Patents

Literature

44results about How to "Avoid performance differences" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

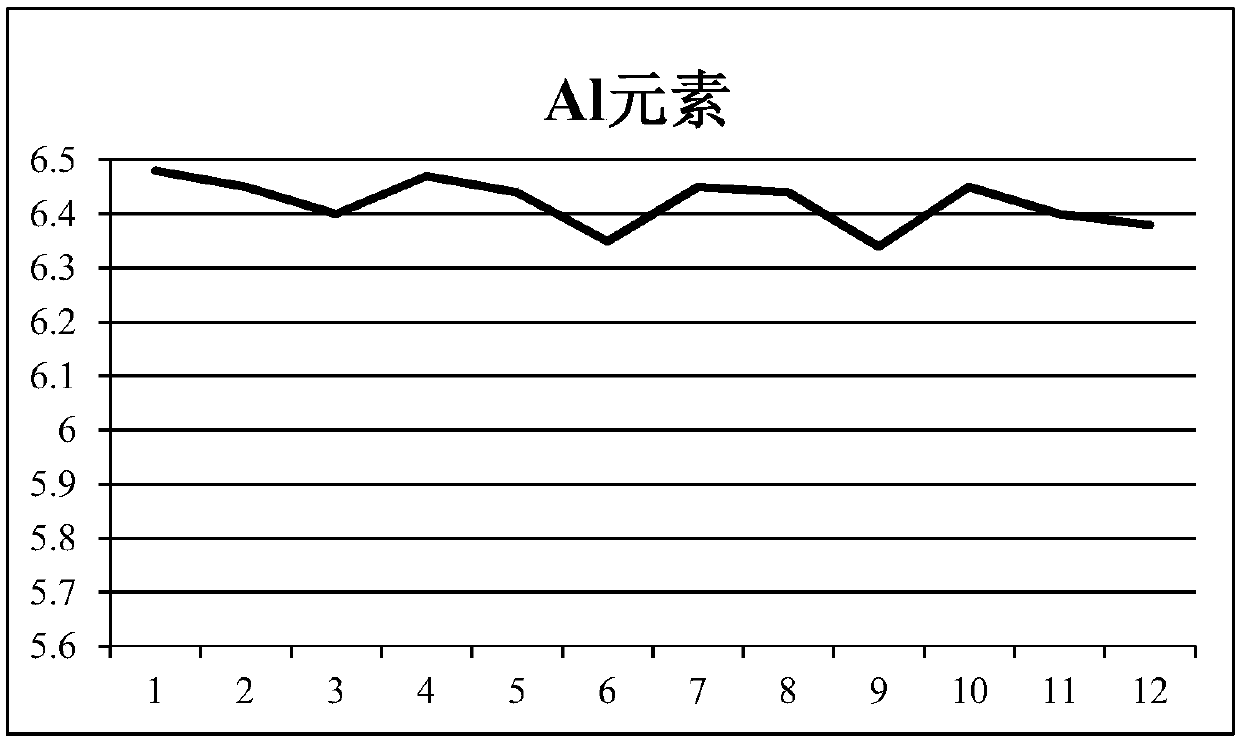

Feeding method for improving uniformity of components of head of TC4 cast ingot

The invention discloses a feeding method for improving the uniformity of components of a head of a TC4 cast ingot. The method comprises the following steps: proportioning sponge titanium and an intermediate alloy according to a proportion required by GB / T3620.1; mixing the materials and pressing the materials into an electrode block; after carrying out vacuum plasma welding on the electrode block,carrying out vacuum arc furnace smelting, wherein in the smelting process, the residual weight and the argon filling pressure of the electrode are strictly controlled in the third time smelting feeding stage; and finally, carrying out surface machining to obtain a finished product cast ingot. The feeding method disclosed by the invention solves the problems that the center Al element of the existing phi720mm specification TC4 cast ingot is relatively low and the phase transformation point of the cast ingot is greatly deviated.

Owner:西部超导材料科技股份有限公司

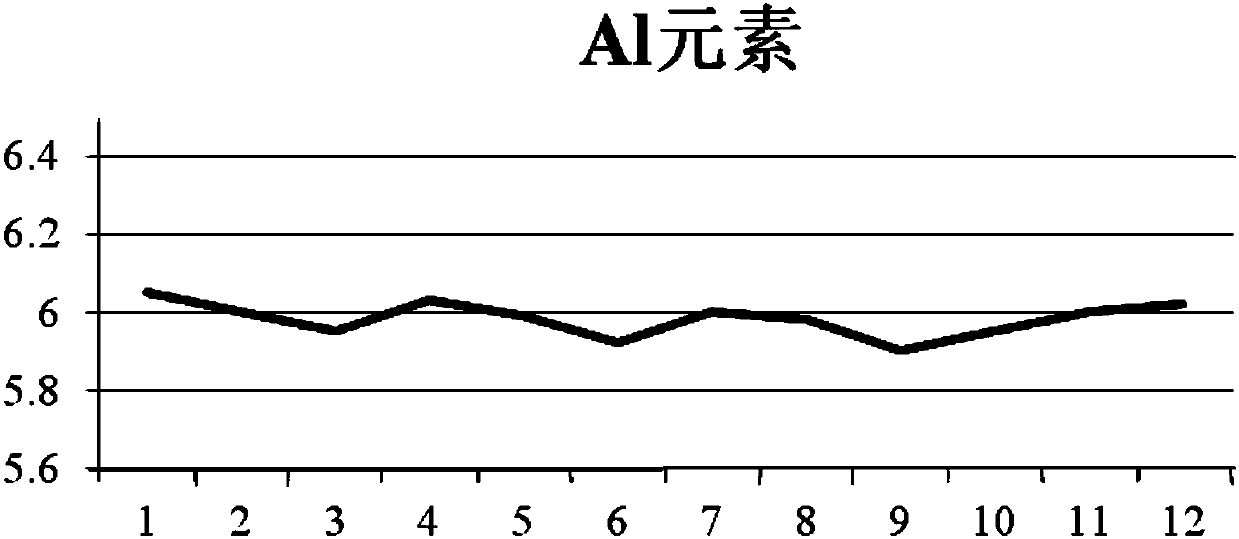

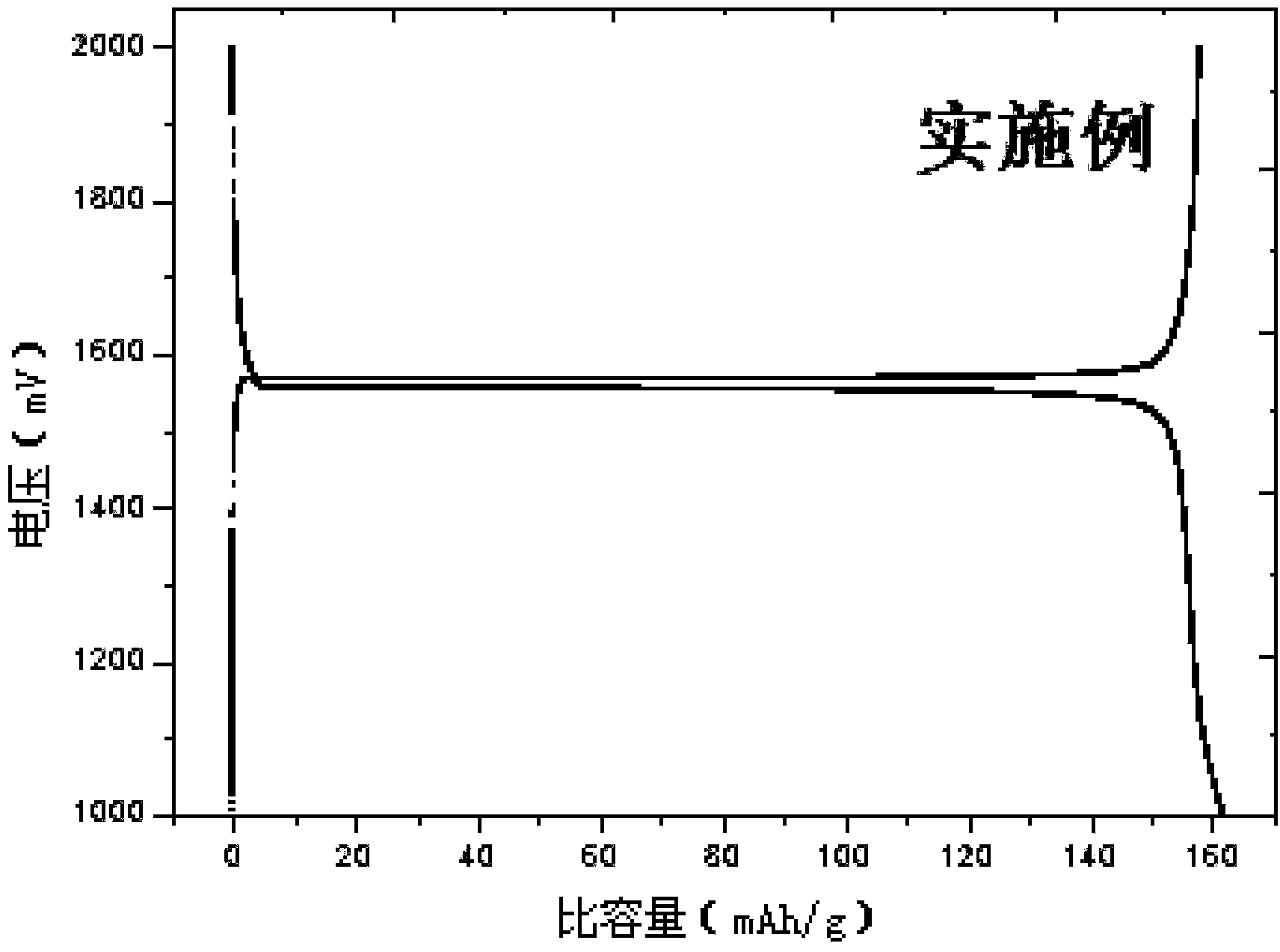

Preparation method for lithium titanate

ActiveCN103474645AImprove process performanceGood stabilityCell electrodesTitanium compoundsHigh rateNitrogen gas

The invention discloses a preparation method for lithium titanate. The preparation method comprises the following steps: (1) preparing a slurry by using a titanium source, a lithium source, an inorganic additive, an organic additive and water; (2) atomizing and drying the slurry prepared by the first step into powder in an atomizing dryer; (3) roasting the powder prepared by the second step at the atmosphere of a hydrogen and nitrogen gas mixture for 5 to 10 hours; (4) cooling the roasted powder obtained by the third step at the atmosphere of the hydrogen and nitrogen gas mixture to room temperature, thereby obtaining the lithium titanate. The lithium titanate prepared by the preparation method is stable in quality; meanwhile, the product has high-rate discharge performance and cycling performance, and is an excellent lithium ion battery anode material.

Owner:四川新锂想能源科技有限责任公司

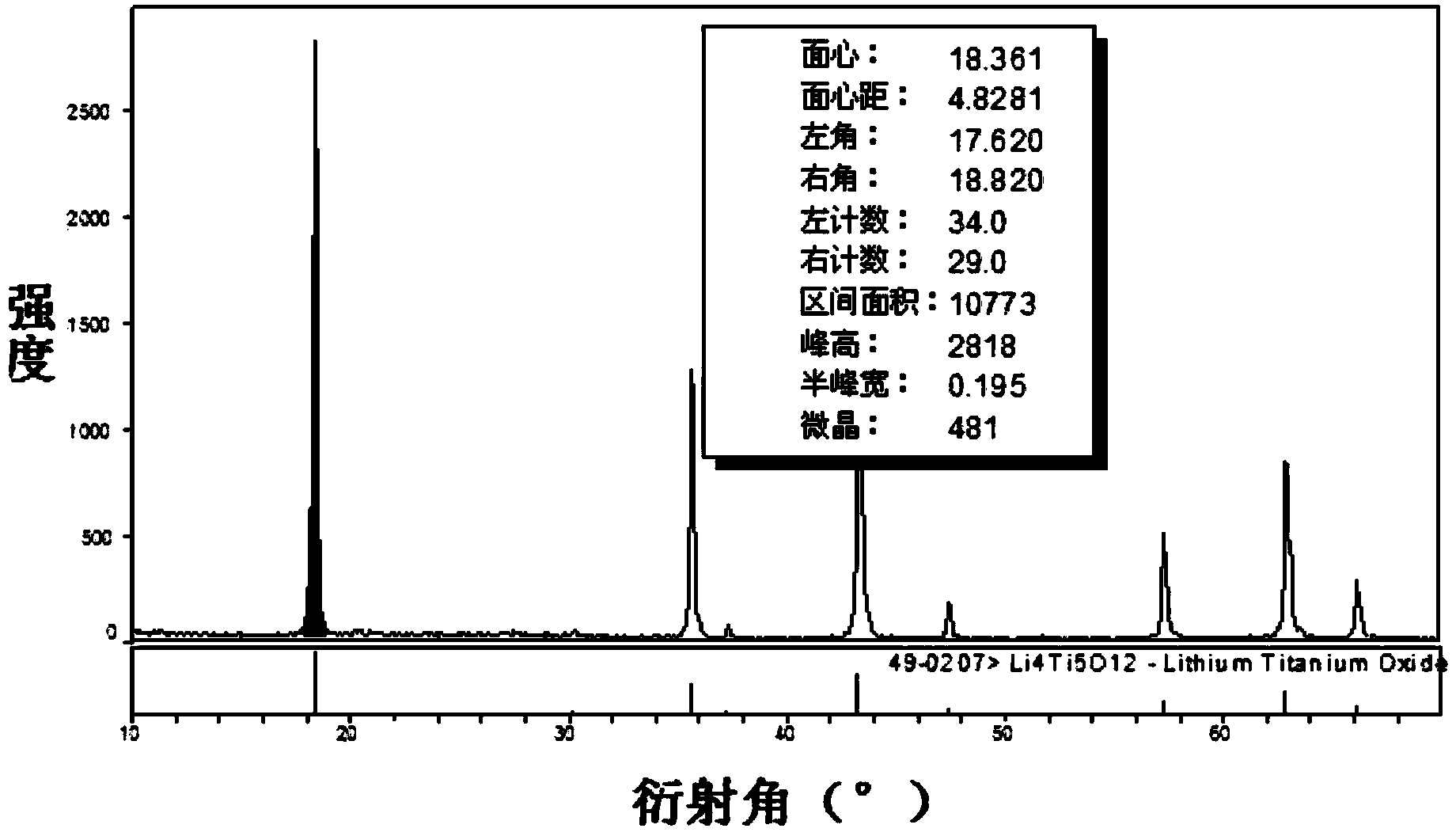

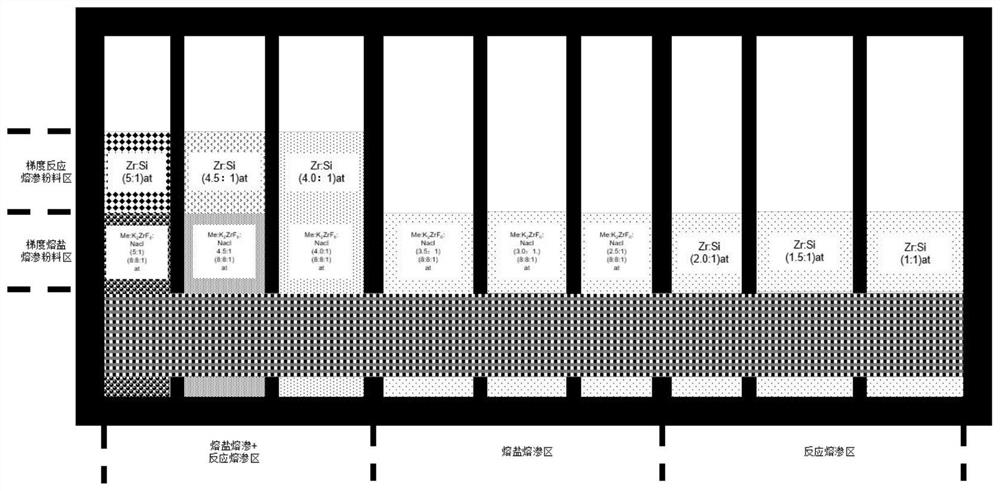

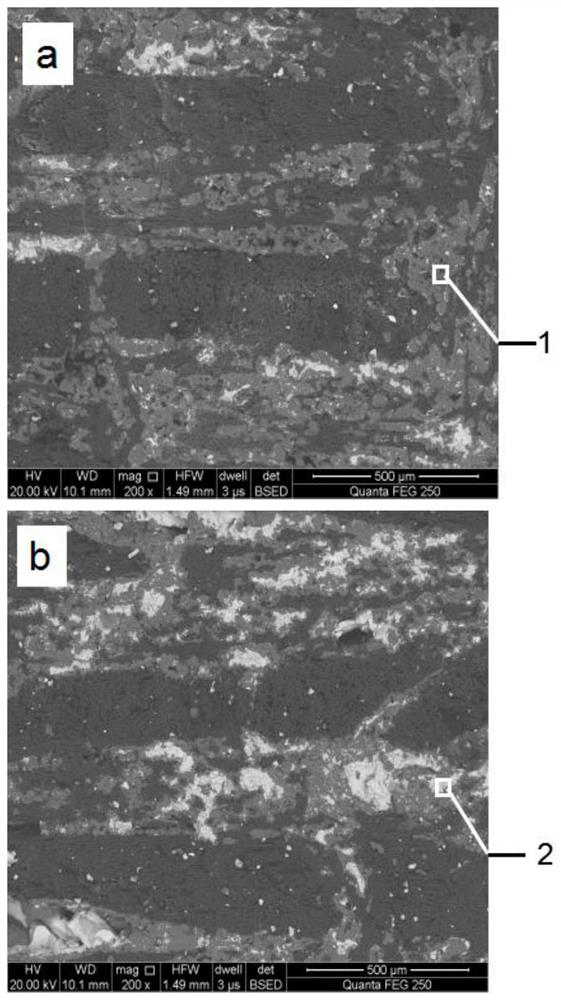

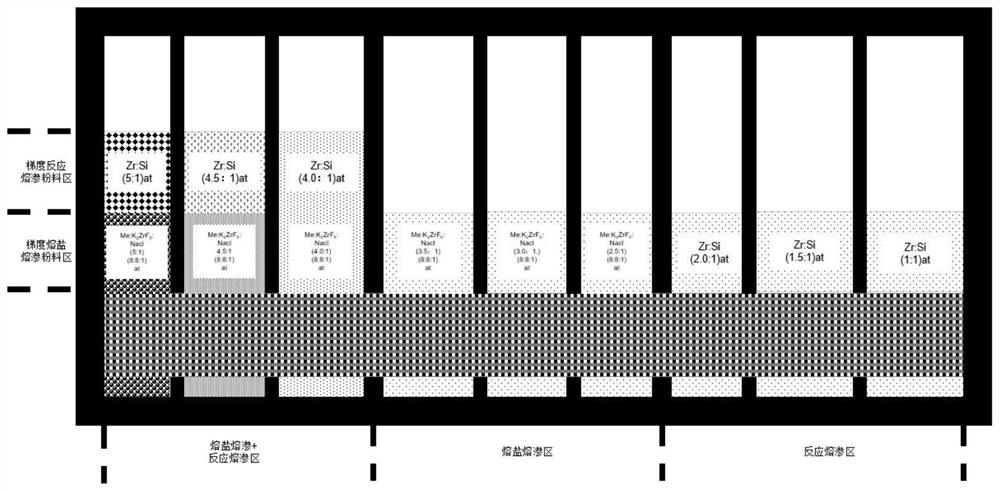

Preparation method of component- gradient -controllable multi-element ultrahigh-temperature ceramic modified C/C composite material

ActiveCN112457056AAvoid stress concentrationImprove anti-ablation performanceCeramicwareMolten saltUltrahigh temperature ceramics

The invention discloses a preparation method of a component-gradient-controllable multi-element ultrahigh-temperature ceramic modified C / C composite material. Through multi-section design of various ultrahigh-temperature ceramics (ZrC, HfC, HfB2 and the like) and high-temperature ceramic (SiC) composite modified C / C composite materials, a ceramic phase forms a continuous component gradient distribution form in a C / C matrix, ablation resistance and oxidation resistance requirements of different temperature range fields are met regionally, and meanwhile the defect that the mechanical property isreduced due to component mutation is overcome. According to the invention, a preparation process of combining molten salt infiltration and common reaction infiltration and gradient infiltration powder configuration are adopted in sections, so that near-ablation-end strong ceramic phase interface design is realized, and ceramic phase distribution realizing that the content of an ultrahigh-temperature ceramic phase is sequentially decreased from the near ablation end to a far ablation end and the high-temperature ceramic phase is sequentially increased is regulated and controlled; finally, thegradient ceramic-based composite material with different ceramic phase components and contents in gradient change and meeting the performance requirements of the material is formed.

