Water supply tank for heat exchanger

A technology for heat exchangers and water tanks, which is applied to heat exchange equipment, indirect heat exchangers, heat exchanger shells, etc., and can solve the problem of not being able to fully ensure the cross-sectional area of the tube 15 channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

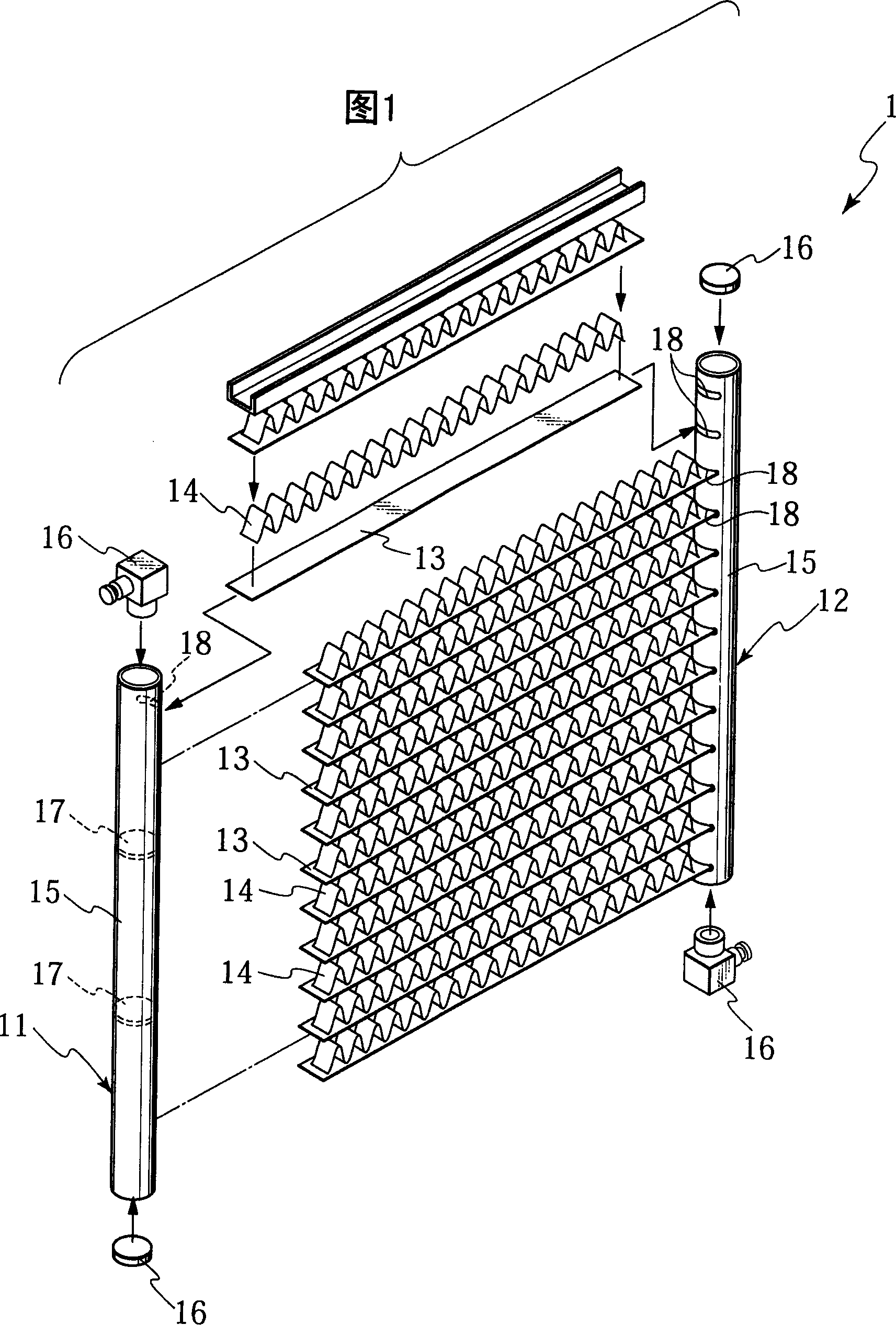

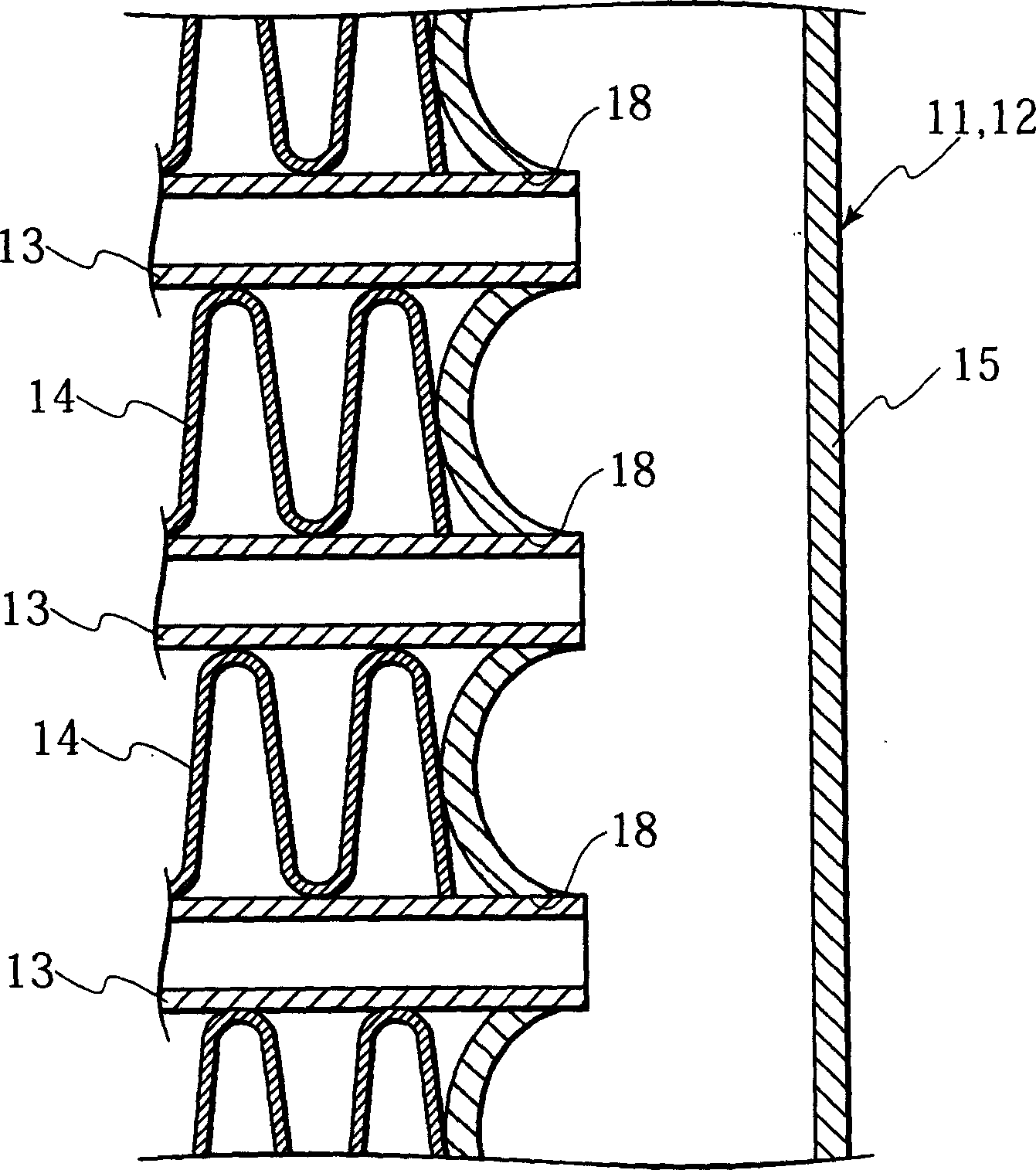

[0031] An embodiment of the present invention will be described with reference to the drawings. In this case, since the entire structure of the heat exchanger is the same as a conventional heat exchanger, description thereof is omitted.

