Patents

Literature

87results about How to "Improve plastic index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

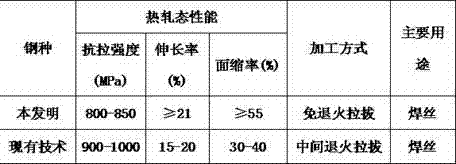

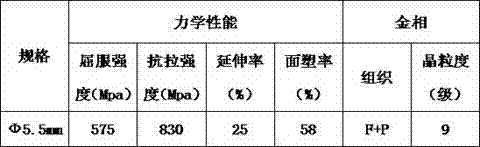

Steel wire rod for annealing-free solder wire and production process thereof

ActiveCN102513725AChemically stableImprove plastic indexWelding/cutting media/materialsSoldering mediaWire rodMechanical property

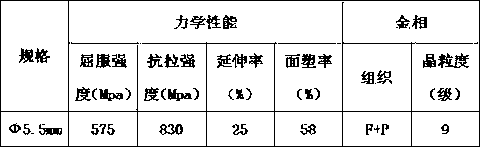

The invention belongs to the metallurgy field and relates to a production process of a steel wire rod, particularly the steel wire rod for an annealing-free solder wire and a production process of the steel wire rod, wherein the steel wire rod comprises elements in weight percentage as follows: 0.07-0.1% of C, 1.25-1.4% of Mn, 0.4-0.6% of Si, less than or equal to 0.02% of P, less than or equal to 0.02% of S, 0.2-0.55% of Mo, 0.5-1.0% of Ni, less than or equal to 0.2% of Cu, less than or equal to 0.2% of Ti and less than or equal to 0.1% of Al with the balance of Fe. The process comprises steps of detecting a blank, heating the steel blank, descaling by high-pressure water, roughly and intermediately rolling, pre-finishing rolling, cooling in a first section by water, finishing rolling bya unit, cooling in a second section by water, diameter reducing and sizing rolling, cooling in a third section by water, spinning, cooling by wind, finishing and delivering to a warehouse. The methodof the invention employs a rolling-controlled and cooling-controlled process to execute process control of the steel wire rod of the solder wire to obtain an F+P tissue appropriate to draw, and has advantages as follows: good comprehensive mechanical property is realized, a solder wire factory can avoid annealing and perform multi-pass drawing without wire breakage, the production efficiency is greatly increased and the production cost is reduced at the same time.

Owner:NANJING IRON & STEEL CO LTD

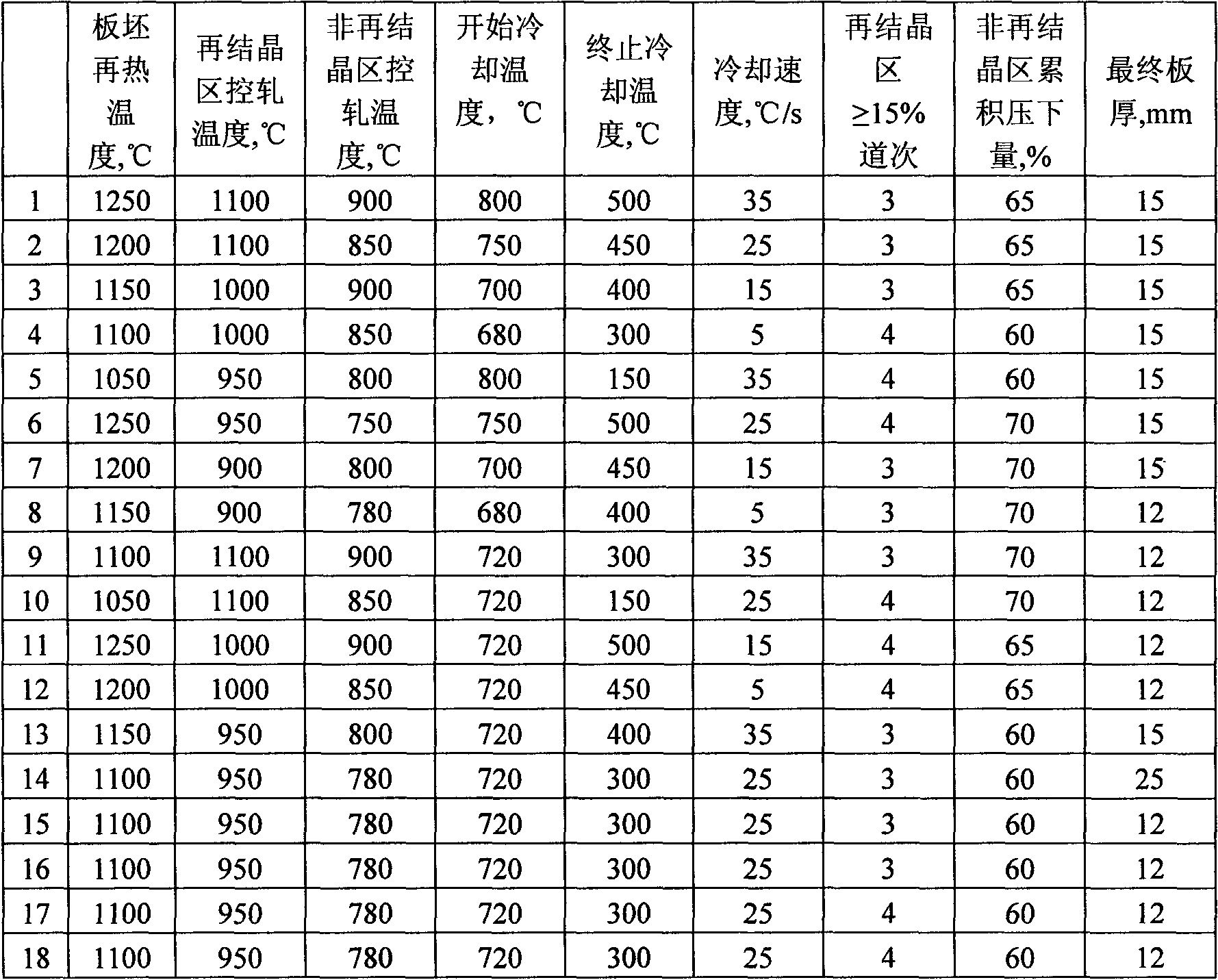

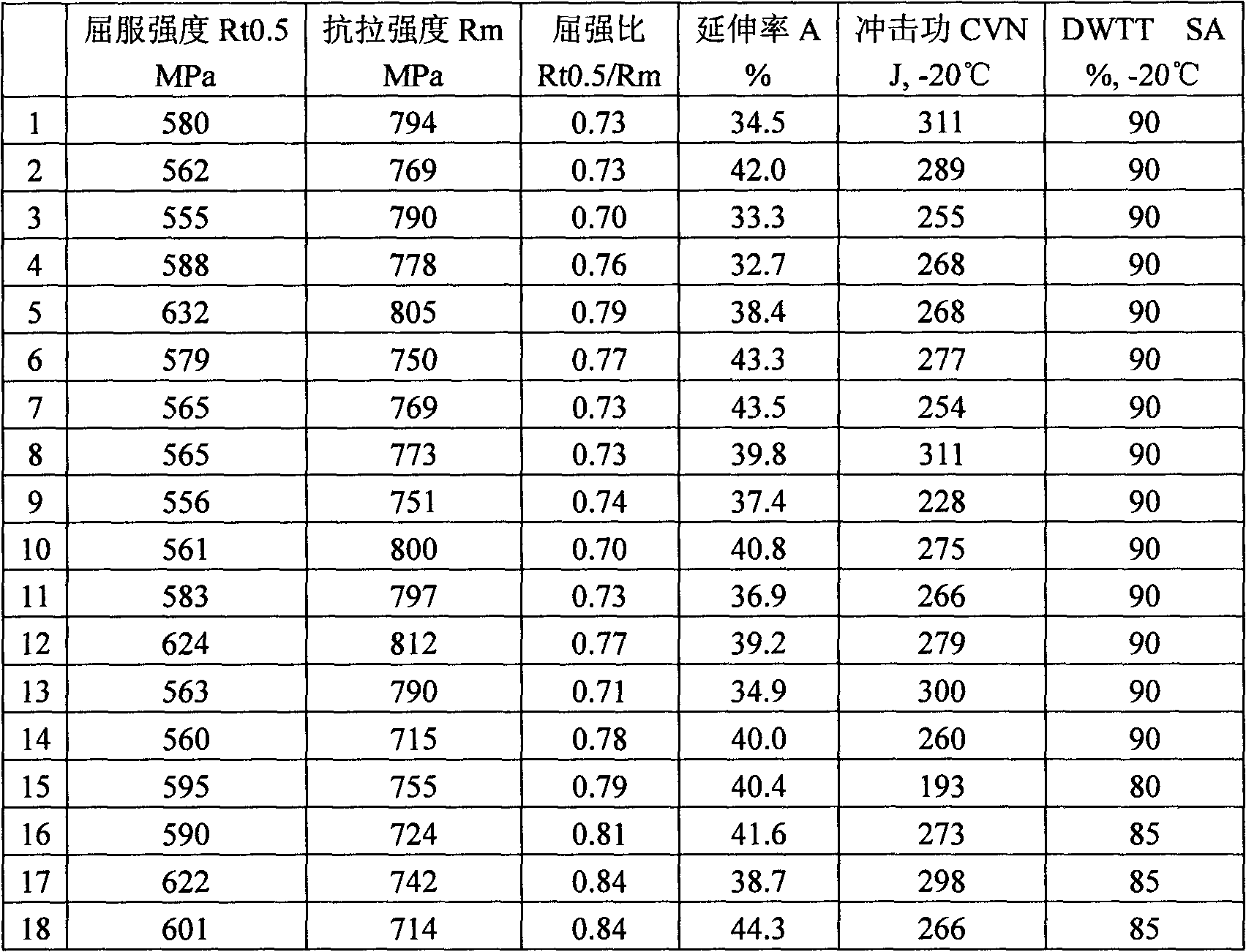

Strain design based economical pipe line steel and its manufacturing method

ActiveCN102828120AReduce manufacturing costShorten the relaxation timeTemperature control deviceSheet steelHeating temperature

