Production method of thick-specification steel S355G11M hot rolled coil for seaside building structure

A technology of S355G11M steel for building structures, applied in the field of steel production and manufacturing, can solve the problems of steel weldability, poor formability, insufficient equipment utilization, long rolling cycle time, etc., to achieve reduced rolling time, low cost, and improved The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

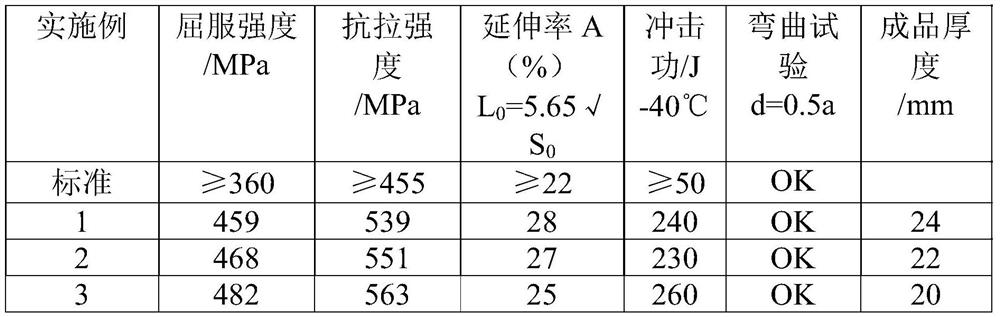

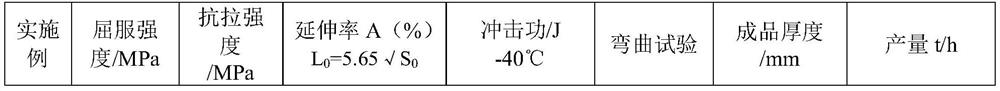

Examples

Embodiment

[0036] The preparation of S355G11M hot-rolled coils is carried out as follows:

[0037] 1) Hot metal pretreatment: pretreat the hot metal, the hot metal pretreatment requires S ≤ 0.0050%, and carry out slag removal treatment;

[0038] 2) Converter: All ladles are preheated and heated to reduce fluctuations in molten steel temperature drop, improve the cleanliness of the ladle, make the ladle clean without residual steel and residue, ensure the air permeability and self-pouring of the ladle, and feed calcium when the ladle is in use. During the decarburization process of the converter, oxygen blowing is only performed once to avoid secondary point blowing of oxygen to reduce carbon. Low-carbon and low-phosphorus ferromanganese and ferrosilicon are used for tapping. , to avoid scattered flow, the aluminum content of the ladle is controlled by 0.005-0.020%, and at the same time, the ladle N≤25ppm is required, the slag is blocked and the steel is tapped, and the amount of slag ent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com