Owner:CENT SOUTH UNIV

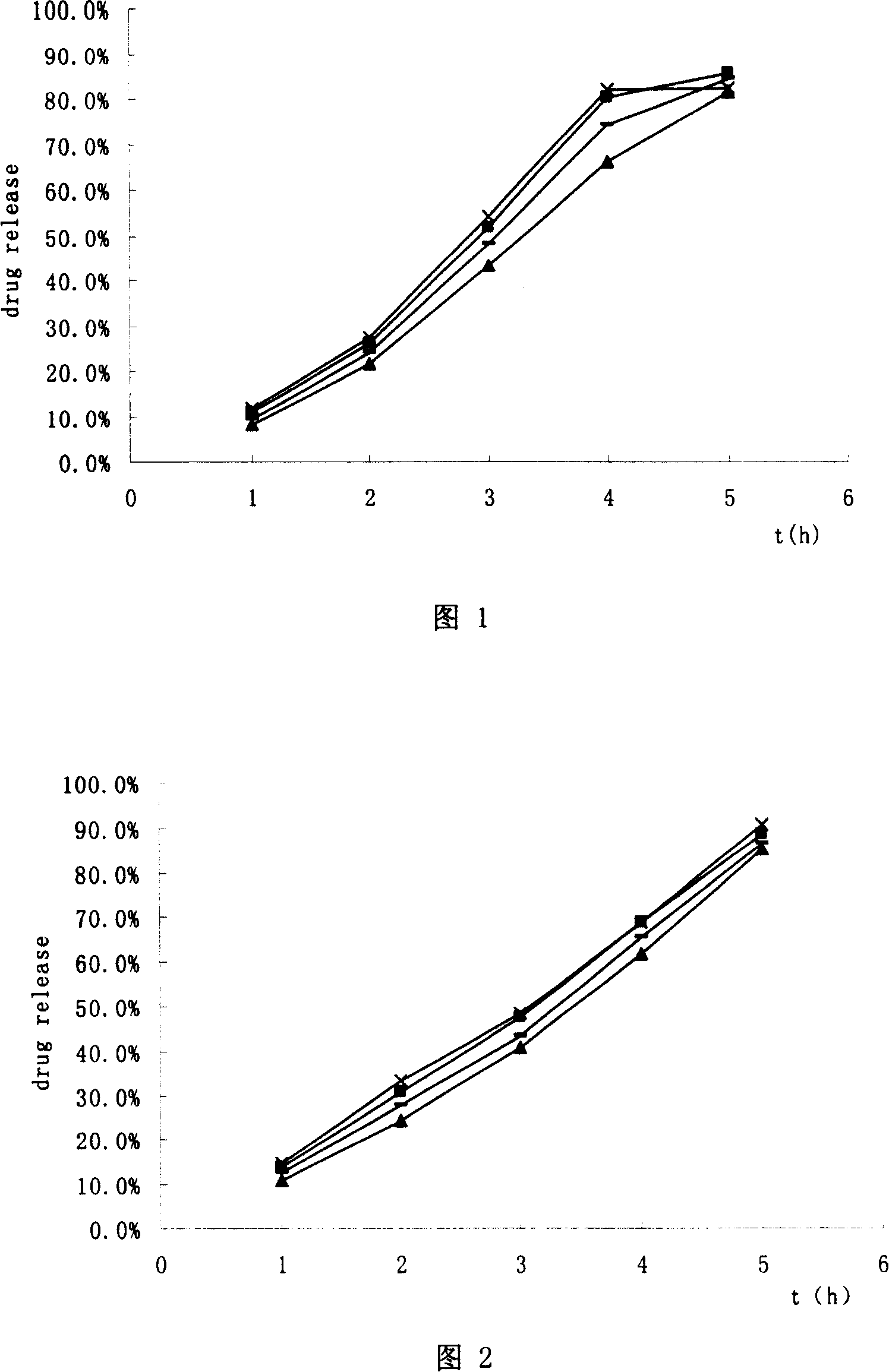

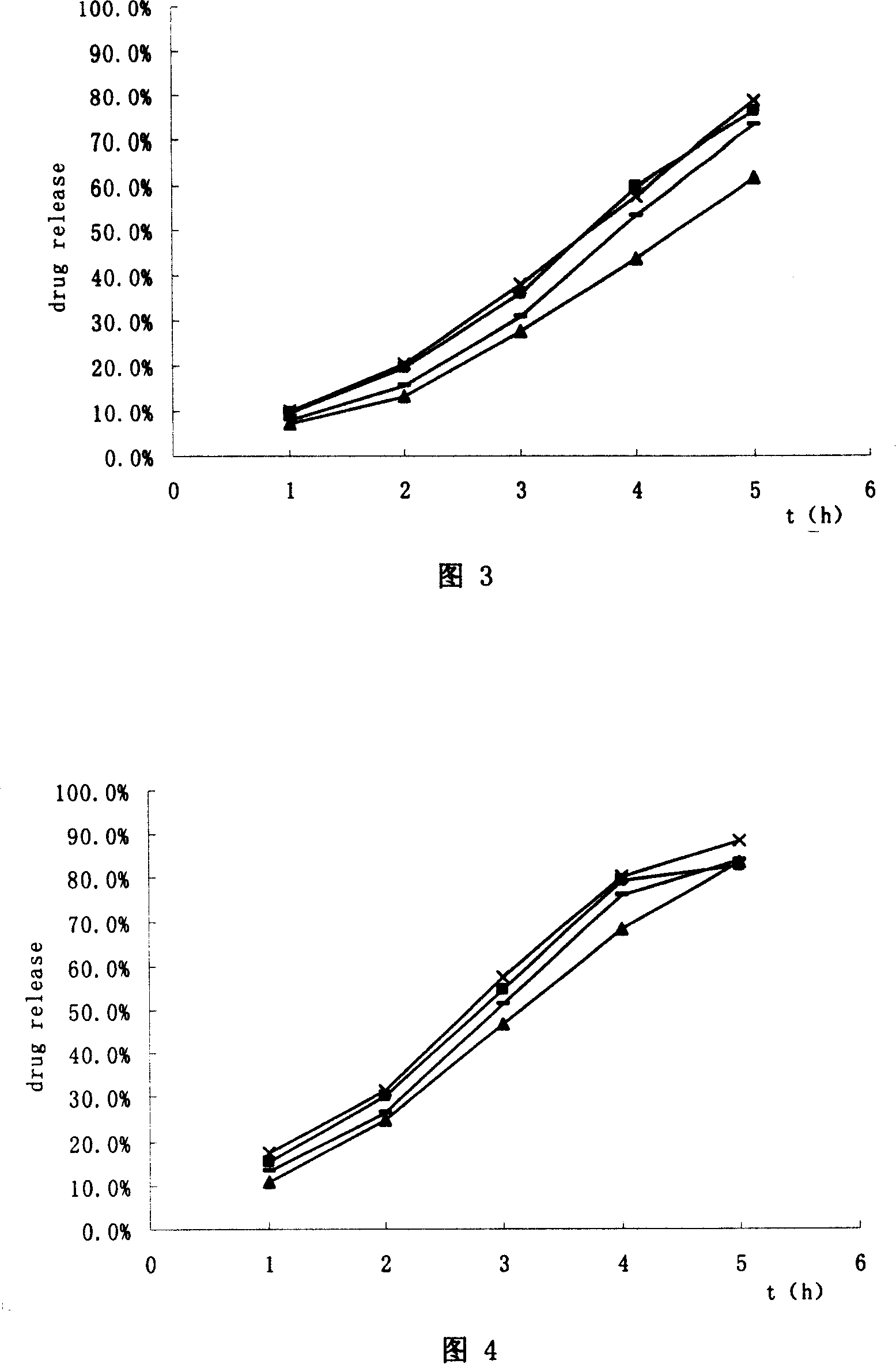

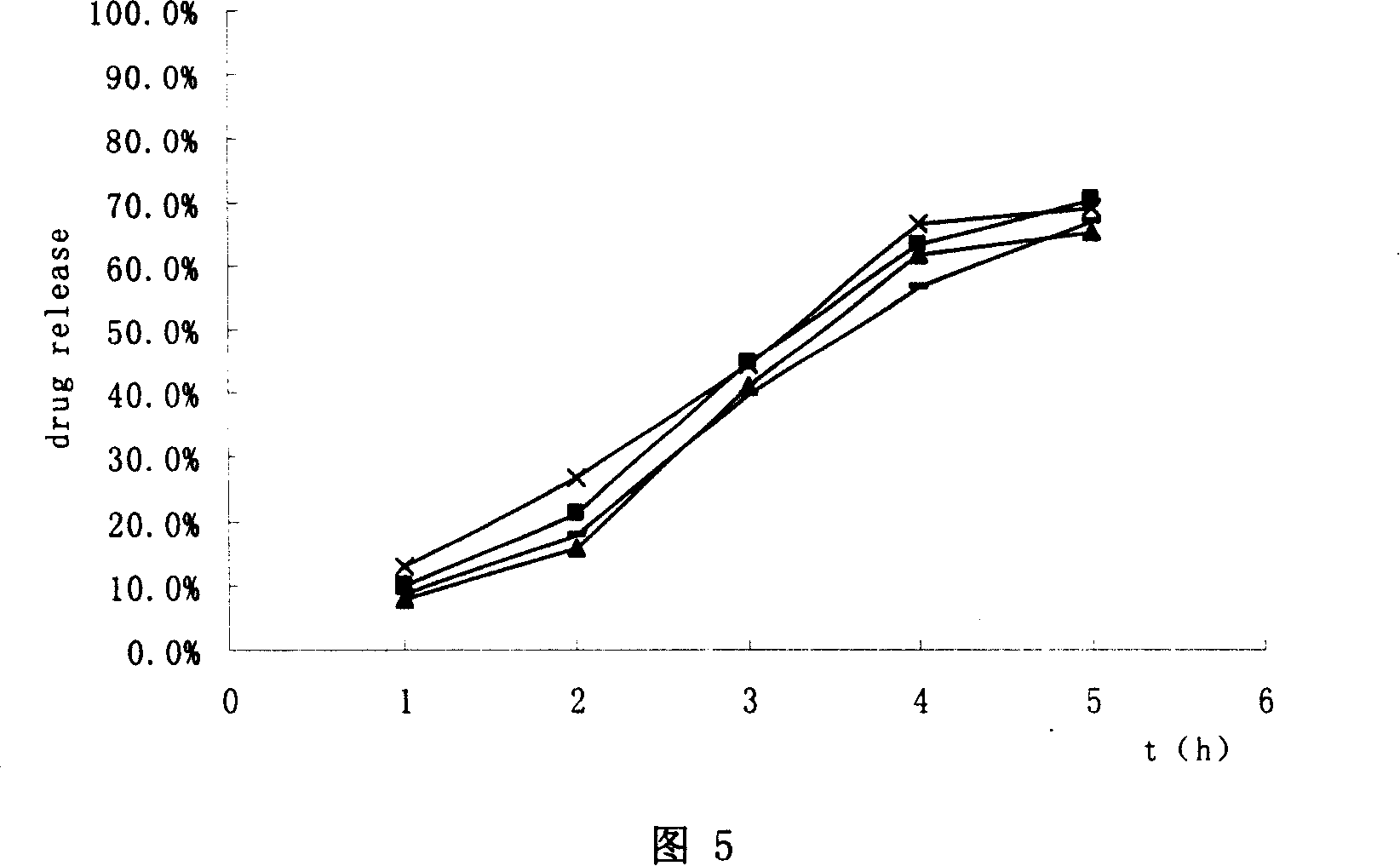

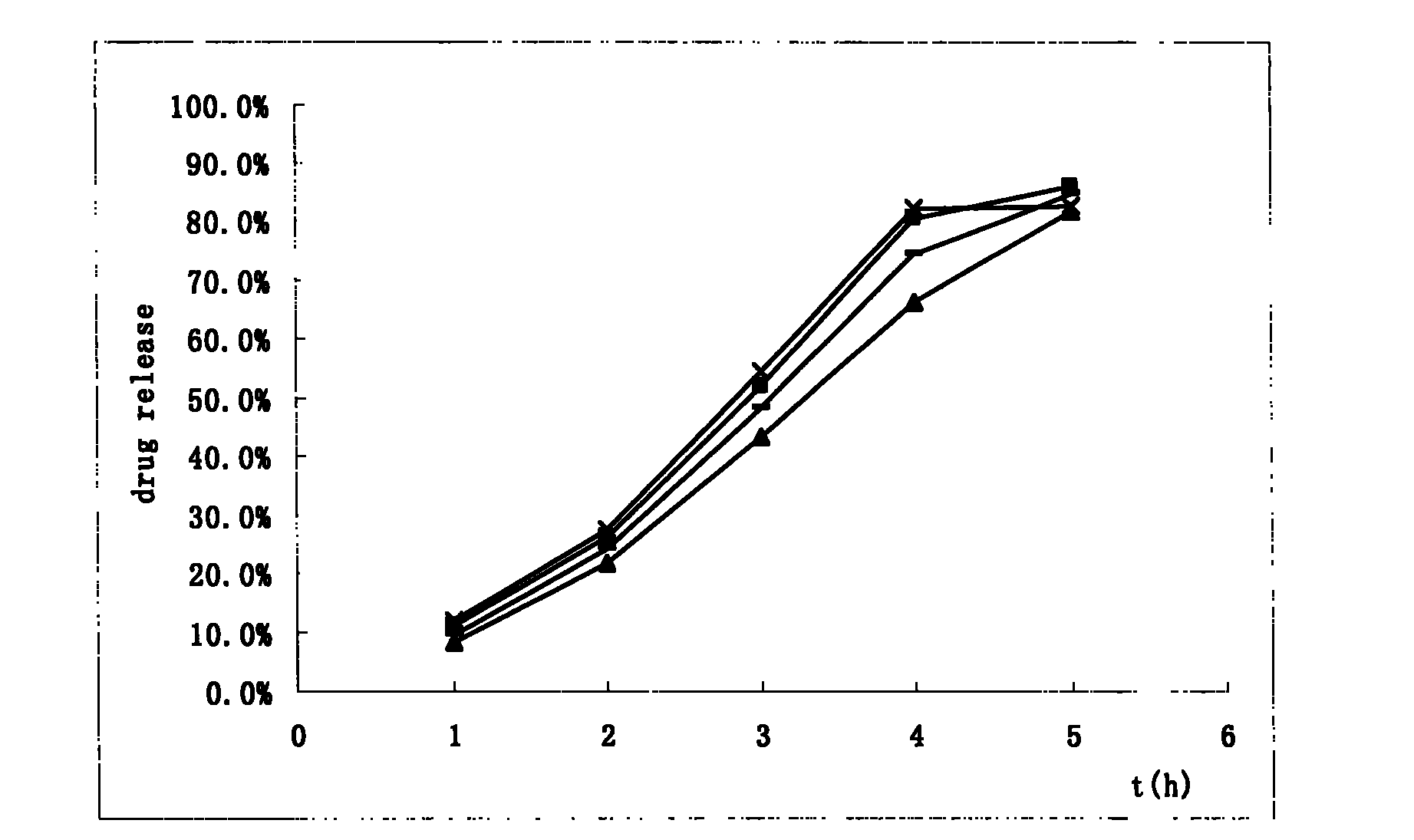

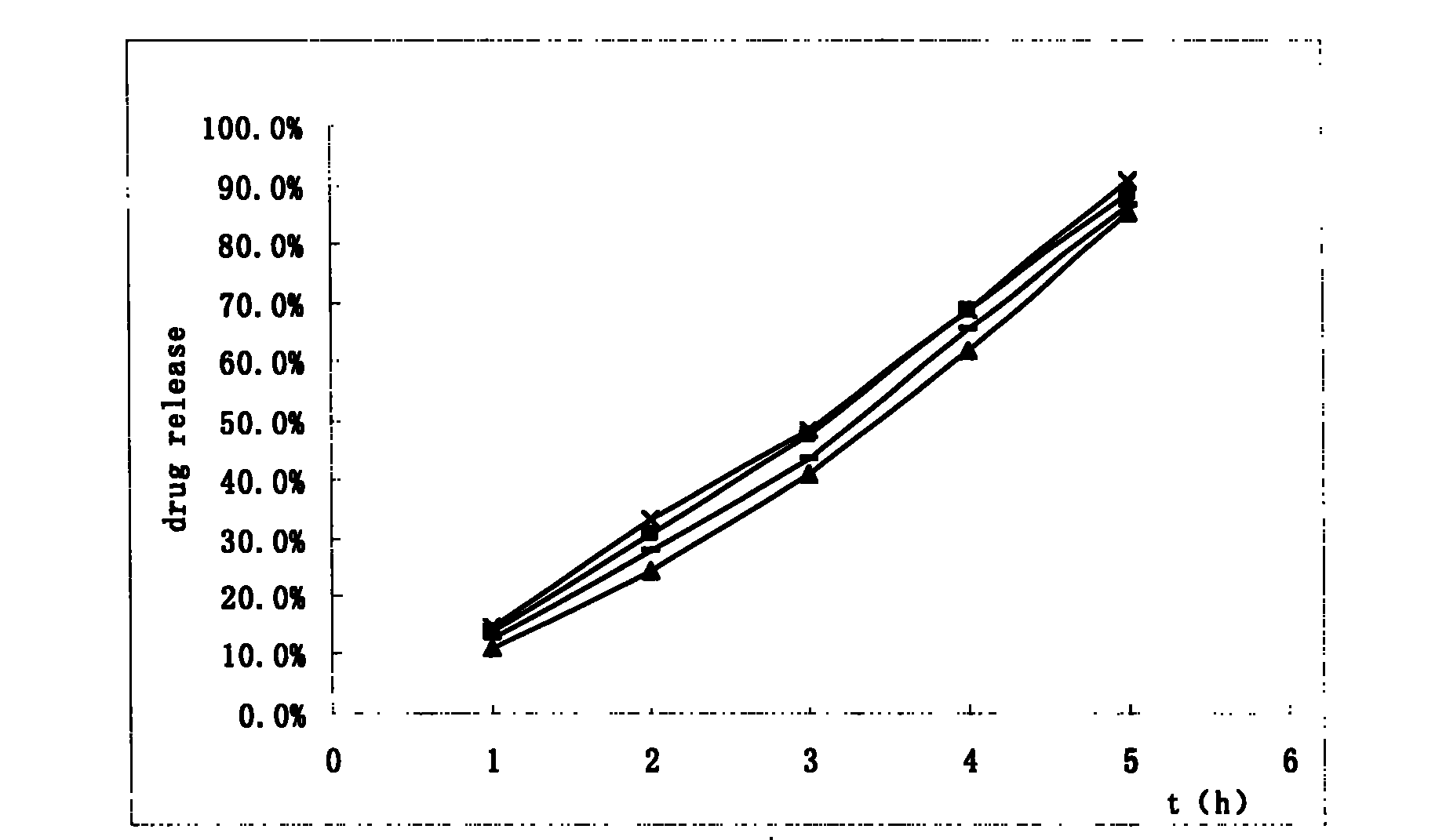

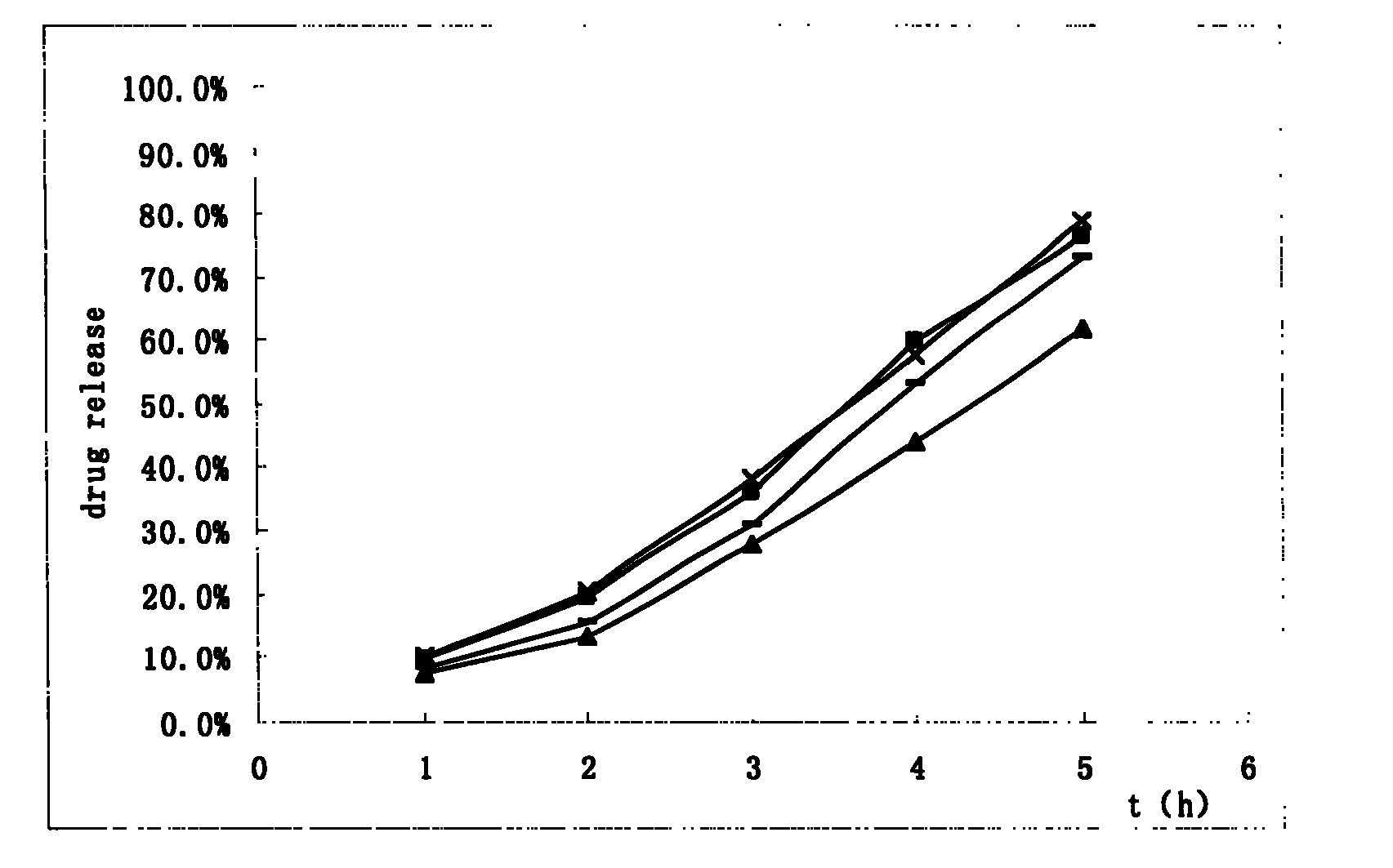

Hydrochloric tamsulosin sustained-release capsule and its preparation method

ActiveCN101125134APrecise Controlled ReleaseControl releaseOrganic active ingredientsPharmaceutical delivery mechanismSide effectOral medication

The present invention provides a tamsulosin hydrochloride sustained-release capsule. The tamsulosin hydrochloride sustained-release capsule of the present invention can avoid the sudden release of the drug tablets and the performance differences generated from the gastric emptying differences, display minor food effect or do not display food effect, and obtain the stable curve of the plasma drug concentration and longer action time simultaneously, so as to reduce the occurrence of cardiovascular side effects, greatly improve the safety, effectiveness and compliance of the medication for the patients. The tamsulosin hydrochloride sustained-release capsule of the present invention can ensure the sustained and regular release of the main ingredient tamsulosin hydrochloride after the oral administration, and the present invention is characterized by convenient administration, durable function, stable efficacy, fewer side effects and so on.