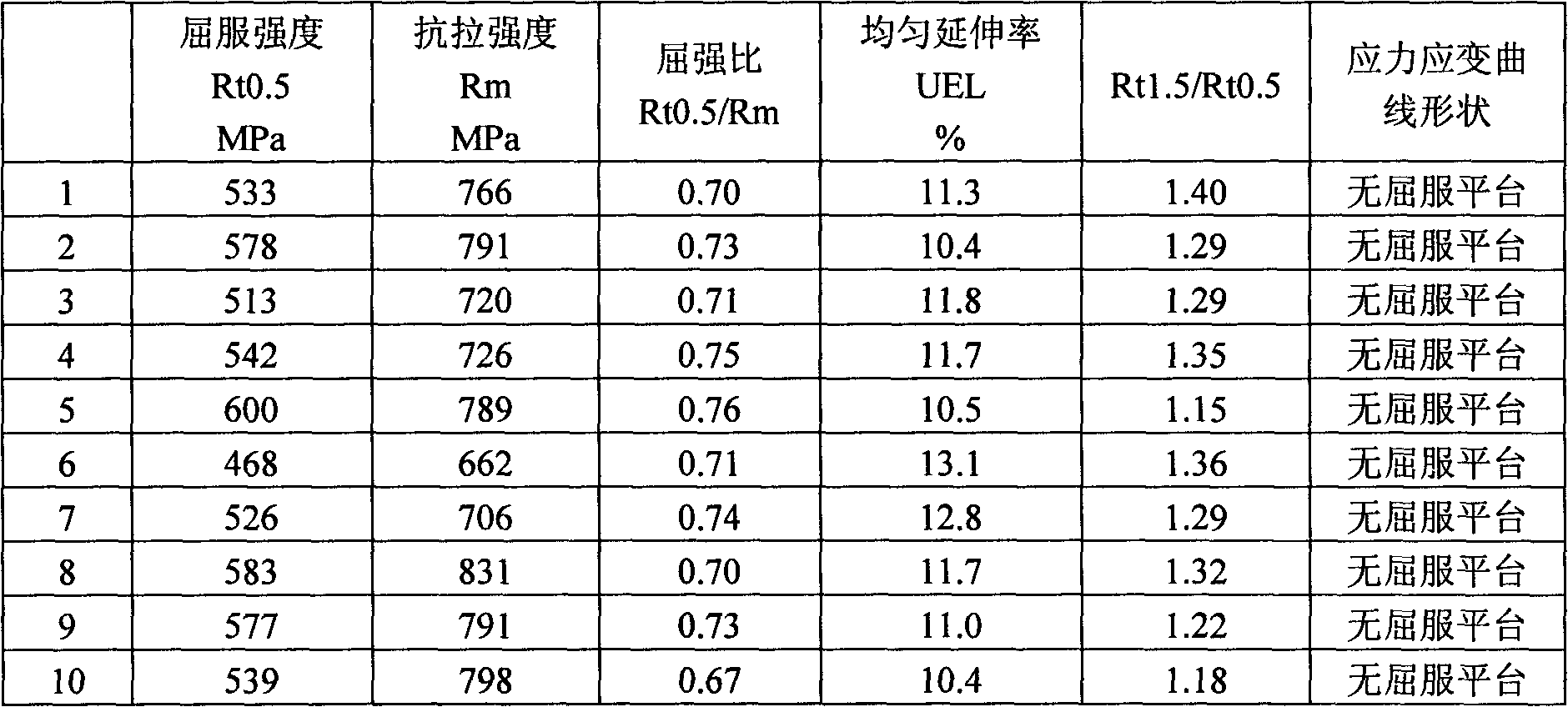

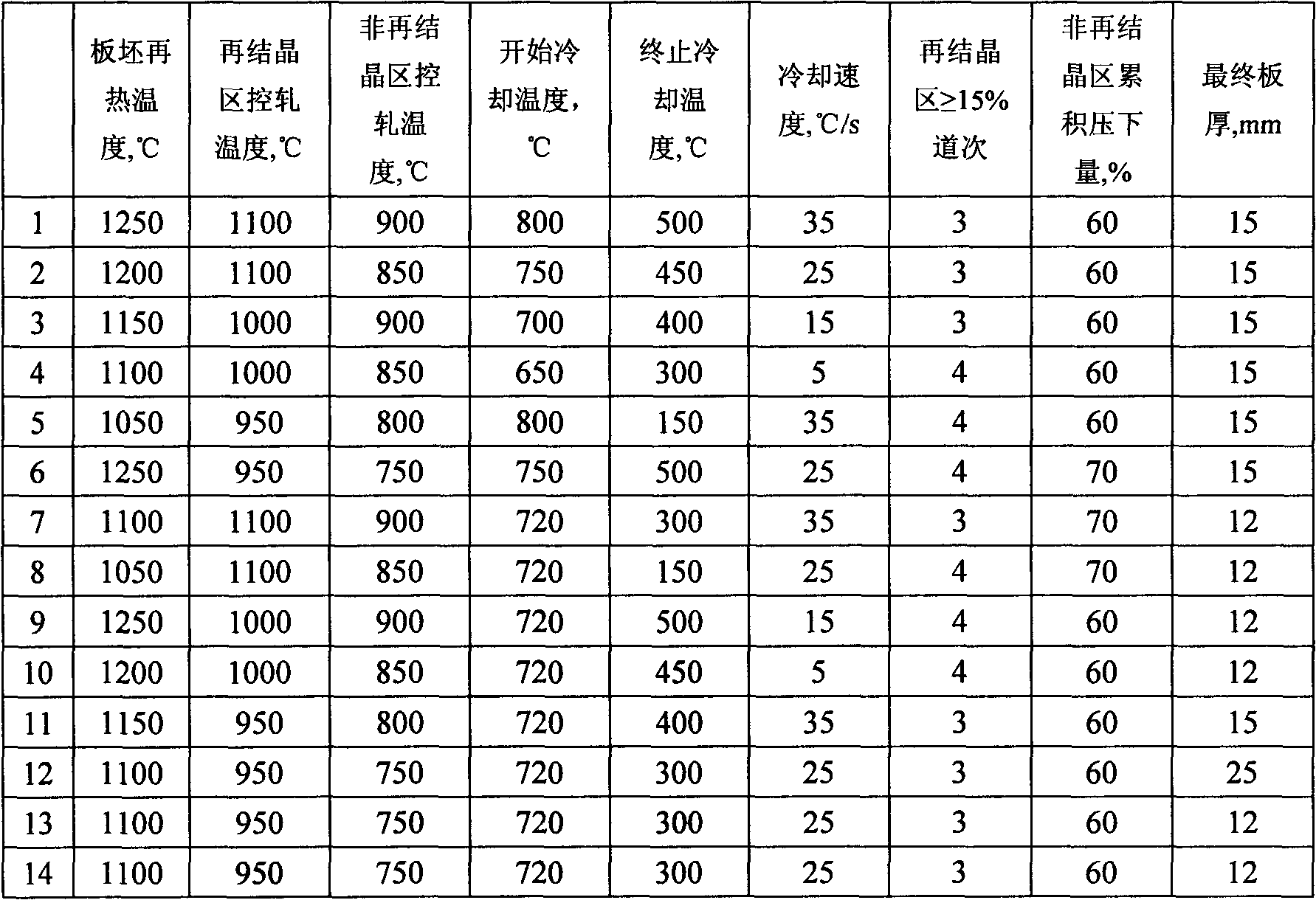

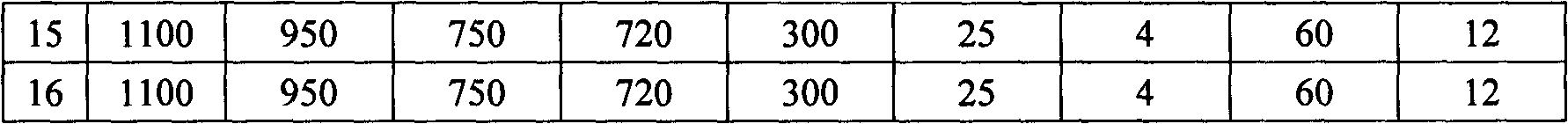

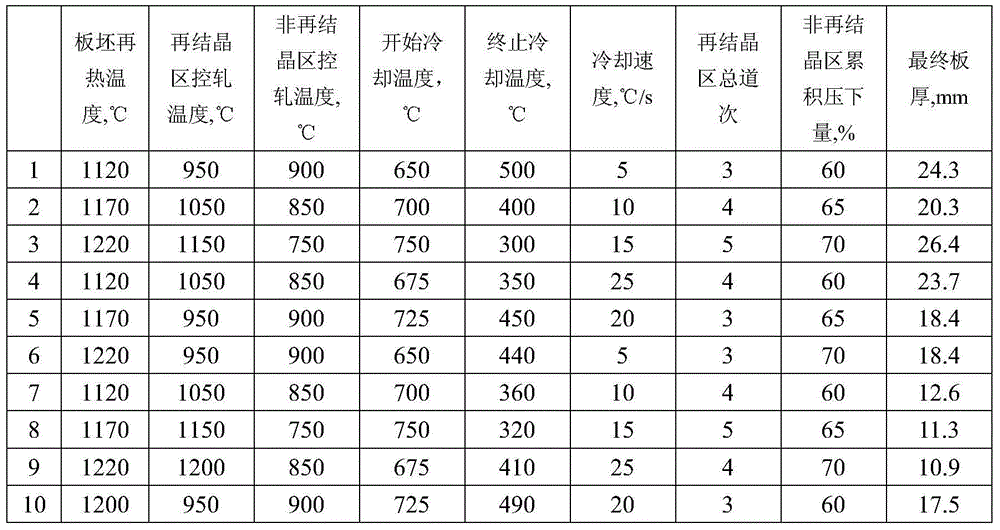

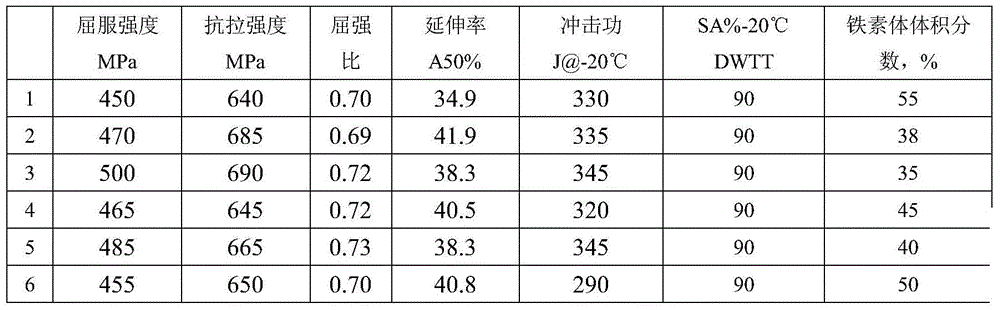

The invention provides strain design based economical pipe line steel and its manufacturing method. The steel comprises the following ingredients of: by weight, 0.06-0.10% of C, 0.1-0.6% of Si, 1.0-2.0% of Mn, P being less than or equal to 0.015%, S being less than or equal to 0.003%, 0.1-0.3% of Cr, 0.01-0.10% of Nb, 0.005-0.03% of Ti, 0.01-0.06% of Al, N being less than or equal to 0.012%, 0-0.5% of Cu, 0-0.5% of Ni and the balance being Fe. The method provided by the invention comprises steps of smelting, secondary refining, casting and hot rolling, and is characterized in that slab heating temperature is 1050-1280 DEG C; controlled rolling temperature in a recrystallization zone is 900-1250 DEG C; controlled rolling temperature in a non-recrystallization zone is 750-950 DEG C; initial cooling temperature is 680-800 DEG C; finish cooling temperature is 100-500 DEG C; and cooling rate is 5-35 DEG C / s. According to the invention, elements of Mo, V, B and the like are not added, and the total amount of Cu, Cr and Ni is low. In addition, subsequent heat treatment is not required, the process is simple and requires low cost, and production efficiency is high. The steel plate not only has high strength but also has low yield ratio and high uniform extension features. By the adoption of the steel, safety of pipeline operation and economy of pipeline construction can be greatly raised.

Owner:ANGANG STEEL CO LTD

Strain design based pipe line steel X70 and its manufacturing method

ActiveCN102828125AExtend evenlyProper extensionTemperature control deviceImpurityHeating temperature

The invention discloses strain design based pipe line steel X70 and its manufacturing method. the steel comprises the following ingredients of: by weight, 0.06-0.10% of C, 0.1-0.6% of Si, 1.0-2.5% of Mn, P being less than or equal to 0.015%, S being less than or equal to 0.003%, Cr being less than 0.1%, 0.05-0.35% of Mo, 0.01-0.15% of Nb, 0.005-0.03% of Ti, 0.01-0.06% of Al, one or two components selected from 0-0.5% of Cu and 0-0.5% of Ni, and the balance Fe and unavoidable microscale impurities. The manufacturing method is characterized in that slab heating temperature is 1050-1280 DEG C by a controlled rolling and controlled