Bubbling device for molten glass

A bubbling device and glass melting technology, applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as inability to adjust, difficult to adjust, and system scrapping, so as to increase system reliability, safety, and cost Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

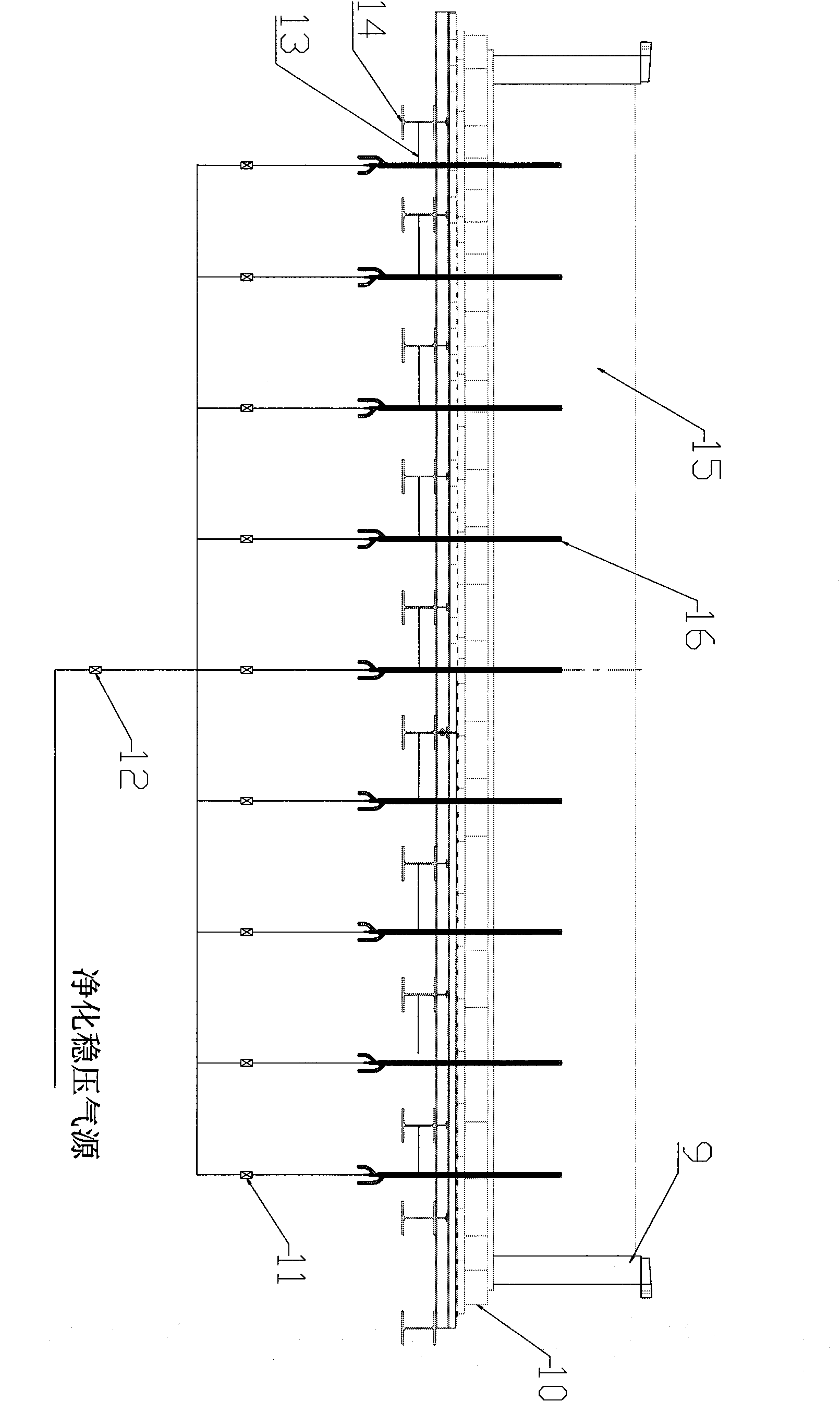

[0019] A glass tank furnace with a daily melting capacity of 400 tons, the cross section is as follows figure 2 Shown, the pool wall (9) and the bottom of the pool (10) form a rectangular pool kiln, and the glass liquid (15) is filled with it, and the width of the pool kiln is 10.3m, and the glass liquid depth is 1.15m. Nine water-cooled porous bubbling devices (16) are arranged, and each bubbling device is connected and fixed to the steel structure (14) at the bottom of the pool through a fixer (13). Loosen the retainer (13) when it is necessary to adjust the depth of the bubbling device in the glass liquid or change it, and keep it fastened in the normal state.

