Tunnel combined-type lining structure with maintainable drainage passage

A drainage channel and composite technology, applied in the field of tunnel lining structure, can solve the problem of not having a short-term drainage of a large amount of groundwater, and achieve the effect of improving reliability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

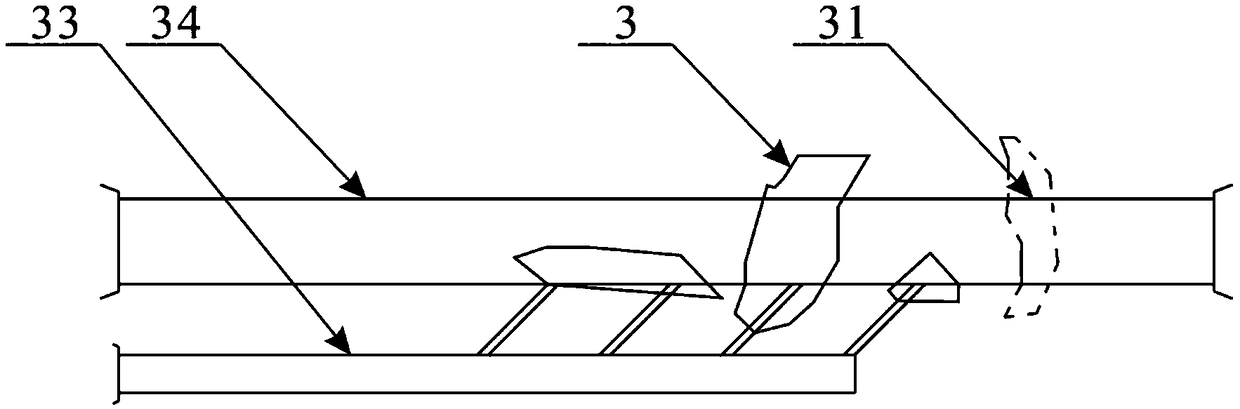

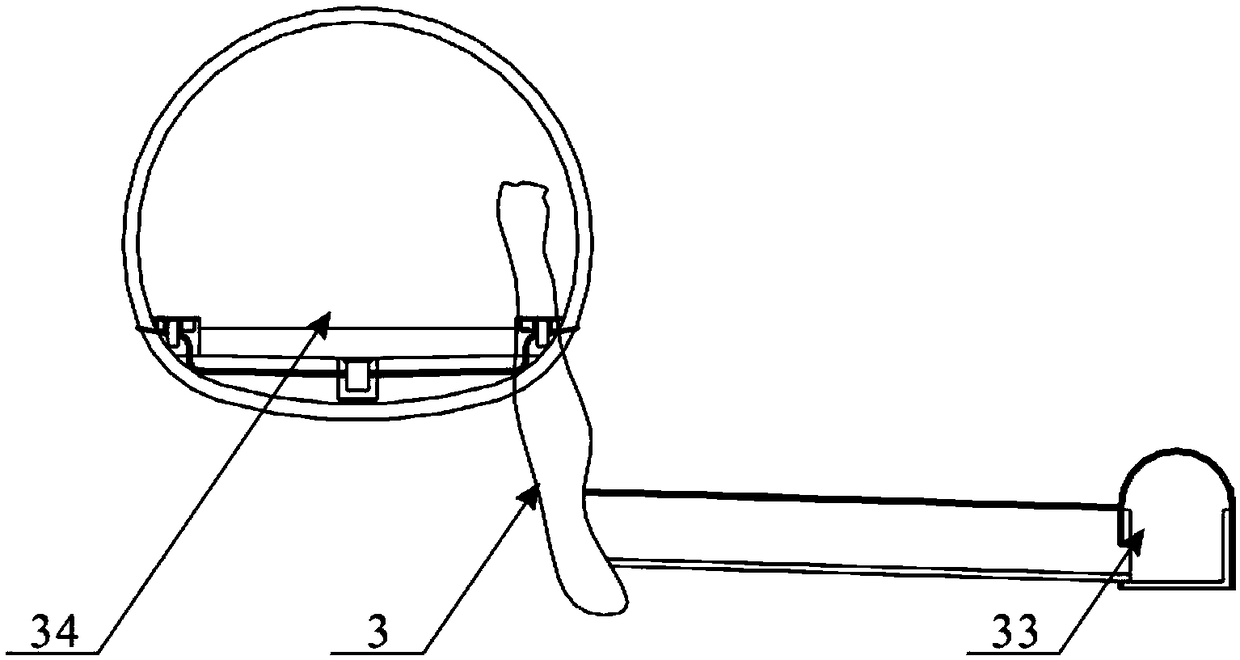

[0028] Such as Figure 5 As shown in , it is a schematic structural diagram of a tunnel composite lining structure with a maintainable drainage channel.

