Metal mold low-pressure casting mold for crankcase of motor train unit air compressor

An air compressor and low-pressure casting technology, which is applied in the field of low-pressure casting molds for metal molds of air compressor crankcases of EMUs, can solve the problems of high scrap rate, low productivity, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

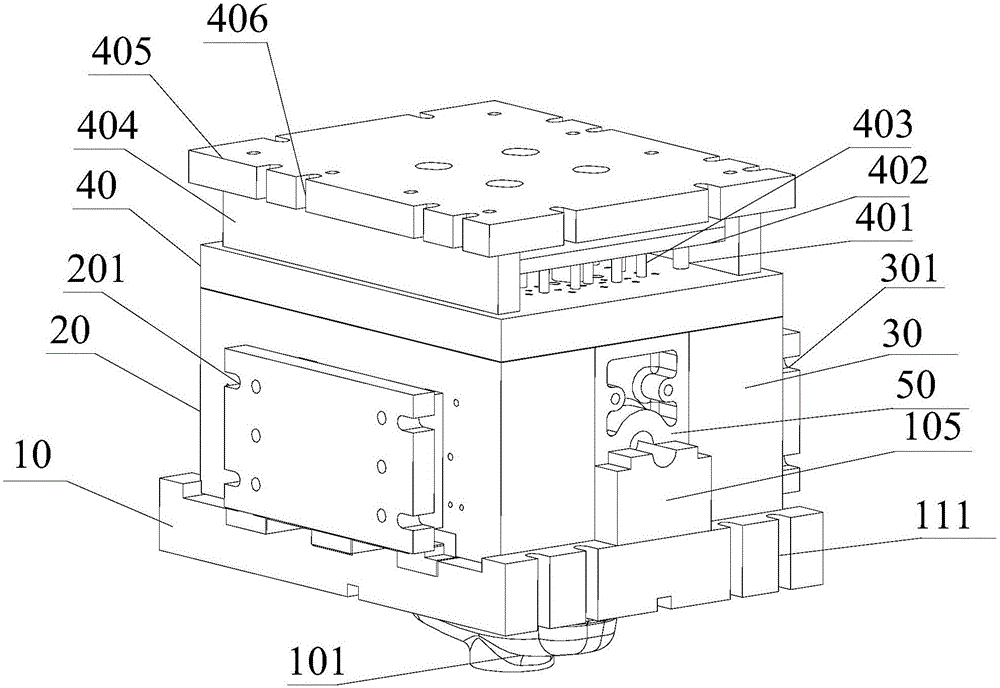

[0031] refer to figure 1 , the present invention proposes a metal type low-pressure casting mold for an air compressor crankcase of an EMU, including a lower mold, a first slider 20, a second slider 30, an upper mold, a manual core pulling 50, and a feeding riser sand core 60 , The lower mold, the first slider 20, the second slider 30, the upper mold, the manual core pulling 50, and the feeding riser sand core 60 form a casting cavity.

