Hollow conductor with reinforcing ribs

A technology of hollow wires and reinforcing ribs, which is applied in the direction of single-tube conductors, transformers/inductor coils/windings/connections, etc., can solve problems such as bending and deformation of hollow wires in the winding process, and achieve the effect of ensuring cross-sectional area and heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make it easy to understand and understand the technical means, creative features, objectives and effects achieved by the present invention, the present invention will be further explained in conjunction with specific embodiments below.

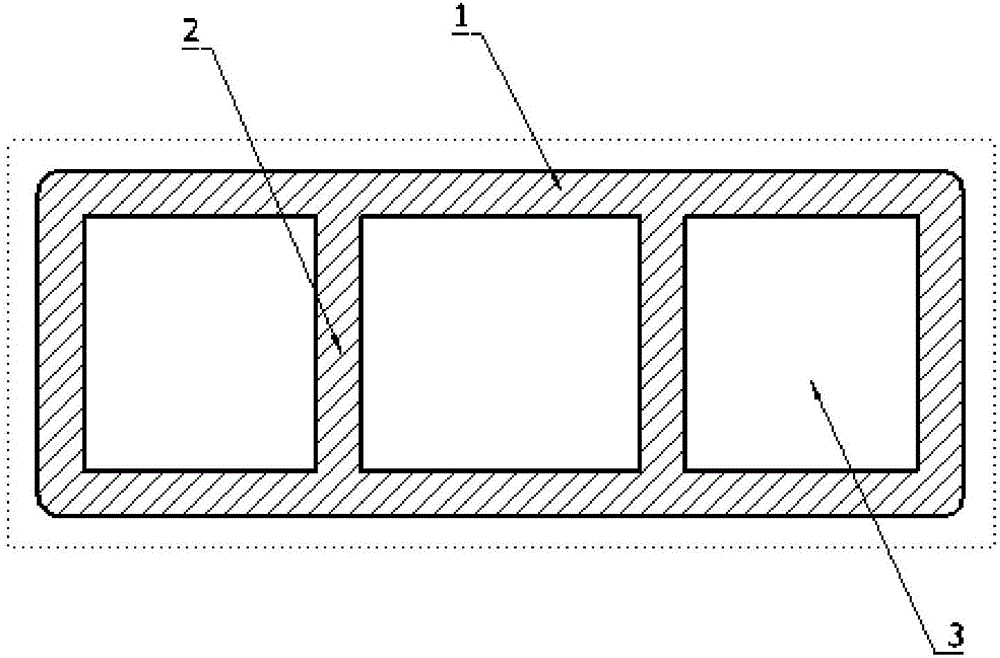

[0015] See figure 1 , Which is a cross-sectional view of the hollow wire with reinforcing ribs of the present invention, including the wire wall 1 of the hollow wire and a plurality of reinforcing ribs 2 arranged in the hollow wire. The reinforcing ribs 2 are arranged in the axial direction of the wire and surround the wire wall 1 The hollow cavity formed is divided into a plurality of water flow channels 3. The reinforcing rib 2 plays a supporting role for the hollow wire, so that the middle of the hollow wire does not dent inward when the coil is wound, so as to ensure the cross-sectional area of the water flow channel and ensure the heat dissipation effect.

[0016] The aforementioned wire material can be aluminum, copper o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com