Preparation method of wide alloy plate

An alloy sheet and wide-width technology, which is applied in the field of wide-width alloy sheet preparation, can solve the problems that affect the application of the sheet, the sheet width is small, and it cannot be integrally formed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

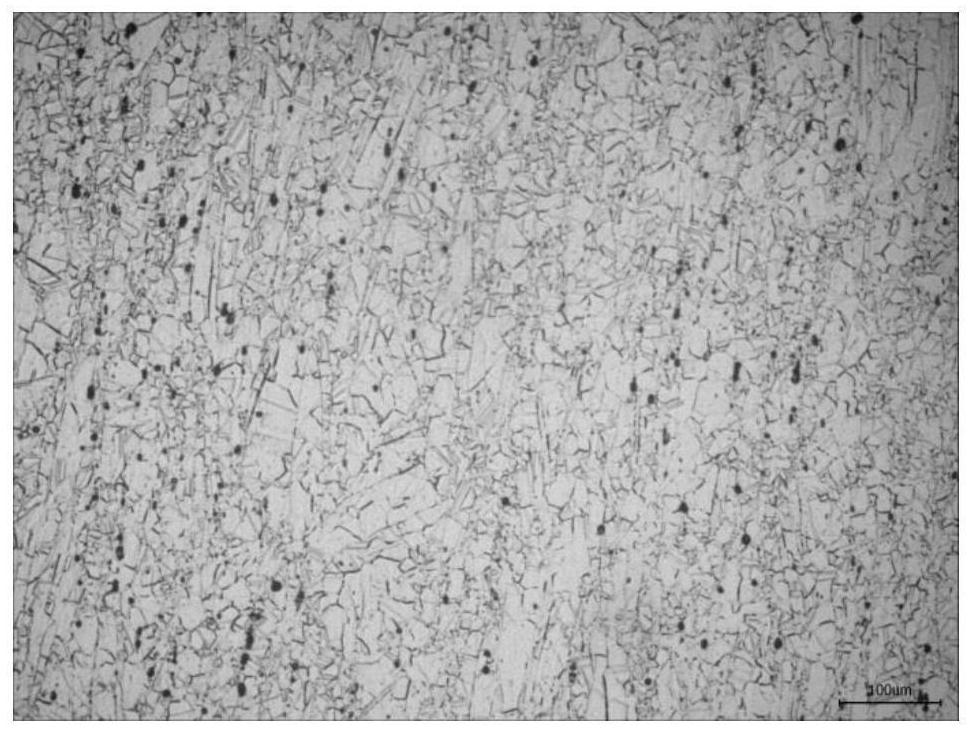

Image

Examples

preparation example Construction

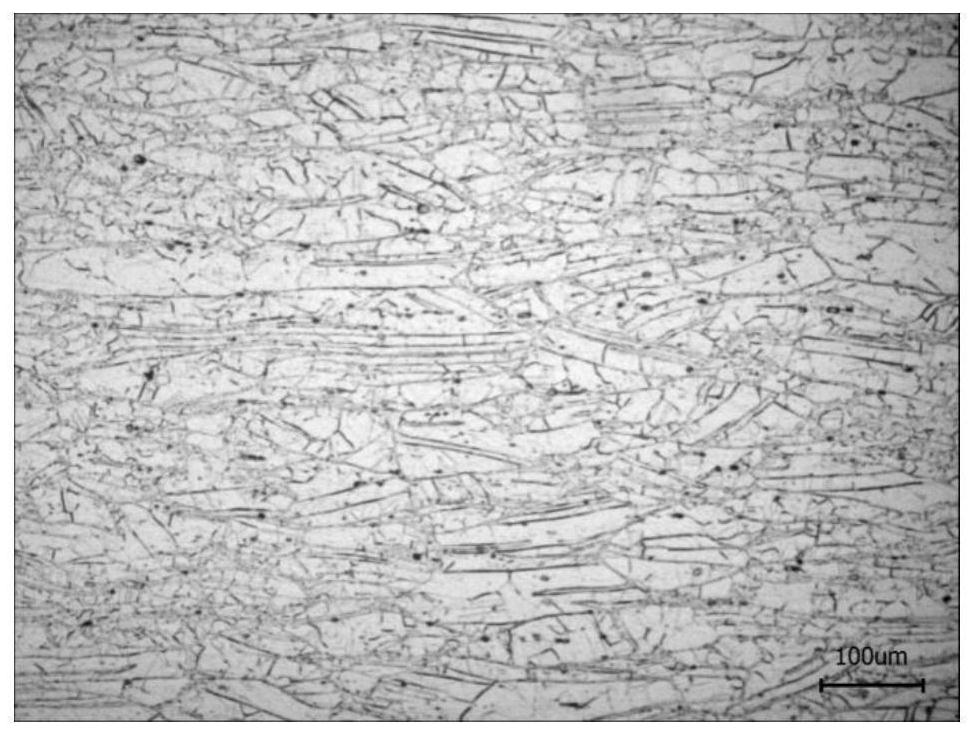

[0031] A method for preparing a wide-width alloy plate, comprising the following steps:

[0032] 1) The mechanical property test of the Inconel625 superalloy slab should meet the requirements of Table 1, and the ultrasonic flaw detection should be carried out, and there is no internal defect.

