Steel wire rod for aluminum-containing steel fibers and used for deep drawing, and rolling method thereof

A steel wire rod, aluminum steel technology, applied in the direction of manufacturing tools, heat treatment process control, heat treatment equipment, etc., can solve the problem of describing the difficulty of mechanical peeling of iron oxide scale thickness, etc., to achieve significant economic and social benefits, mechanical properties Excellent, the effect of improving deep drawing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

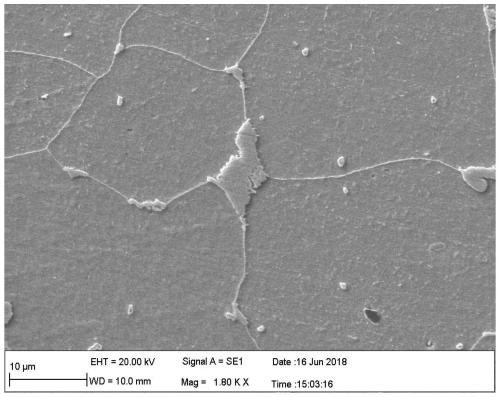

Embodiment 1

[0032] The composition of the continuous casting slab in Example 1 is: [C]: 0.045%, [Si]: 0.08%, [Mn]: 0.30%, [P]: 0.011%, [S]: 0.006%, [Al]: 0.026%, [Ti]: 0.020%, [B]: 0.0055%, [N]: 46ppm, and the rest are Fe and unavoidable impurities.

[0033] (1) The heating of the slab is divided into three sections for heating, which are heating section one, heating section two and soaking section in turn. Among them, the heating temperature of the heating section is 725-785°C; the heating temperature of the second heating section is 923-988°C; the temperature of the soaking section is 1030-1070°C, and the total heating time is 150min;

[0034] (2) High-pressure water descaling is used to remove scale, the pressure is 18MPa, the rolling start temperature is 910-970°C, and the tapping rhythm is ≥60 seconds;

[0035] (3) Strictly control the process parameters of the wire rod during the rolling process. The temperature before finishing rolling is 880-920°C, the temperature after finishing...

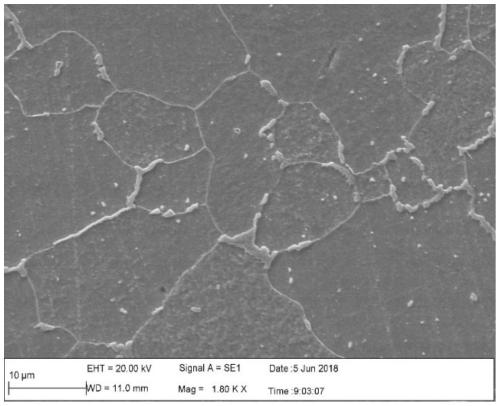

Embodiment 2

[0038] The composition of the continuous casting slab in Example 2 is: [C]: 0.052%, [Si]: 0.07%, [Mn]: 0.29%, [P]: 0.012%, [S]: 0.007%, [Al]: 0.025%, [Ti]: 0.021%, [B]: 0.0054%, [N]: 45ppm, and the rest are Fe and unavoidable impurities.

[0039] The difference between the continuous casting slab production process of Example 2 and Example 1 is that the temperature before the sizing unit is 885-915°C, the spinning temperature is 900-920°C, and the rest of the operations are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com