Preparation method for lithium titanate

A technology of lithium titanate and lithium titanate, applied in chemical instruments and methods, titanium compounds, inorganic chemistry, etc., can solve the problems of poor material performance, high equipment requirements, long process flow, etc., to improve conductivity and follow-up Processability, improvement of ionic conductivity, and improvement of process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

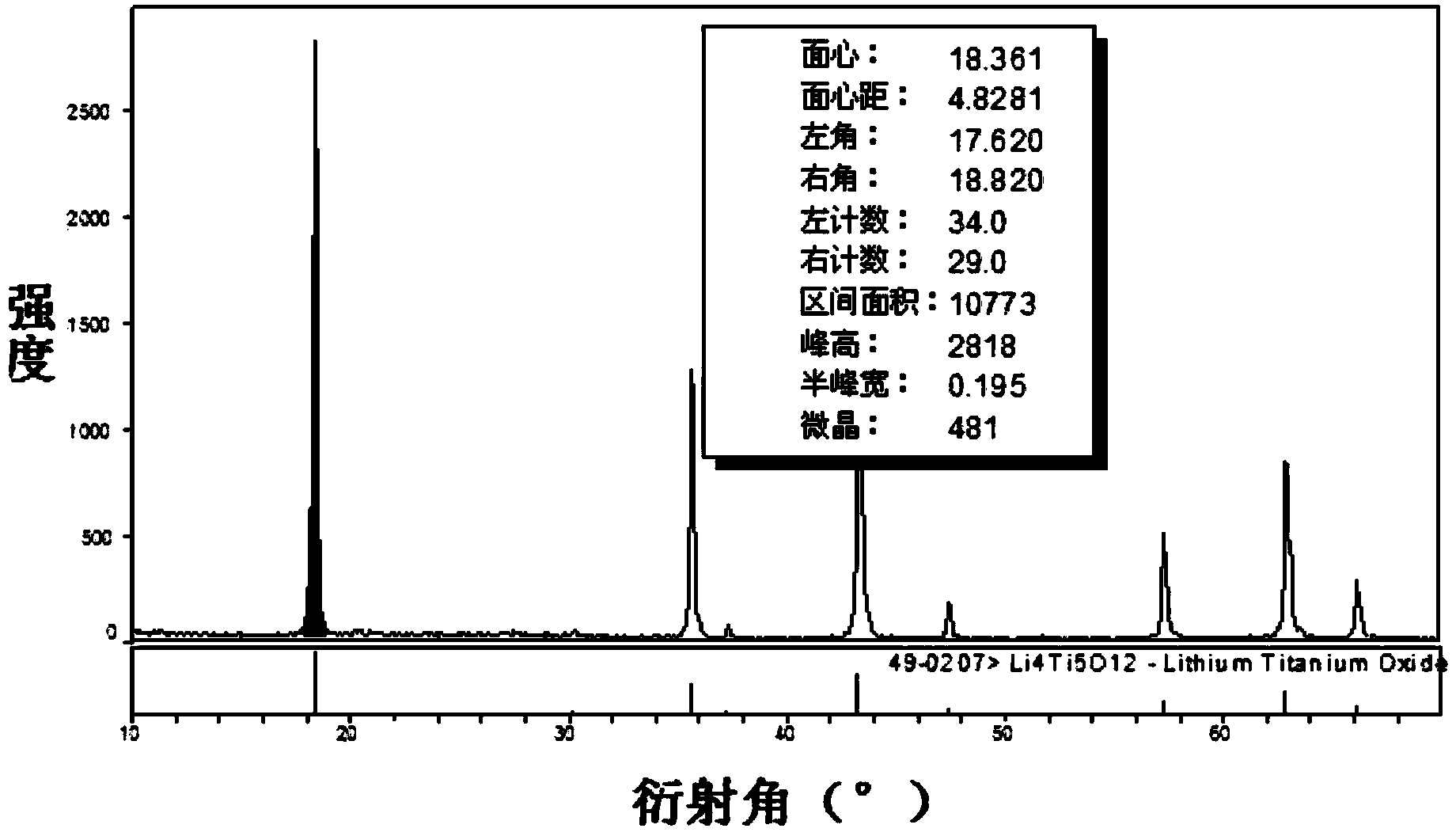

Embodiment 1

[0036] (1) The raw materials (see Table 1 for the specific ratio, Li weight in LiOH: TiO 2 Medium Ti weight = 4:5) Accurately weigh with a 600g electronic balance (accuracy: 0.01g), put it into a stirring grinder with a capacity of 3L, add 1400mL of deionized water, stir and grind at a speed of 1200 rpm for 2 hours made into slurry;

[0037] (2) When the spray dryer is preheated to an outlet temperature of 140°C, add the prepared slurry above to the nozzle for atomization and drying. 92-95°C, 478.00 g of pale white powder was obtained;

[0038] (3) Put the above-mentioned powder into the tubular rotary furnace, close the furnace mouth and pass in nitrogen-hydrogen mixed gas containing 10% (volume fraction) of hydrogen, and start the rotary furnace after 20 minutes (set the rotary speed of the rotary furnace at 2 to 5 revolutions per minute, no special requirements for other parameters), power on and heat up (heating rate 3-5°C / s, other no special requirements) to 790-810°C a...

