Asphalt mixture capable of resisting water damage and preparation method of asphalt mixture

A technology of asphalt mixture, water damage, applied in the field of highway engineering, to achieve strong hydrophobicity, improve dispersion, and avoid performance differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The present invention provides a method for preparing an asphalt mixture resistant to water damage described in the above technical solution, comprising:

[0054] Heat the aggregate, SBS modified asphalt, talcum powder, polysiloxane, 3-(methacryloyloxy)propyltrimethoxysilane and white carbon black respectively;

[0055] The heated talc powder, the heated white carbon black and the heated 3-(methacryloyloxy)propyltrimethoxysilane are mixed for the first time and then kept for the first heat preservation to obtain the suspension A;

[0056] performing a second mixing of the suspension A, the heated polysiloxane, and the heated aggregate to obtain a mixture;

[0057] The mixture and the heated SBS modified asphalt are mixed for a third time and then kept for a second heat preservation to obtain an asphalt mixture resistant to water damage.

[0058] In the present invention, the heating temperature is preferably 150-160°C, more preferably 153-157°C, most preferably 155°C. ...

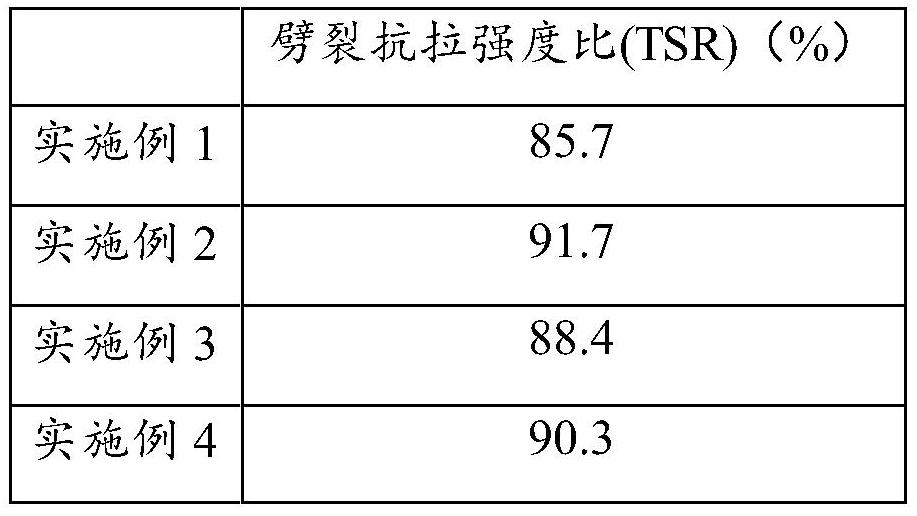

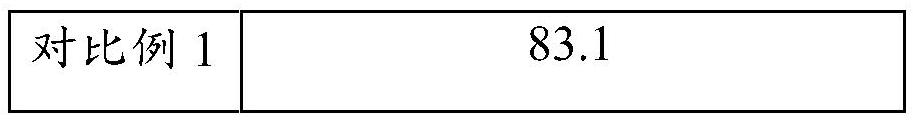

Embodiment 1

[0074] The composition of the asphalt mixture resisting water damage provided by Example 1 of the present invention is:

[0075] 90 wt% aggregate (basalt); 5 wt% SBS modified bitumen; 3 wt% talc; 2 wt% 3-(methacryloyloxy)propyltrimethoxysilane (KH-570).

[0076] The preparation method is: heating the aggregate, SBS modified asphalt, talcum powder and 3-(methacryloxy)propyltrimethoxysilane respectively; heating the heated talc powder and heated 3-(methacrylic acid) Acyloxy)propyltrimethoxysilane is firstly mixed and then firstly kept warm to obtain a suspension A; the suspension A is mixed with the heated aggregate to obtain a mixture; the mixture and heated After the SBS modified asphalt is mixed for the third time, the second insulation is carried out to obtain an asphalt mixture resistant to water damage;

[0077] The heating temperature is preferably 160°C;

[0078] The first mixing method includes: adding the heated talc powder into the heated 3-(methacryloyloxy)propyltr...

Embodiment 2

[0082] The composition of the asphalt mixture resisting water damage provided by Embodiment 2 of the present invention is:

[0083] 85wt% aggregate (basalt); 5wt% SBS modified bitumen; 2wt% talc; 2wt% polysiloxane powder; 5wt% 3-(methacryloyloxy)propyltrimethoxysilane (KH-570); 1 wt% of white carbon black.

[0084] The preparation method is as follows: heating aggregate, SBS modified asphalt, talcum powder, polysiloxane, 3-(methacryloyloxy)propyltrimethoxysilane and white carbon black respectively; heating the heated talc powder, The heated silica and the heated 3-(methacryloyloxy)propyltrimethoxysilane are first mixed and then first kept warm to obtain a suspension A; the suspension A and the heated The polysiloxane and the heated aggregate are mixed for a second time to obtain a mixture; the mixture and the heated SBS modified asphalt are mixed for a third time and then kept for a second heat preservation to obtain an asphalt mixture resistant to water damage;

[0085] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com