Production method of high-quality thick steel plate

A production method and thick-gauge technology, applied in the field of iron and steel materials, can solve the problems of low rolling rhythm and low efficiency of high-strength toughness steel plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

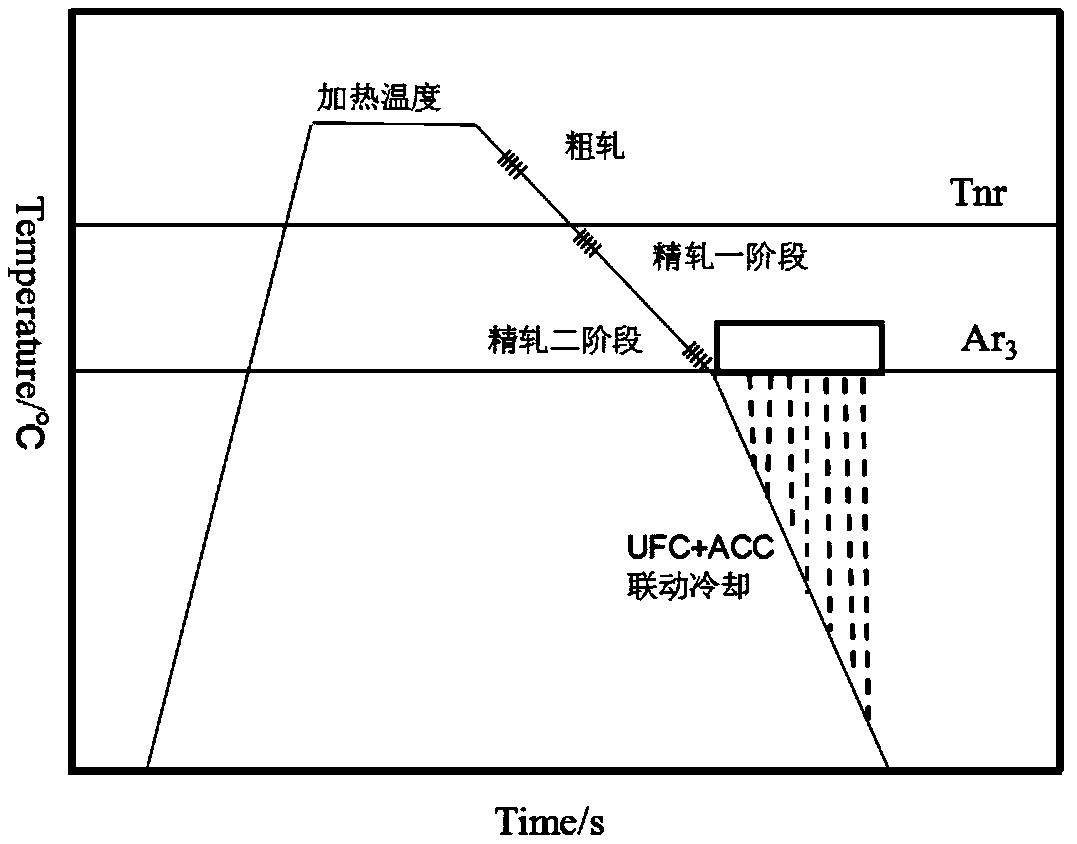

Method used

Image

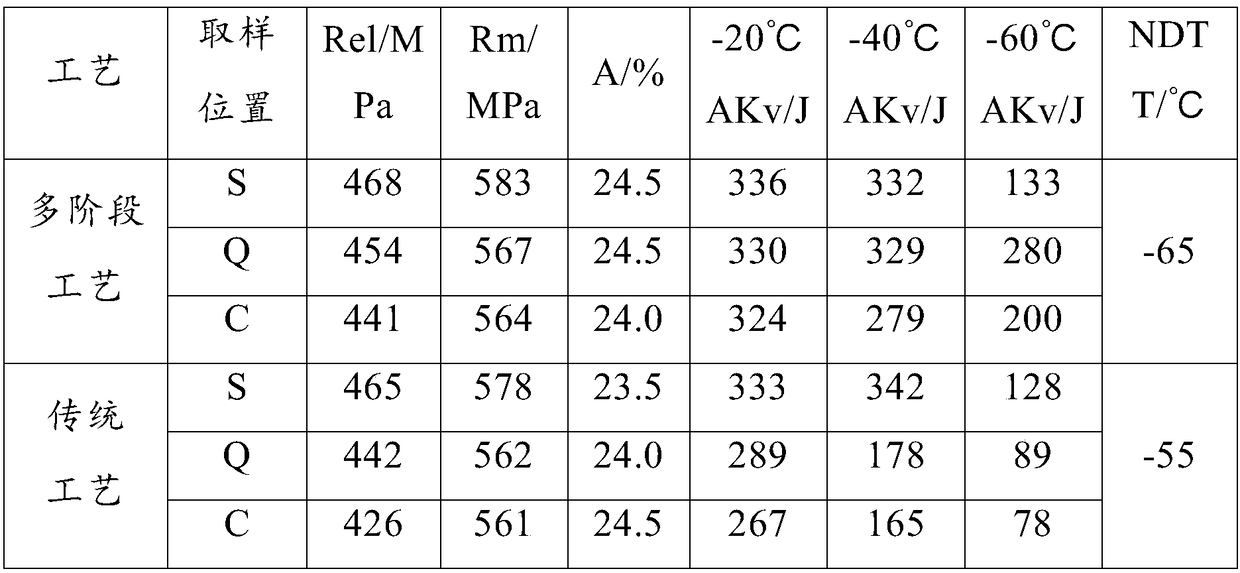

Examples

Embodiment 1

[0068] Described production method specifically comprises:

