Thin heat pipe having wicks of crisscross structure

A liquid absorbing core and heat pipe technology, applied in the direction of tubular elements, heat exchange equipment, heat exchanger shells, etc., can solve the problems of loss of working fluid, increase of thermal resistance of heat pipe 201, and improvement of productivity, etc., to reduce flow resistance, The effect of improving discharge efficiency and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

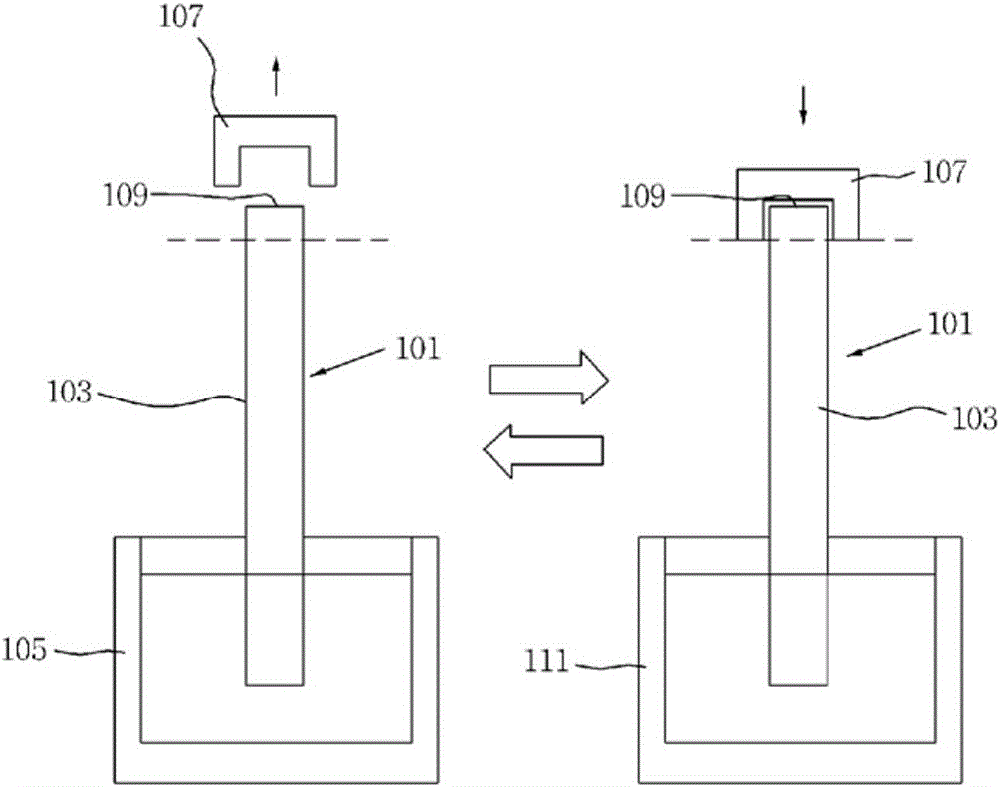

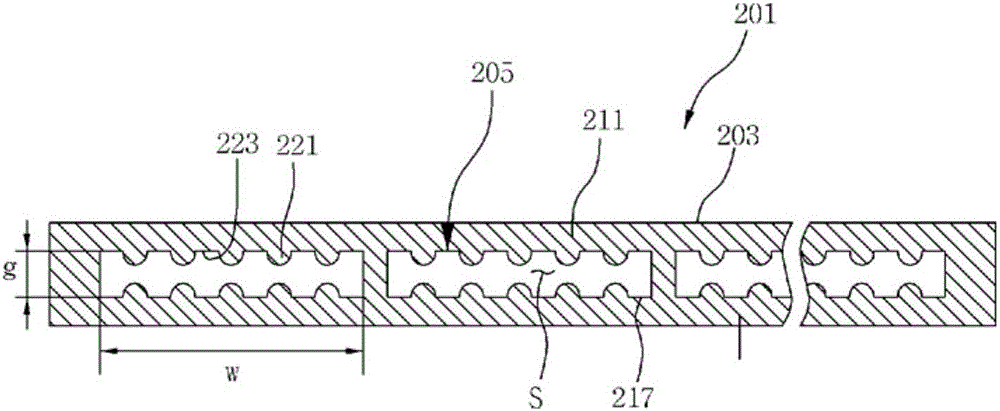

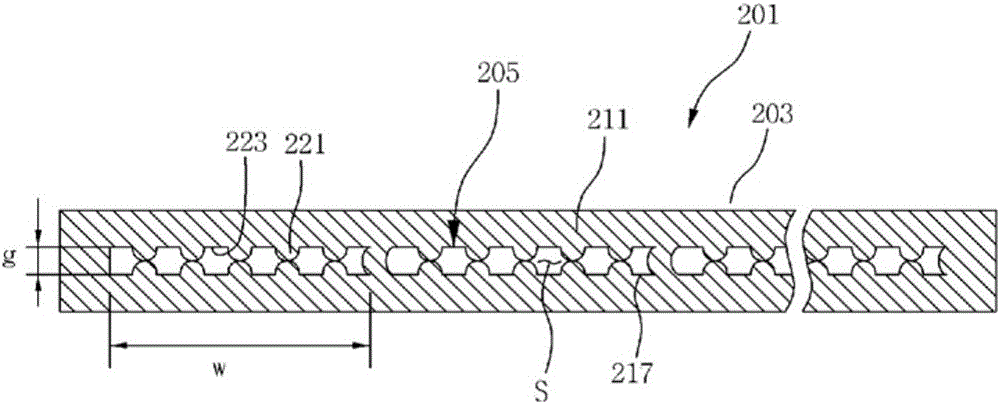

[0037] Hereinafter, a thin heat pipe having liquid-absorbing wicks with a staggered structure according to an embodiment of the present invention will be described in detail with reference to the accompanying drawings.

[0038] Such as Figure 4 to Figure 7 Denoted by reference numeral 1 in the middle, the heat pipe of the present invention generally includes a casing 3 , a working fluid and a liquid-absorbing wick 5 .

[0039] Here, firstly, the casing 3 is a part that constitutes the outer body of the heat pipe 1, such as Figure 4 As shown, the housing 3 includes: a pair of flat bodies 11, which are arranged oppositely up and down in the figure; a pair of side walls 13, which are connected to the sides of the flat bodies 11 The left and right sides; the rear wall body, which is not shown in the figure, is used to connect the rear end of the plate body 11; the final processing end, the final processing end is located in the front, and is used for final processing by stampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com