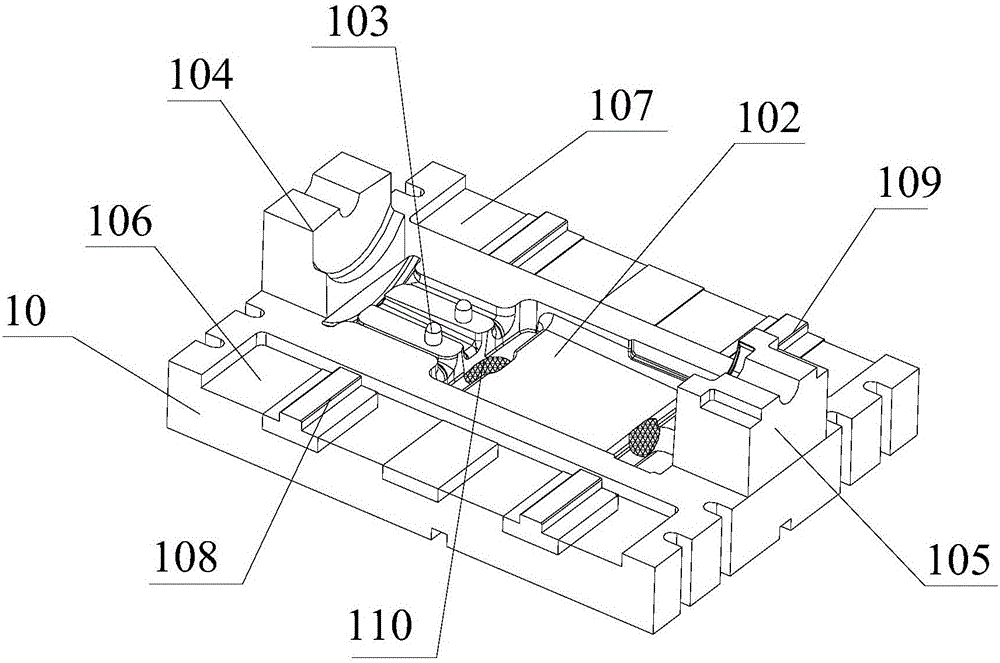

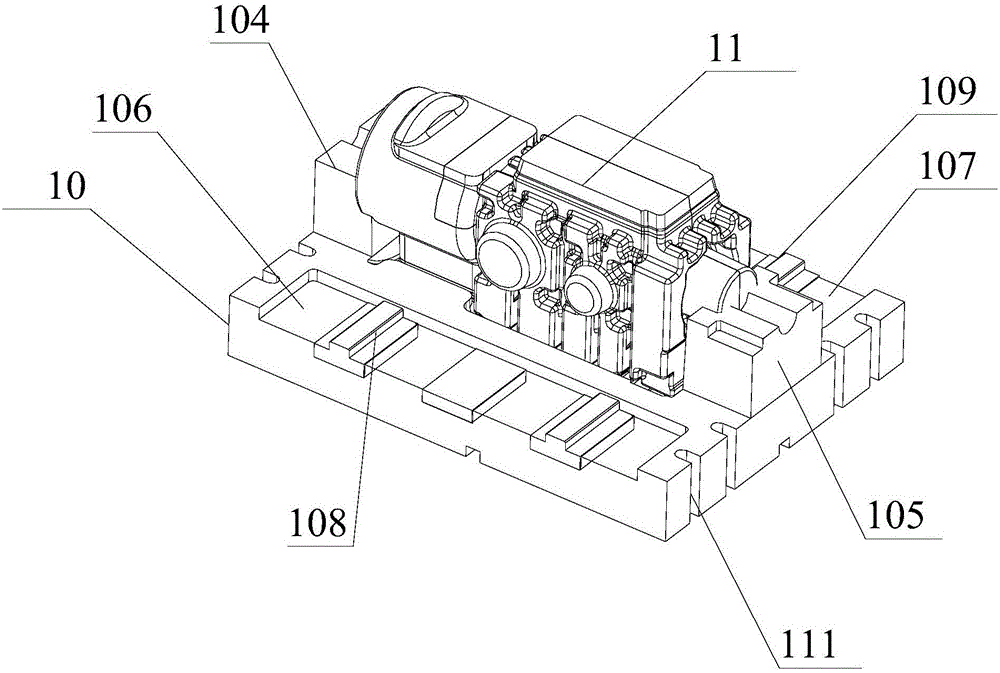

[0032] Such as figure 1 , figure 2 , image 3 , Figure 7 , Figure 8 , Figure 11 As shown, the lower mold in the present embodiment includes a lower mold base 10 and an inner cavity sand core 11, the lower mold base 10 is provided with a rising liquid sprue basin 101, and the rising liquid gate basin 101 is provided with a splitter plate 112, and the lower mold base 101 is provided with a splitter plate 112. The seat 10 is provided with a first sand core positioning groove 102 on the side away from the liquid-lift gate basin 101, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com