A paste composition for a solar cell electrode

A technology of solar cells and compositions, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problem of high resistance value of anti-reflection film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Hereinafter, an embodiment of the present invention will be described in detail with reference to the drawings. Furthermore, in the following embodiments, the drawings are appropriately simplified or deformed, and the dimensional ratios, shapes, etc. of each part are not necessarily accurately drawn.

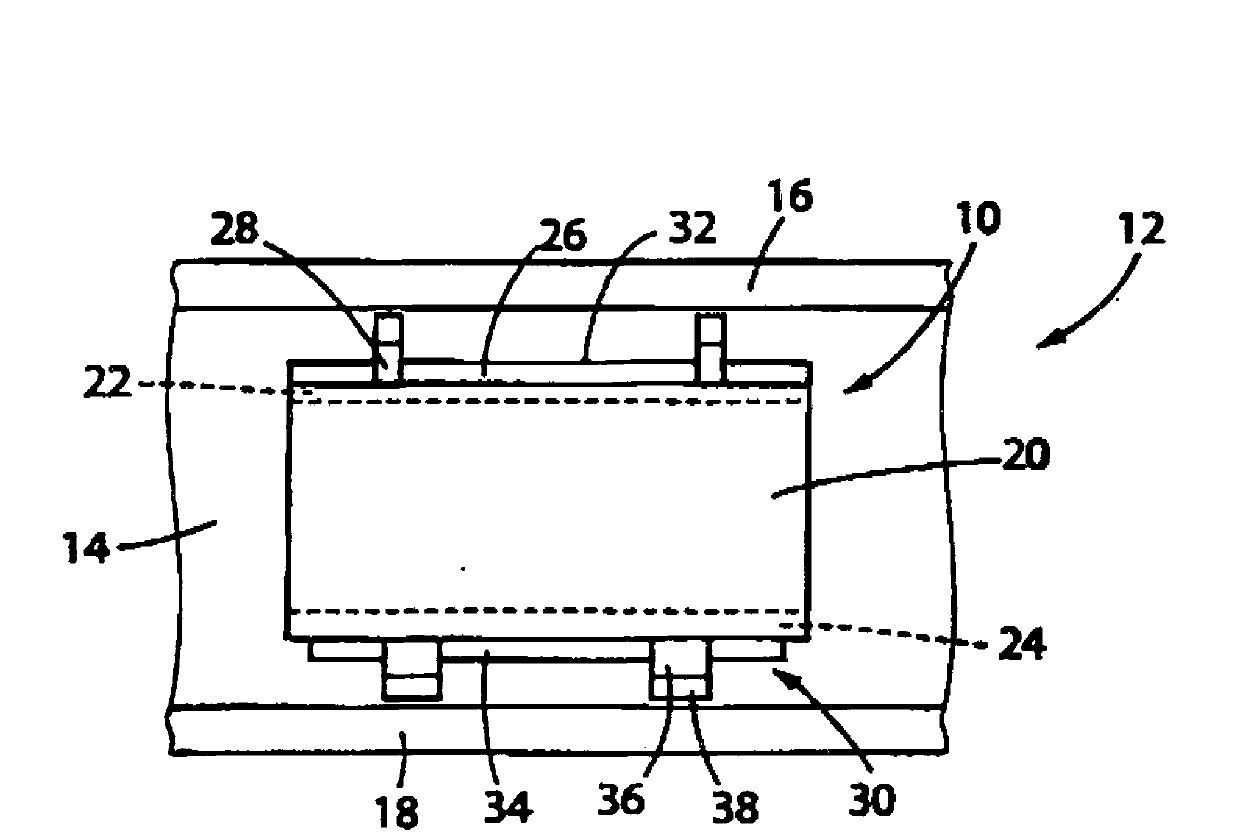

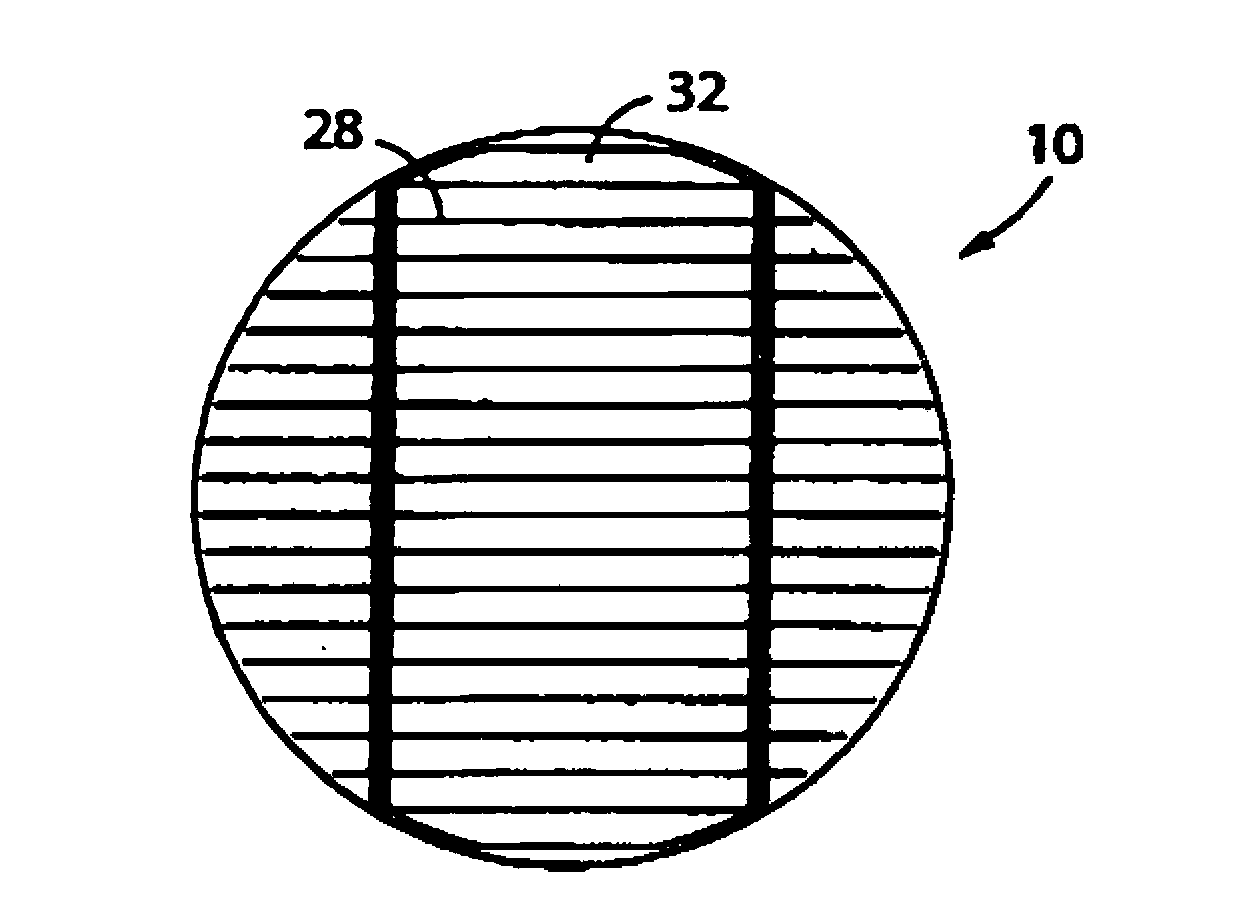

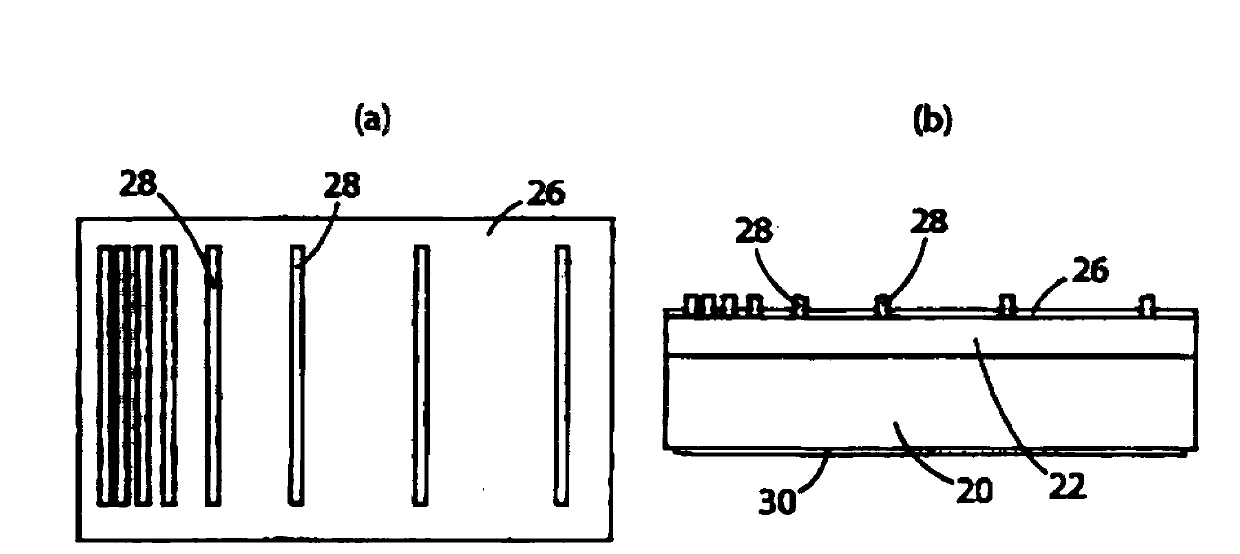

[0052] figure 1 It is a diagram schematically showing a cross-sectional structure of a solar cell module 12 having a silicon-based solar cell 10 to which a conductive composition according to an example of the present invention is applied. exist figure 1 Among them, the solar cell module 12 has: the above-mentioned solar cell 10, a package 14 encapsulating the solar cell 10, a surface glass 16 provided on the package 14 on the light-receiving surface side, and a 14 and set the protective film (ie the rear plate) 18. The above-mentioned package 14 is a package made of, for example, EVA, and a cross-linking agent, an ultraviolet absorber, an adhesive protecting agent, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com