[0033] 2) One-fire rolling:

[0034] Heating: raise the temperature of the superalloy slab to 1130℃~1150℃, and the holding time is calculated according to the thickness of the superalloy slab 0.4mm / min~0.7mm / min; Rolling force, multi-pass small deformation rolling is selected for one-fire billet rolling.) Specifically, the holding time t=h*(0.4mm / min~0.7mm / min). h is the thickness of the superalloy slab. For example, if the thickness is 2.8mm, the holding time is 4-7min.

[0035] Among them, rolling passes: 7 to 9 passes;

[0036] Total deformation: 45% to 55%;

[0037] Pass deformation: 5% to 8%.

[0038] 1) Divide the material: divide the double-footed plate after the first-fire...

Embodiment 1

[0057] A method for preparing a wide-width alloy plate, comprising the following steps:

[0058] 1) The mechanical performance test of the slab should meet the requirements in Table 1, and the ultrasonic flaw detection should be carried out, and there should be no internal defects.

[0059] 2) One-fire rolling:

[0060] Heating: Heating up to 1150°C for 60 minutes.

[0061] Deformation: The total deformation is 50%;

[0062] Deformation passes: 7 passes

[0063] Pass deformation: 8%→8%→8%→7%→7%→6%→6%

[0064] 3) Ingredients:

[0065] 4) Second fire rolling:

[0066] Heating: Heating up to 1150°C for 30 minutes.

[0067] Deformation: The total deformation is 51%;

[0068] Deformation passes: 4 passes

[0069] Pass deformation: 13%→13%→13%→12%

[0070] 5) Ingredients:

[0071] 6) Three-fire rolling:

[0072] Heating: 1080°C holding time is 18min.

[0073] Deformation: The total deformation is 73%;

[0074] Deformation passes: 5 passes

[0075] Pass ...

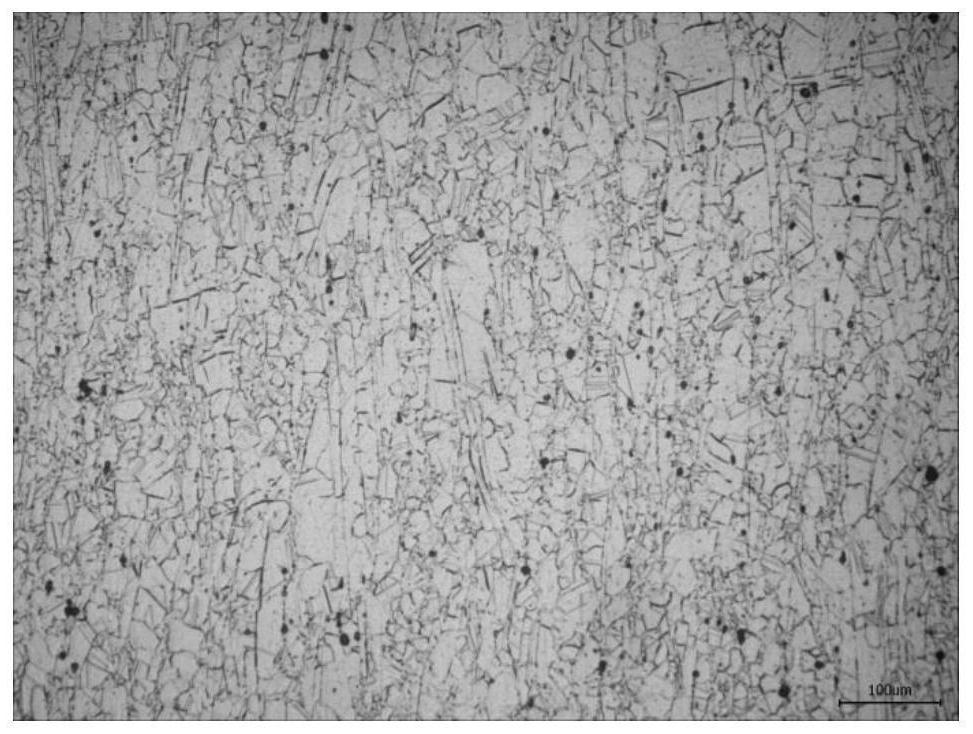

Embodiment 2

[0083] A method for preparing a wide-width alloy plate, comprising the following steps:

[0084] 1) The mechanical performance test of the slab should meet the requirements in Table 1, and the ultrasonic flaw detection should be carried out, and there should be no internal defects.

[0085] 2) One-fire rolling:

[0086] Heating: Heating up to 1130°C for 60 minutes.

[0087] Deformation: The total deformation is 50%;

[0088] Deformation passes: 9 passes;

[0089] Pass deformation: 7%→7%→6%→5%→5%→5%→5%→5%→5%;

[0090] 3) Ingredients:

[0091] 4) Second fire rolling:

[0092] Heating: Heating up to 1130°C for 30 minutes.

[0093] Deformation: The total deformation is 51%;

[0094] Deformation passes: 6 passes;

[0095] Pass deformation: 10%→9%→9%→8%→8%→7%;

[0096] 5) Ingredients:

[0097] 6) Three-fire rolling:

[0098] Heating: 1050°C holding time is 18min.

[0099] Deformation: The total deformation is 72%;

[0100] Deformation passes: 6 passes

[0101...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com