Turbine housing for twin-scroll turbocharger

A technology for turbochargers and turbine housings, applied in the direction of machines/engines, stators, engine components, etc., can solve problems such as engine performance degradation, differences in operating conditions, narrow layout, etc., to suppress flow resistance, prevent performance degradation, The effect of securing the cross-sectional area of the flow path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Next, the present invention will be described in detail using the illustrated embodiments. However, the scope of the present invention is not limited to dimensions, materials, shapes, relative arrangements, and the like of components described in the embodiments unless otherwise specified.

[0034] (Embodiment 1)

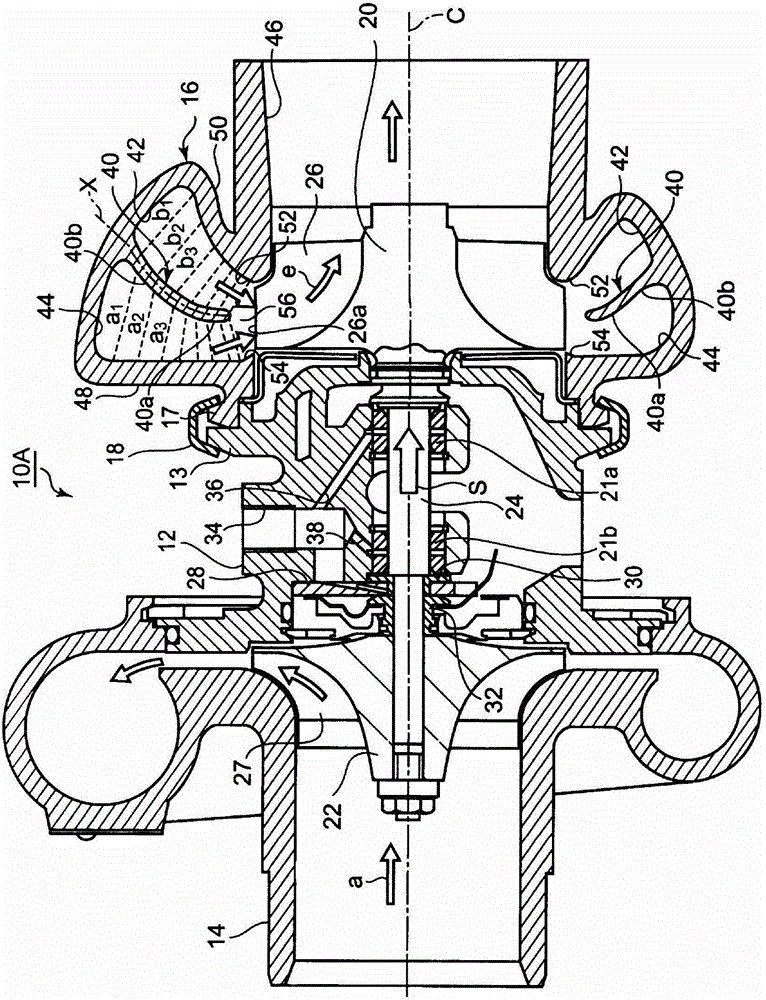

[0035] Now according to figure 1 A first embodiment in which the turbine housing of the present invention is applied to a small twin-scroll turbocharger equipped in a small vehicle such as a car equipped with a multi-cylinder engine will be described. figure 1 In the housing of the illustrated twin scroll turbocharger 10A, a compressor housing 14 and a turbine housing 16 are disposed with a bearing housing 12 interposed therebetween, and these housings on both sides are joined to the bearing housing 12 . The bearing housing 12 and the turbine housing 16 are connected to flanges 13 , 17 at the ends of these housings by means of an annular coupling 18 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com