Vertical envelope feeding machine

It is a vertical and set machine technology, which is applied to tires, other household appliances, household appliances, etc. It can solve the problems of easy inclination of the bottom, small contact area, intersection, etc., so as to avoid relative sliding, ensure the cross-sectional area, and avoid cross-short circuits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

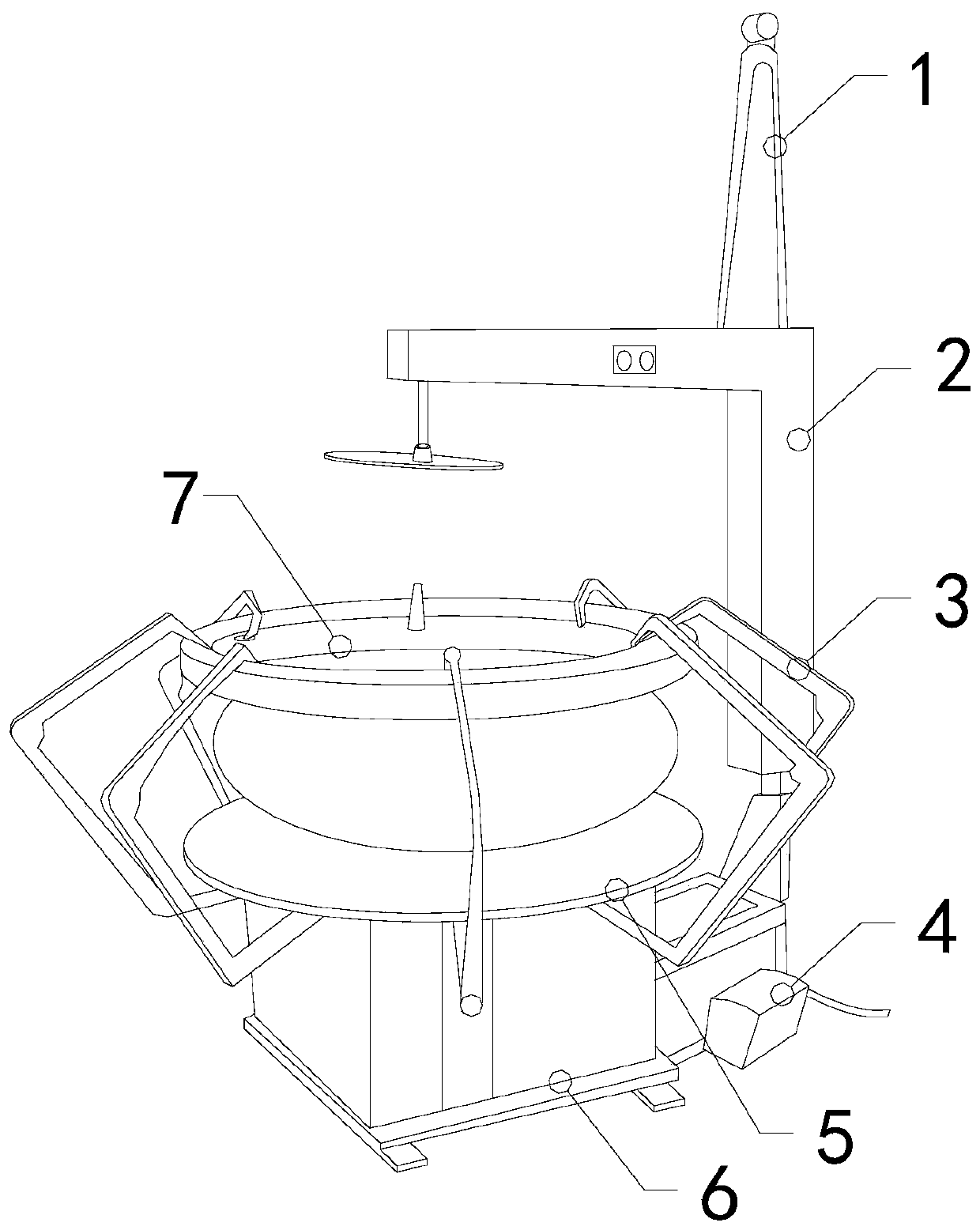

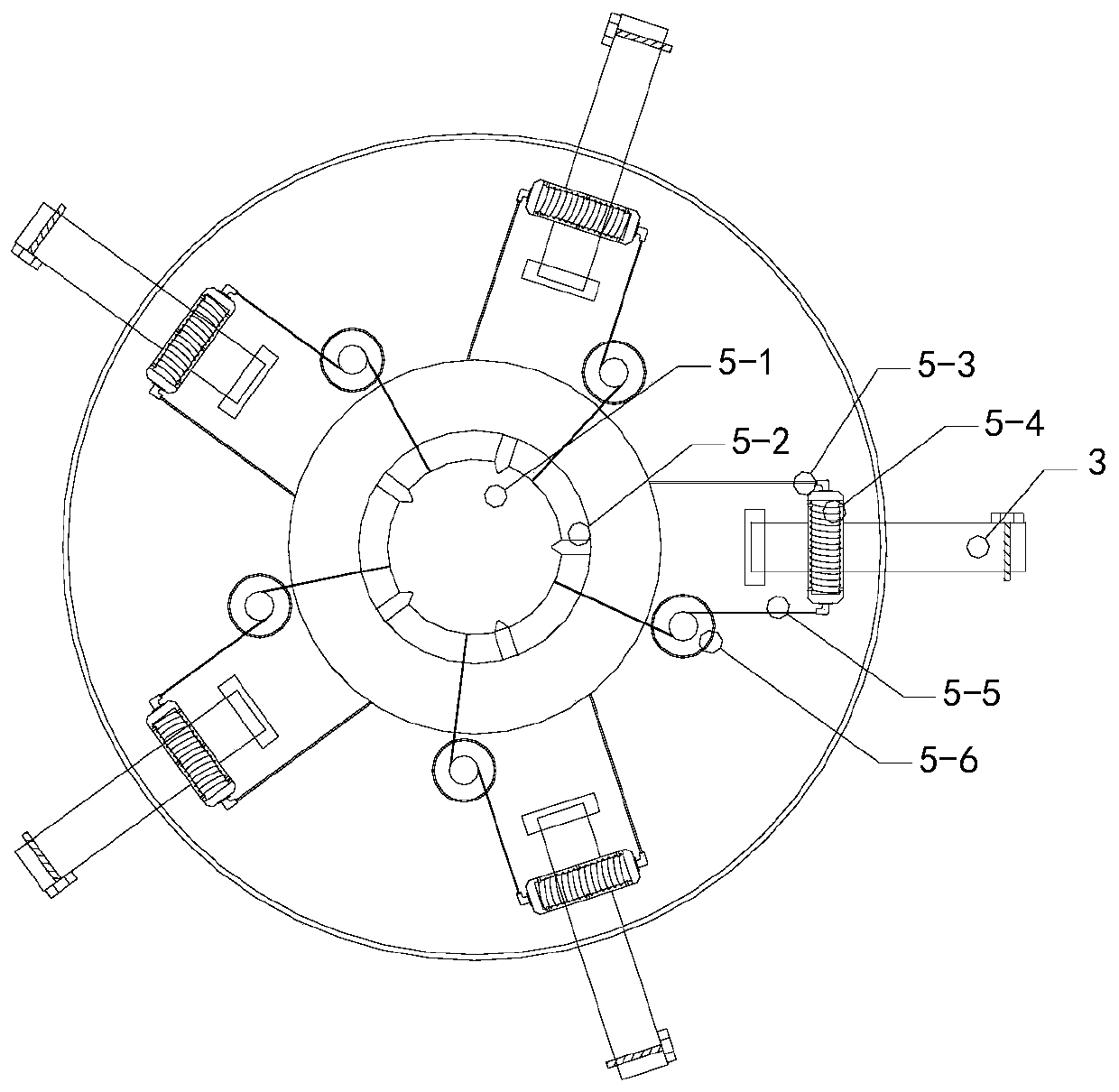

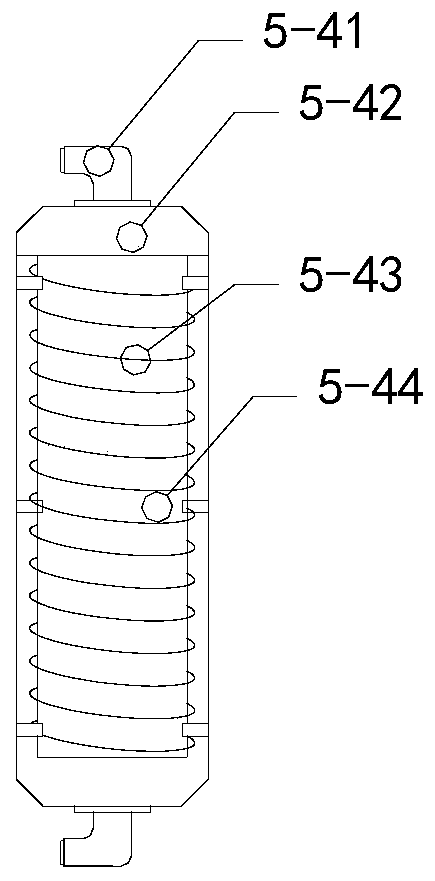

[0030] see Figure 1-Figure 8 , the present invention provides a vertical upper encapsulation machine, the structure of which includes a support column 1, a support shelf 2, a fixed claw 3, an electric control box 4, a repelling structure 5, a base 6, and a contactor 7, and the base 6 is directly above the top More than two fixed claws 3 are installed, and the fixed claws 3 are distributed evenly and equidistantly. A shelf 2 is installed on one side of the base 6, and an electric control box 4 is arranged on the front end of the shelf 2. The electric control box 4 is in movable contact with the shelf 2, the top of the shelf 2 is vertically provided with a support shelf 2, the support shelf 2 and the shelf 2 are welded by a welding machine, and a support column 1 is also installed on the top surface of the support shelf 2, and the fixed A repelling structure 5 is provided near the bottom of the claw 3 near the base 6 , and a contactor 7 is installed at the end of the fixed claw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com