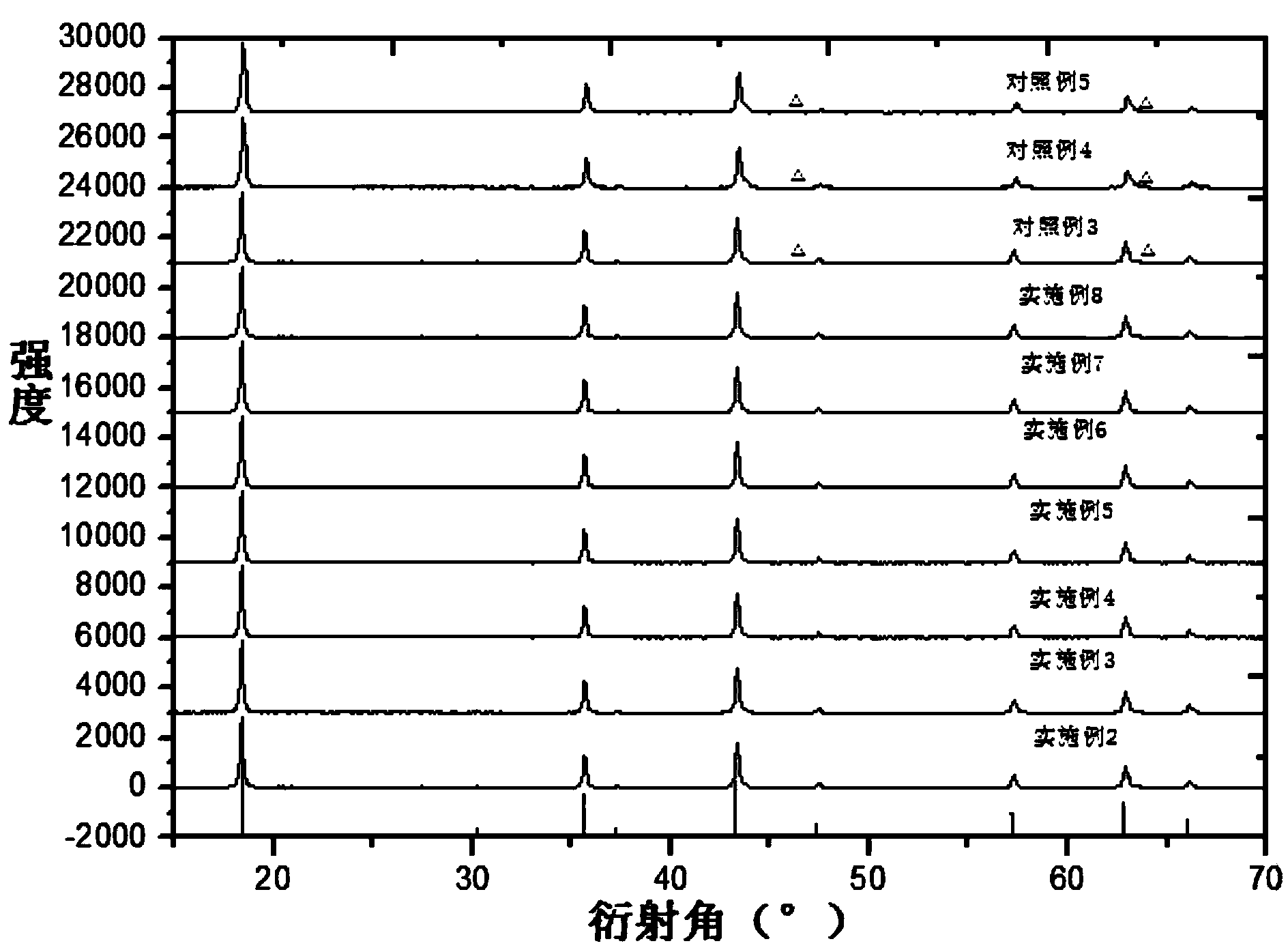

Embodiment 2

[0042] (1) The raw materials (see Table 1 for the specific ratio, Li weight in LiOH: TiO 2 Medium Ti weight = 4.02:5) Accurately weigh 600 grams of electronic balance (accuracy 0.01 grams), put it into a stirring grinder with a capacity of 3 L, add 2600 mL of distilled water, stir and grind for 3 hours at a speed of 500 rpm slurry;

[0043] (2) When the spray dryer is preheated to an outlet temperature of 160°C, add the prepared slurry above to the nozzle for atomization and drying. 95-98°C, 492.00 g of pale white powder was obtained;

[0044] (3) Put the above-mentioned powder into the tubular rotary furnace, close the furnace mouth and pass in nitrogen-hydrogen mixed gas containing 8% (volume fraction) of hydrogen, and start the rotary furnace after 20 minutes (set the rotary speed of the rotary furnace at 2 to 5 revolutions per minute, no special requirements for other parameters), power on and heat up (heating rate 3-5°C / s, other no special requirements) to 790-810°C and...

Embodiment 3

[0048] (1) The raw materials (see Table 1 for the specific ratio, Li weight in LiOH: TiO 2 Medium Ti weight=4.05:5) Weigh accurately with 600g electronic balance (accuracy 0.01g), put it into a stirring grinder with a capacity of 3L, add 1350mL of deionized water, stir and grind at 1500 rpm for 4.5 hours made into slurry;

[0049] (2) When the spray dryer is preheated to an outlet temperature of 150°C, add the prepared slurry above to the nozzle for atomization and drying. 95-100°C, 498.00 g of pale white powder was obtained;

[0050] (3) Put the above-mentioned powder into the tubular rotary furnace, close the furnace mouth and pass in nitrogen-hydrogen mixed gas containing 12% (volume fraction) of hydrogen, and start the rotary furnace after 20 minutes (set the rotary speed of the rotary furnace at 2-5 revolutions per minute, no special requirements for other parameters), power on and heat up (heating rate 3-5°C / s, other no special requirements) to 790-810°C and keep warm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com