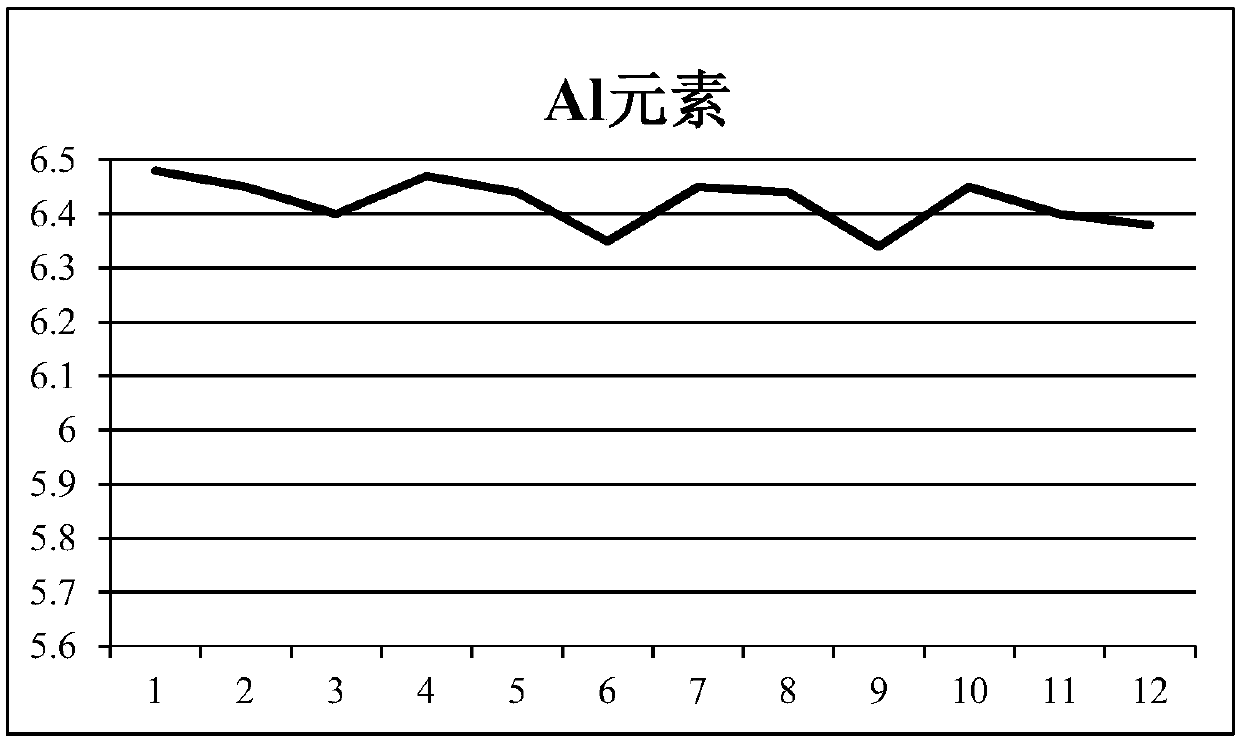

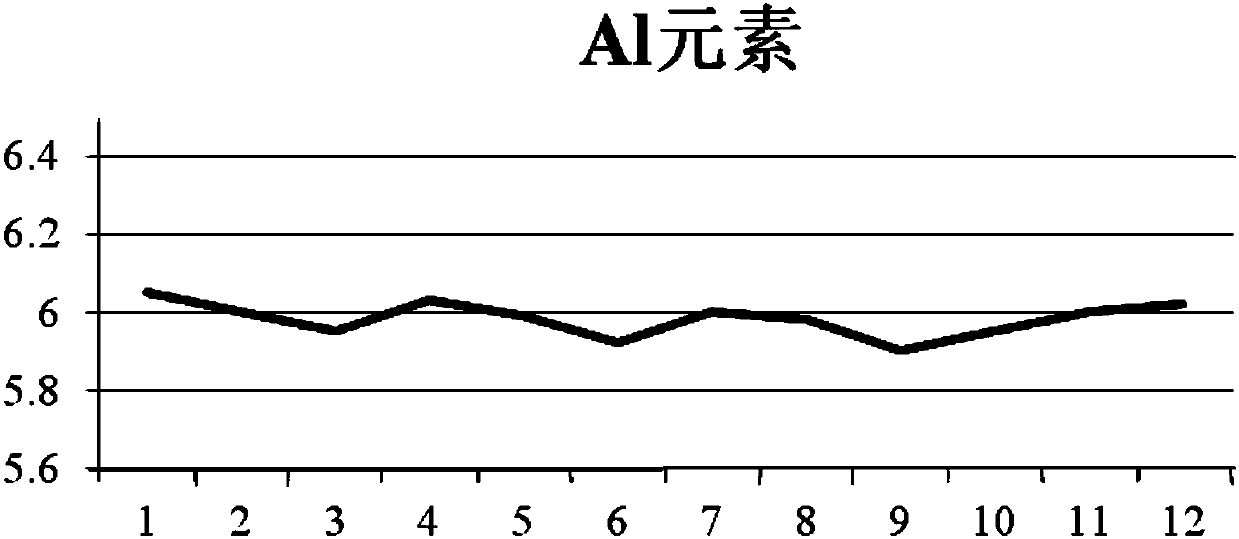

Feeding method for improving uniformity of components of head of TC4 cast ingot

A technology of uniformity and ingot casting, which is applied in the field of feeding to improve the uniformity of the composition of the TC4 ingot head, can solve the problem of low Al element in the core, and achieve the effect of uniform distribution of Al element

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Step 1: Mix the national standard zero-grade or grade-one sponge titanium, pure aluminum, aluminum-vanadium alloy, and titanium dioxide powder according to the mass of Al: 6.0%, V: 3.5%, O: 0.08%, and the balance is Ti to obtain a mixture. ;

[0018] Step 2: Press the mixture into an electrode block, control the pressing pressure at 20Mpa, and keep the pressure for 8 seconds;

[0019] Step 3: Use plasma welding in the furnace to weld several electrode blocks together to obtain consumable electrodes, and avoid oxidation caused during the welding process in a vacuum environment; use copper plasma torch tips to avoid W caused by tungsten torch tip welding Inclusion;

[0020] Step 4: Melt the consumable electrode three times in a vacuum electric arc furnace:

[0021] The first smelting uses a Φ560mm crucible. During the smelting process, the vacuum degree is controlled below 5Pa (Pa), the smelting current is 10-20kA, the smelting voltage is 25-30V, and the cooling time af...

Embodiment 2

[0027] Step 1: Mix the national standard zero-grade or grade-one sponge titanium, pure aluminum, aluminum-vanadium alloy, and titanium dioxide powder according to the mass of Al: 6.4%, V: 4.3%, O: 0.13%, and the balance is Ti to obtain a mixture. ;