cooling method; the temperature for controlled rolling in a recrystallization zone is controlled within the range of 900-1250 DEG C; the temperature for controlled rolling in a non-recrystallization zone is controlled within the range of 700-950 DEG C; initial cooling temperature is 650-800 DEG C; finish cooling temperature is 100-500 DEG C; and cooling rate is 5-35 DEG C / s. According to the invention, elements of V, B and the like are not added, and the total amount of Mo, Cu, Cr and Ni is low. In addition, subsequent heat treatment is not required, the process is simple and requires low cost, and production efficiency is high.

Owner:ANGANG STEEL CO LTD

Spring steel wire rod with cryogenic drawing performance, spring steel wire, spring and manufacturing method thereof

ActiveCN111041372AImprove mechanical propertiesReduce depthProcess efficiency improvementWire rodTempering

The embodiment of the invention provides a spring steel wire rod with cryogenic drawing performance, a spring steel wire, a spring and a manufacturing method thereof, and relates to the field of wirerods. The spring steel wire rod with cryogenic drawing performance comprises the following chemical components in percentage by mass: 0.32%-0.40% of Si and 0.016%-0.030% of Als. The manufacturing method of the spring steel wire comprises the steps that the spring steel wire rod is directly subjected to cold drawing, and the maximum reduction rate of drawing reaches 95%; the drawn steel wire is subjected to low-temperature stress relief annealing treatment, the percentage reduction of area is greater than or equal to 35% and the bending fatigue life is greater than or equal to 20 times. The low-alloy spring steel wire rod with good comprehensive mechanical properties is developed, the wire rod can be directly cold-drawn to produce a thin spring steel wire with large deformation without intermediate annealing, the cold-drawn steel wire can be directly wound into the spring without oil quenching and tempering treatment, the requirement for bending fatigue resistance of the steel wire canalso be met and the production cost is greatly reduced.

Owner:SGIS SONGSHAN CO LTD

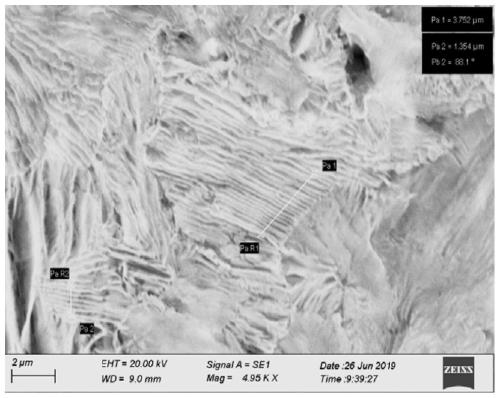

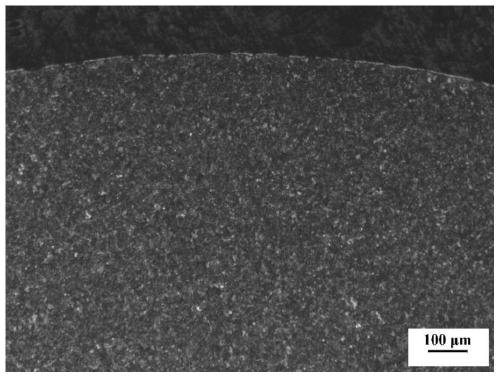

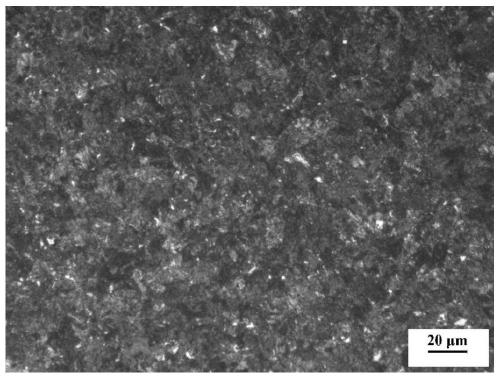

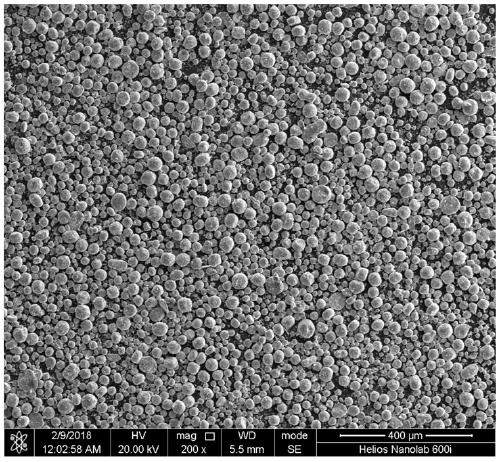

Method for preparing titanium-based nano composite material based on selective laser melting 3D printing