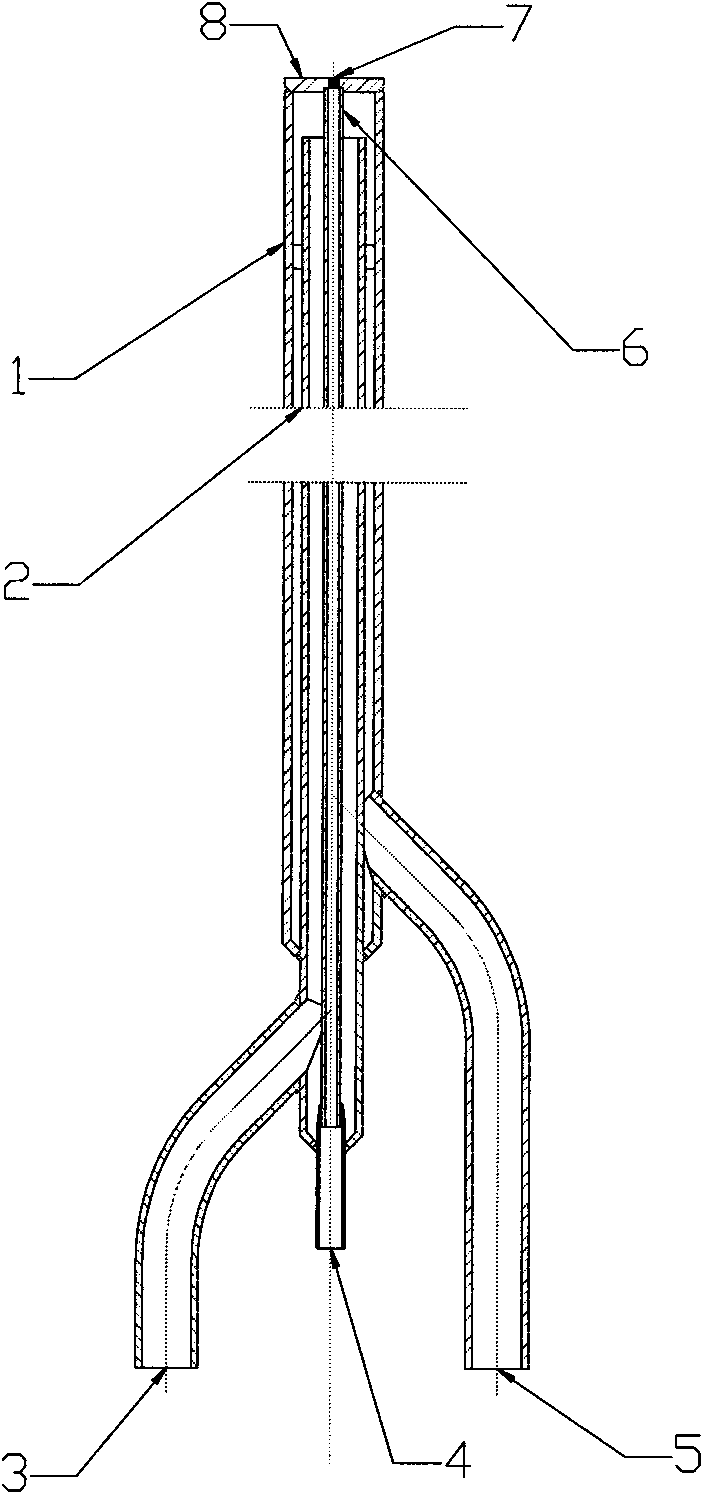

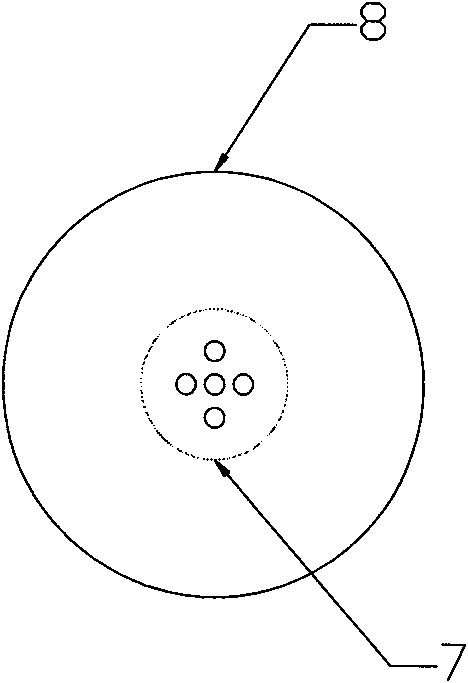

[0020] Water-cooled porous bubbling device such as figure 1 As shown, the cooling pipeline is composed of outer pipe (1), inner pipe (2), water inlet pipe (3) and water outlet pipe (5); the material is heat-resistant stainless steel; the outer diameter of the outer pipe (1) is 42mm, and the inner pipe (2 ), water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com