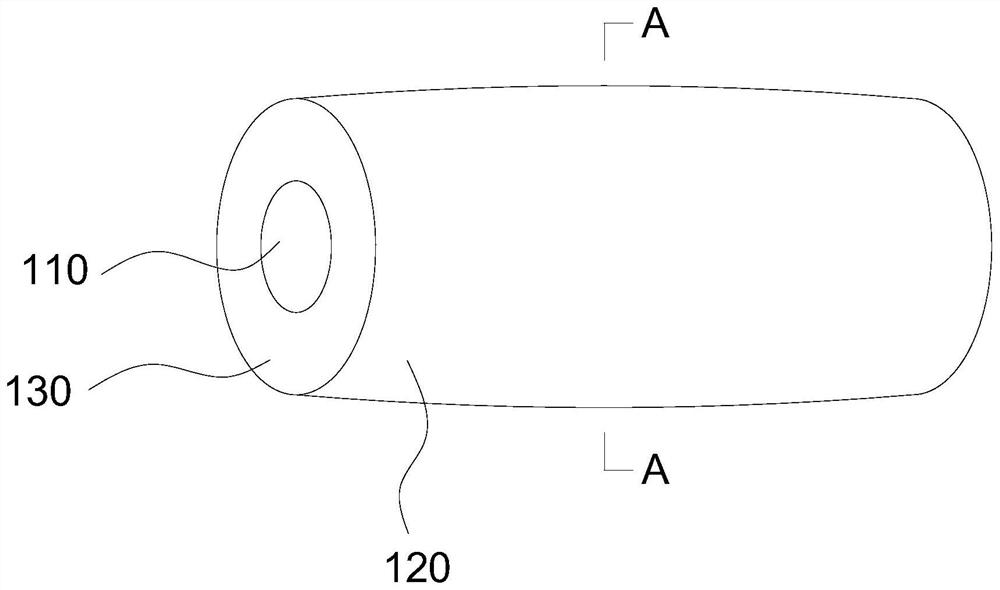

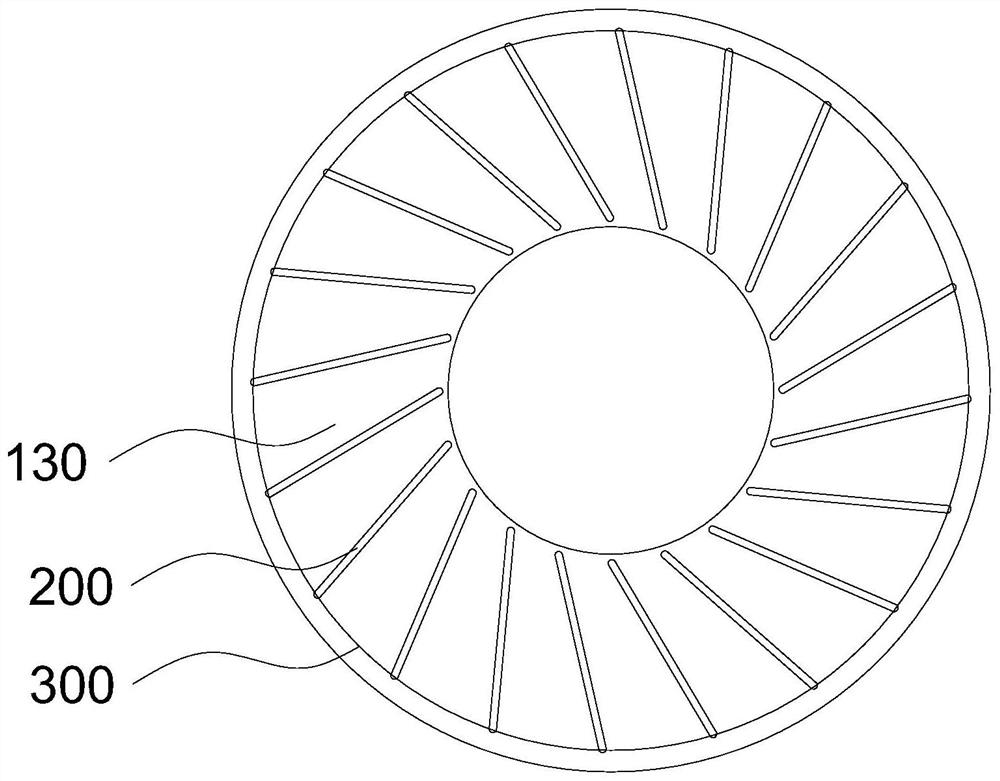

A kind of vascular stent installation device

The invention discloses a method for installing a vascular stent and an installation device, which belong to the technical field of biomedical implants. The installation method includes the following steps: angiography, constructing a three-dimensional model of a blood vessel; analyzing and evaluating a diseased blood vessel, and selecting a vascular stent; Select the installation device for the stent, and the air bag of the installation device is an annular air bag that can allow blood to pass through after expansion; use the installation device to install the vascular stent; angiography to detect whether the vascular stent has expanded to a predetermined size, and if so, take out the installation device; otherwise, return to the step of installing the vascular stent . The present invention adopts the mounting device with the annular air bag, and the blood can pass through smoothly during the process of deploying the annular air bag to install the vascular stent, and the tissue will not be damaged due to ischemia even if the installation time is long.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com