Structure and method for conductive connection between copper materials or between copper material and other components

A technology for conductive connection structures and components, which is used in the field of connection between copper materials or between copper materials and other objects. Direct connection, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

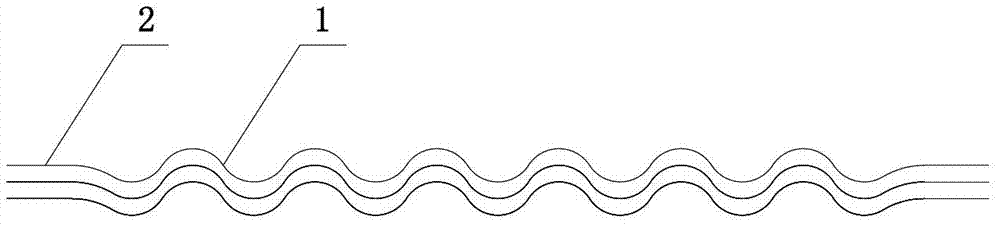

[0044] Such as Figure 1-2As shown, the conductive connection structure and method between copper materials or between copper materials and other components of the present invention adopts a multi-layer copper foil flexible soft connection structure to connect between copper materials or between copper materials and other components. The connection structure is a multi-layer structure formed by stacking wavy or serpentine or unfolded spiral copper foil strips. The two ends of the wavy or serpentine or unfolded spiral copper foil strips are connected to copper or On other components, the wavy or serpentine or unfolded spiral copper foil in the middle is in a free layered state (natural state after superimposition), and the two layers of the multilayer structure wave or serpentine or unfolded spiral copper foil The end is directly connected to copper or other components.

[0045] The copper foil soft connection parts (copper foil strips) used in the present invention are stacke...

Embodiment 2

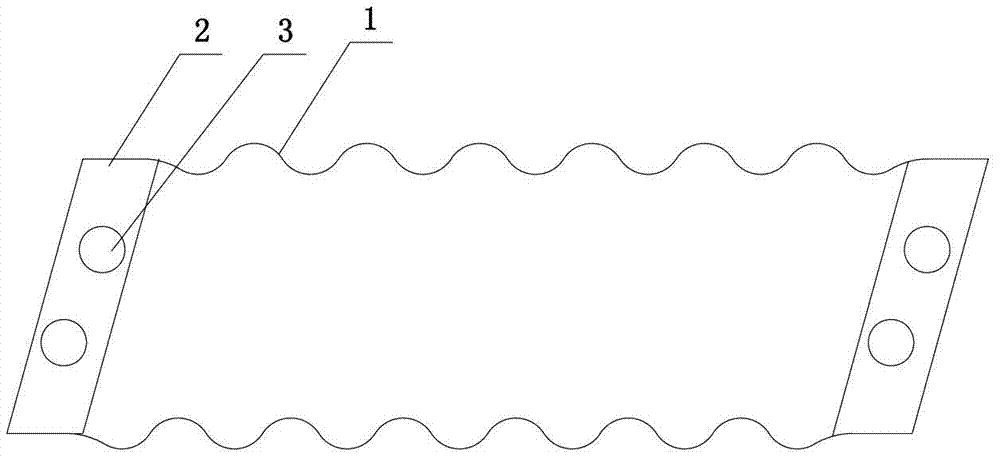

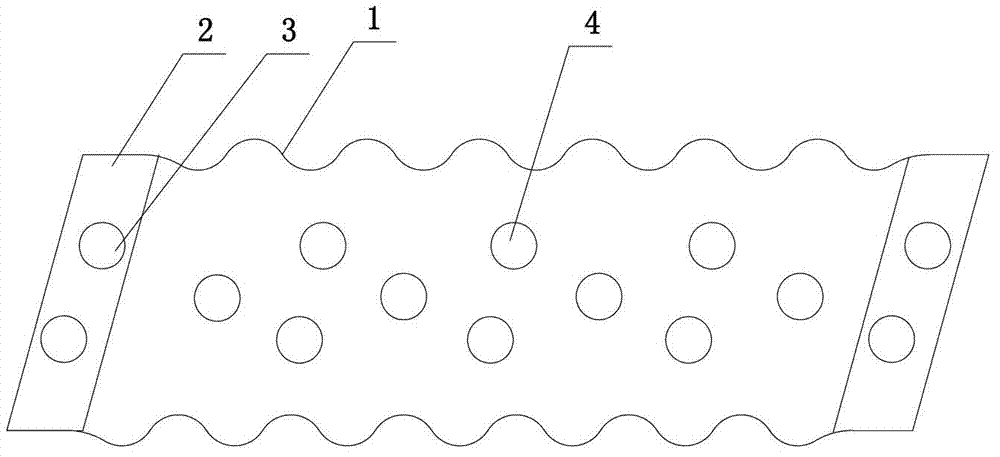

[0047] Such as image 3 As shown, in the copper foil flexible connection structure of this embodiment, the middle part 1 of the copper foil is wavy or serpentine or unfolded spirally, and the two ends of the middle part 1 of the copper foil are the copper foil end plane 2 respectively, and the copper foil end Copper foil end screw holes 3 are opened on the top plane 2, and the copper materials or between copper materials and other components are connected through a copper foil soft connection structure, and the copper material or other components and the copper foil end plane 2 are connected through matching Copper bolts and copper foil end screw holes 3 are connected. In this embodiment, the middle part of the copper foil 1 is provided with an opening 4 in the middle part of the copper foil, which can increase the heat dissipation without affecting the convenience of passing large currents, and the vibration can be better isolated, and thermal expansion and contraction can ca...

Embodiment 3

[0050] The flexible connection structure is used to connect the conductive copper rings of the N and S pole damping windings, which is used to directly short-circuit the damping strips of all magnetic poles. After the copper solder is welded into a whole, it is connected with bolts. The main disadvantages are as follows:

[0051] 1) After the safety inspection and maintenance of the equipment, the replaced soft copper bars are not conducive to recycling and cannot more effectively meet environmental protection requirements;

[0052] 2) Welded with silver-copper solder as a whole, the vibration isolation effect is poor;

[0053] 3) The "U-shaped" structure takes up a lot of space.

[0054] In this case, the present embodiment designs the connection structure, see Figure 1-3 with Figure 5 , Image 6 shown. The copper foil flexible connection structure adopted in this embodiment is composed of wavy or serpentine or unfolded spiral copper foil and copper bolts 5. Copper fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com