Owner:CHANGZHOU NO 4 PHARMA FACTORY

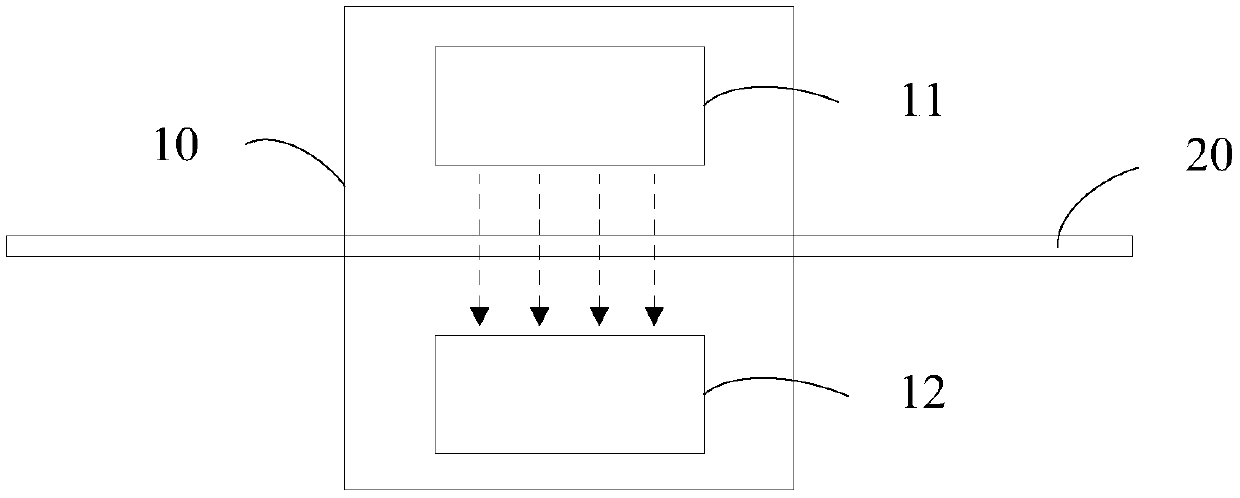

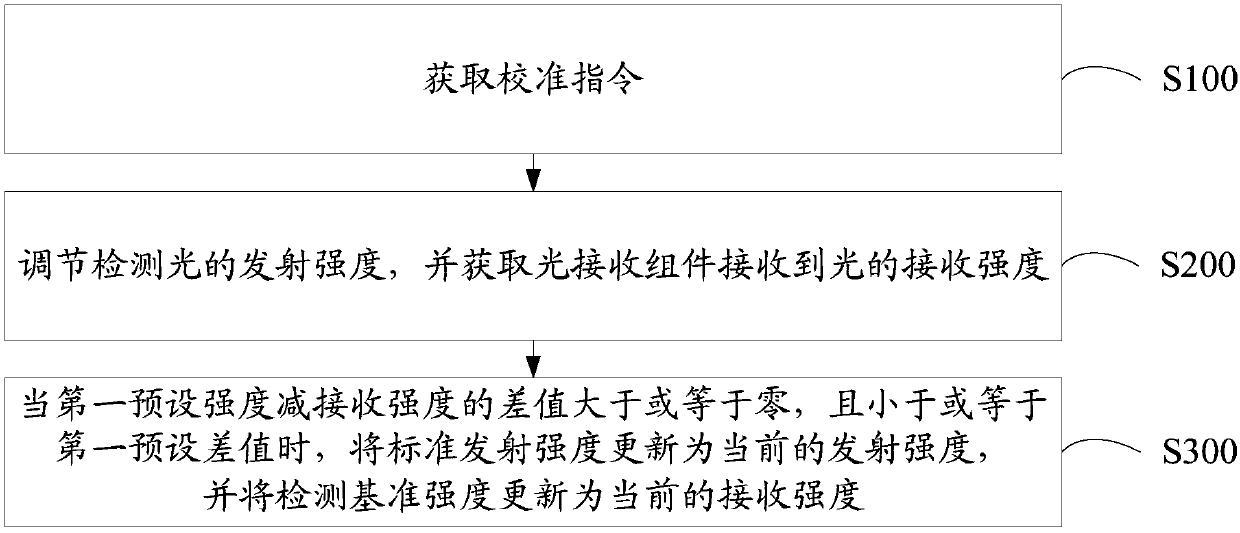

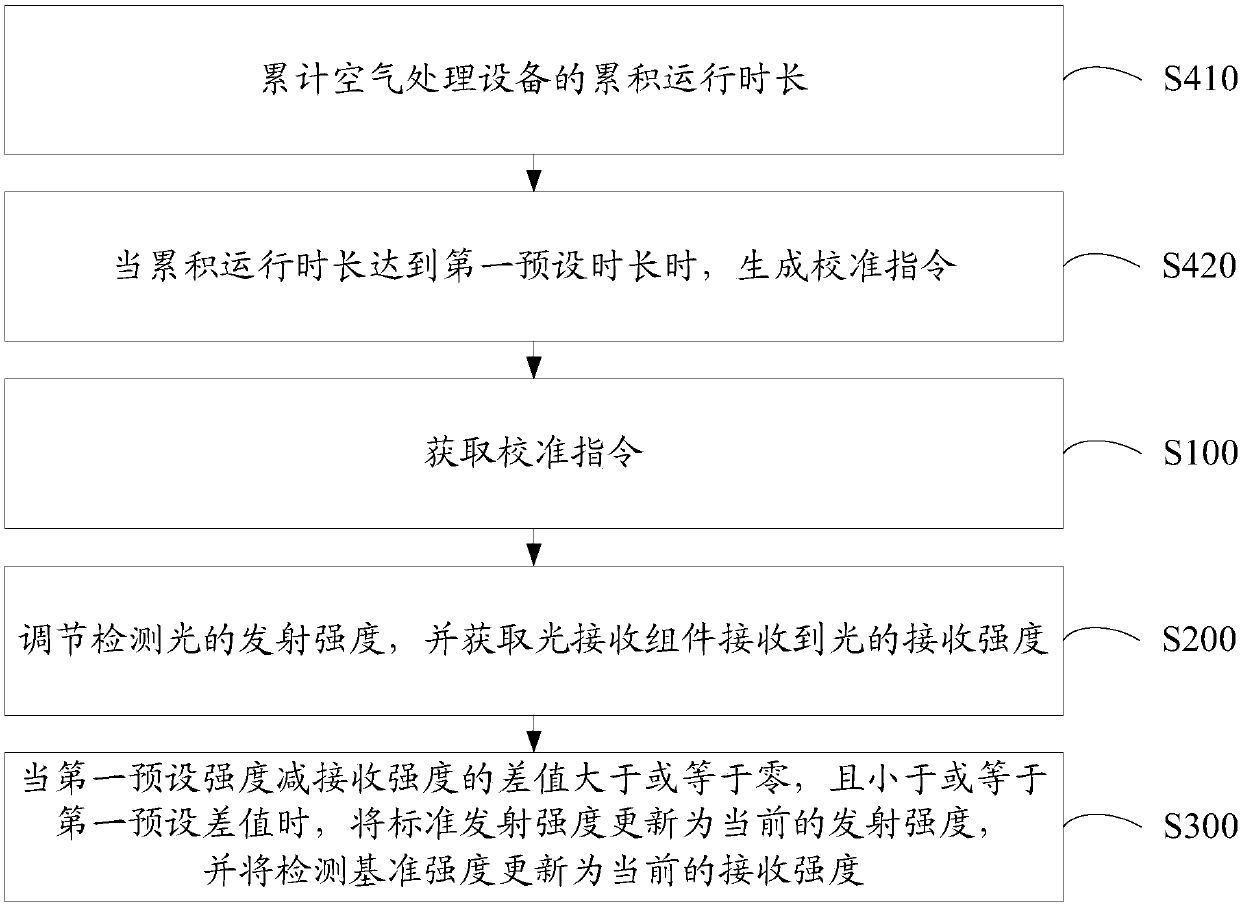

Sensor calibration method, sensor and air treatment equipment

ActiveCN107907468AImprove consistencyAvoid performance differencesPermeability/surface area analysisAir treatmentTransducer calibration

The invention discloses a sensor calibration method, a sensor and air treatment equipment. The sensor calibration method comprises the following steps: acquiring a calibration instruction; adjusting emission light intensity of detection light, and acquiring receiving light intensity of light received by a light receiving assembly; when a difference value obtained by subtracting first preset lightintensity by the receiving light intensity is more than or equal to zero, and less than or equal to a first preset difference value, updating standard emission light intensity to the current emissionlight intensity, and updating detection reference light intensity to the current receiving light intensity. The sensor calibration method improves the consistency of sensors.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

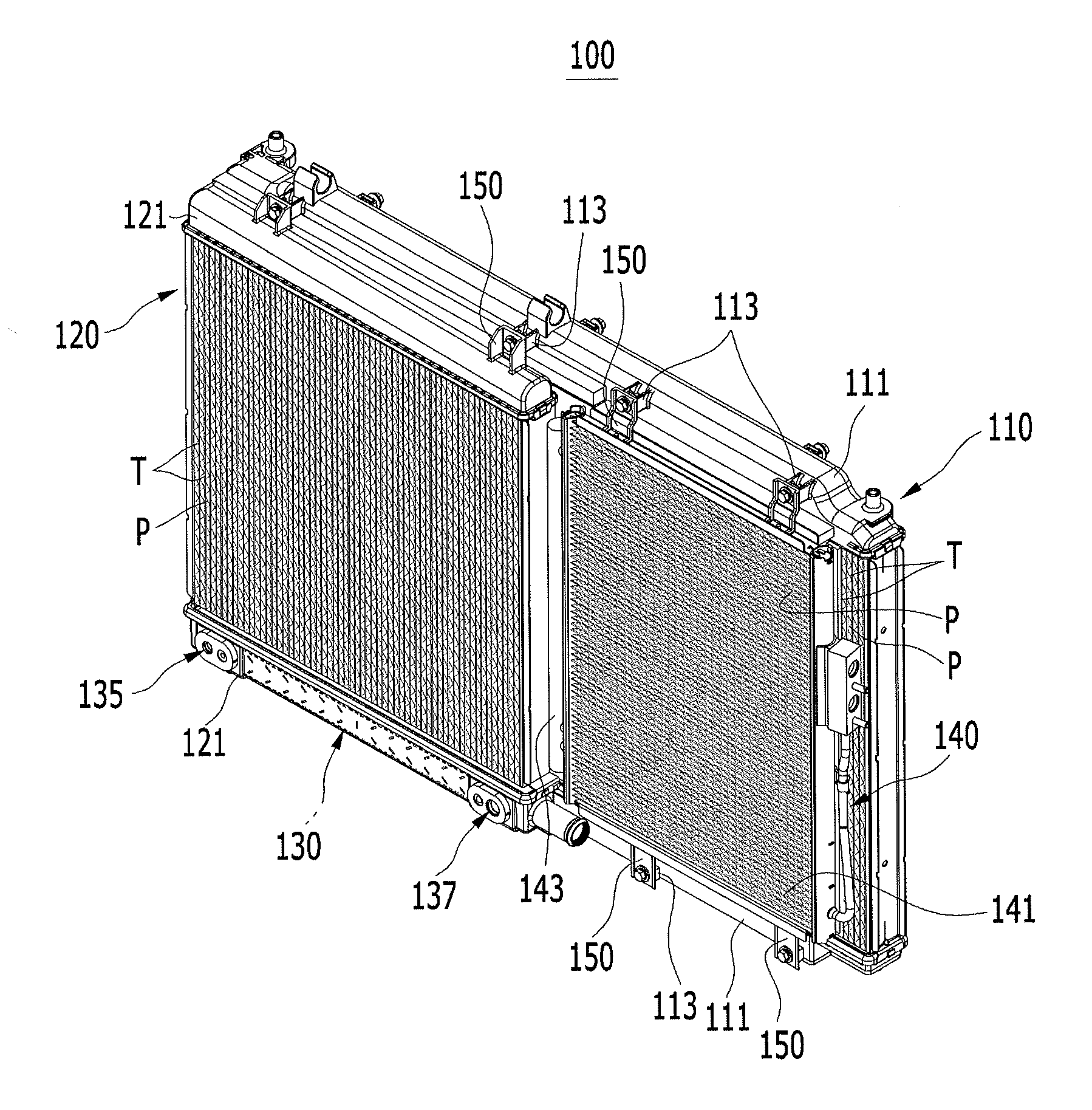

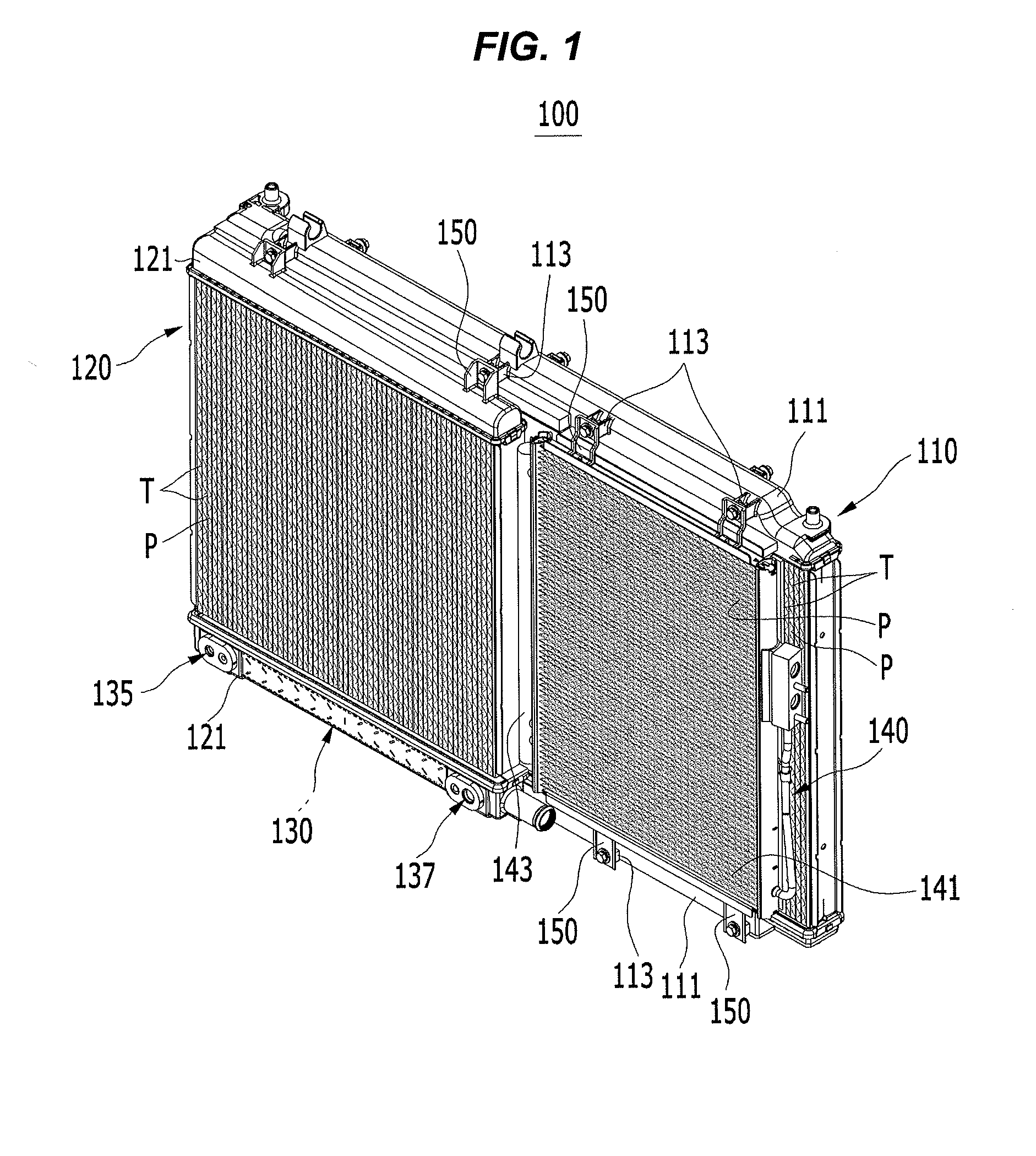

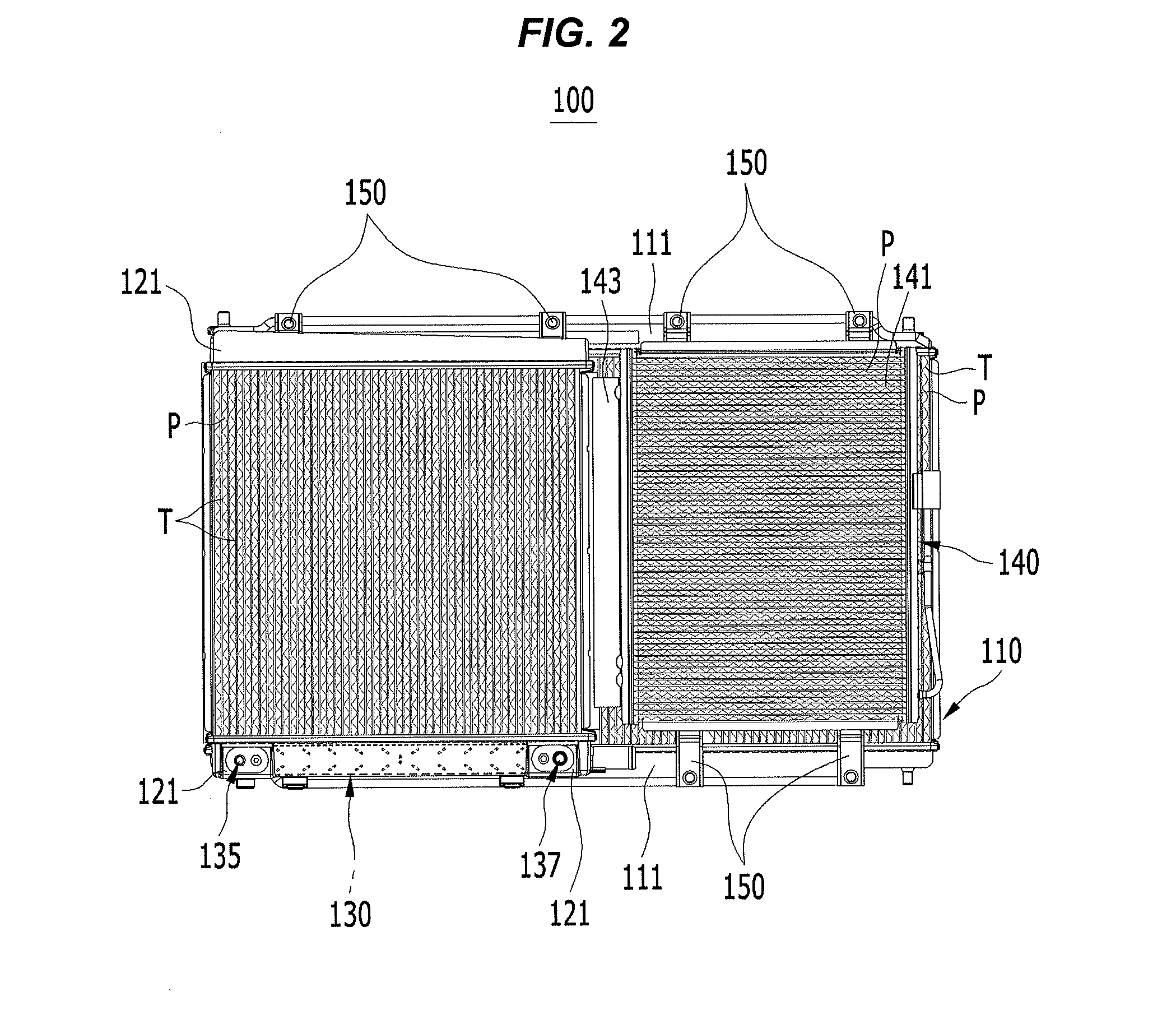

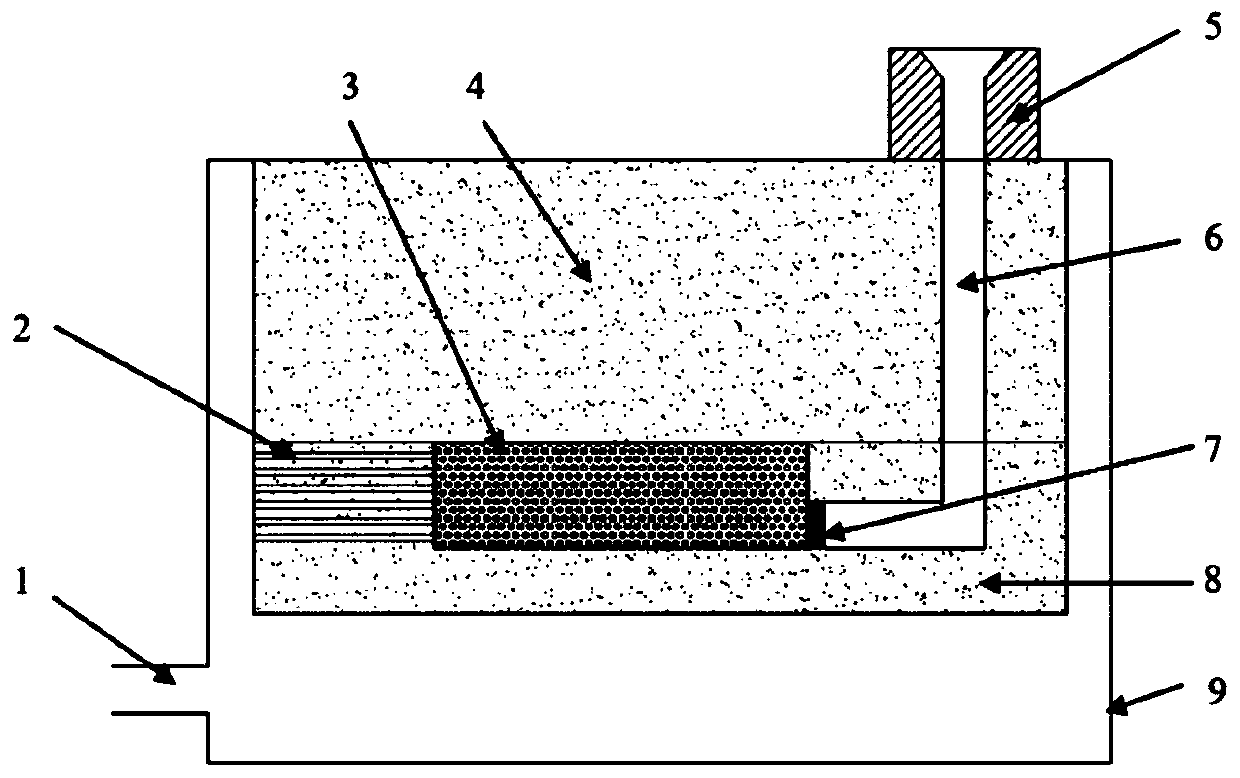

Cooling module for vehicle

InactiveUS20150101778A1Improve performanceAvoid performance differencesLiquid coolingAir-treating devicesComputer moduleAir conditioning

A cooling module for a vehicle connected to an operating system and an air conditioning system. The cooling module may include a radiator for a stack that is disposed at a rear side based on a front / rear direction of a vehicle, a radiator for electric devices that is disposed at one side based on a width direction of a vehicle at a front side of the radiator for a stack, a first condenser that is disposed inside a header tank of the radiator for electric devices to condense refrigerant as a first condensing process, and a second condenser that is disposed at the other side based on a width direction of a vehicle at a front side of the radiator for a stack and is connected to the first condenser to condense the refrigerant that is exhausted from the first condenser as a second condensing process.