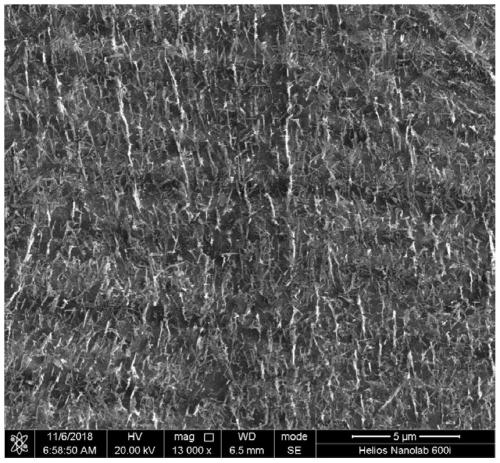

InactiveCN109943786ALight in massHigh thermodynamic stabilityAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingTitanium matrix composites

The invention discloses a method for preparing a titanium-based nano composite material based on selective laser melting 3D printing, relates to a method for preparing the titanium-based nano composite material, and aims at solving the problem of poor cutting processing performance of titanium and the titanium-based composite material. The method comprises the steps that preparation is conducted,wherein composite powder is prepared through ball milling, and the content of B4C powder in the composite powder is (0.5-1) wt%; selective laser melting 3D printing is utilized for shaping. The methodhas the advantages that the mass of the prepared composite material is light, the thermodynamic stability is high, the strength is high, the wearing resistance is high, fixture tools or molds are notneeded in the shaping process, 'near net shape forming' is easily achieved, the composite material can be massively prepared in a short time, and sources of raw materials are wide; substrate crystalline grains of the prepared composite material are significantly fined, in-site generated complete nano scale TiB whiskers are diffusely distributed on boarders of substrate crystalline grains, an obvious enhancing effect on the composite material is achieved, the mechanical performance is significantly improved, and the method is suitable for preparing the titanium-based nano composite material through 3D printing.

Owner:HARBIN INST OF TECH

Magnesium alloy with warm extrusion property and preparation method of magnesium alloy extrusion material

ActiveCN102433479AImprove plastic indexAlleviate the problem of high peak extrusion forceMetallic materialsIngot

The invention belongs to the technical fields of metal materials and metallurgy and particularly relates to a magnesium alloy with warm extrusion property and a preparation method of a magnesium alloy extrusion material. The magnesium alloy is an Mg-Zn-Cu (or Mg-Zn-Ni) magnesium alloy and comprises the following components by weight percent: 3.0%-6.0% of Zn, 1.5%-5.0% of Cu or Ni, 0-1.0% of Y, Nd, Gd, Ce or MM and the balance Mg. The preparation method of the magnesium alloy extrusion material comprises the following steps: preparing magnesium alloy ingots by adopting a low-frequency electromagnetic oil lubricating semicontinuous casting method; performing warm extrusion to the Mg-Zn-Cu (or Mg-Zn-Ni) magnesium alloy ingots at 160-240 DEG C by using an indirect extrusion device, wherein the extrusion ratio is 8-20 and the extrusion speed is 4.5-8m / min; and thus obtaining Mg-Zn-Cu (or Mg-Zn-Ni) magnesium alloy extrusion bars. After the Mg-Zn-Cu (or Mg-Zn-Ni) magnesium alloy extrusion bars are subjected to T4 or T6 heat treatment, the elongation rate is 20%-35%.