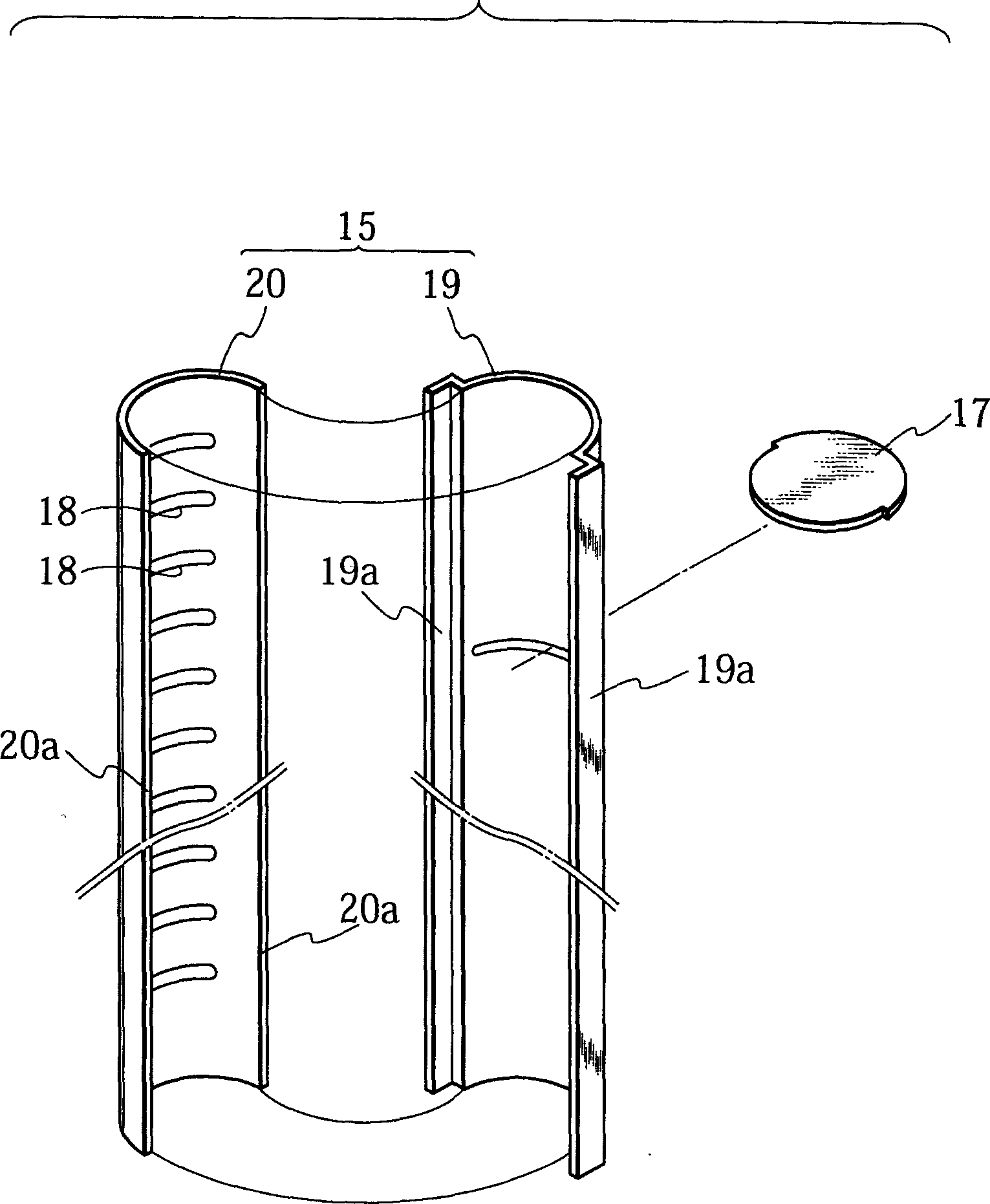

[0032] refer to Figure 5 , according to the present embodiment, the header tank 31 has a pipe 32, a closure member (not shown) that closes the openings at both ends of the pipe 32, and a partition plate (not shown) that separates the channels extending longitudinally in the pipe 32. .

[0033] The tube 32 will be described in detail below. Such as Figures 5 to 7B As shown, the tube 32 is formed into a tubular shape by joining two longitudinally separate bodies 32A and 32B.

[0034] The first independent body is formed in a C-shaped cross-sectional shape while being provided with a tube holding wall portion 34 and a pair of straight portions 36 protruding from both ends of the tube holding wall portion 34 in approximately vertical direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com