Owner:HYUNDAI MOTOR CO LTD

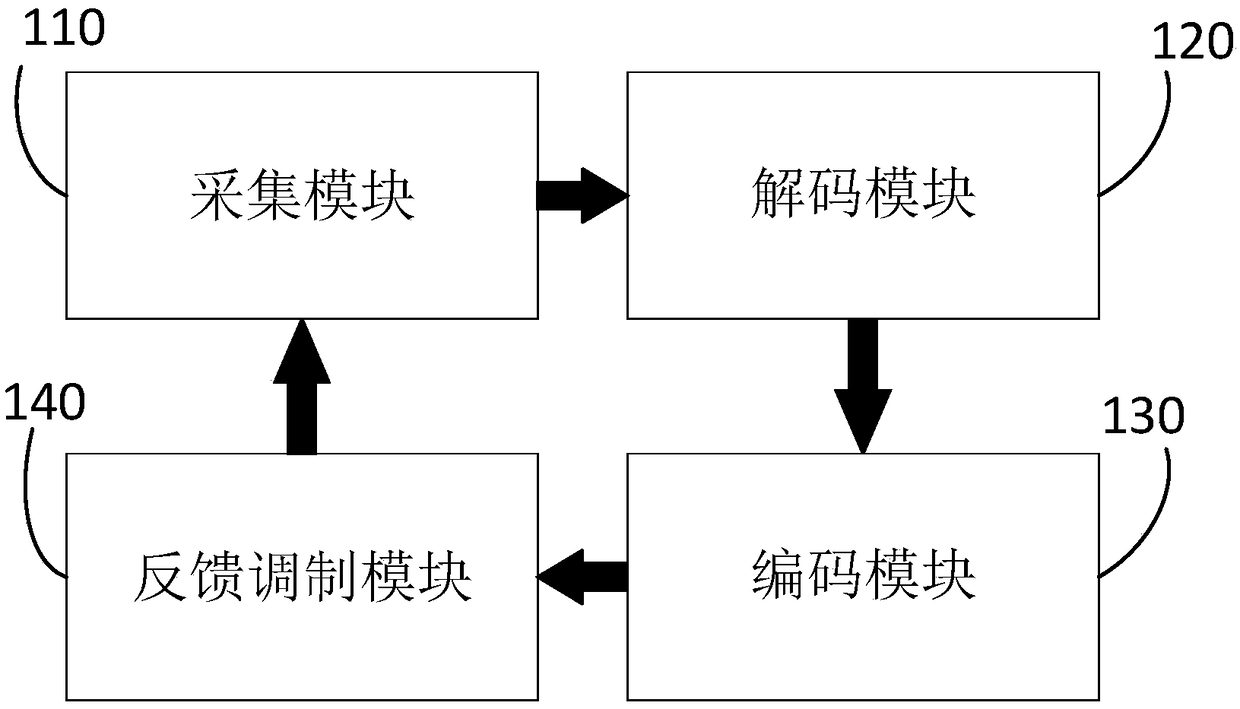

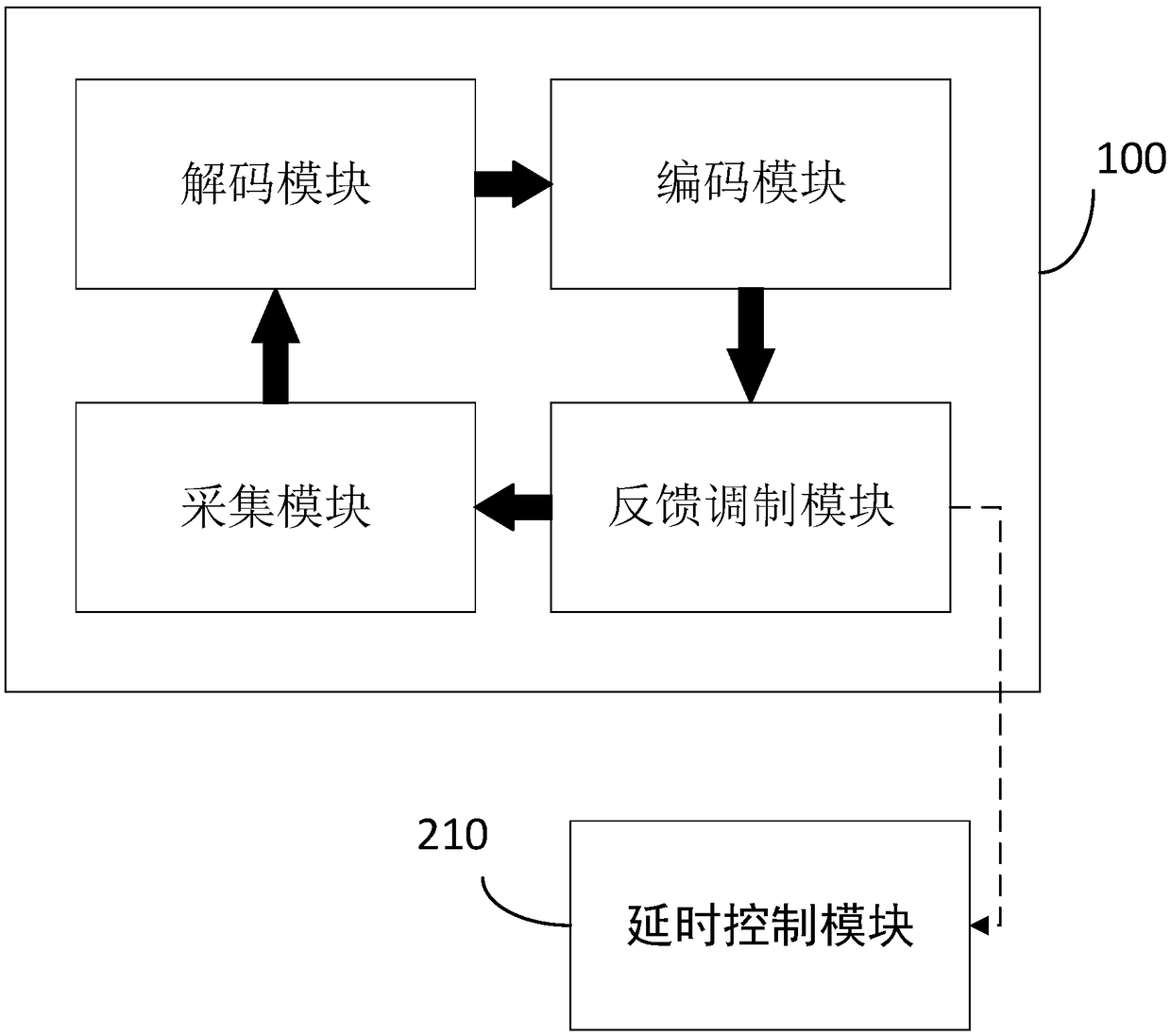

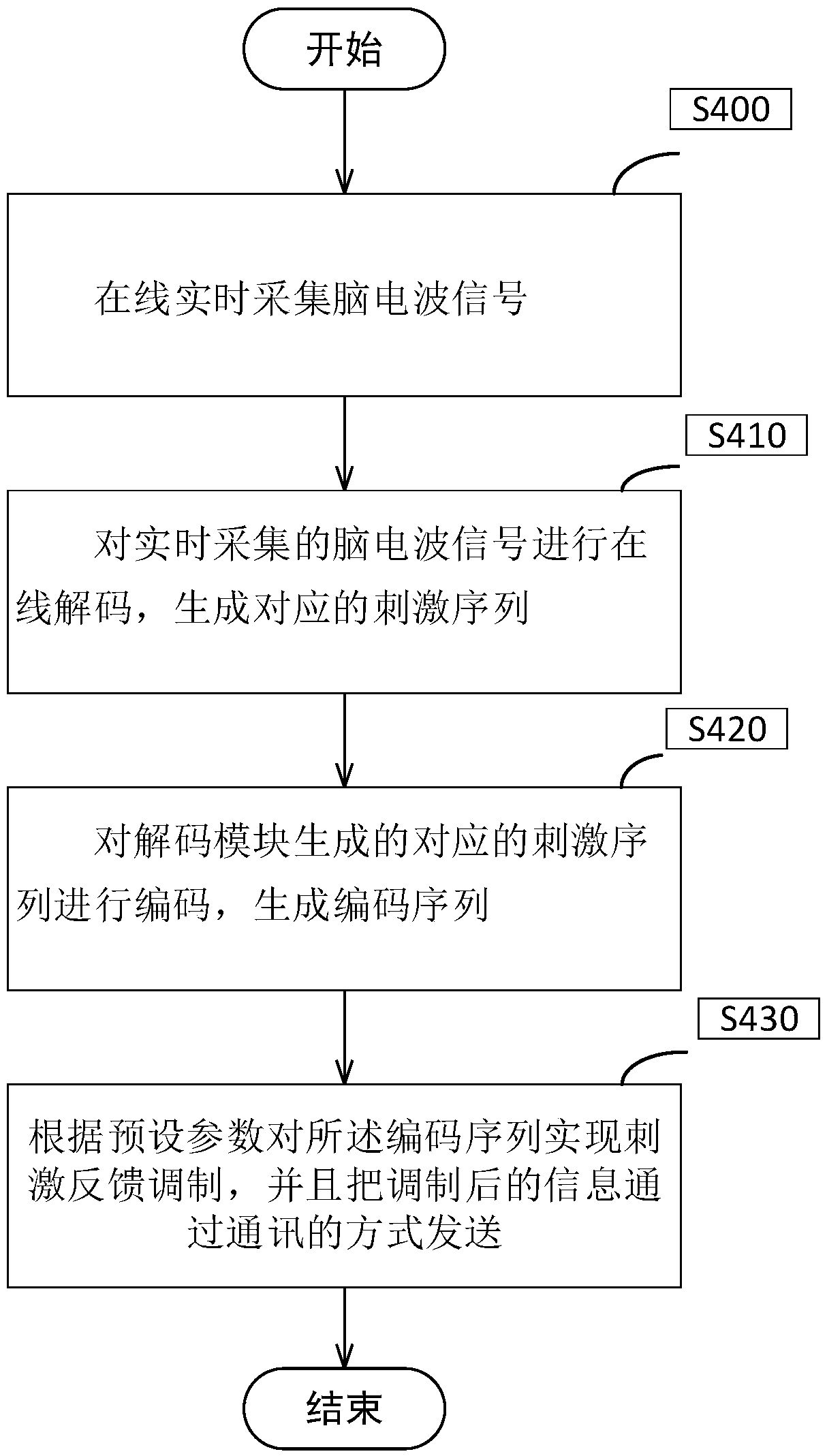

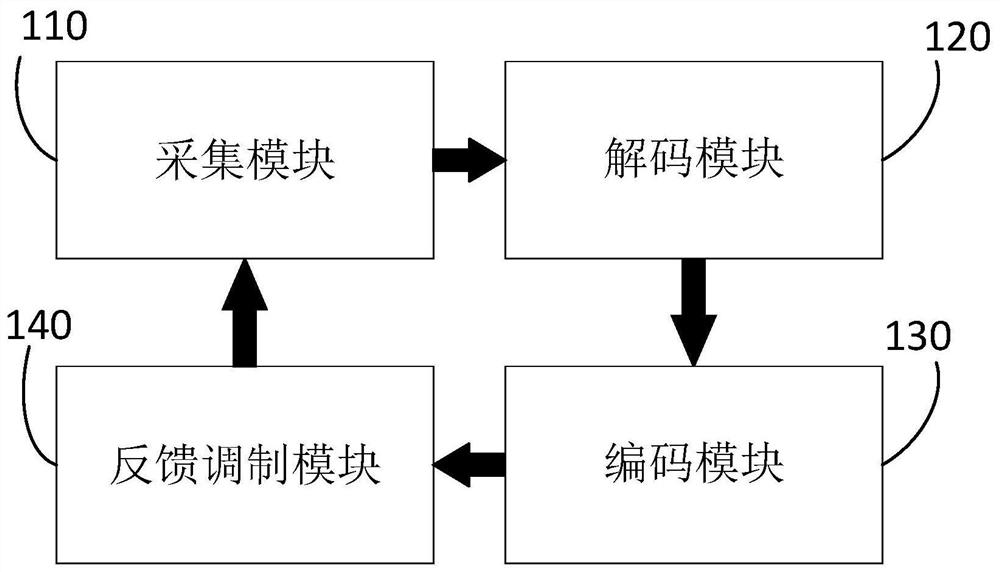

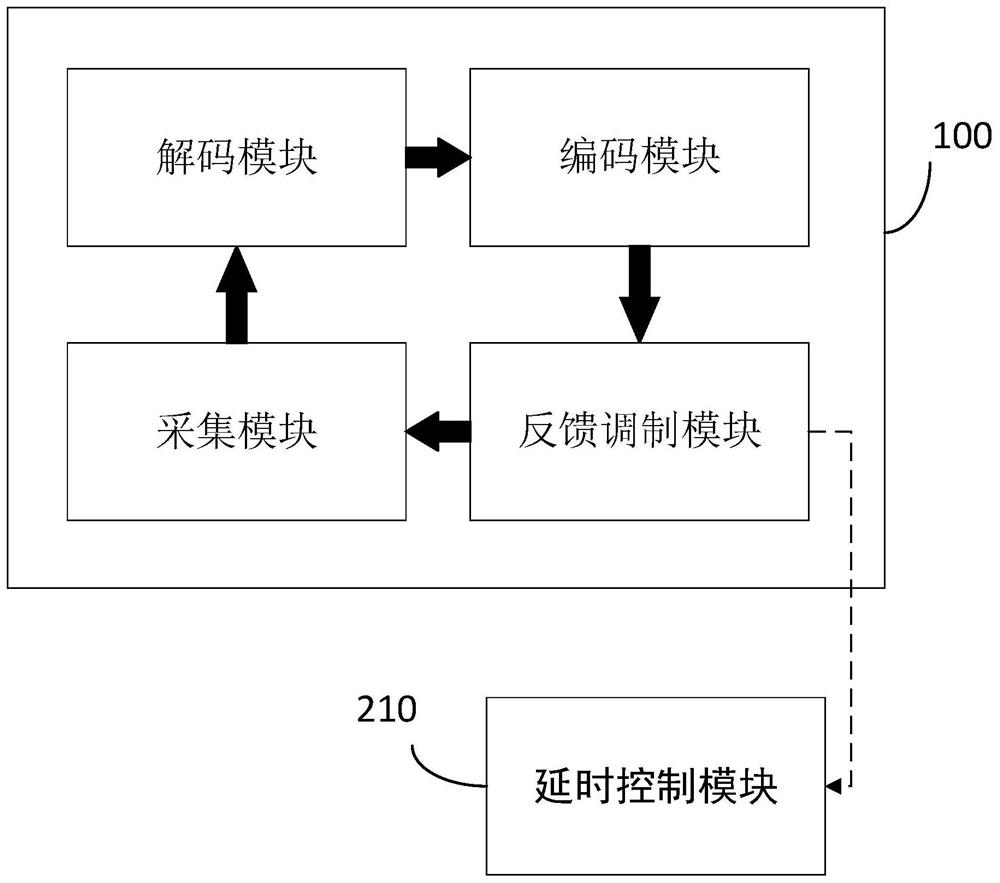

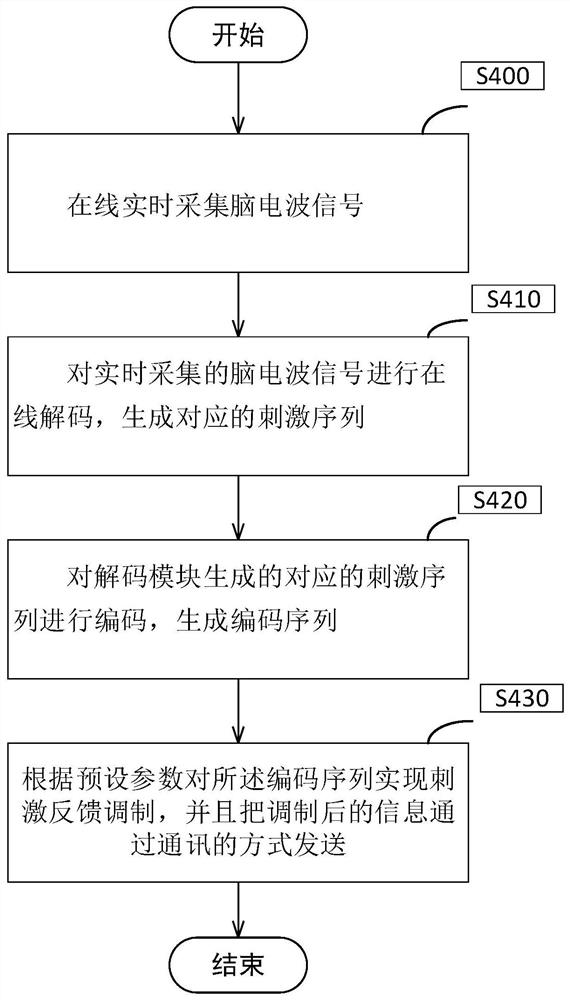

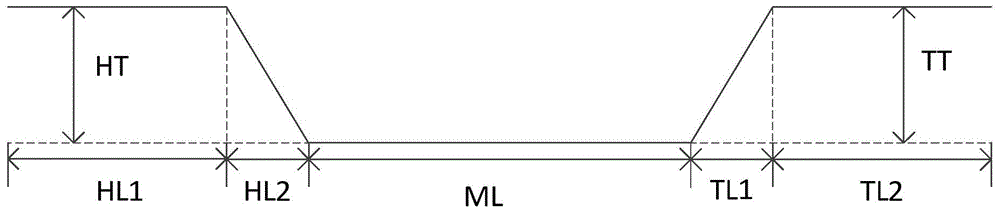

Real-time nerve feedback device, system and method and computer storage medium

ActiveCN108814594AThe modulation process is fast and straightforwardAvoid performance differencesDiagnostic recording/measuringSensorsCode moduleElectricity

The invention provides a real-time nerve feedback device, system and method and a computer storage medium, and relates to the technical field of nerve feedback. The real-time nerve feedback device comprises a collecting module, a decoding module, a coding module and a feedback modulation module, after the collecting module, the decoding module, the coding module and the feedback modulation moduleare electrically connected successively, and the feedback modulation module is connected with the collecting module to from a closed-loop dynamic real-time nerve feedback device. The problems of adaptability, effectiveness and accuracy in an existing nerve feedback technology are solved, the self-adaptive, dynamic and accurate regulation and control are achieved on specific electroencephalogram rhythm amplitude phases, and effect differences caused by factors of user experience and the like can be avoided as far as possible.

Owner:SHENZHEN UNIV

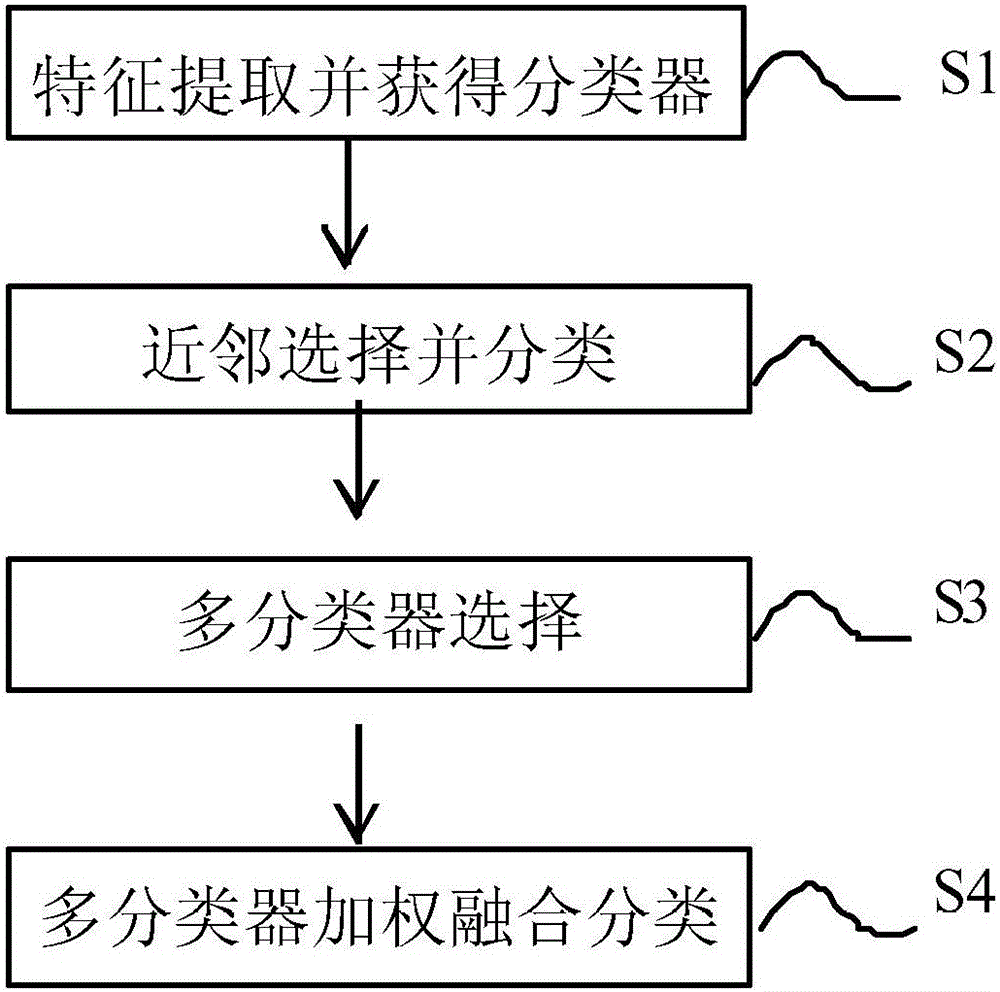

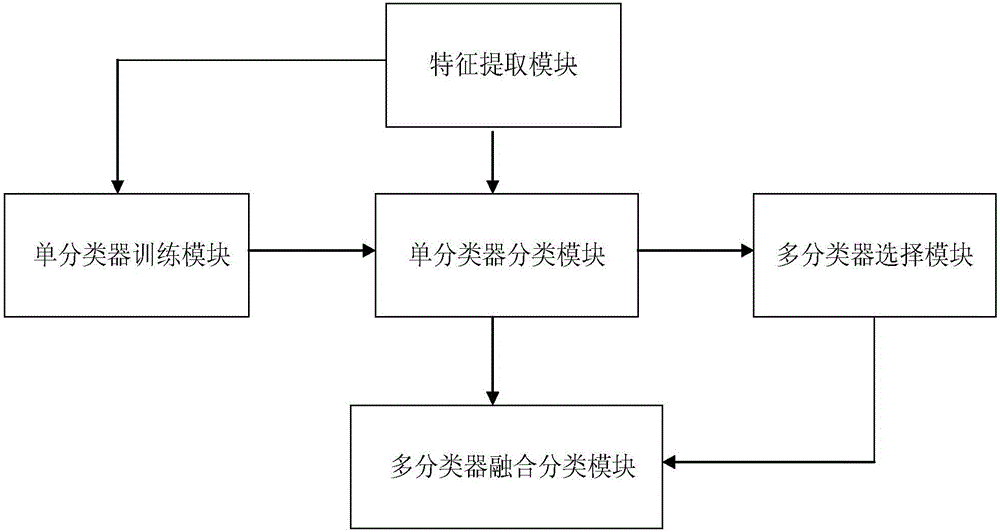

License plate recognition method and license plate recognition system

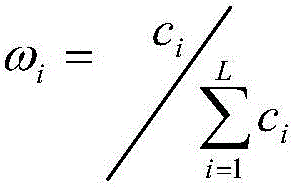

InactiveCN106295635AAvoid performance differencesAdaptableCharacter and pattern recognitionFeature extractionImaging processing

The invention is applied to the technical field of multimedia (especially to the field of image processing), and proposes a license plate recognition method and a license plate recognition system based on multi-classifier selection. The license plate recognition method comprises the following steps: extracting the features of a data sample and a to-be-tested sample, and training the samples to get multiple single classifiers; selecting neighbors for the to-be-tested sample, and classifying the to-be-tested sample and the selected neighbor training samples; performing multi-classifier selection through weight calculation of the neighbor training samples; and classifying the to-be-tested sample based on multi-classifier weighted fusion. Through the steps, the weights of the multiple classifiers are changing dynamically for each to-be-tested sample. Therefore, multi-classifier classification fusion based on the method is of high adaptability, and the precision of classification is improved.