Owner:中天时代镁业有限公司

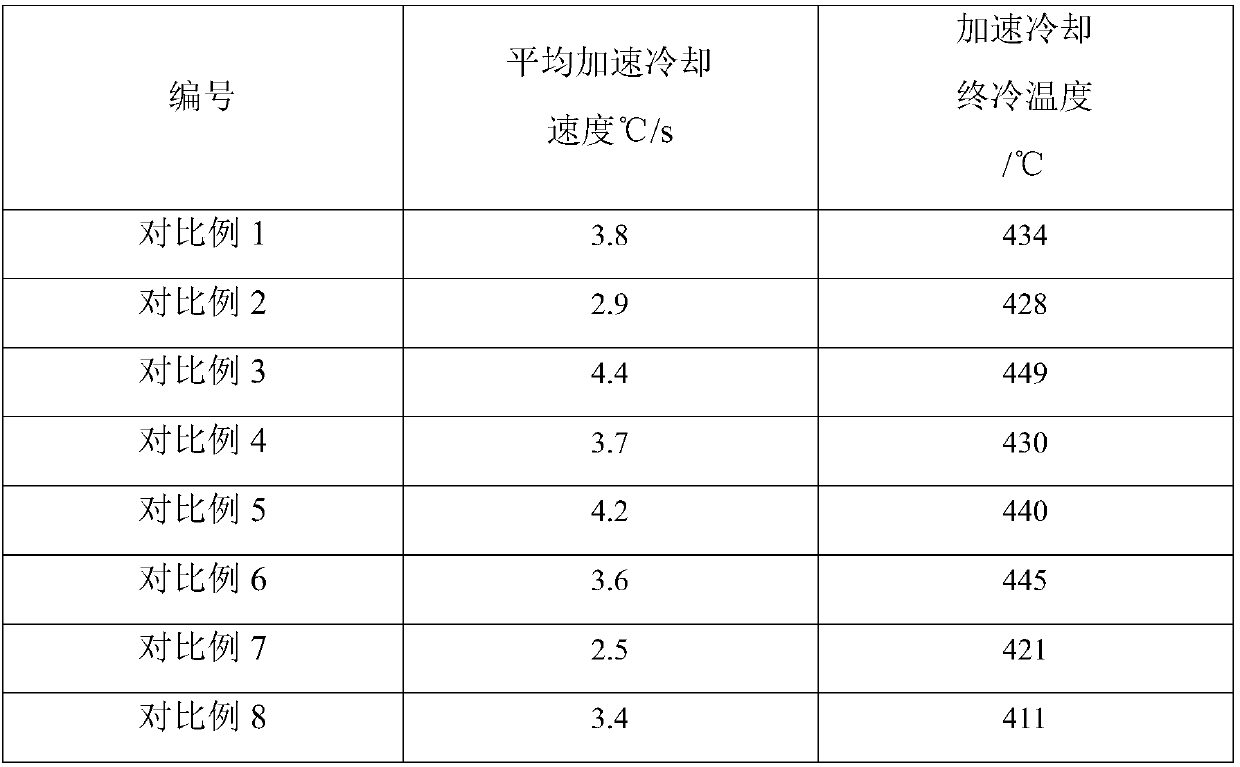

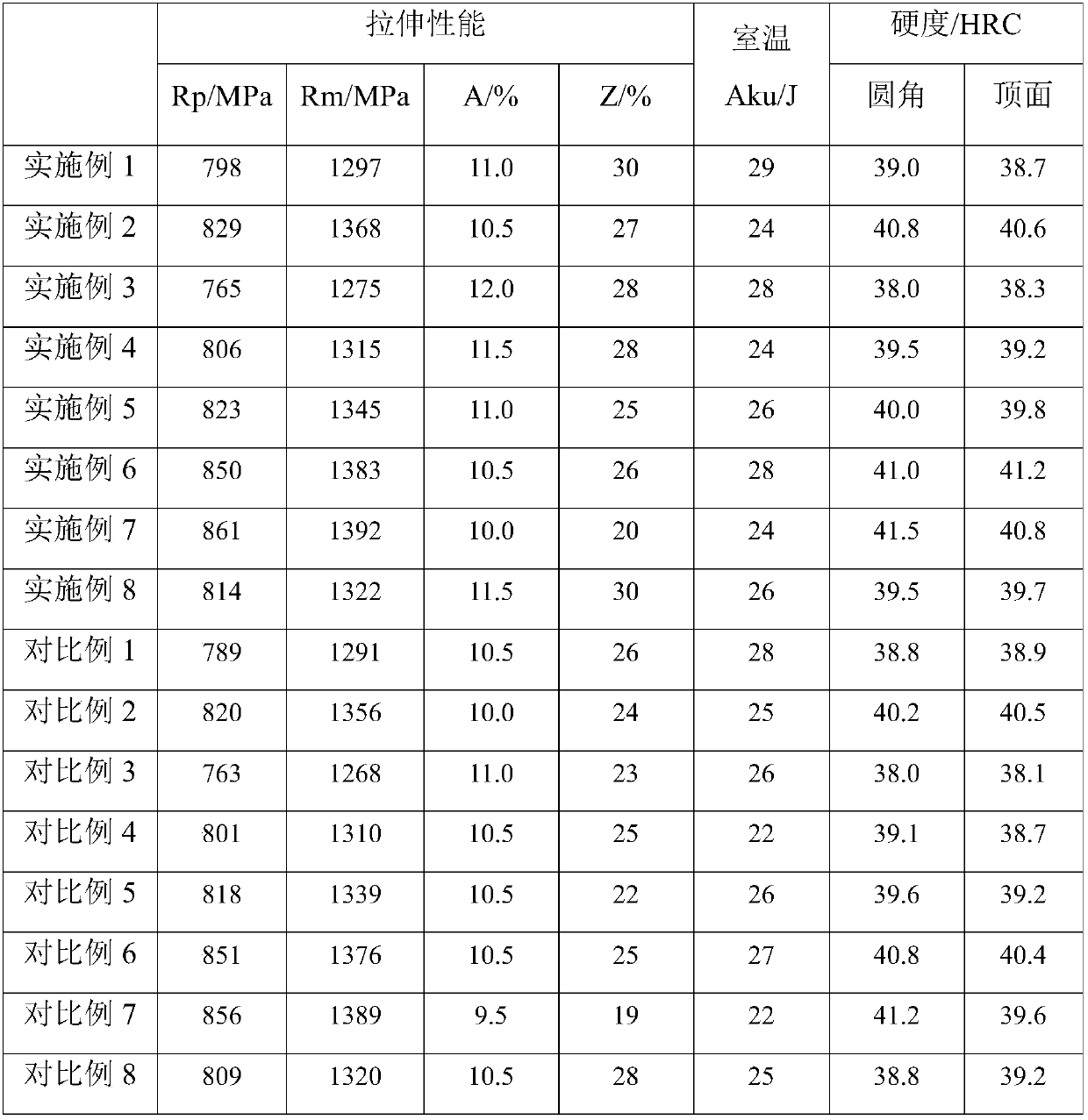

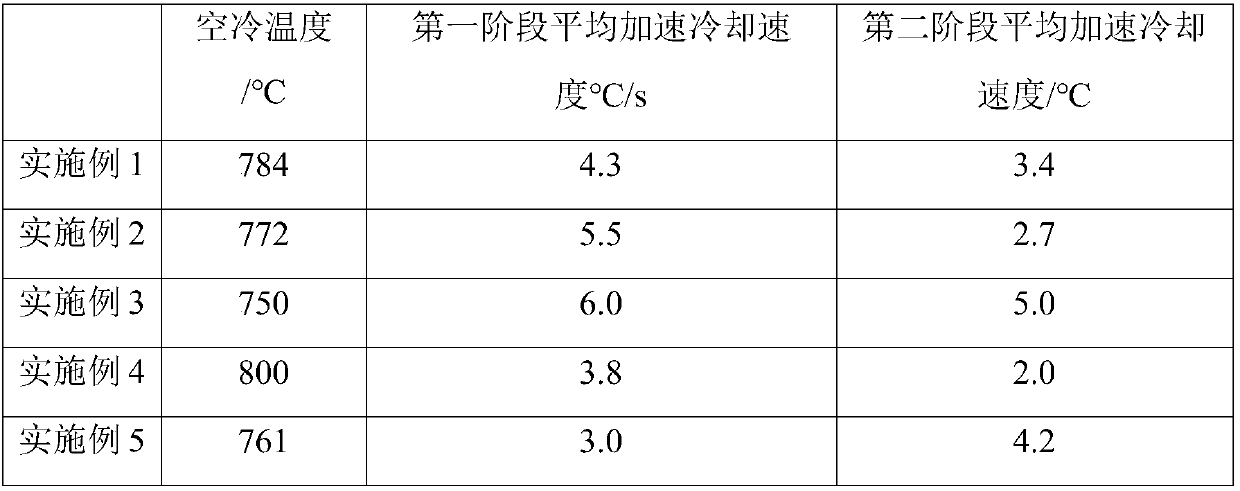

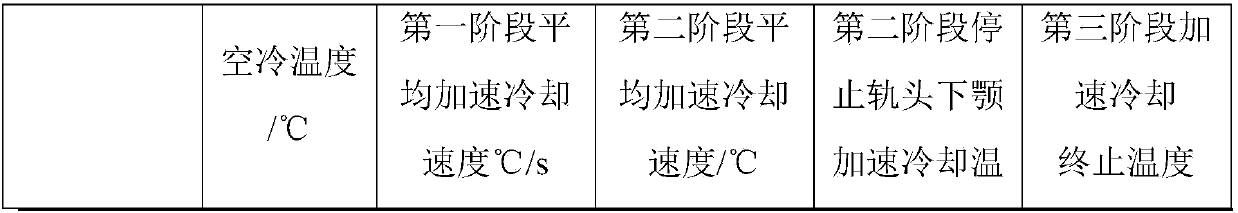

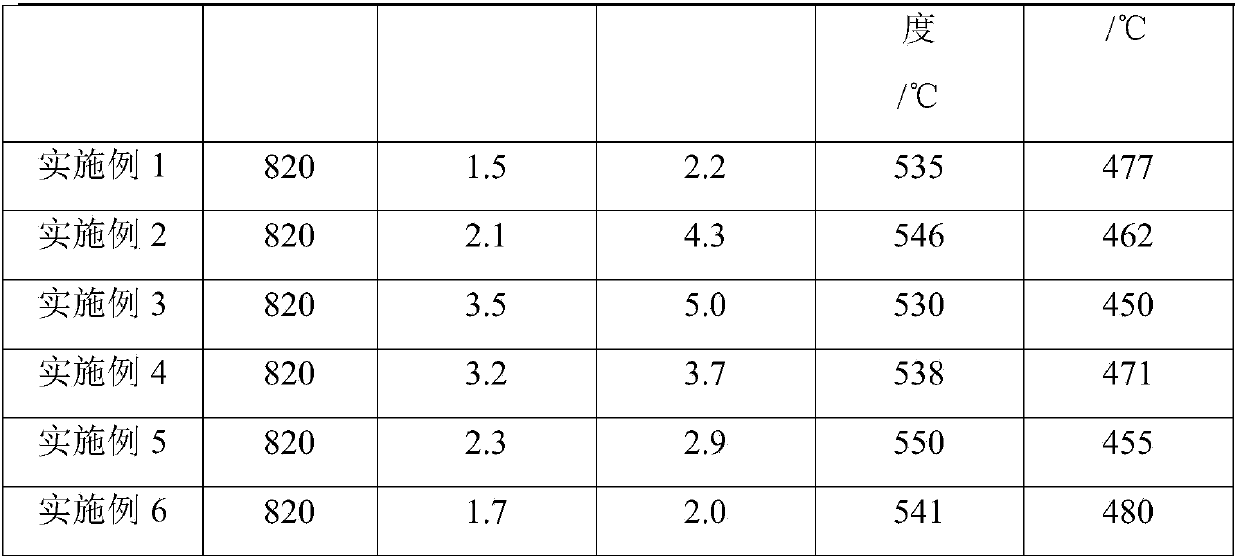

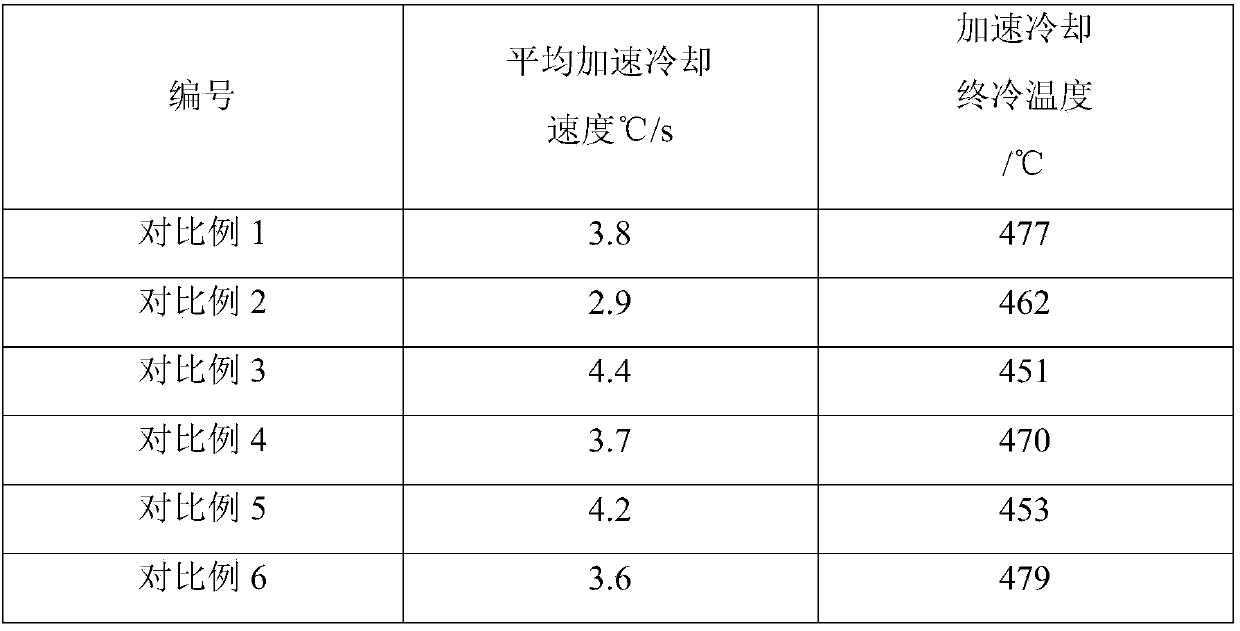

High-carbon high-strength tough pearlitic steel rail and production method thereof

ActiveCN107675084AExtended service lifeHigh strengthTemperature control deviceFurnace typesManufacturing technologyHigh carbon

The invention belongs to the technical field of production of steel rails and particularly relates to a high-carbon high-strength tough pearlitic steel rail and a production method thereof. In order to solve the problems of non-uniform section performance and low performance of the pearlitic steel rail produced by the prior art, the invention provides a production method of a high-carbon high-strength tough pearlitic steel rail. The method comprises the following steps: a, hot rolling a steel billet into a steel rail, wherein the final rolling temperature is 900-1000 DEG C; and b, spraying cooling media to the top surface of the rail head, two sides of the rail head and low jaws of the two sides of the rail head when the temperature of the center of the top surface of the steel rail is cooled to 800-850 DEG C through air, cooling till the temperature of the center of the top surface is 480-530 DEG C, and cooling through air to the room temperature. Through manners of controlling the steel components and carrying out two-stage accelerated cooling, the high-carbon steel rail with higher strength and high toughness can be produced; the produced steel rail is applied to heavy haul railways.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

High-strength steel plate for ocean engineering and production method thereof

InactiveCN105586537APlay a role in diffusion strengtheningImprove low temperature toughnessQuenchingMechanical property

The invention discloses a high-strength steel plate for ocean engineering and a production method thereof. The production method comprises the working procedures of smelting, continuous casting, heating, rolling, heat stacking and heat treatment, wherein the molten steel obtained in the smelting procedure comprises the following chemical ingredients with contents in percentage by mass: 0.05-0.09% of C, 0.10-0.30% of Si, 1.1-1.35% of Mn, not greater than 0.010% of P, not greater than 0.003% of S, 0.15-0.4% of Ni, 0.15-0.35% of Cr, 0.10-0.30% of Mo, 0.020-0.050% of Nb, 0.03-0.05% of V, 0.020-0.050% of TAl, and balance Fe and inevitable impurities; a