Hydraulic hammer head and preparation method thereof

A technology of hydraulic breaker and cermet, which is applied in the directions of additive manufacturing, mechanically driven excavators/dredgers, earthmovers/shovels, etc. Poor anti-corrosion performance and other problems, to achieve the effect of reducing early scrap, improving process performance, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation method of the hydraulic breaking hammer head is as follows:

[0033] Mix 10g of chromium, 5g of silicon, 30g of iron, 5g of carbon, 30g of nickel, 1g of molybdenum, and 1g of tungsten to make a cermet mixed powder with a mesh size of 200 mesh or more, and use a 3D printer to generate high-energy particle beams to achieve cermet mixing Powder fusion with an energy density of 90J / mm for the high-energy particle beam 2 , the laser melting time is 2 minutes. After the melting is completed, the cermet is sprayed on the steel surface of the hydraulic crushing hammer base with a 3D printer to form a dense cermet layer. It is integrally formed without splicing gaps and has stronger stability.

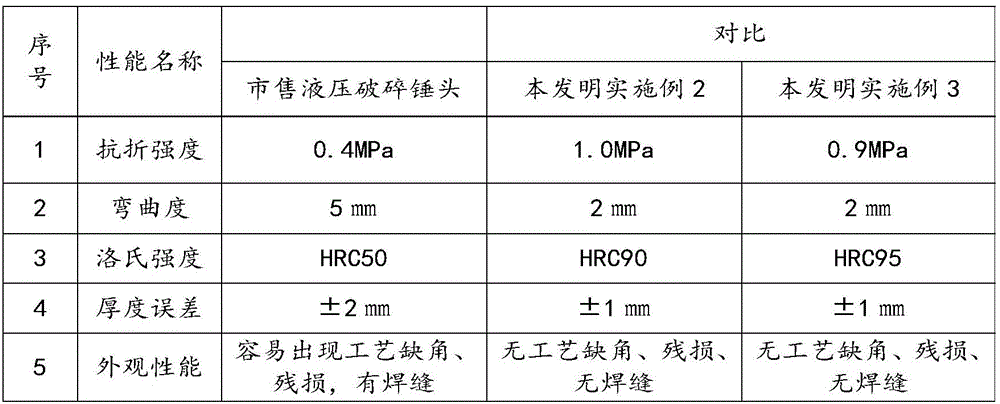

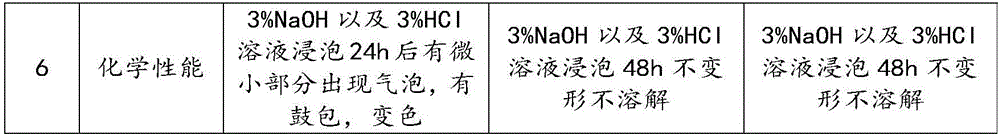

Embodiment 2

[0035] The preparation method of the hydraulic breaking hammer head is as follows:

[0036] Mix 30g of chromium, 12g of silicon, 40g of iron, 13g of carbon, 40g of nickel, 2g of molybdenum, and 2g of tungsten to make a cermet mixed powder with a mesh size of 300 mesh. The mixing rate is controlled at 300rad / min, and a 3D printer is used to produce high-energy particles. The beam realizes the melting of metal-ceramic mixed powder, and the energy density of the high-energy particle beam is 100J / mm 2 , the time of laser melting is 3min. After the melting is completed, the cermet is sprayed on the steel surface of the hydraulic crushing hammer base with a 3D printer to form a dense cermet layer. The thickness of the cermet layer is 1.6mm. The hammer head base is composed of three layers: metal layer, metal-ceramic composite layer, and ceramic layer from inside to outside. It is integrally formed, without splicing gaps, and has stronger stability.

Embodiment 3

[0038] The preparation method of the hydraulic breaking hammer head is as follows:

[0039] Mix 15g of chromium, 7g of silicon, 32g of iron, 6g of carbon, 30g of nickel, 1.2g of molybdenum, and 1.2g of tungsten to make a cermet mixed powder with a mesh size of 200 mesh. The mixing rate is controlled at 100rad / min, and it is produced by a 3D printer. The high-energy particle beam realizes the melting of metal-ceramic mixed powder, and the energy density of the high-energy particle beam is 120J / mm 2 , the laser melting time is 2.5min. After the melting is completed, the cermet is sprayed on the steel surface of the hydraulic crushing hammer base with a 3D printer to form a dense cermet layer. The thickness of the cermet layer is 1.7mm. The base of the crushing hammer is composed of three layers: ceramic layer, metal-ceramic composite layer and metal layer from the inside to the outside. It is integrally formed without splicing gaps and has stronger stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com