Silver conductive composition without screen printing and used for line manufacturing

A conductive composition and screen printing technology, applied in the field of electronics, can solve problems such as difficult printing, achieve the effects of improving conductivity, ensuring cross-sectional area, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

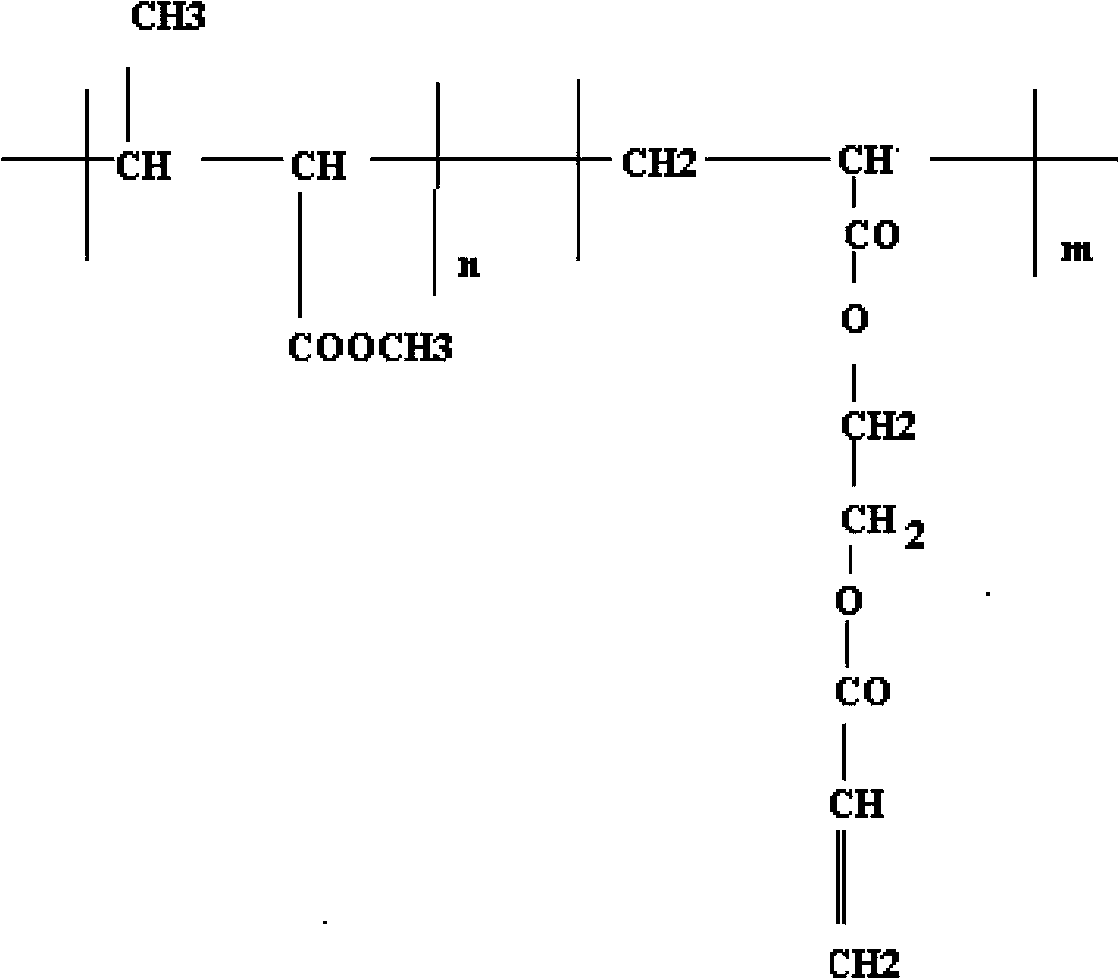

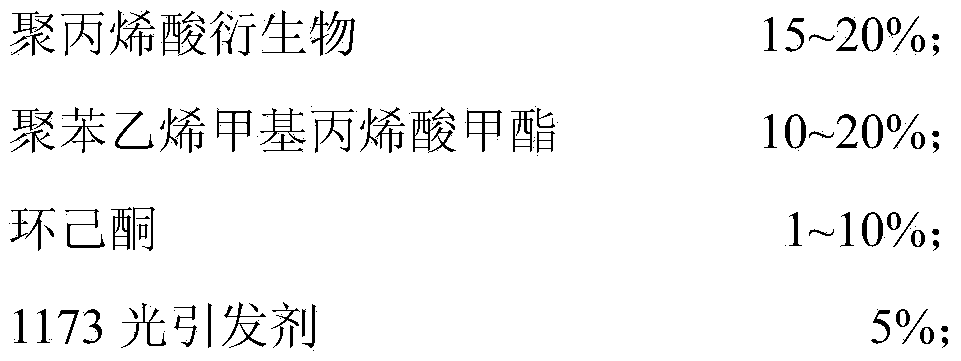

[0030] A kind of silver conductive composition that does not need screen printing for circuit manufacturing, it comprises the component of following percentage by weight:

[0031]

[0032] The preparation method of the above-mentioned silver conductive composition without screen printing for circuit manufacturing: mix polyacrylic acid derivatives, polystyrene methyl methacrylate, 1173 photoinitiator, triphenylamine and silver in the formula amount, dissolve in In cyclohexanone, stir under dark conditions, and then grind until the particle size is below 5 μm.

[0033] The method for manufacturing the circuit from the above-mentioned silver conductive composition is as follows: the silver conductive composition used for circuit manufacturing that does not require screen printing is coated on the substrate by roll coating, spray coating, or spin coating, and after drying, it is dried The thickness of the paint film is controlled at 25-50 μm according to the needs of electrical...

Embodiment 2

[0036] A kind of silver conductive composition that does not need screen printing for circuit manufacturing, it comprises the component of following percentage by weight:

[0037]

[0038] The method for preparing the silver conductive composition without screen printing and the method for manufacturing the circuit are the same as in Example 1.

[0039] Effects of Examples: Under the conditions of 80°C and 300W ultraviolet light irradiation, the artificial accelerated aging test has an aging resistance time of 100d and a temperature resistance of 300°C. Resistance 4*10 -5 Ω.cm. The printed line width is 25 microns, the lines are clear, the edges are neat, and there is no adhesion. The light curing time is 15 seconds.

Embodiment 3

[0041] A kind of silver conductive composition that does not need screen printing for circuit manufacturing, it comprises the component of following percentage by weight:

[0042]

[0043] The method for preparing the silver conductive composition without screen printing and the method for manufacturing the circuit are the same as in Example 1.

[0044] Effects of Examples: Under the conditions of 80°C and 300W ultraviolet light irradiation, the artificial accelerated aging test has an aging resistance time of 95 days and a temperature resistance of 280°C. Resistance 1.9*10 -4 Ω.cm. The printed line width is 50 microns, the lines are clear, the edges are neat, and there is no adhesion. The light curing time is 30 seconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com