quenching and tempering process is adopted in the heat treatment procedure; during the quenching process, a heating temperature is 880-910 DEG C, and a total heating time is PLC +(20-40) minutes; and during the tempering process, a heating temperature is 580-620 DEG C, a total heating time is 1.5-2 minutes per millimetre, and air cooling is carried out after discharge. According to the method disclosed by the invention, through adjustment and optimization for the proportion of alloy elements in the steel plate, and quenching and low-temperature short-time tempering, good mechanical properties of the steel plate can be guaranteed under a low-carbon-equivalent condition, and the steel plate is enabled to have good structure, comprehensive property and welding property.

Owner:WUYANG IRON & STEEL

High strength tough pearlite steel rail and manufacturing method thereof

ActiveCN107475616AExtended service lifeHigh strengthFurnace typesHeat treatment furnacesSurface layerRoom temperature

The invention belongs to the technical field of steel rail manufacturing and in particular relates to a high strength tough pearlite steel rail and a manufacturing method thereof. In order to solve the problem that the obtained pearlite steel rail is poor in performance as the fracture surface performance of a railhead of the pearlite steel rail in the prior art is not uniform, the invention provides the manufacturing method of the high strength tough pearlite steel rail. The manufacturing method comprises the following steps of: a, performing hot rolling on a steel blank to a steel rail, wherein the finishing temperature is 900-1000 DEG C; b, spraying a cooling medium to the top surface of the railhead and two side faces of the railhead by means of finishing waste heat when the central temperature of the top surface of the steel rail is air-cooled to 800 DEG C and performing cooling till the central temperature of the top surface of the steel rail is 750 DEG C; and c, spraying the cooling medium to the top surface of the railhead, two side faces of the railhead and lower jaws of two sides of the railhead, and performing air-cooling to room temperature after the temperature of the surface layer of the railhead is smaller than or equal to 450 DEG C. By way of control of the components of steel and accelerated cooling in two sections, steel which is more excellent in performance is prepared. The method provided by the invention is simple to operate, not high in equipment demand and suitable for being popularized and used.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