Owner:BEIJING ICETECH SCI & TECH CO LTD

Coating rubber roller for high-grade automobile plate production line and manufacturing method thereof

ActiveCN103613861AGood compatibilityGood dispersionLiquid surface applicatorsCoatingsPolyesterEngineering

Owner:南京金三力橡塑有限公司 +1

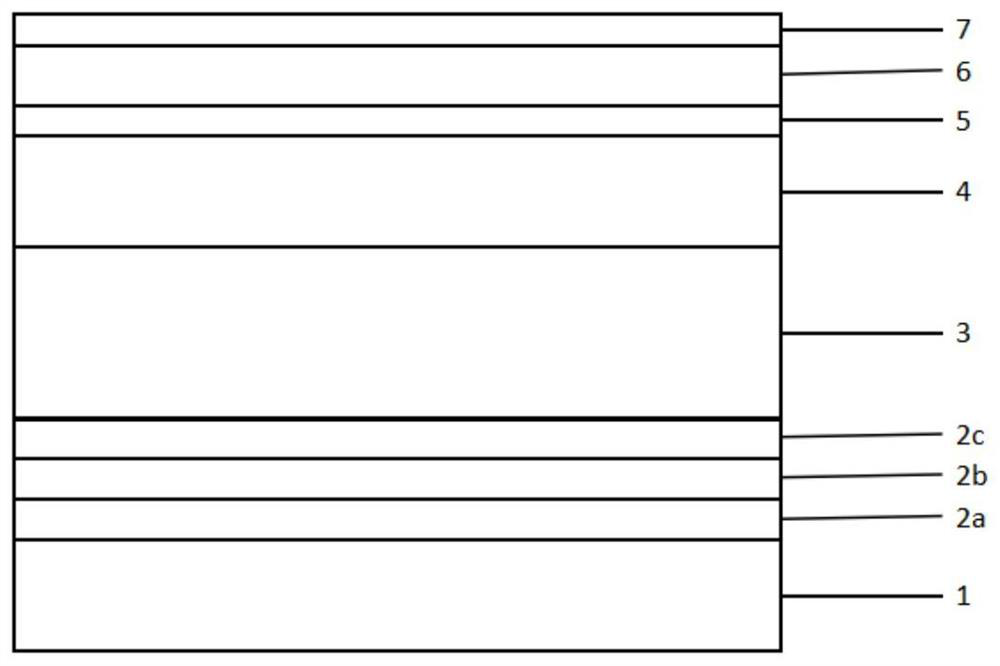

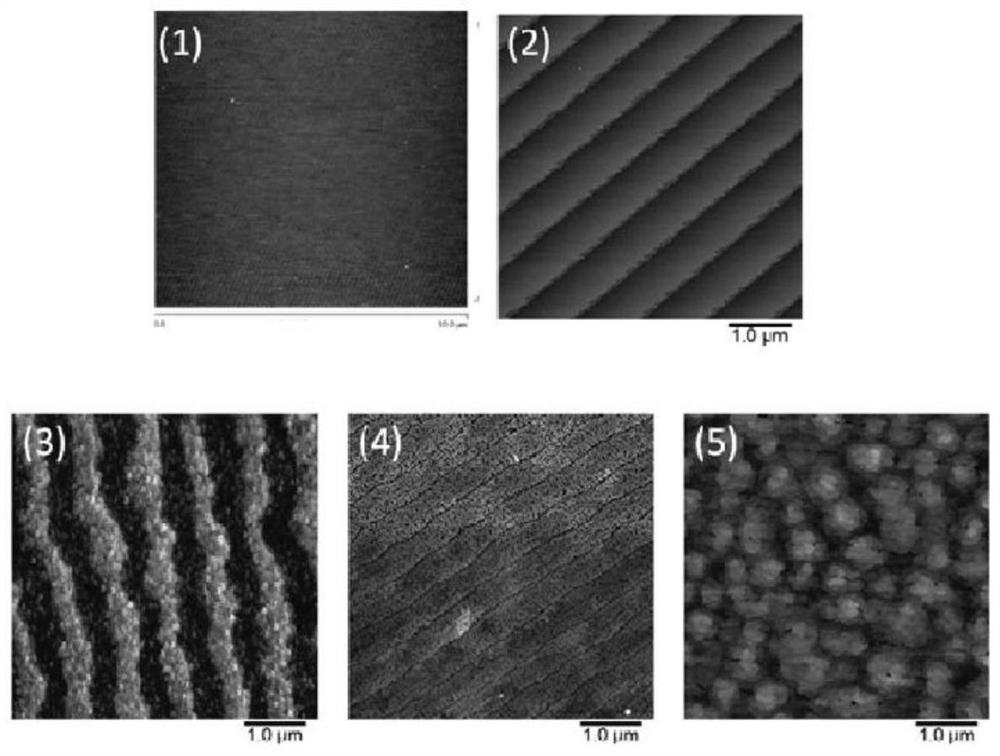

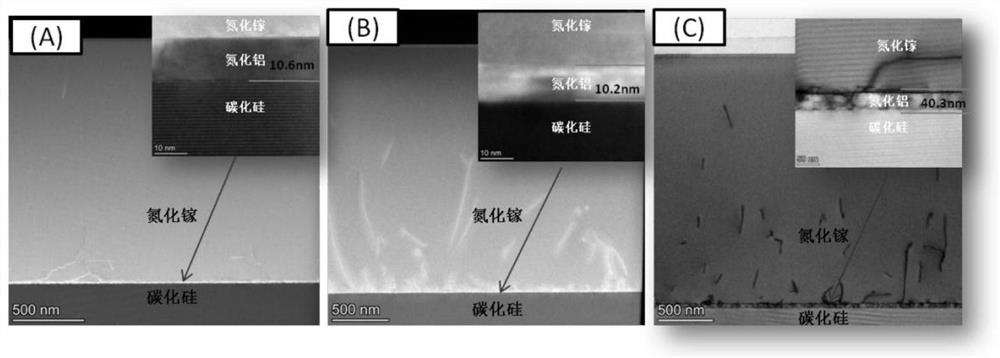

Preparation method of low-thermal-resistance gallium nitride high-electron-mobility transistor epitaxial material

ActiveCN112670161AGuaranteed quality characteristicsGuaranteed electrical characteristicsSemiconductor/solid-state device manufacturingSemiconductor devicesInterfacial thermal resistanceGallium nitride

The invention discloses a preparation method of a low-thermal-resistance gallium nitride high-electron-mobility transistor epitaxial material, and belongs to the technical field of semiconductor epitaxial materials. According to the invention, the method comprises the steps: employing high-temperature chemical vapor deposition equipment for carrying out high-temperature etching on the surface of a silicon carbide substrate, so the surface of the substrate presents controllable atomic-scale step morphology; carrying out the atomic-scale aluminum nitride nucleation on silicon carbide atomic steps by utilizing a metal organic chemical vapor deposition technology; transversely and rapidly combining the aluminum nitride nucleation points in an intermittent source supply mode, and performing layered deposition, so high-quality nanoscale aluminum nitride nucleation layer growth is achieved, and the gallium nitride high-electron-mobility transistor is prepared by taking aluminum nitride as a substrate. According to the method, the thickness of the aluminum nitride nucleating layer can be greatly reduced, the interface thermal resistance introduced by the aluminum nitride nucleating layer can be effectively reduced, the heat dissipation characteristic of the gallium nitride power device can be improved, and the method has extremely important significance for improving the power performance of the gallium nitride microwave power device.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

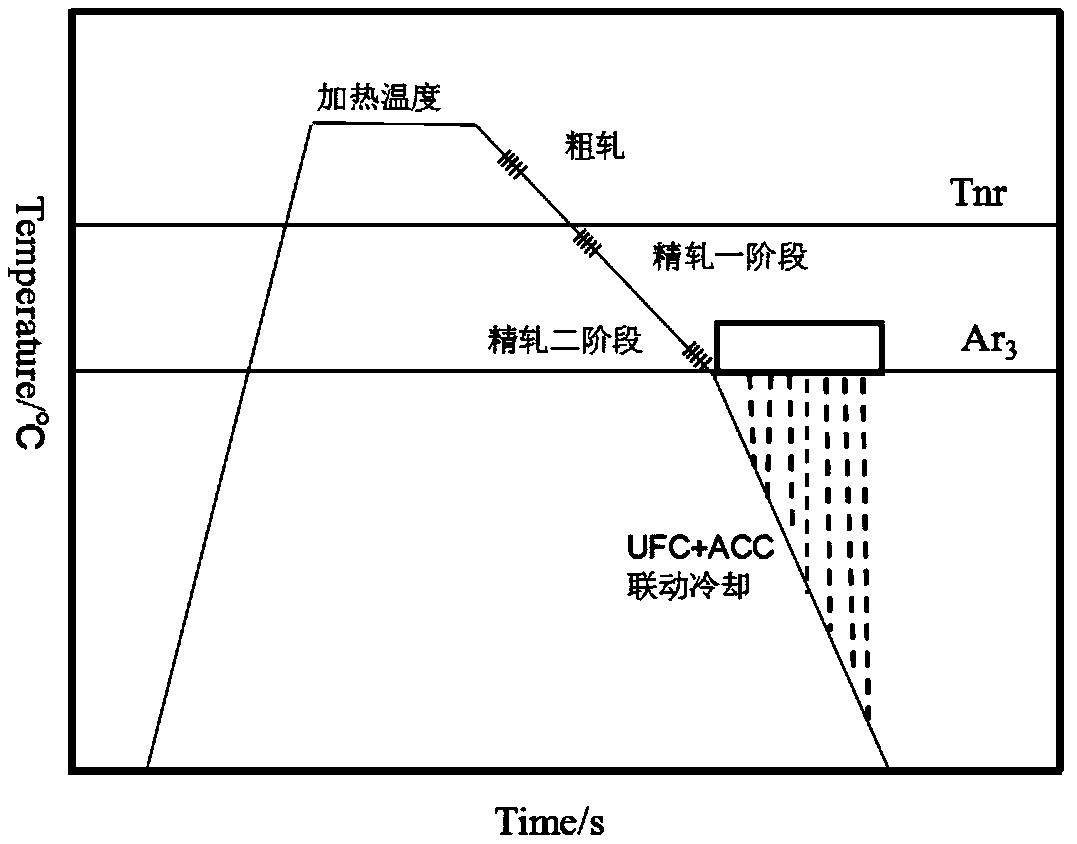

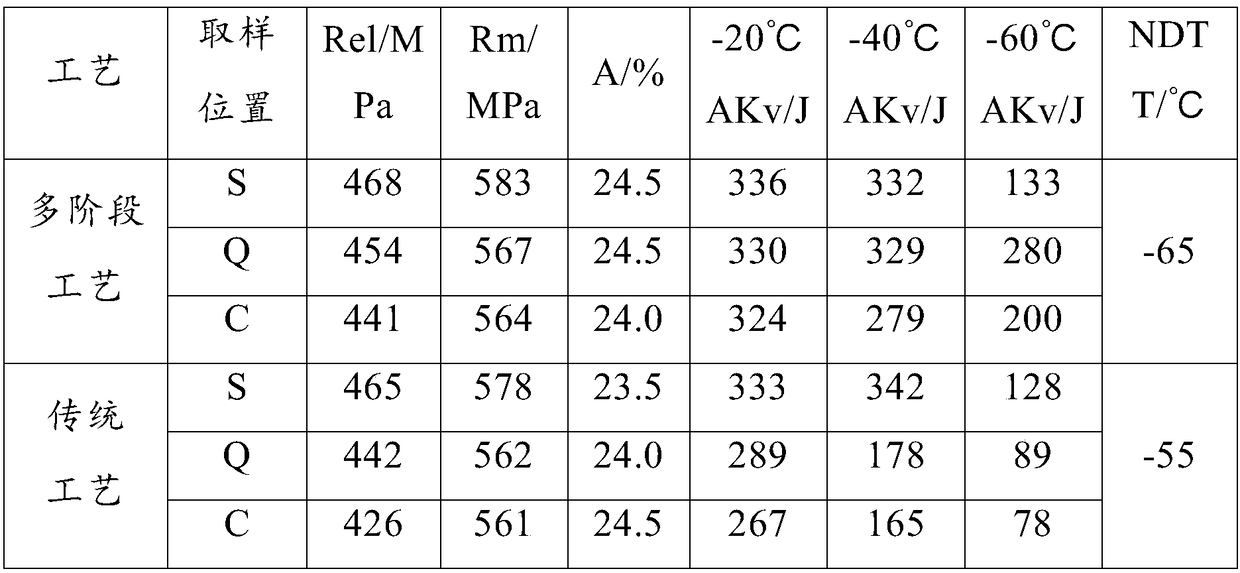

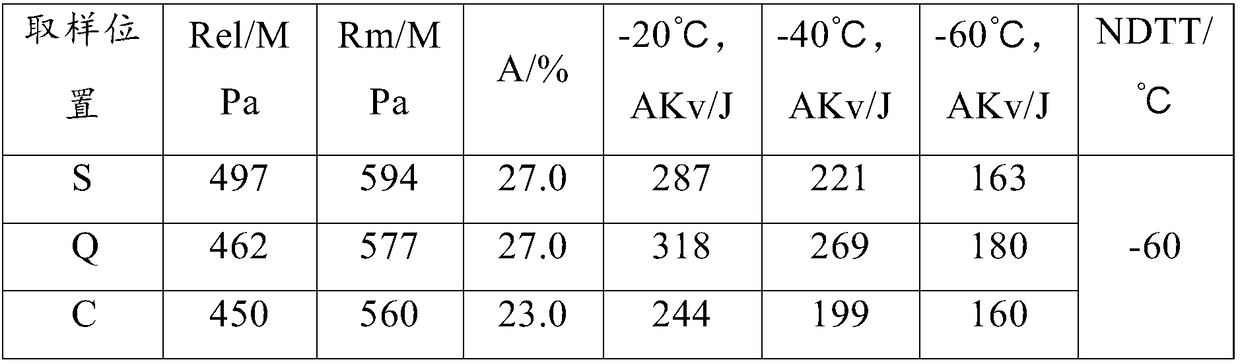

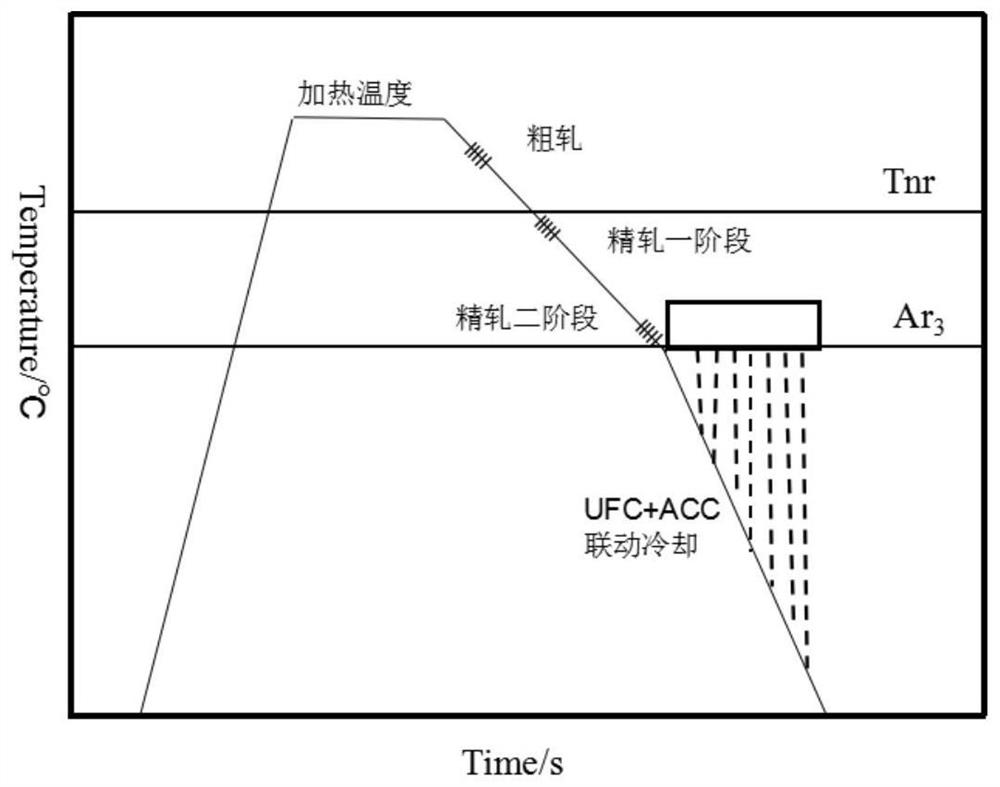

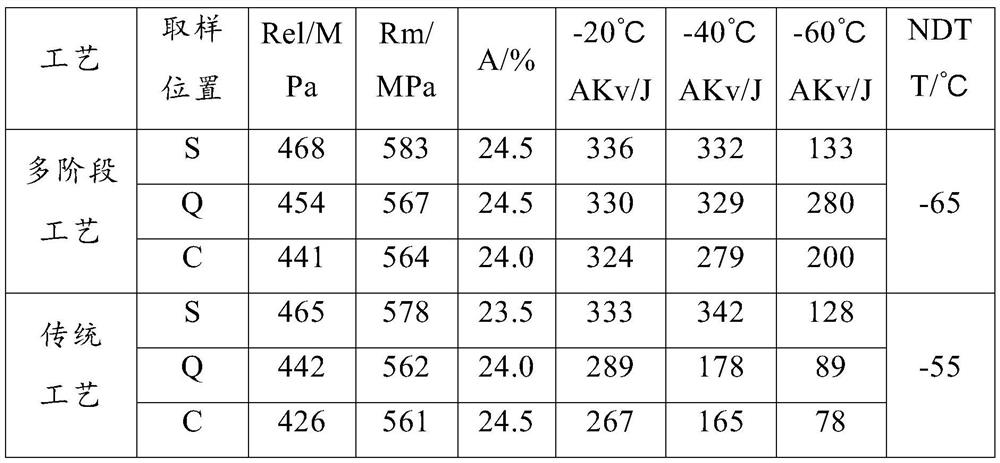

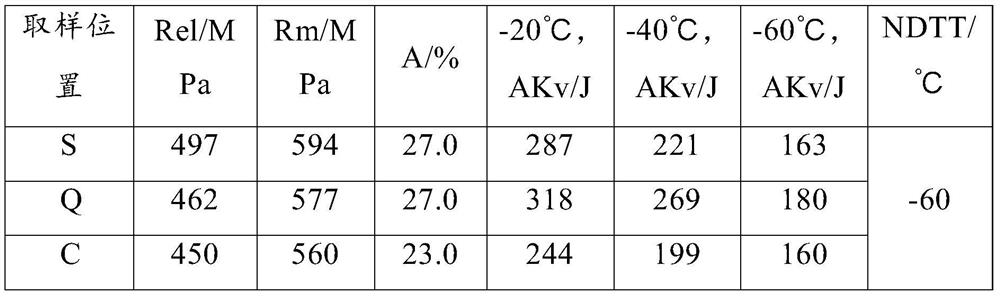

Production method of high-quality thick steel plate

ActiveCN109295290AImprove cross-section low temperature impact toughnessPromote precipitationSheet steelLow speed

The invention belongs to the technical field of steel materials, and discloses a production method of a high-quality thick steel plate. The production method comprises the steps that the procedure ofhigh-temperature rolling and the procedure of low-temperature rolling are conducted in a non-recrystallization area in the rolling process, wherein the procedure of high-temperature rolling comprise afirst finish rolling stage, and in the first finish rolling state, a low-speed high-pressure rolling process is adopted, the initial rolling temperature is 900-930 DEG C, a required cumulative rolling rate is equal to or greater than 15%, and the maximum single-pass rolling rate is equal to or greater than 12%; the procedure of low-temperature rolling comprises a second finish rolling stage, andin the second finish rolling stage, a low-temperature high-pressure rolling process is adopted, the initial rolling temperature of a steel plate is 780-820 DEG C, and the finish rolling temperature is760-780 DEG C; and steel is discharged after being rolled and then rapidly enters water to be cooled. By adoption of the production method of the high-quality thick steel plate, the performance of the high-strength and high-tenacity thick steel plate produced through a continuously cast plate is improved, and meanwhile, the technical problems of slow rolling rhythm and low efficiency are solved.

