Preparation method of petroleum asphalt anti-stripping agent suitable for acid stone

A technology of petroleum asphalt and anti-stripping agent, which is applied in the direction of building insulation materials, building components, buildings, etc., can solve the problems of poor heat resistance and poor long-term effect, and achieve the effect of simple application method and improved water damage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] The present invention is suitable for The preparation method of the petroleum asphalt antistripping agent of acid stone, its step is:

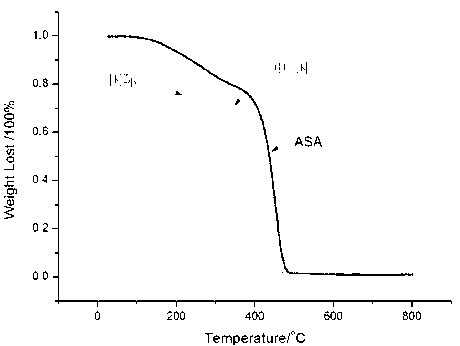

[0014] (1) Weigh 100 parts of tungoleic acid, 5~20 parts of organic bentonite, mechanically stir the tungoleic acid and organic bentonite under the protection of carbon dioxide gas, and gradually heat to 280~300 o C, keep 2~4h, obtain nano-phyllosilicate / tung oil dimer acid;

[0015] (2) Slowly add nano-layered silicate / tung oil dimer acid into the system of diethylenetriamine, heat to 100-130 o C, nitrogen protection, at 200 ~ 250 o After keeping at the temperature of C for 2-4 hours, carry out vacuum dehydration, recover diethylenetriamine, and obtain polyamide-based nanocomposites;

[0016] (3) Wait until the temperature drops to 40-80 o At C, add diluent and compatibilizer, stir evenly, and then mix asphalt mixture.

[0017] According to the preparation method described above, slowly put nano-layered silicate / tung oil dimer ac...

Embodiment 1

[0022] Take by weight 100 parts of oleic acid, 5 parts of organic bentonite, 80 parts of diethylenetriamine, 5 parts of glycerol, 5 parts of dibutyl phthalate, and 5 parts of hard asphalt.

[0023] Tung oilic acid and organic bentonite were mechanically stirred under the protection of carbon dioxide gas, and gradually heated to 300 o C kept for 2h to obtain nano-phyllosilicate / tung oil dimer acid; slowly drop into nano-phyllosilicate / tung oil dimer acid in the system of diethylenetriamine, and heat to 120 o Nitrogen protection after C, 220 o C for 3 hours, vacuum deliquification, recovery of diethylenetriamine, polyamide nanocomposite material. When the temperature drops to 80 o At C, add diluent and compatibilizer, and mechanically stir evenly to prepare a new type of petroleum asphalt anti-stripping agent.

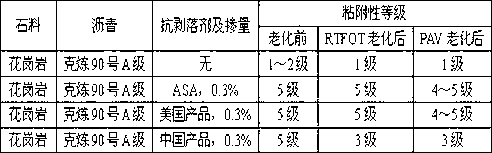

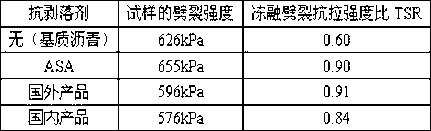

[0024] The above-mentioned new petroleum asphalt anti-stripping agent was added to No. 90 A-grade asphalt of Xinjiang Karamay Oil Refinery (referred to as Kelian), an...

Embodiment 2

[0046] Take by weight 100 parts of oleic acid, 10 parts of organic bentonite, 100 parts of diethylenetriamine, 5 parts of glycerol, 5 parts of dibutyl phthalate, and 5 parts of hard asphalt.

[0047] Tung oilic acid and organic bentonite were mechanically stirred under the protection of carbon dioxide gas, and gradually heated to 300 o C kept for 2h to obtain nano-phyllosilicate / tung oil dimer acid; slowly drop into nano-phyllosilicate / tung oil dimer acid in the system of diethylenetriamine, and heat to 100 o C after nitrogen protection, 210 o C for 2 hours, vacuum deliquification, recovery of diethylenetriamine, polyamide nanocomposite material. When the temperature drops to 60 o At C, add diluent and compatibilizer, and mechanically stir evenly to prepare a new type of petroleum asphalt anti-stripping agent.

[0048] The anti-stripping agent prepared above was added to Korean SK90 A-grade asphalt, and two foreign and domestic anti-stripping agents were selected for compar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com