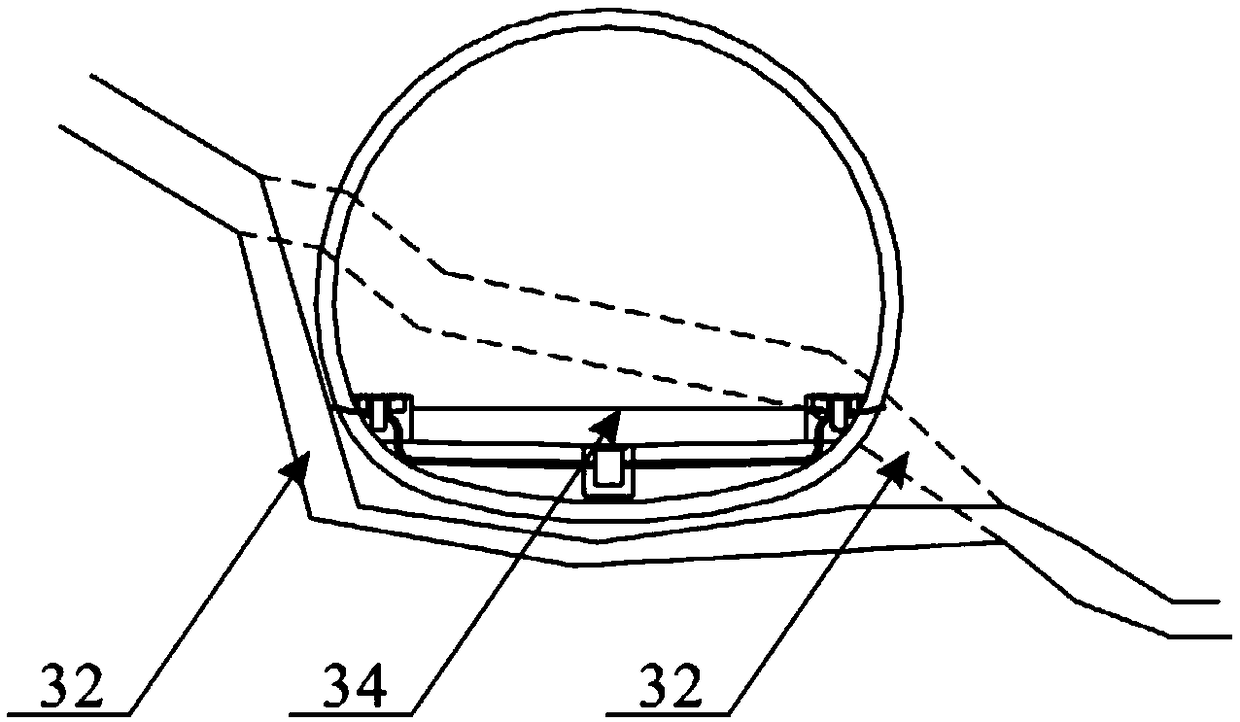

[0029] The tunnel composite lining structure with a maintainable drainage channel of the present invention comprises an arch wall lining 1, the lower end of the arch wall lining 1 is connected with an inverted arch lining 14, a construction joint 11 is arranged at the connection part, and an inverted arch lining 14 is provided with Several invert lining openings 141.

[0030] The upper supporting arch structure 2 is erected on the inverted arch lining 14, and the drainage channel 24 is formed between the inverted arch lining 14 and the upper supporting arch structure 2; the initial support 13 of the wall corner is enlarged to ensure the stability of the upper supporting arch structure; The structure 2 is filled with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com