Owner:SHOUGANG CORPORATION

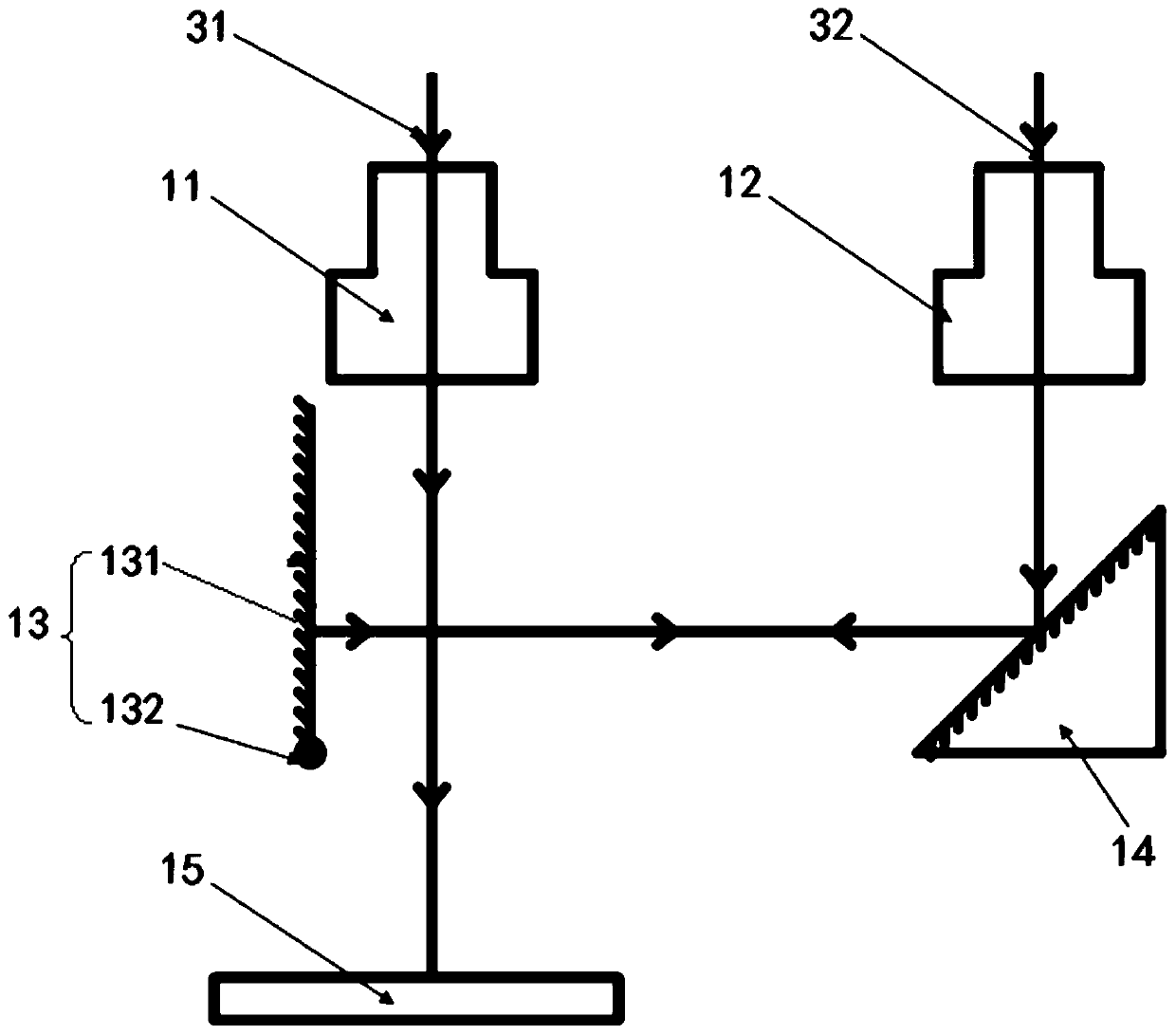

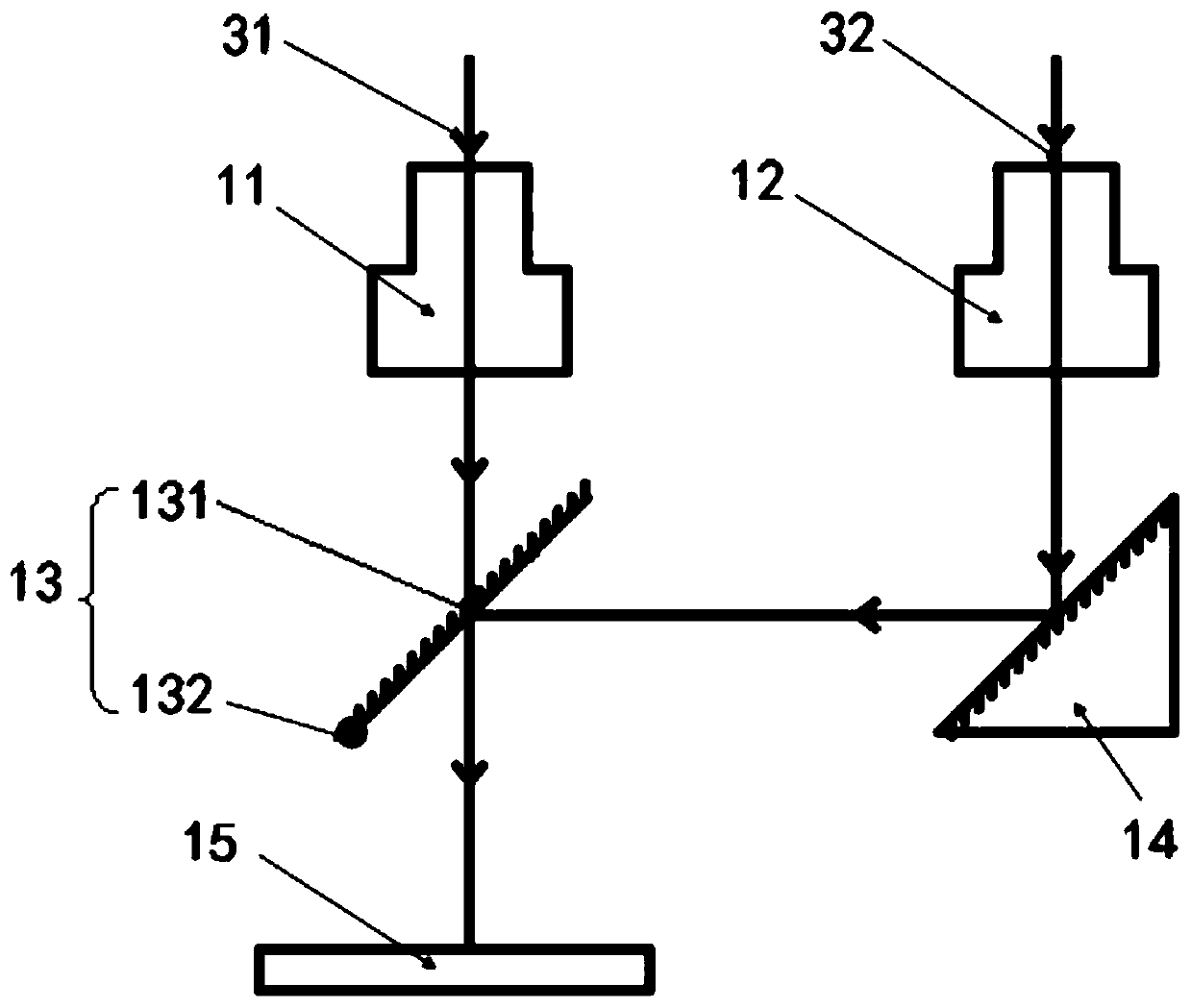

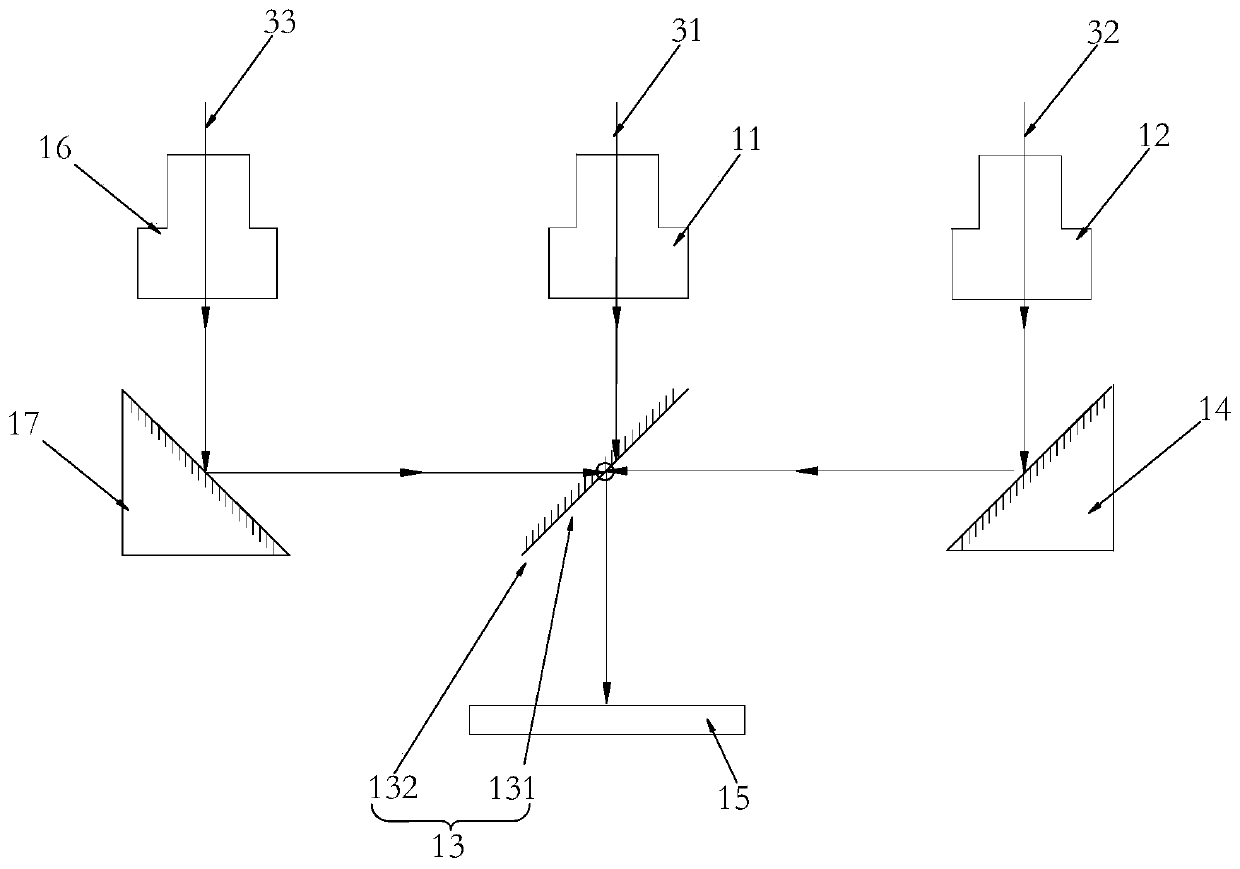

Auxiliary camera module and camera device with auxiliary camera module

InactiveCN110944108ARealize multi-camera functionReduce in quantityTelevision system detailsColor television detailsLight beamEngineering

The invention discloses an auxiliary camera module and a camera device with the auxiliary camera module. The auxiliary camera module comprises an auxiliary lens group, a first photoreceptor and a reflection device group, the auxiliary lens group comprises a first auxiliary lens used for collecting a first light beam and a second auxiliary lens used for collecting a second light beam. The reflection device group is used for being driven to rotate to reflect one of the first light beam and the second light beam into the first photoreceptor, and the first light beam or the second light beam is imaged in the first photoreceptor after being emitted into the first photoreceptor. By arranging the reflection device group, one of the different auxiliary lenses is selected to be matched with the photosensitive chip for use, so that a multi-camera function based on one photosensitive chip is realized, the number of the photosensitive chips is reduced, and the production cost is reduced; in addition, the same photosensitive chip is adopted in the process of switching the auxiliary lens, so that the effect difference caused by the difference between the photosensitive chips can be avoided.

Owner:HUAQIN TECH CO LTD

Steel wire rod for aluminum-containing steel fibers and used for deep drawing, and rolling method thereof

InactiveCN111485175AImprove flowUniform tissueHeat treatment process controlWire rodSmelting process

The invention belongs to the field of metal materials, and specifically discloses a steel wire rod for aluminum-containing steel fibers and used for deep drawing, and a rolling method thereof. A continuous casting billet comprising specific components is obtained according to an aluminum-containing pure steel smelting process, reasonable heating temperature and heating time of the continuous casting billet are controlled in a heating furnace, and the process parameters of the wire rod in a rolling process and the cooling process parameters of the wire rod on a Stelmor cooling line are optimized, so that the produced wire rod for the steel fibers is high in universality, uniform in structure, small in crystal grain, excellent in mechanical property, and good in plasticity index, and an ironoxide sheet has a thickness of 10-20[mu]m, and is suitable for mechanical shelling and low in wire fracture; and the wire rod produced by the method has tensile strength Rm of 350-390MPa, percentageelongation A of not less than 40% after fracture, area reduction Z of not less than 80%, and ferrite grain size of 7-8, the wire fracture in a drawing process of a user can be controlled to be less than 0.25 times per ton, and the technical requirement of a wire rod for high-grade steel fibers is completely met.

Owner:ZENITH STEEL GROUP CORP +1

Large-diameter thick walled pipe postweld heat treatment method

ActiveCN107641702AGuarantee the quality of heat treatmentGuaranteed one-time successFurnace typesHeat treatment furnacesEconomic benefitsTemperature difference

The invention provides a large-diameter thick walled pipe postweld heat treatment method. By adopting the large-diameter thick walled pipe postweld heat treatment method provided by the invention, insulating temperature is determined according to a hardness range of a base material in the postweld heat treatment process, simultaneous heating of an inner wall and an outer wall is adopted, a heatingwidth is determined according to a formula, a power of a heater is determined according to a formula, and thus the heat treatment quality of a weld crater is effectively ensured, a temperature difference between the inner wall and the outer wall of the weld crater in postweld heat treatment is lowered to meet the standard requirement or a higher standard to avoid the phenomenon of base material overburning or difference between the weld crater properties of the inner wall and the outer wall caused by a temperature deviation, weld crater heat treatment can be ensured to mold at a time at the same time to avoid the phenomenon of heat treatment again, the heat treatment effect is improved, and the economic benefit is very considerable.

Owner:POWERCHINA SEPCO1 ELECTRIC POWER CONSTR CO LTD

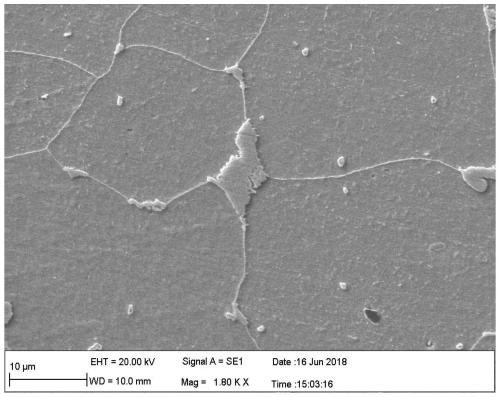

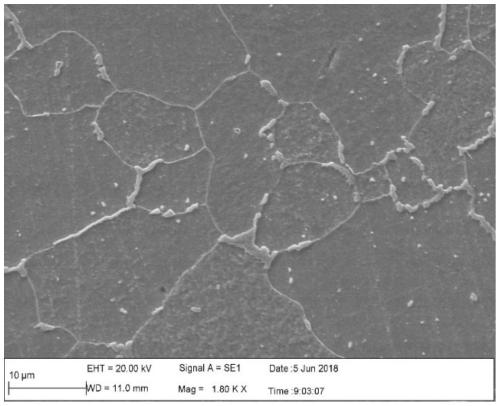

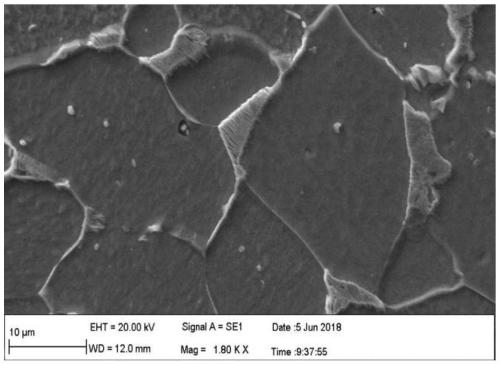

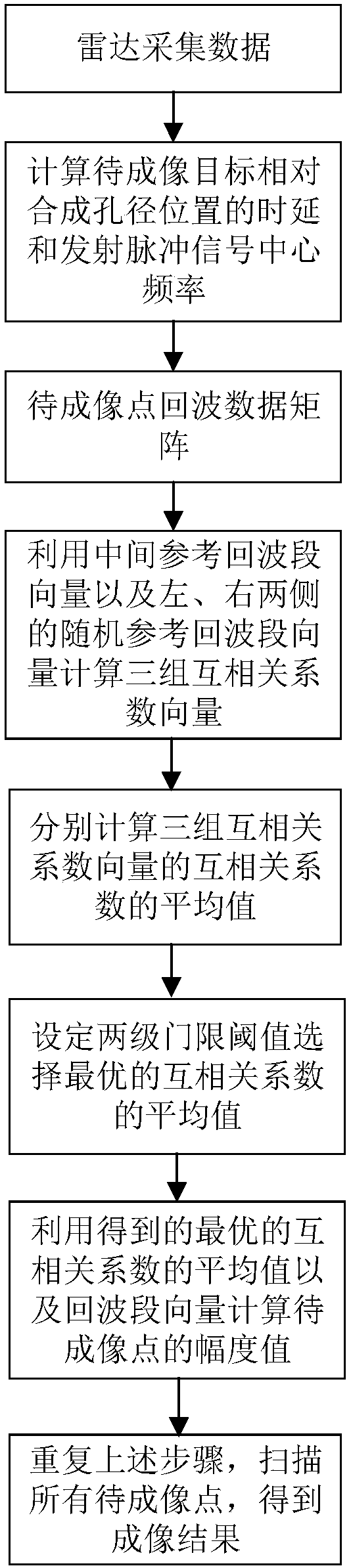

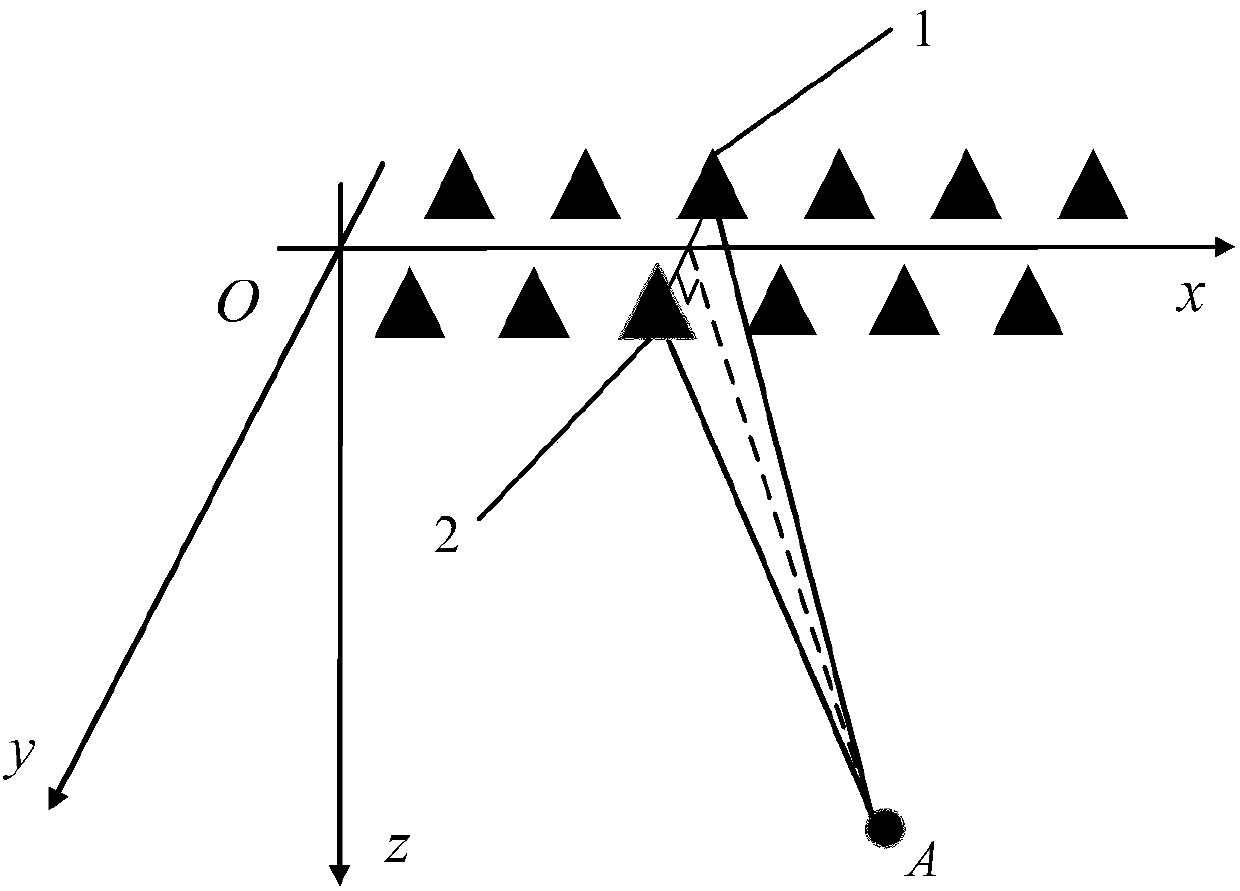

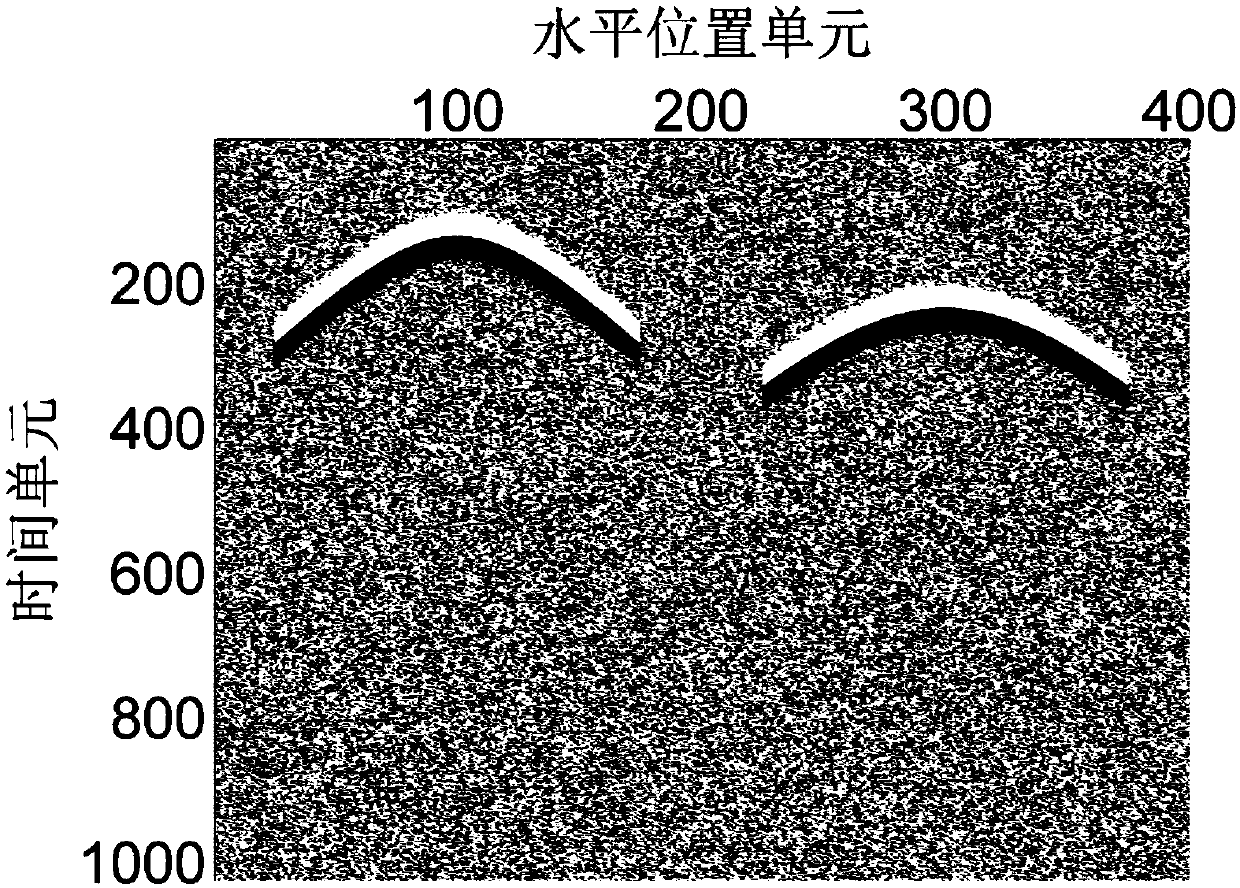

Backward projection imaging method based on random reference average cross-correlation information

ActiveCN107678029AImprove robustnessAvoid performance differencesRadio wave reradiation/reflectionCorrelation coefficientImaging processing

The invention provides a backward projection imaging method based on random reference average cross-correlation information, belongs to the technical field of radar image processing, and solves the problems of high sidelobe and interference and poor imaging performance of the conventional backward projection imaging method. The concrete process of the backward projection imaging method comprises the following steps that step one, as for the radar acquisition data, the time delay of a target to be imaged relative to the synthetic aperture location and the transmitting pulse single center frequency are calculated so as to obtain the echo data matrix of points to be imaged; step two, three sets of cross-correlation coefficient vectors are calculated by using an intermediate reference echo vector and random reference echo vectors of the left and right sides, and the average value of the cross-correlation coefficients of the three sets of cross-correlation coefficient vectors is calculated;step three, two thresholds are set and the average value of the optimal cross-correlation coefficients is selected; and step four, the amplitude value of the points to be imaged is calculated by using the obtained average value of the optimal cross-correlation coefficients and the echo vectors; and the steps one to four are repeated and all the points to be imaged are scanned so as to obtain theimaging result. The backward projection imaging method can be used for the field of radar image processing.

Owner:HARBIN INST OF TECH

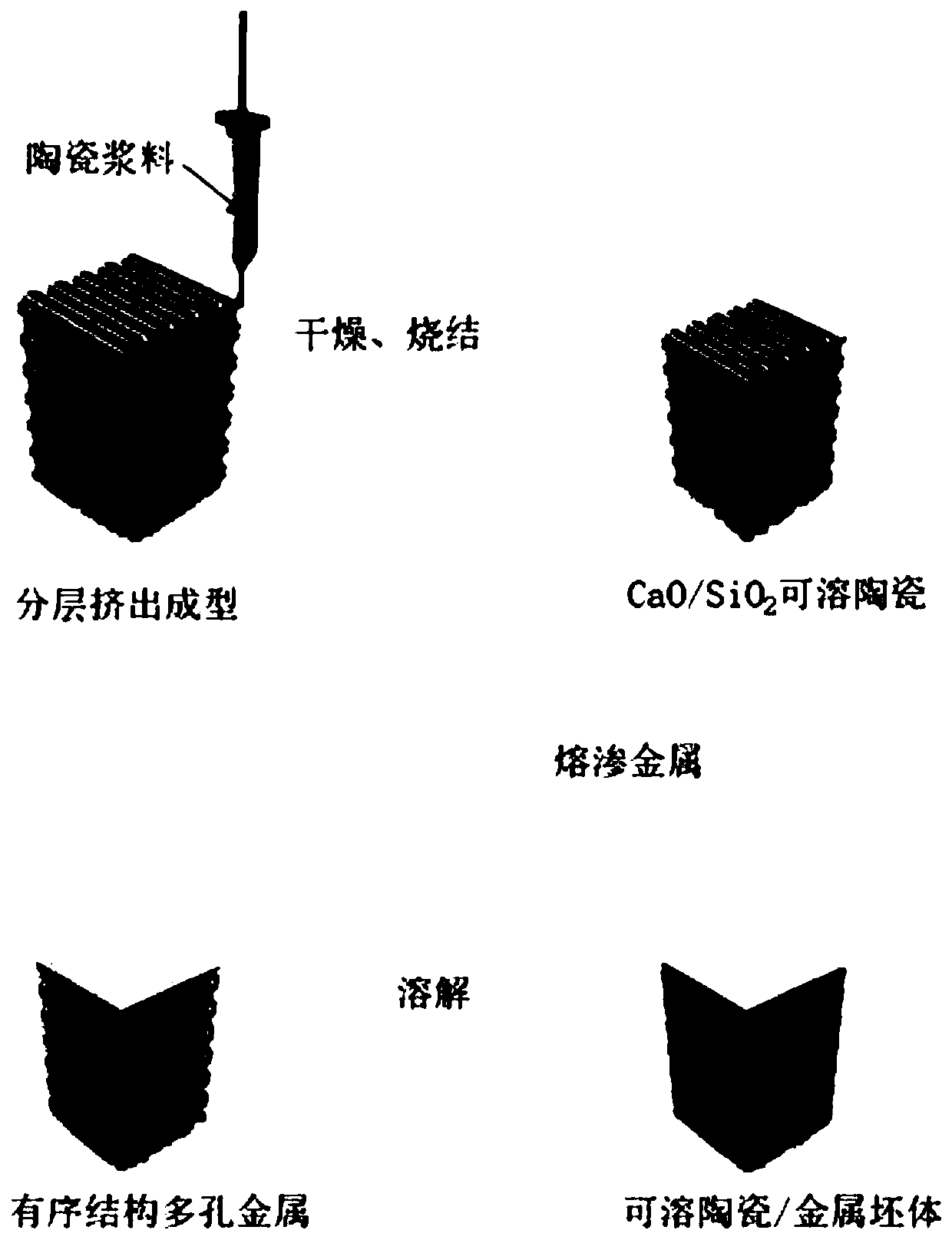

Porous metal material and preparation method thereof

PendingCN110983089AReduce manufacturing costEasy to manufactureAdditive manufacturing apparatusCeramic shaping apparatusMetallic materialsCeramic metal

The invention belongs to the related technical field of porous material preparation and discloses a porous metal material and a preparation method thereof. The method comprises steps of (1) preparinga porous ceramic green body corresponding to a porous metal material to be prepared by adopting a 3D printing extrusion molding process, and drying and sintering the porous ceramic green body to formsoluble porous ceramic; (2) infiltrating molten metal into the soluble porous ceramic, and filling a cavity of the soluble porous ceramic with the molten metal so as to obtain a soluble ceramic / metalcomposite green body; and (3) putting the obtained soluble ceramic / metal composite green body into the boiling water to dissolve the soluble ceramic in the soluble ceramic / metal composite green body so as to obtain the porous metal material. The method is simple in preparation process, relatively low in cost, wide in application range and environment-friendly.