[0069] Smelting: Converter smelting, top blowing or top-bottom composite blowing, LF furnace and RH furnace vacuum treatment to reduce the content of O, H and other harmful gases and S;

[0070] Continuous casting: the thickness of the continuous casting slab is 400mm, the compression ratio is 5.7, the width of the continuous casting slab is 2000mm, the width ratio is 1.2, and the cumulative reduction of the longitudinal rolling passes is 263mm;

[0071] Heating system: heat the billet to 1180°C, the total time in the furnace is 390min, and the tapping temperature is 1176°C;

[0072] Rough rolling stage: Low-speed and high-reduction process is adopted, the rolling start temperature is 1120°C, the cumulative reduction rate is 57.5%, the maximum single-pass reduction rate is 15.7%, and the thickness of one-time waiting temperature is 170mm;

[0073] The first stage of finishing rolling: low-speed and high-reduction pr...

Embodiment 2

[0089] Described production method specifically comprises:

[0090] Smelting: Converter smelting, top blowing or top-bottom composite blowing, LF furnace and RH furnace vacuum treatment to reduce the content of O, H and other harmful gases and S;

[0091] Continuous casting: the thickness is 400mm, the compression ratio is 4.44, the width is 2400mm, the expansion ratio is 1.17; the cumulative reduction of longitudinal rolling passes is 253mm;

[0092] Heating system: heat the billet to 1180°C, the total time in the furnace is 390min, and the tapping temperature is 1178°C;

[0093] Rough rolling stage: low-speed and high-reduction process is adopted, the rolling start temperature is 1120°C, the cumulative reduction rate is 50%, the maximum single-pass reduction rate is 17.0%, and the thickness of one-time waiting temperature is 200mm;

[0094] The first stage of finishing rolling: low-speed and high-reduction process is adopted, the rolling start temperature is 890°C, the cumu...

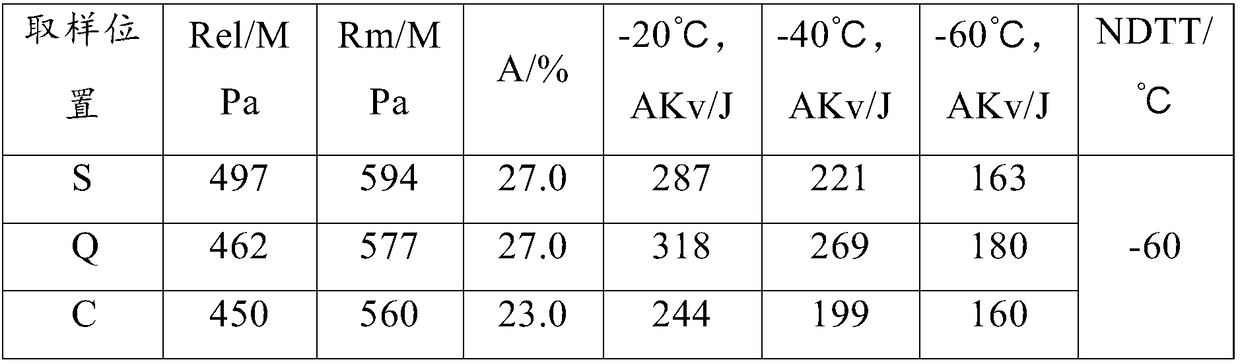

Embodiment 3

[0102] Described production method specifically comprises:

[0103] Smelting: Converter smelting, top blowing or top-bottom composite blowing, LF furnace and RH furnace vacuum treatment to reduce the content of O, H and other harmful gases and S;

[0104] Continuous casting: the thickness is 400mm, the compression ratio is 3.33; the width is 2400mm, without widening; the cumulative reduction of longitudinal rolling passes is 280mm;

[0105] Heating system: heat the billet to 1180°C, the total time in the furnace is 398min, and the tapping temperature is 1176°C;

[0106] Rough rolling stage: Low-speed and large-reduction process is adopted, the rolling start temperature is 1120°C, the cumulative reduction rate is 45%, the maximum single-pass reduction rate is 16.9%, and the thickness of one-time waiting temperature is 220mm;

[0107] The first stage of finishing rolling: low-speed and high-reduction process is adopted, the rolling start temperature is 890°C, the cumulative red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com