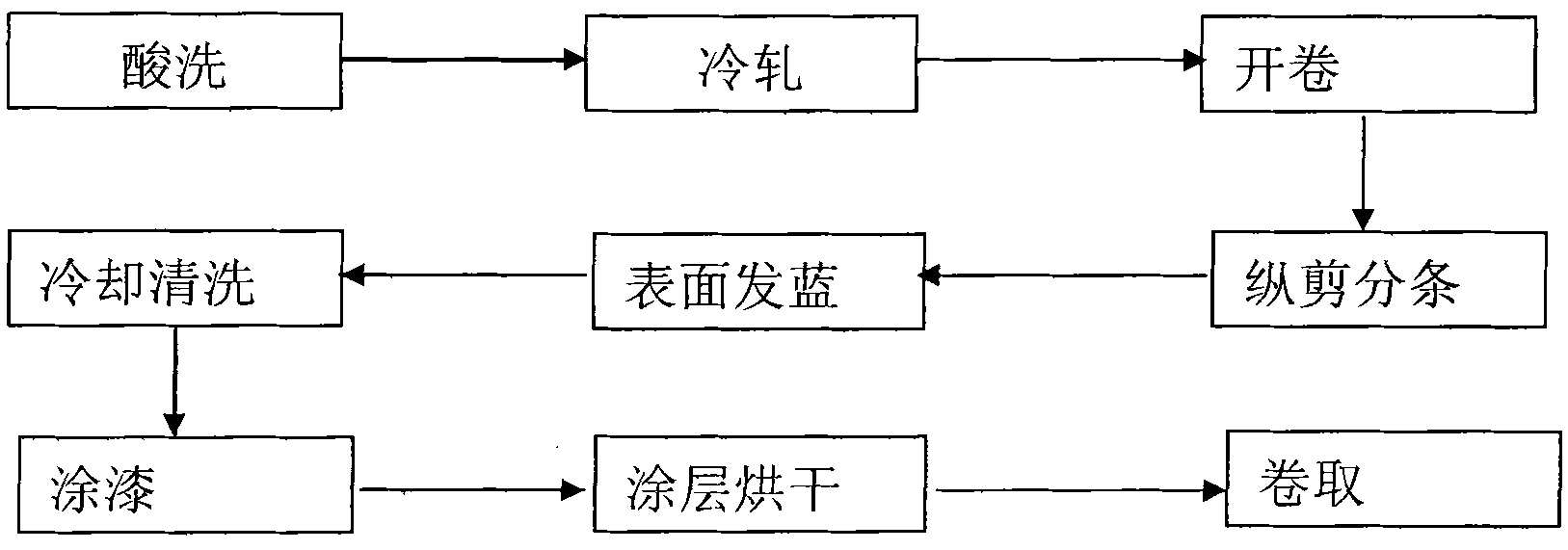

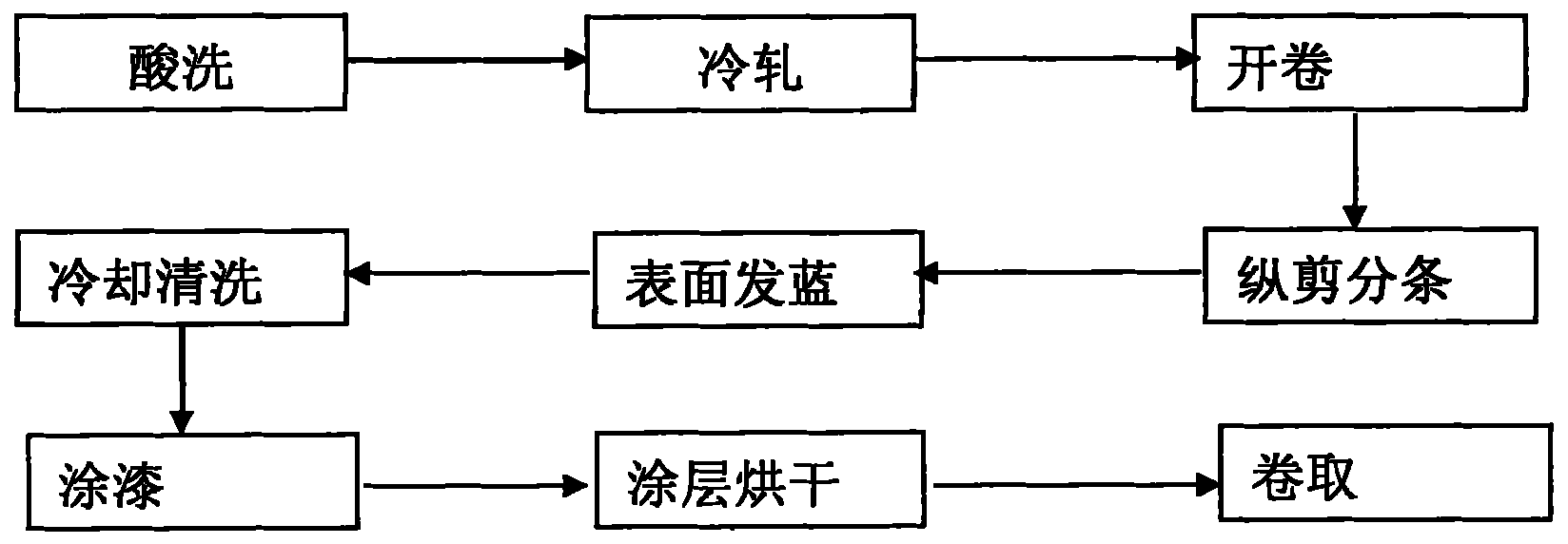

Medium-strength packaging steel strip and production method thereof

ActiveCN101886217ALow plastic indexReduce manufacturing costLiquid surface applicatorsSolid state diffusion coatingSteel beltCoating

The invention relates to a steel strip, in particular to a medium-strength packaging steel strip and a production method thereof. The medium-strength packaging steel strip comprises the following components in percentage by weight: 0.05 to 0.10 percent of C, 0.10 to 0.15 percent of Si, 1.00 to 1.55 percent of Mn, less than or equal to 0.05 percent of P, less than or equal to 0.050 percent of S and the balance of Fe. The production method of the medium-strength packaging steel strip comprises the following steps: a) cold-rolled roll unrolling; b) steel strip longitudinal cutting and stripping; c) surface blueing; d) cooling and washing; e) painting; f), drying coatings; and g) rolling. The medium-strength packaging steel strip solves the technical problem that the packaging steel strip produced by using a cold-rolled roll with a carbon content of less than 0.10 percent has a tensile strength which cannot be kept over 800MPa stably and a breakage elongation of more than 6 percent.

Owner:上海宝钢新材料技术有限公司

Warming forging precision forming manufacture process for steering bearing ring of motorcycle

InactiveCN104139151AAvoid violent oxidationImprove plastic indexEngine componentsWater basedSpray coating

The invention discloses a manufacture process for a blank of a steering bearing ring of a motorcycle. A warm forging precision forming method is adopted and comprises the following steps of cutting and blanking a hot-rolled unannealed GCr15 cylindrical rodlike blank, heating the blank to the temperature of 200DEG C, soaking in a compound water-based graphite lubricant, taking out, heating the blank to the temperature of 750DEG C through medium frequency induction heating, and upsetting the blank in a high speed upsetter, so that the blank in the same specification can be processed into bearing rings in different size specifications; putting the upset blank into a die forging machine for warm forging, spray-coating the compound water-based graphite lubricant into a die cavity of a warm forging die, and preheating at the temperature of 200DEG C; performing spherodizing annealing on a forge piece formed through warm forging, so that the hardness is reduced and preparation for the subsequent finishing is carried out. The formed blank is not required to be cut or is only required to be subjected to a small amount of cutting to meet the requirement of a product, materials are greatly saved, forming procedures are simple, the efficiency is high and the cost is low; a metal flow line of a material is not cut off, and the comprehensive mechanical properties are improved through forging and extrusion.