[0028] Step 2: Press the mixture into an electrode block, control the pressing pressure at 30Mpa, and keep the pressure for 83 seconds;

[0029] Step 3: Use plasma welding in the furnace to weld several electrode blocks together to obtain consumable electrodes, and avoid oxidation caused during the welding process in a vacuum environment; use copper plasma torch tips to avoid W caused by tungsten torch tip welding Inclusion;

[0030] Step 4: Melt the consumable electrode three times in a vacuum electric arc furnace:

[0031] The first smelting uses a Φ560mm crucible. During the smelting process, the vacuum degree is controlled below 4Pa, the smelting current is 20-30kA, the smelting voltage is 27-35V, and the cooling time after ...

Embodiment 3

[0037] Step 1: Mix the national standard zero-grade or grade-one sponge titanium, pure aluminum, aluminum-vanadium alloy, and titanium dioxide powder according to the mass of Al: 6.2%, V: 4.0%, O: 0.10%, and the balance is Ti to obtain a mixture. ;

[0038] Step 2: Press the mixture into an electrode block, control the pressing pressure at 28Mpa, and keep the pressure for 6 seconds;

[0039] Step 3: Use plasma welding in the furnace to weld several electrode blocks together to obtain consumable electrodes, and avoid oxidation caused during the welding process in a vacuum environment; use copper plasma torch tips to avoid W caused by tungsten torch tip welding Inclusion;

[0040] Step 4: Melt the consumable electrode three times in a vacuum electric arc furnace:

[0041] The first smelting uses a Φ560mm crucible. During the smelting process, the vacuum degree is controlled below 5Pa (Pa), the smelting current is 10-20kA, the smelting voltage is 25-30V, and the cooling time af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com