Owner:HUAZHONG UNIV OF SCI & TECH

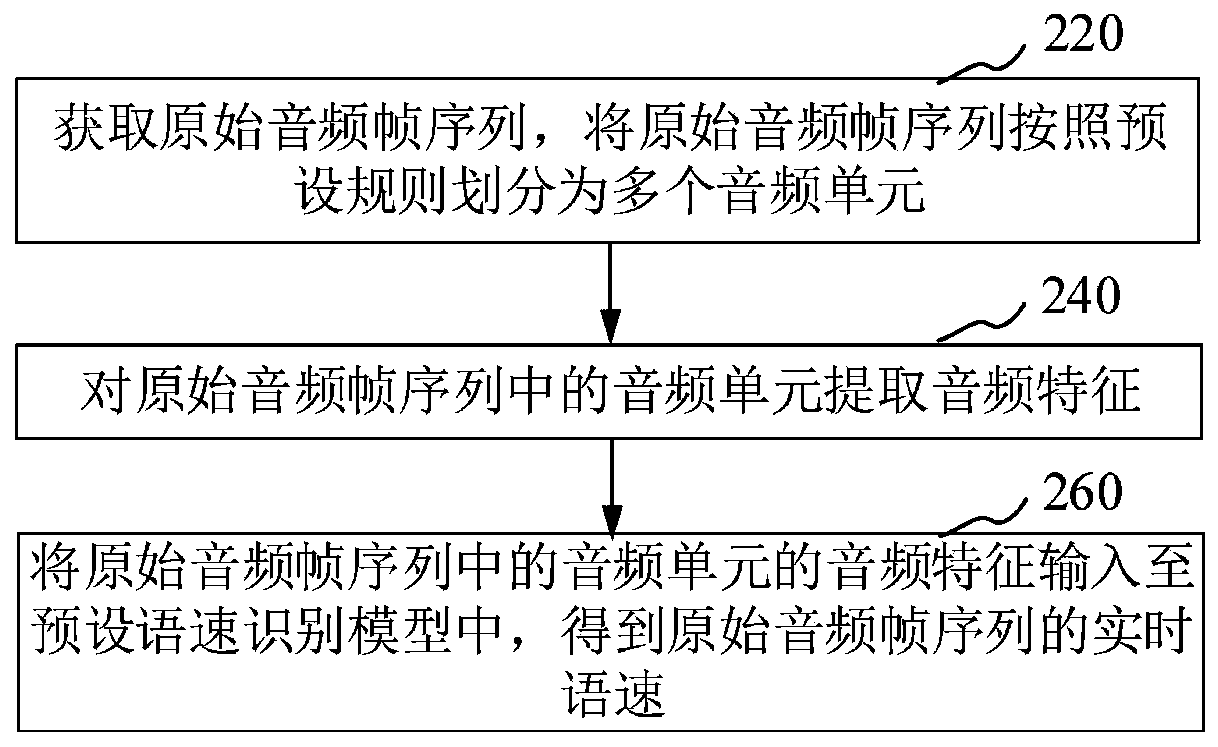

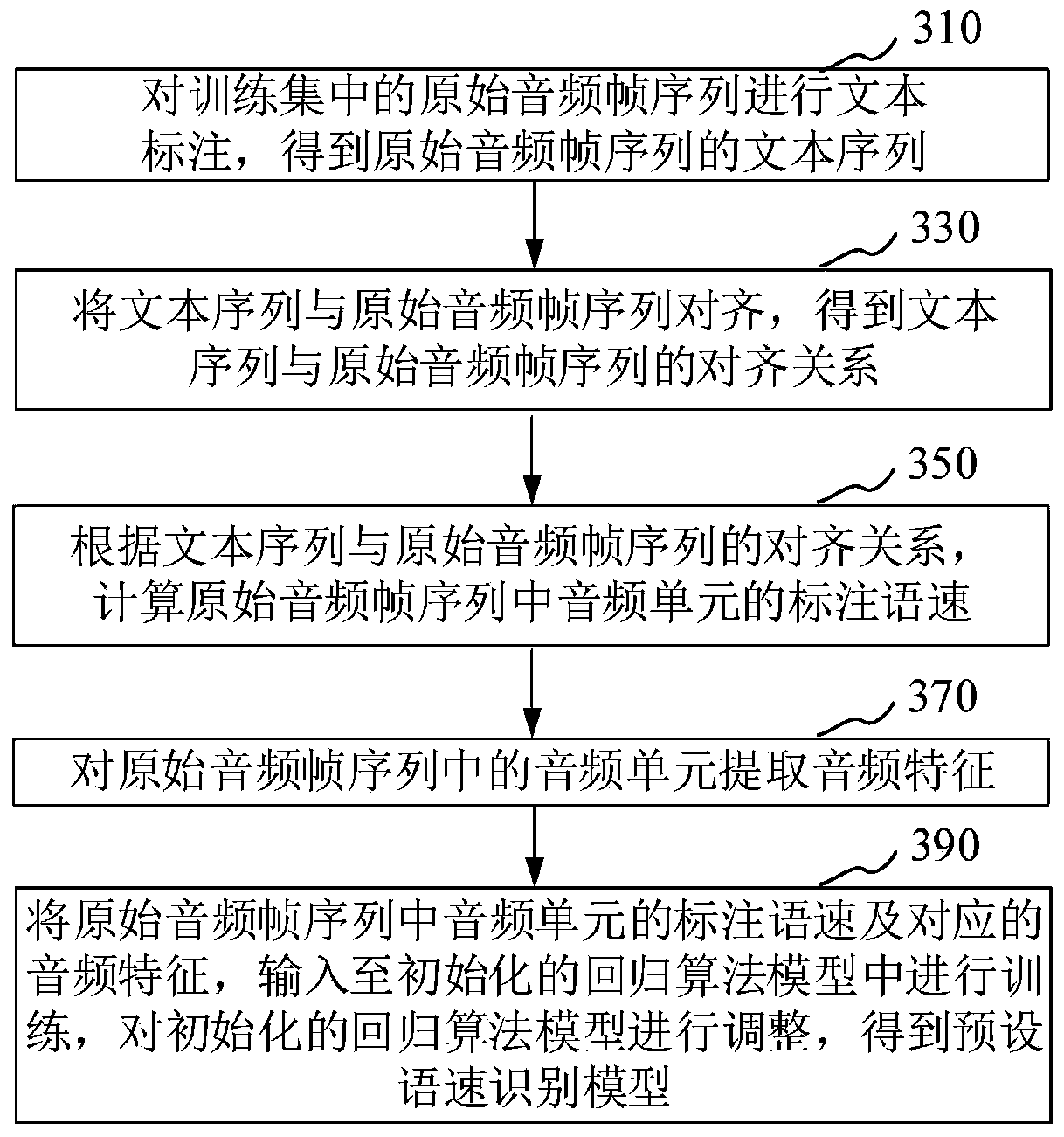

Speech speed recognition method and device, server and computer readable storage medium

InactiveCN111179910AImprove accuracyAvoid performance differencesSpeech recognitionNeural architecturesSpeech rateFrame sequence

The application relates to a speech speed recognition method and device, a server and a computer readable storage medium. The method comprises the steps: dividing an original audio frame sequence intoa plurality of audio units according to a preset rule, extracting audio features of the audio units in the original audio frame sequence, and inputting the audio features of the audio units into a preset speech speed recognition model. The speech speed does not need to be calculated in a specified time period, so that the effect difference caused by different sizes of the specified time period isavoided; and the accuracy of the speech speed identified by the trained preset speech speed identification model is relatively high. Moreover, the preset speech speed recognition model can recognizethe real-time speech speed of the original audio frame sequence according to the audio features of the audio unit, thereby capturing the dynamic change condition of the speech speed of the user, and satisfying the demands of more scenes.

Owner:SHENZHEN ZHUIYI TECH CO LTD

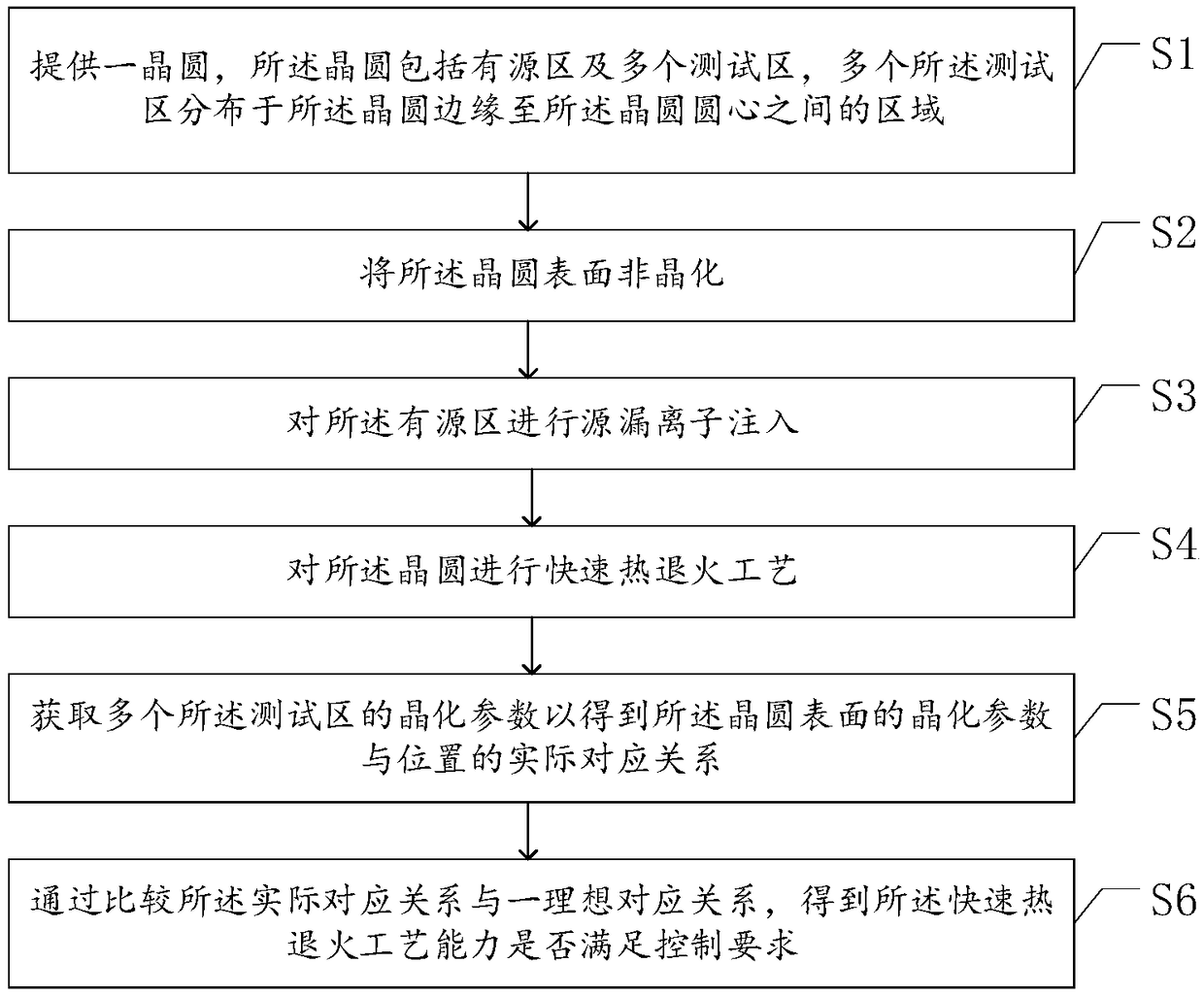

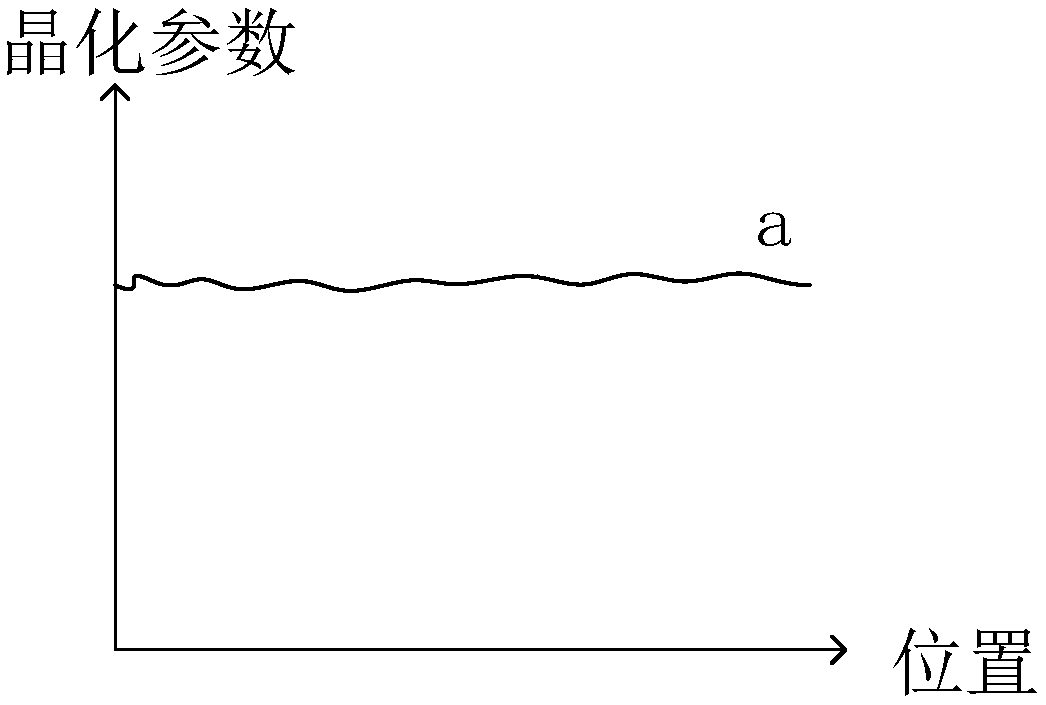

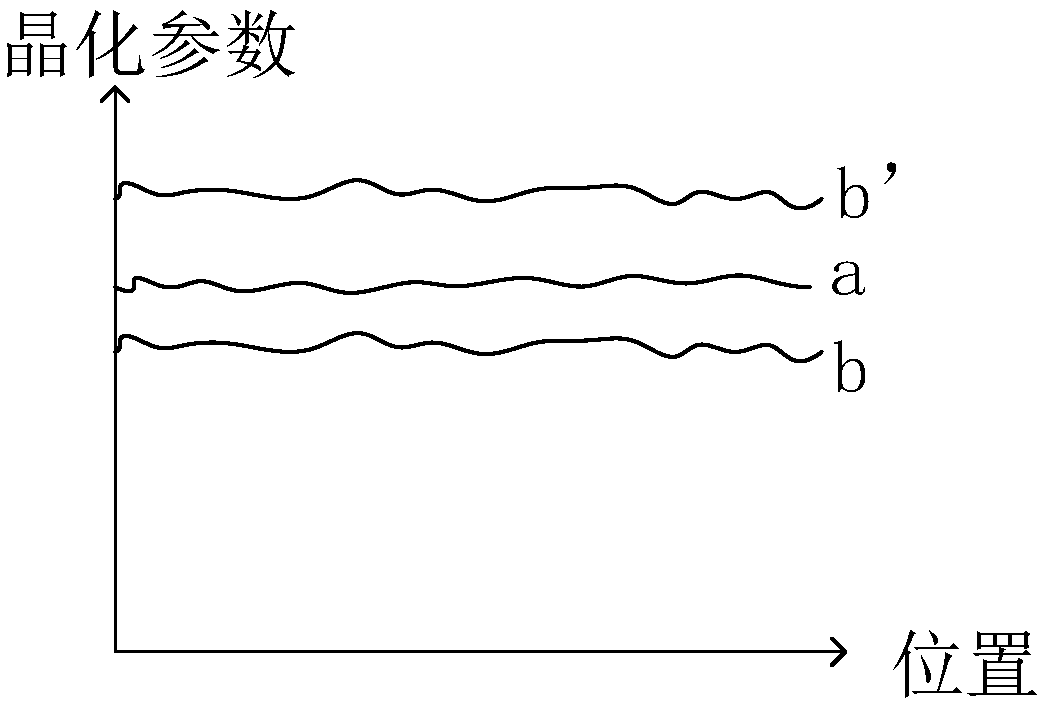

Rapid thermal annealing process capability monitoring method

ActiveCN108878274ARealize online monitoringAvoid performance differencesSemiconductor/solid-state device manufacturingLattice defectsTest region

The invention provides a rapid thermal annealing process capability monitoring method. A plurality of test zones are arranged in an area between a wafer edge and a wafer circle center, and then the surface of the wafer is subjected to non-crystallizing; next, an active region is subjected to normal source-drain ion implantation and rapid thermal annealing process, wherein the rapid thermal annealing process is used for repairing and activating the impurities injected in the active region, and the crystal lattice defect caused by non-crystallizing of the surface of the wafer is repaired; the actual corresponding relation between the crystallization parameter of the surface and the position of the wafer is obtained by acquiring the crystallization parameters of the test region; the actual corresponding relation is compared with an ideal corresponding relation, and whether the rapid thermal annealing process capability meets the control requirements or not can be judged, so that the online monitoring of the rapid thermal annealing process is realized, and the performance difference of the device caused by differences between different batches of wafers is avoided.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Hydrochloric tamsulosin sustained-release capsule and its preparation method

ActiveCN101125134BOvercoming transfer time differencesLess irritatingOrganic active ingredientsPharmaceutical delivery mechanismSide effectFOOD EFFECT

The present invention provides a tamsulosin hydrochloride sustained-release capsule. The tamsulosin hydrochloride sustained-release capsule of the present invention can avoid the sudden release of the drug tablets and the performance differences generated from the gastric emptying differences, display minor food effect or do not display food effect, and obtain the stable curve of the plasma drug concentration and longer action time simultaneously, so as to reduce the occurrence of cardiovascular side effects, greatly improve the safety, effectiveness and compliance of the medication for the patients. The tamsulosin hydrochloride sustained-release capsule of the present invention can ensure the sustained and regular release of the main ingredient tamsulosin hydrochloride after the oral administration, and the present invention is characterized by convenient administration, durable function, stable efficacy, fewer side effects and so on.

Owner:CHANGZHOU NO 4 PHARMA FACTORY

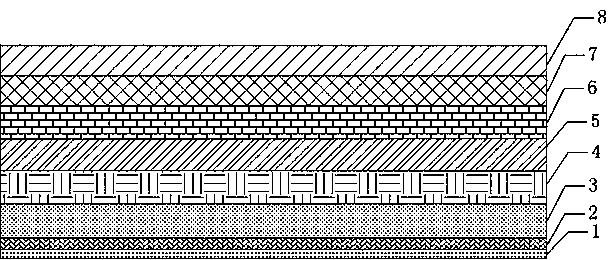

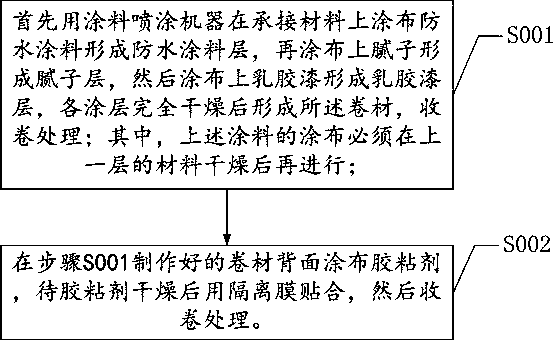

Building coating pre-coating coiled material and manufacture method thereof

PendingCN107859259APrevent appearanceAvoid performance differencesCovering/liningsAdhesive cementConstruction engineering

The invention provides a building coating pre-coating coiled material and a manufacture method thereof. The coiled material includes a connecting material layer, a waterproof coating layer, a putty layer and a latex paint layer, wherein the connecting material layer is covered with the waterproof coating layer, the putty layer and the latex paint layer sequentially, and the connecting material layer is made of building substrates which are capable of crimping. The manufacture method uses mass production of mechanization, firstly, multi-coating coiled materials are made of connecting materialsand coating, and secondly, isolating membranes are pasted on back surfaces of the coiled materials with adhesives. Technological operation is simple, site operation time is greatly shortened, the pollution problem of organic matter in the construction site can be avoided, and check-in time is shortened. The coiled materials are produced in mass with machines, the standard is unified, the technology is normalized, and the differences of appearance and performance between finished products are avoided.

Owner:GUANGDONG YINYANG ENVIRONMENT FRIENDLY NEW MATERIALS CO LTD

A preparation method of multi-component ultra-high temperature ceramic modified c/c composite material with controllable composition gradient

ActiveCN112457056BAvoid performance differencesAvoid damageCeramicwareUltra-high-temperature ceramicsMolten salt

The invention discloses a method for preparing a composition gradient controllable multivariate ultra-high temperature ceramic modified C / C composite material. 2 etc.) and high-temperature ceramics (SiC) composite modified C / C composite material with multi-stage design, so that the ceramic phase forms a continuous composition gradient distribution form inside the C / C matrix, and realizes anti-ablation and anti-oxidation for different temperature fields in different regions Performance requirements, while avoiding the disadvantages of reduced mechanical properties caused by compositional mutations. The present invention adopts the preparation process combining molten salt infiltration and ordinary reaction infiltration in sections, and the gradient infiltration powder configuration, which realizes the strong ceramic phase interface design near the ablation end, and the near ablation end to the far ablation end According to the direction, the content of ultra-high temperature ceramic phases decreases sequentially, while the high-temperature ceramic phases increase sequentially. The distribution of ceramic phases is controlled, and finally a gradient ceramic matrix composite material with different ceramic phase components and contents that meet the material performance requirements is formed.

