Preparation method of component- gradient -controllable multi-element ultrahigh-temperature ceramic modified C/C composite material

A technology of ultra-high temperature ceramics and composite materials, which is applied in the field of preparation of multi-element ultra-high temperature ceramic modified C/C composite materials with controllable composition gradient, which can solve the problems of reduced mechanical properties, improve heat insulation performance, reduce inert weight, The effect of ensuring mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

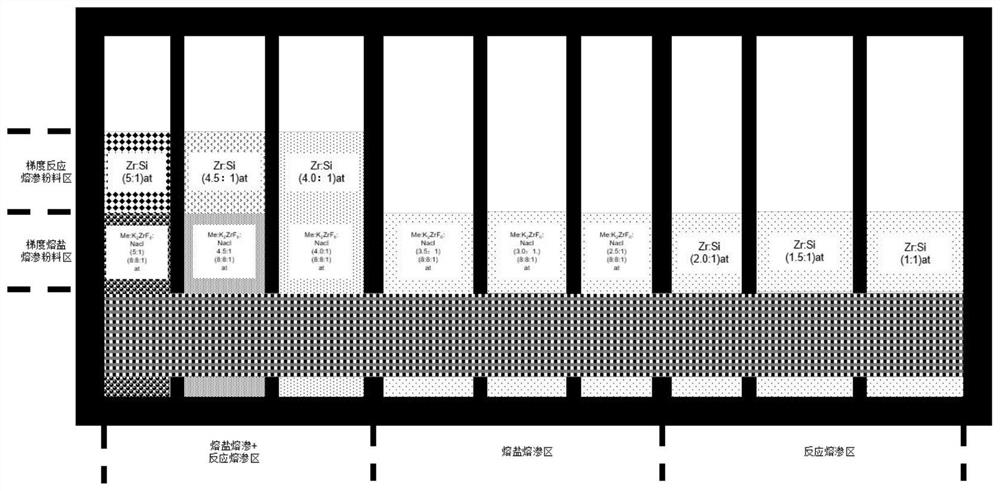

[0046] Such as figure 1 As shown, it is a schematic diagram of the placement of the graphite tank body and the powder used in this embodiment. The graphite tank body is a hollow cube, and 8 pairs of slots are sequentially opened along the length direction of the cube, and graphite plates are inserted in the slots. The graphite tank body is divided into 9 sections, from left to right, the 1st-3rd section is the front end area, the 4th-6th section is the middle end area, and the 7th-9th section is the rear end area.

[0047] (1) Add 1.2g / cm 3 The C / C composite material is polished and cleaned with absolute ethanol, and placed in an oven at 100°C for 12 hours for later use; the particle size of Zr and Si metal powders are both <200 mesh, and mixed with alcohol according to the set atomic ratio. Dry and sieve after mixing in a drum type ball mill for 12 hours for subsequent use;

[0048] (2) First, lay Zr-Si mixed common reaction infiltration powder and K 2 ZrF 6 Zr-Si mixed m...

Embodiment 2

[0053] Adopt the graphite tank body of embodiment 1 and the placement mode of powder:

[0054] (1) Add 1.2g / cm 3 After the C / C composite material is polished and polished as a whole, it is washed with absolute ethanol, and placed in an oven to dry for 12 hours at 100°C for use; the particle size of Hf and Si metal powders are both <200 mesh, and they are mixed with alcohol according to the set atomic ratio. Dry and sieve after mixing in a drum type ball mill for 12 hours for subsequent use;

[0055] (2) Firstly lay Hf-Si mixed ordinary reaction infiltration powder and K 2 ZrF 6 Hf-Si mixed molten salt infiltration powder doped with alkali metal salt, and K 2 ZrF 6 Hf-Si mixed molten salt infiltration powder doped with alkali metal salt, Hf-Si mixed ordinary reaction infiltration powder is laid on the bottom plate of the graphite tank in the 7th-9th section, and then the C / C composite material is placed on Inside the graphite tank, insert the required graphite plates on bo...

Embodiment 3

[0060] like Figure 4 As shown, it is a schematic diagram of the placement of the graphite tank body and the powder used in this embodiment. The graphite tank body is a hollow cube, and 8 pairs of slots are sequentially opened along the length direction of the cube, and graphite plates are inserted in the slots. The graphite tank body is divided into 9 sections, from left to right, the 1st-3rd section is the front end area, the 4th-6th section is the middle end area, and the 7th-9th section is the rear end area; in this embodiment, each section The amount of powder placed is the same as in Example 1. The scheme of Example 1 is a one-step molding process, while the second scheme of this example is a two-step molding process. The difference in the way of powder placement is only the K in Example 1. 2 ZrF 6 Lay together with alkali metal salt doped Zr-Si mixed molten salt infiltration powder and Me-Si mixed common reaction infiltration powder, and K in this embodiment 2 ZrF 6 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com