Double-hole concentric heat tube

A technology of heat pipes and concentric circles, which is applied in the field of pipes in heat pipe networks, can solve the problems of large heat loss and large surface area of double pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

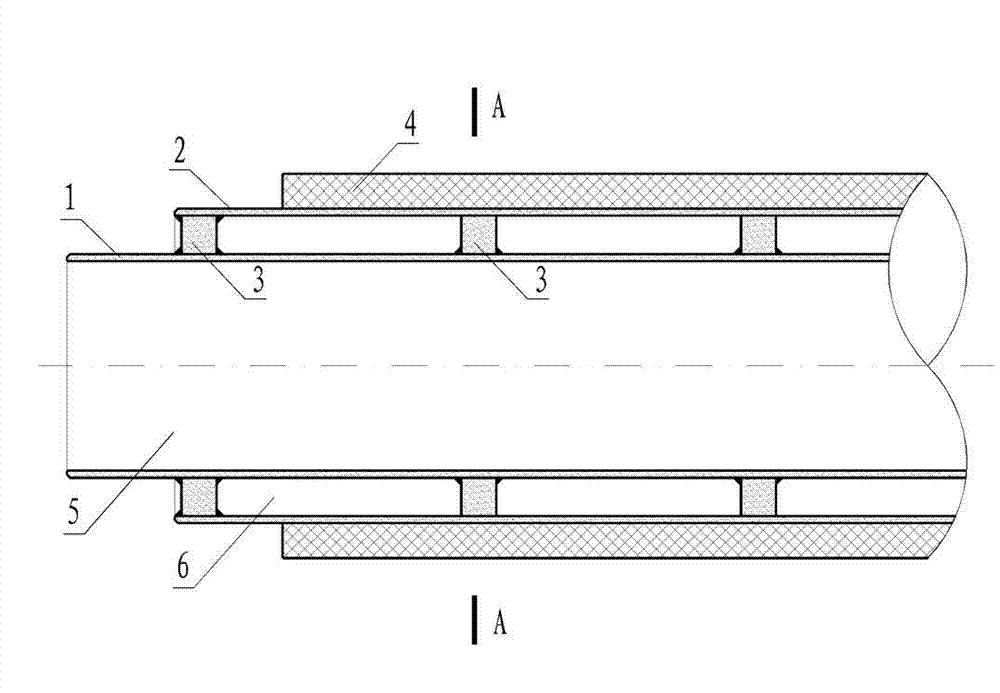

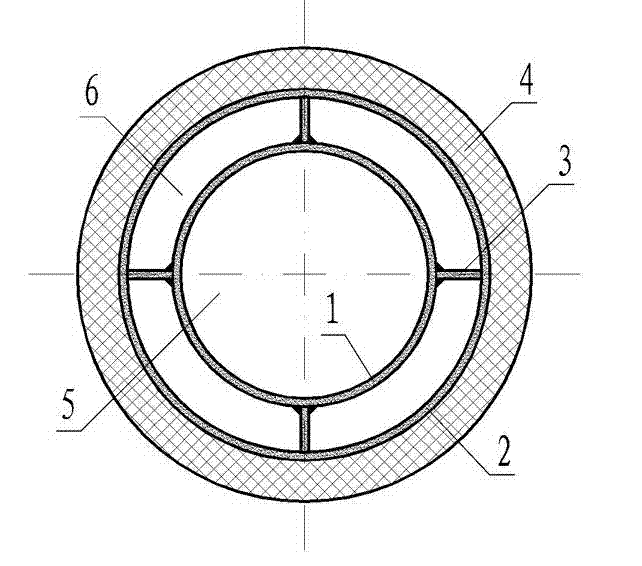

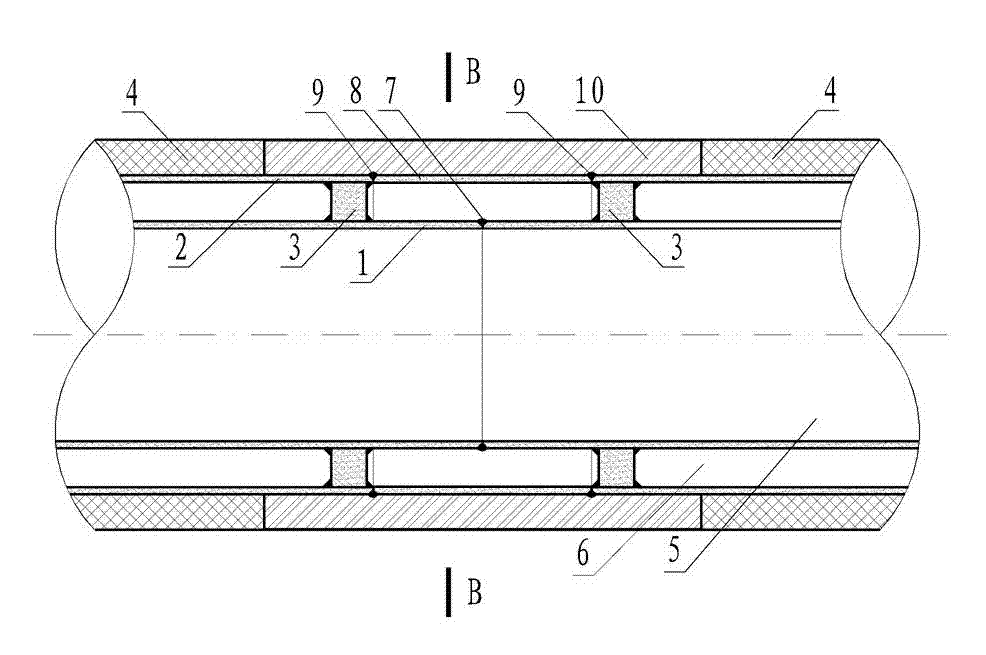

[0021] The double-hole concentric heat pipe of the present invention adopts seamless steel pipe, arc welding or high-frequency welding to weld the spiral seam steel pipe, and the steel material should meet the requirements of "Code for Design of Urban Heating Pipeline Network" (CJJ34-2010). Calculate the diameter of the outer tube 2 according to the diameter and wall thickness of the inner tube 1, determine the size of the positioning tenon 3, the length of the inner tube 1 is 200mm longer than the length of the outer tube 2 on each side. The two ends of the outer wall of the inner tube 1 are welded with a positioning tenon 3 corresponding to the nozzle of the outer tube 2, and each of the four is evenly distributed at 90°. 500mm or so welding one. The nozzles of the inner pipe 1 and the outer pipe 2 should be processed into bevels for joint welding. After the inner pipe 1 and the outer pipe 2 are manufactured, carry out anti-corrosion treatment, insert the inner pipe 1 into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com