Double-hole parallel thermal power tube

A technology of heat pipes and tubes, which is applied in the field of double-hole parallel heat pipes and heat pipe network engineering, can solve the problems of large heat loss and large surface area of double pipes, and achieves the reduction of steel consumption, material consumption, and material consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

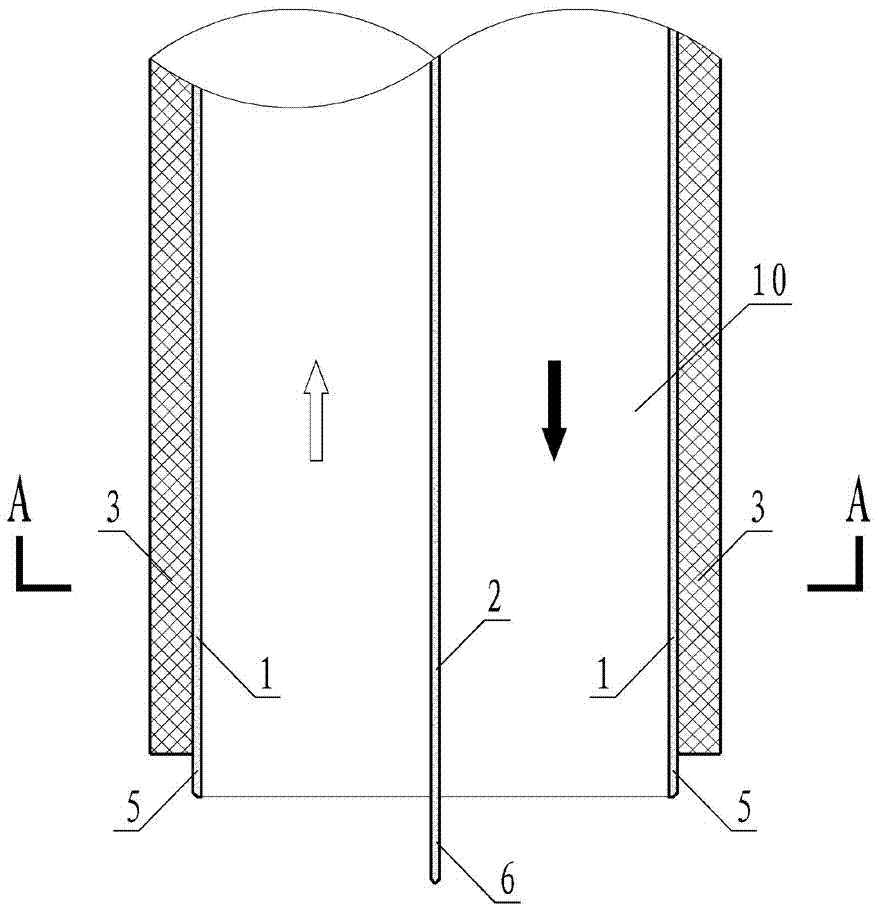

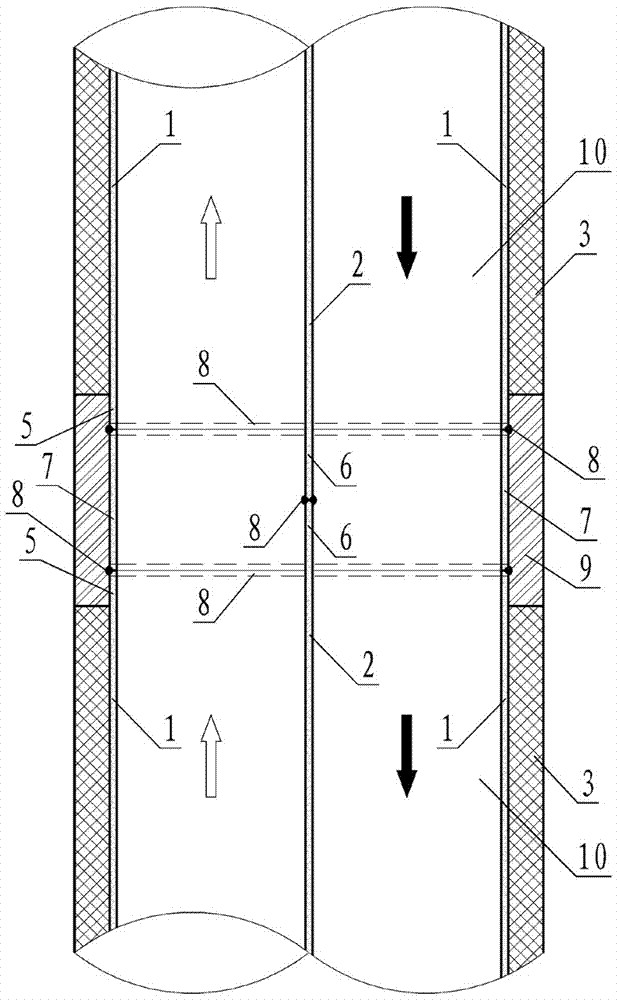

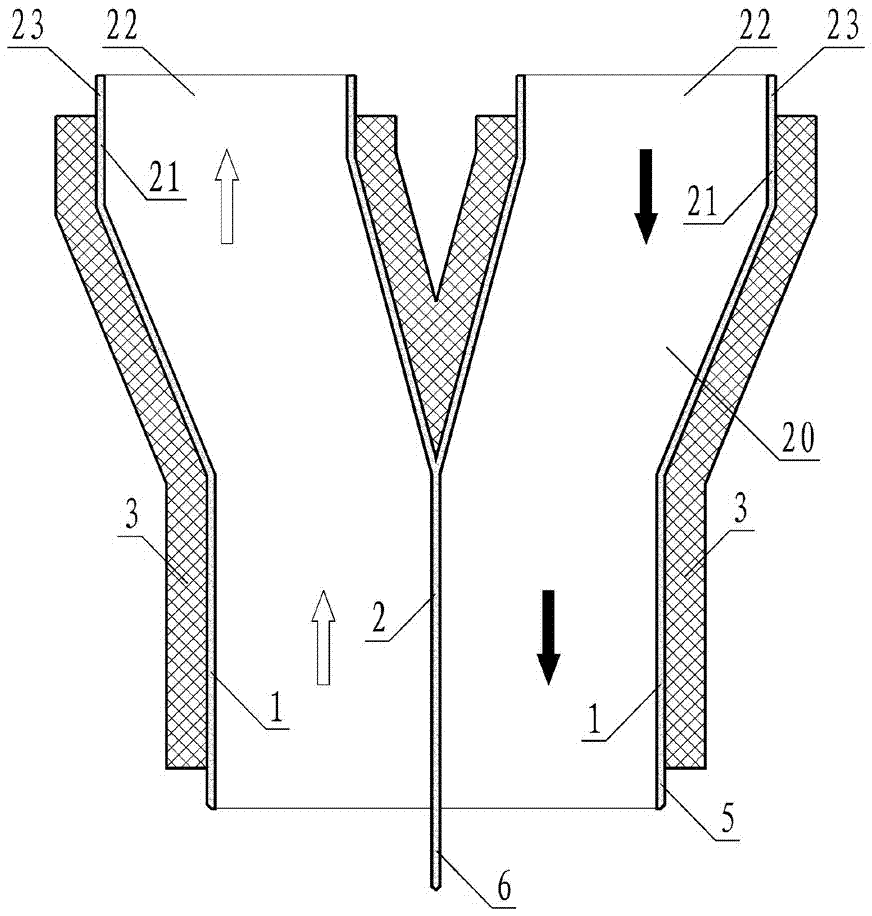

[0024] The dual-hole parallel heat pipe of the present invention includes a pipe joint 10 , a separation pipe 20 , a reducing pipe 30 , a bypass tee 40 , and a branch tee 50 . The pipe joint 10 is the main material, and the separation pipe 20, the reducer pipe 30, the bypass tee 40, and the branch pipe tee 50 are accessories constituting the heat pipe network. The pipe joint 10 is composed of the pipe wall 1, the middle partition 2, and the insulation layer 3. The pipe wall 1 is left and right symmetrical to the middle partition 2 in a horizontal "θ" shape. The pipe wall 1 and the middle partition 2 form two horizontal The juxtaposed tube holes 4 form a water supply pipe and a water return pipe respectively. Each tube hole 4 is composed of a semicircle section and a rectangle section, and the section of the tube hole 4 is "D" shaped. The length of the pipe joint 10 is 6-12m, the pipe wall 1 and the middle partition 2 are made of steel, the two ends are provided with the pipe w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com