Owner:CENT SOUTH UNIV

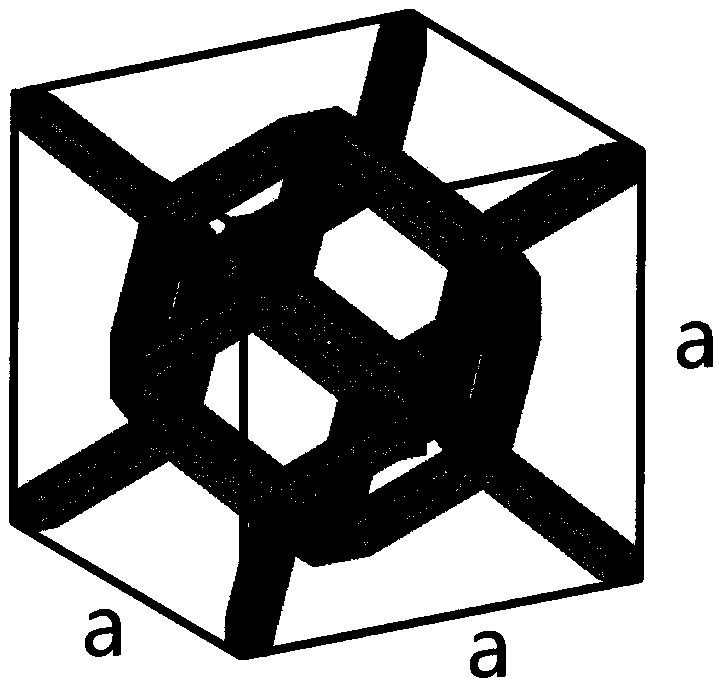

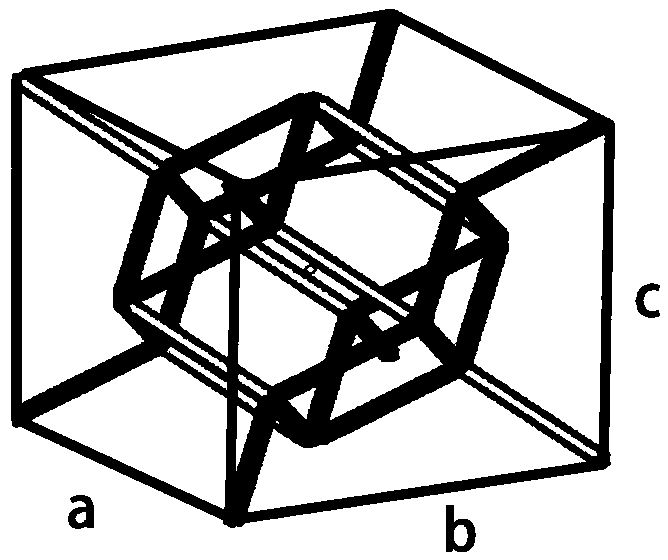

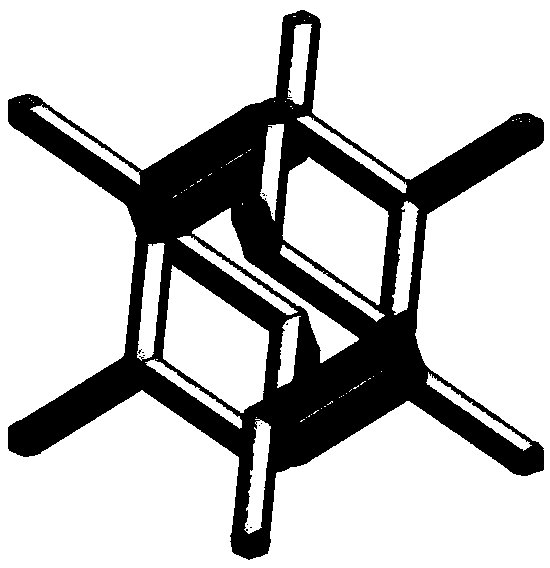

A hollow unit body for metal 3D printing and parts with the unit body

ActiveCN106247159BSmooth transitionMeet actual load requirementsElongated constructional elementsJoint implantsDodecahedronDiagonal

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

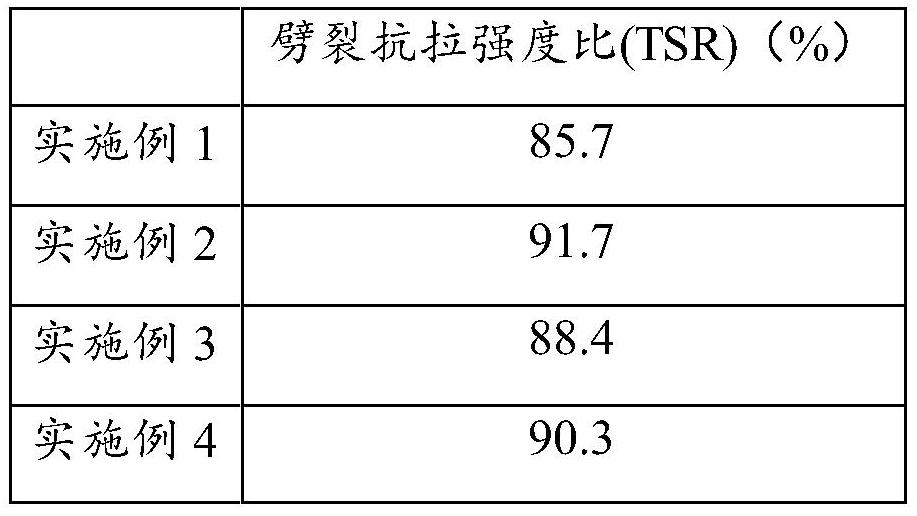

Asphalt mixture capable of resisting water damage and preparation method of asphalt mixture

The invention provides asphalt concrete capable of resisting water damage. The asphalt concrete is prepared from 85 to 90 weight percent of aggregate, 4 to 6 weight percent of SBS modified asphalt, 0 to 2 weight percent of polysiloxane powder, 0 to 2 weight percent of talcum powder, 0 to 5 weight percent of 3-(methylacryloyloxy)propyltrimethoxysilane and 0 to 2 weight percent of white carbon black. According to the invention, the 3-(methacryloyloxy)propyltrimethoxysilane can improve the bonding strength of asphalt and aggregate and resist the erosion of water; the white carbon black has better dispersity, so the uniformity of the coating thickness of the suspension on the surface of the aggregate can be improved, and performance difference caused by non-uniform thickness is avoided; and the polysiloxane powder has good bonding strength with asphalt, has strong hydrophobicity, can repel erosion of water to an asphalt-aggregate interface, and can effectively solve the problem of water damage to asphalt concrete. The invention also provides a preparation method of the asphalt concrete capable of resisting water damage.

Owner:CENT SOUTH UNIV

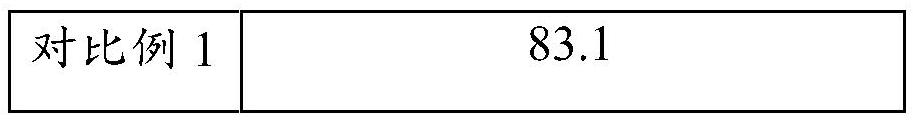

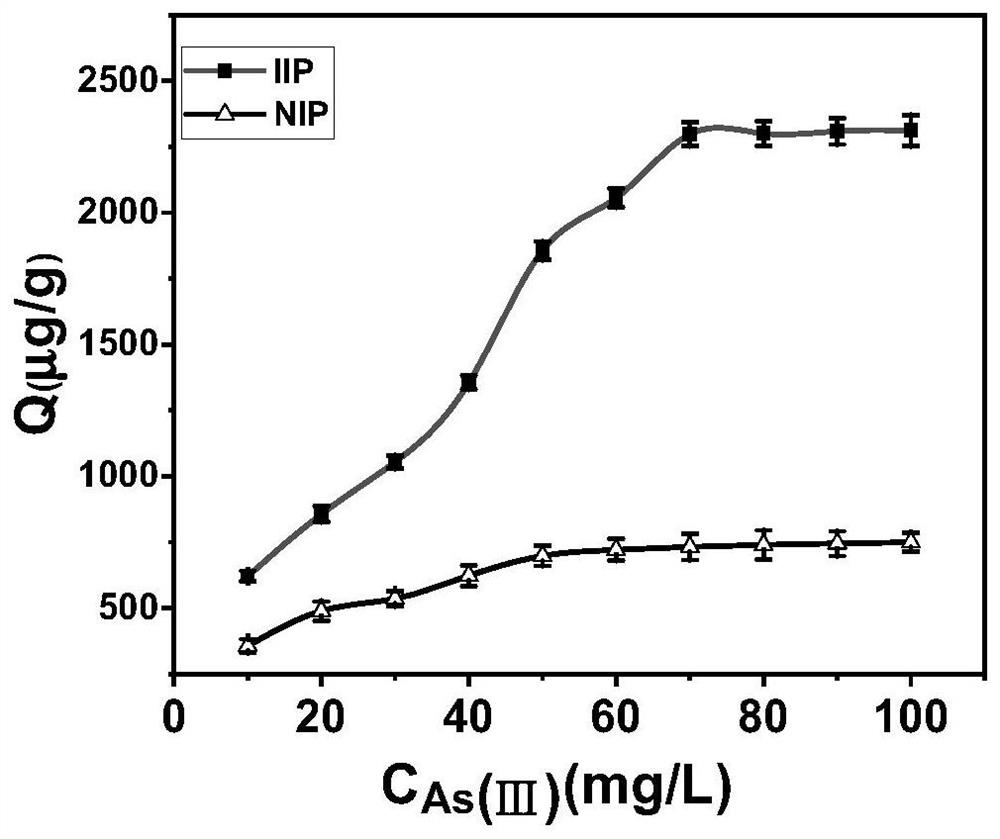

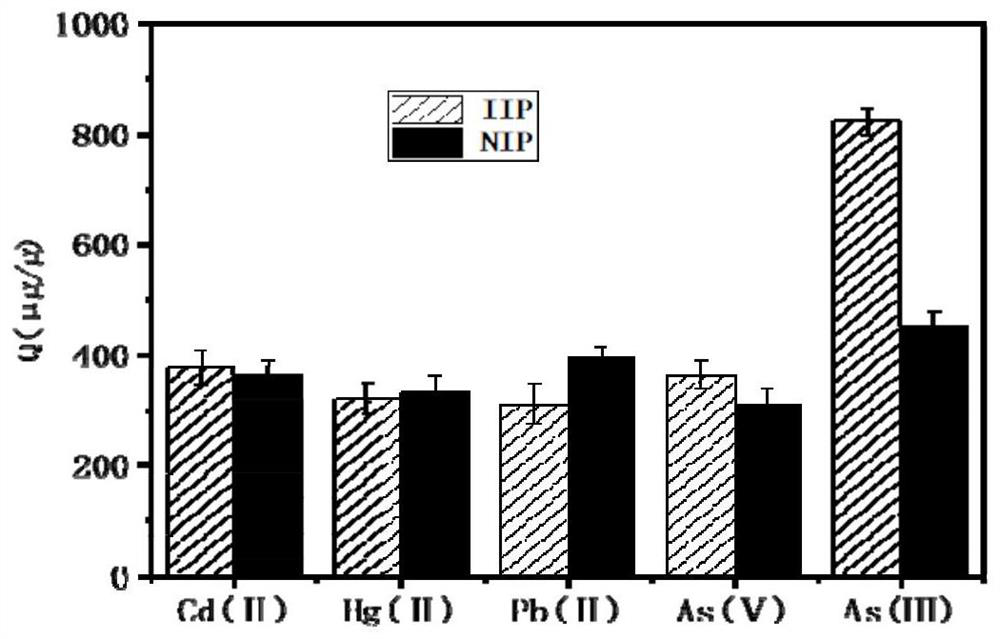

Preparation of an ion-imprinted polymer based on ribonucleotide functional monomers

ActiveCN109772273BHigh selectivityAvoid performance differencesOther chemical processesFunctional monomerAminophenylboronic acid

The present invention provides a method for preparing an ion-imprinted polymer based on functional monomers of ribonucleotides, which is characterized by comprising: dissolving inorganic salts of template ions in double distilled water, then adding ribonucleotides, at 450-550 rpm Stir for 1~2h, add aminophenylboronic acid to the above solution, use 50-100mmol / L sodium hydroxide to adjust the pH of the solution to 8-10, pass nitrogen and deoxygenate, add nano-silica and 0.05~0.2mol / L permeate. Ammonium sulfate solution, nitrogen blowing for 20-40min, continuous magnetic stirring reaction for 10-14h, after the reaction is over, centrifuge to collect the product, use 50-100mmol / L sulfhydryl-containing compound to elute the template ion, then use double distilled water to wash, centrifuge The product was collected and dried at 60-80°C to obtain an ion-imprinted polymer based on ribonucleotide functional monomer. In the preparation process of the present invention, ribonucleotides with good affinity for metal ions are selected as functional monomers, and the selectivity of ion imprinting can be further improved through the synergistic effect of the imprinting monomer and the imprinting cavity.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

A post-weld heat treatment method for large-diameter thick-walled pipes

ActiveCN107641702BGuarantee the quality of heat treatmentGuaranteed one-time successFurnace typesHeat treatment furnacesEconomic benefitsThick wall

The invention provides a large-diameter thick walled pipe postweld heat treatment method. By adopting the large-diameter thick walled pipe postweld heat treatment method provided by the invention, insulating temperature is determined according to a hardness range of a base material in the postweld heat treatment process, simultaneous heating of an inner wall and an outer wall is adopted, a heatingwidth is determined according to a formula, a power of a heater is determined according to a formula, and thus the heat treatment quality of a weld crater is effectively ensured, a temperature difference between the inner wall and the outer wall of the weld crater in postweld heat treatment is lowered to meet the standard requirement or a higher standard to avoid the phenomenon of base material overburning or difference between the weld crater properties of the inner wall and the outer wall caused by a temperature deviation, weld crater heat treatment can be ensured to mold at a time at the same time to avoid the phenomenon of heat treatment again, the heat treatment effect is improved, and the economic benefit is very considerable.

Owner:POWERCHINA SEPCO1 ELECTRIC POWER CONSTR CO LTD

Manufacturing method of high-strength, toughness and layered tear-resistant steel plate with a thickness of 50-80 mm

Owner:XINYU IRON & STEEL CO LTD

A kind of production method of high-quality thick-gauge steel plate

ActiveCN109295290BImprove cross-section low temperature impact toughnessPromote precipitationMetallurgySteel plates

The invention belongs to the technical field of steel materials, and discloses a production method of a high-quality thick steel plate. The production method comprises the steps that the procedure ofhigh-temperature rolling and the procedure of low-temperature rolling are conducted in a non-recrystallization area in the rolling process, wherein the procedure of high-temperature rolling comprise afirst finish rolling stage, and in the first finish rolling state, a low-speed high-pressure rolling process is adopted, the initial rolling temperature is 900-930 DEG C, a required cumulative rolling rate is equal to or greater than 15%, and the maximum single-pass rolling rate is equal to or greater than 12%; the procedure of low-temperature rolling comprises a second finish rolling stage, andin the second finish rolling stage, a low-temperature high-pressure rolling process is adopted, the initial rolling temperature of a steel plate is 780-820 DEG C, and the finish rolling temperature is760-780 DEG C; and steel is discharged after being rolled and then rapidly enters water to be cooled. By adoption of the production method of the high-quality thick steel plate, the performance of the high-strength and high-tenacity thick steel plate produced through a continuously cast plate is improved, and meanwhile, the technical problems of slow rolling rhythm and low efficiency are solved.

Owner:SHOUGANG CORPORATION

A real-time neurofeedback device, system, method and computer storage medium

ActiveCN108814594BThe modulation process is fast and straightforwardAvoid performance differencesDiagnostic recording/measuringSensorsSoftware engineeringComputer engineering

Owner:SHENZHEN UNIV

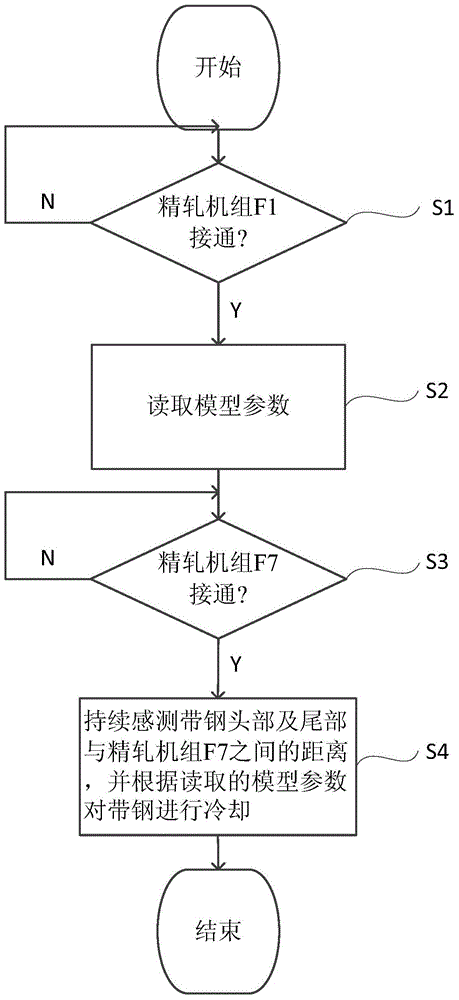

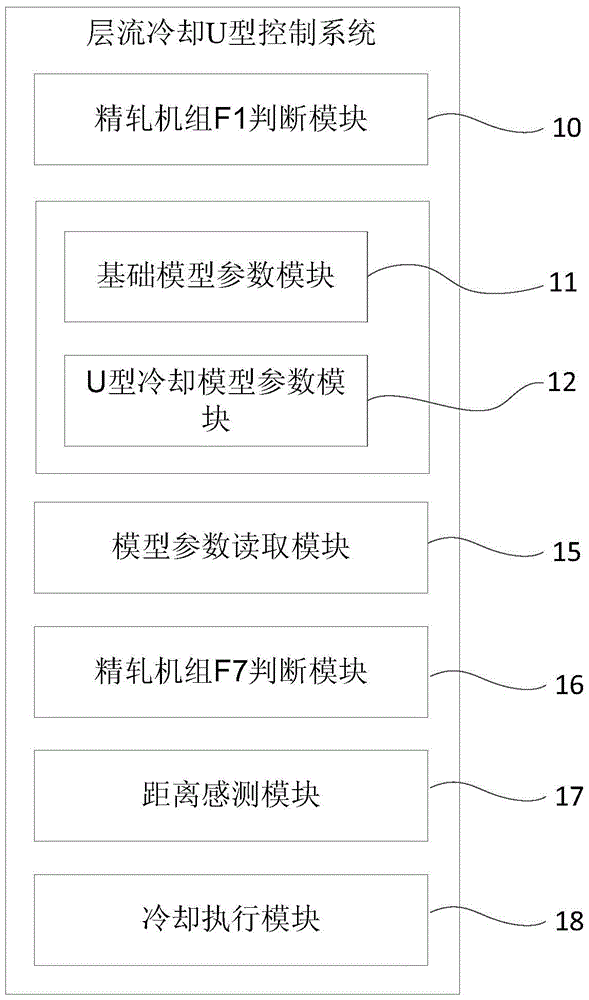

Laminar Cooling U-Shape Control System for Hot Rolled Strip

ActiveCN105499281BOffset performance differencesAvoid extreme temperature fluctuationsTemperature control deviceControl systemStrip steel

Owner:武汉钢铁有限公司

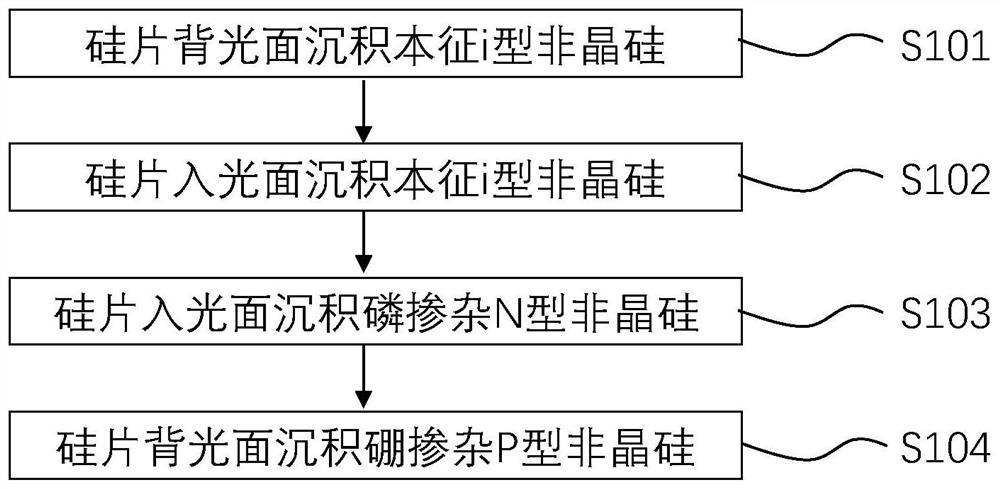

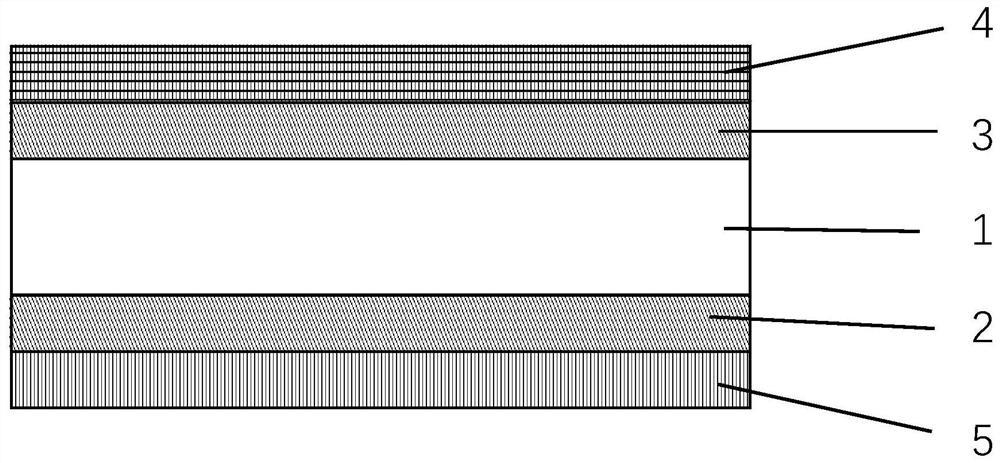

PECVD coating method of efficient heterojunction solar cell

PendingCN113193072AReduce contentIncrease contentFinal product manufactureChemical vapor deposition coatingHeterojunctionAmorphous silicon

The invention relates to a PECVD coating method of an efficient heterojunction solar cell. The PECVD coating method comprises a gradient I layer deposition method. According to the gradient type I layer deposition method, a PECVD method is used for decomposing reaction gas to conduct intrinsic I type amorphous silicon deposition, the hydrogen content in the reaction gas is gradually increased, and the intrinsic I type amorphous silicon deposition rate is gradually reduced. According to the PECVD coating method for the efficient heterojunction solar cell provided by the invention, the passivation effect can be improved, and the performance of an intrinsic I-type amorphous silicon film can be optimized to the greatest extent.

Owner:GOLD STONE (FUJIAN) ENERGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com