PECVD coating method of efficient heterojunction solar cell

A solar cell and heterojunction technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of polluting the surface of silicon wafers, affecting the passivation effect, and affecting the stability of the battery process, so as to reduce the saturation dark current and improve Passivation effect, effect suitable for industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

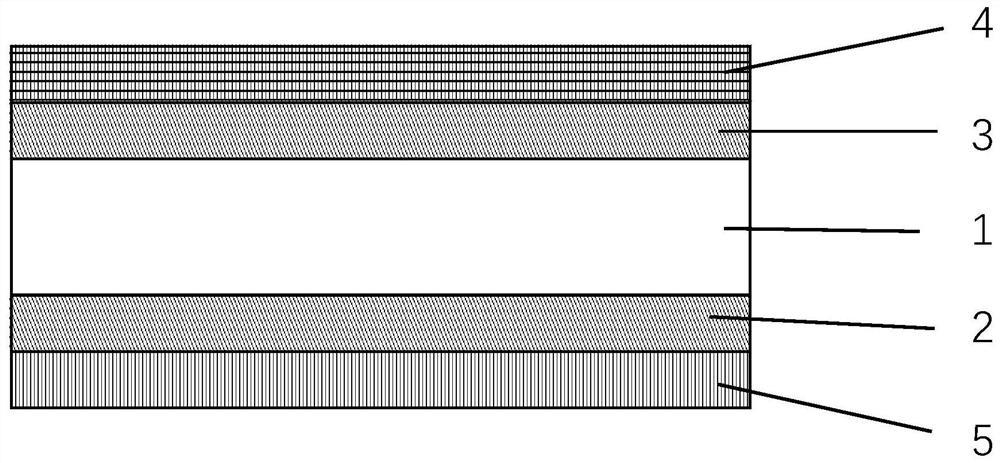

[0016] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments of the description:

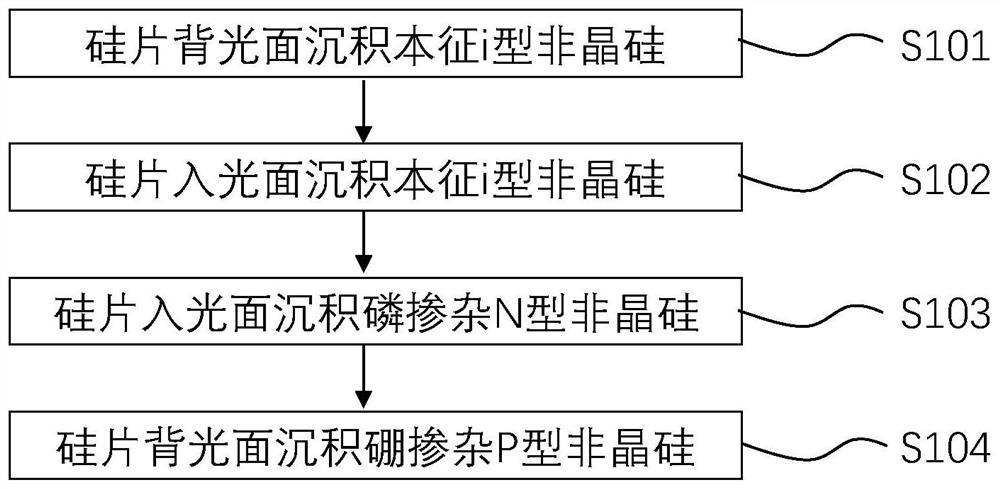

[0017] A PECVD coating method for a high-efficiency heterojunction solar cell, which includes a gradual deposition I-layer method; the gradual deposition I-layer method is to use the PECVD method to decompose the reaction gas for intrinsic I-type amorphous silicon deposition, and the reaction gas As the hydrogen content gradually increases, the deposition rate of intrinsic type I amorphous silicon decreases gradually.

[0018] The pressure of the reaction gas is 30-150Pa, and the gas partial pressure of the hydrogen is gradually increased from 0-10Pa to 80Pa-150Pa; the intrinsic I-type amorphous silicon deposition rate is gradually reduced to

[0019] The reactive gases include silane and hydrogen.

[0020] The thickness of the intrinsic type I amorphous silicon film is

[0021] The PECVD coating method of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com