Owner:CHINA UNIV OF MINING & TECH

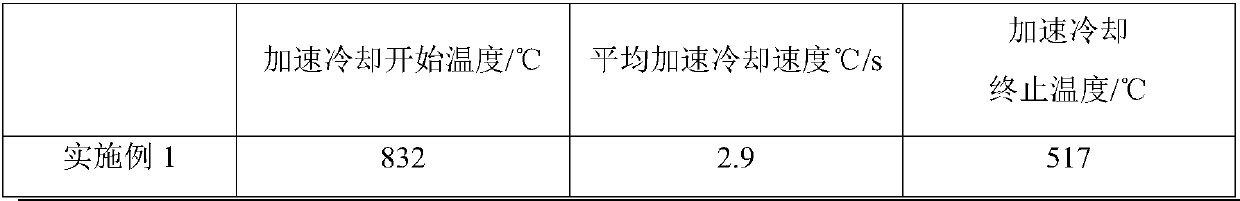

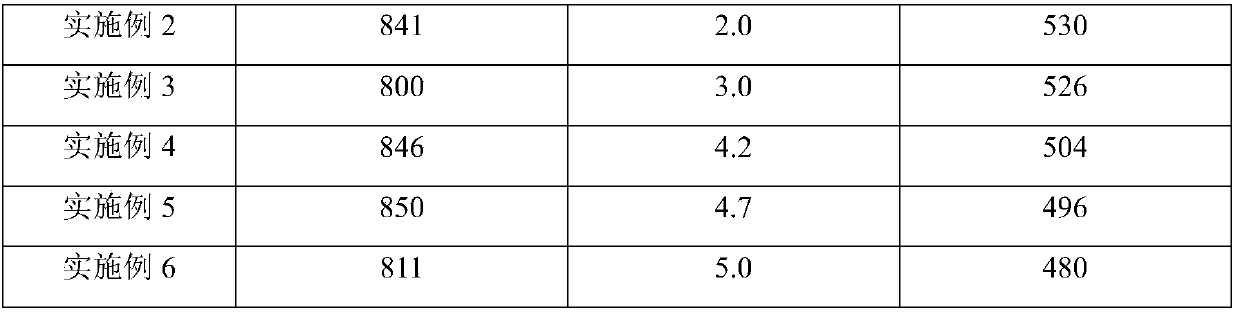

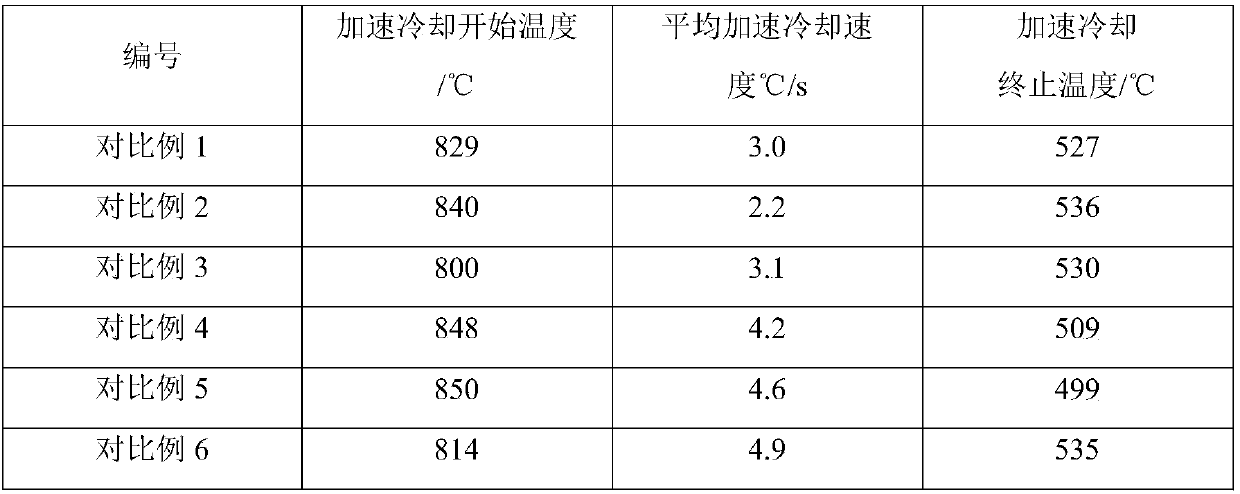

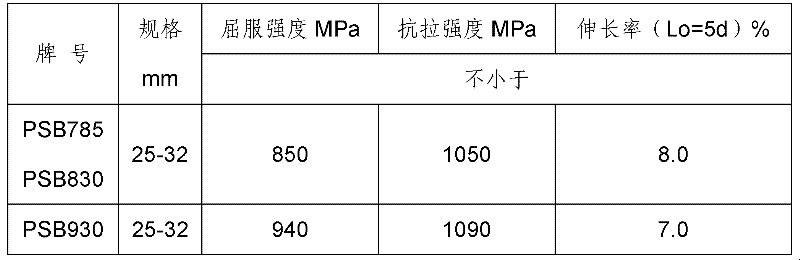

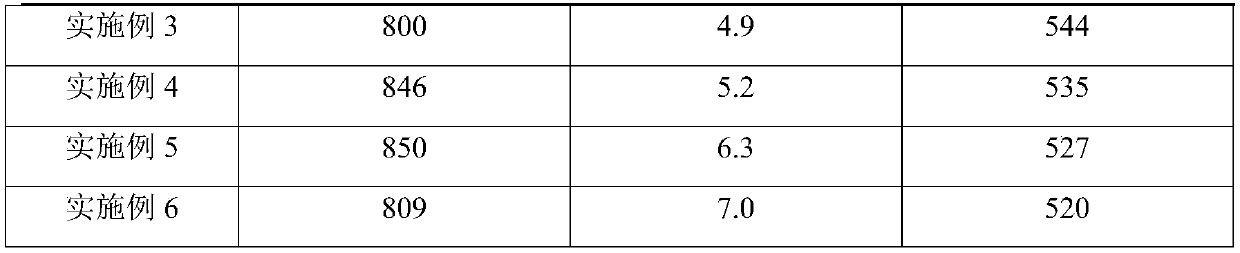

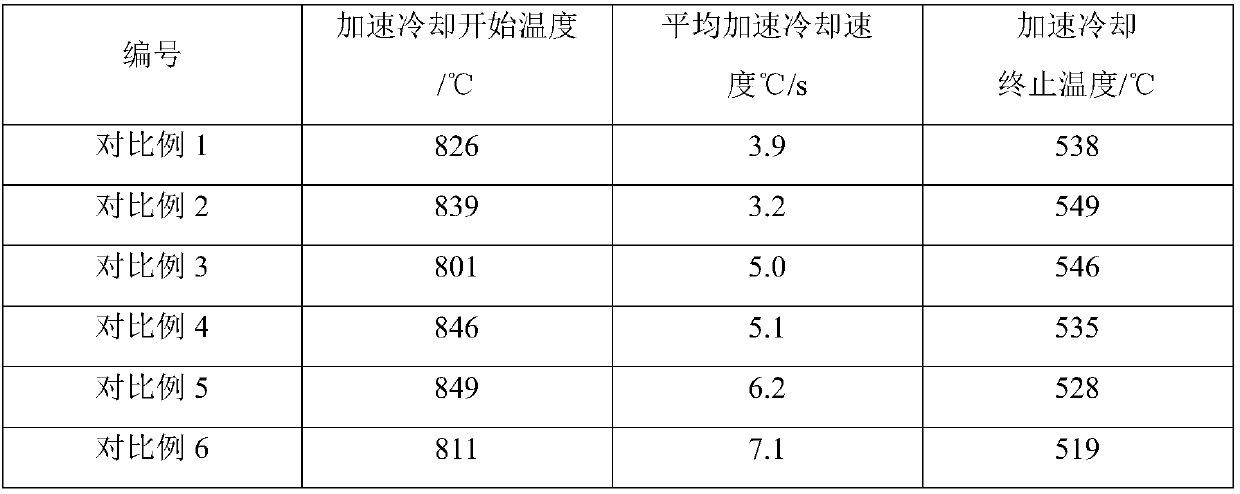

Production technology of finish-rolled ribbed bars

ActiveCN102363832AShort process flowReduce manufacturing costHeat treatment process controlCarbon steelRebar

The invention belongs to the technical field of ferrous metallurgy technology, and especially provides a production technology of finish-rolled ribbed bars. The technological line provided by the invention comprises steps of billet heating, rolling, on-line controlled cooling, cold bed natural cooling, scaling, and stack cooling. Medium-carbon steel is adopted in square billets with a dimension of 150mm*150mm. A three-stage heating method comprising preheating, heating, and soaking is adopted in the heating process. An initial rolling temperature is controlled at 1000 DEG C to 1100 DEG C in the rolling process. In the on-ling controlled cooling process, the temperature is controlled at 920 to 1000 DEG C when the billets are delivered into a water tank; a one-step cooling method is adopted; self-tempering temperatures of PSB785 and PSB830 are controlled at 480 to 550 DEG C; and a self-tempering temperature of PSB930 is controlled at 430 to 480 DEG C. The cooling speed is controlled at 1-5 DEG C / s in the cold bed natural cooling process. Off-line stack cooling under a temperature of 150 to 350 DEG C is carried out in the stack cooling process, wherein a stack cooling time is lower than 48 hours. Various properties of the finish-rolled ribbed bars provided by the invention can completely satisfy the requirements of users.

Owner:TIANJIN IRON & STEEL GRP

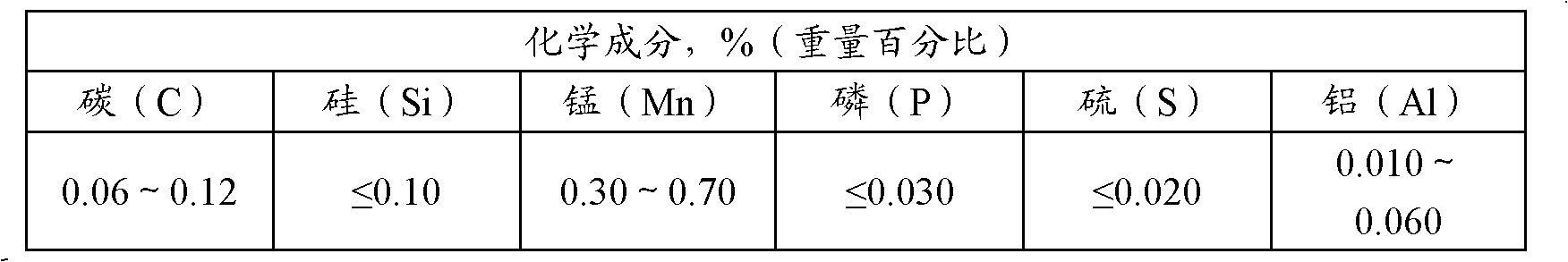

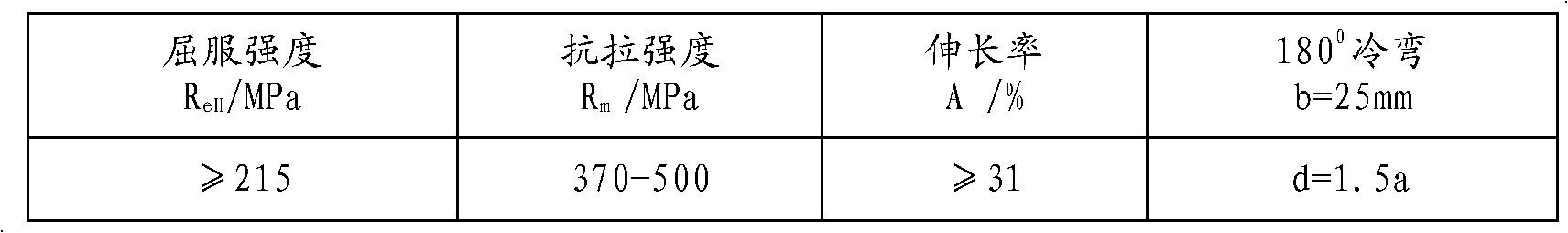

Hot-rolled steel for automobile wheel rim and its production process

The invention provides hot rolled steel for a vehicle wheel steel ring, which comprises the following chemical components in percent by weight: 0.06-0.12 percent of C, not more than 0.10 percent of Si, 0.30-0.70 percent of Mn, not more than 0.030 percent of P, not more than 0.020 percent of S and 0.010-0.060 percent of Al. A production process of the hot rolled steel comprises the steps of: LF (Low Frequency) external refining on molten steel meeting the requirement of the chemical components and being obtained through smelting, slab continuous casting, heating of a step type heating furnace, continuous casting of a 2032mm hot continuous casting unit, laminar flow cooling, coiling, checking, storing and delivering. The hot rolled steel for the vehicle wheel steel ring is suitable for cold machining forming, and meets the demands on the cold machining forming.

Owner:LIUZHOU IRON & STEEL

Internal-damage-resistant pearlite steel rail and manufacturing method thereof

ActiveCN107723594AExtended service lifeHigh strengthTemperature control deviceFurnace typesManufacturing technologyRoom temperature

The invention belongs to the technical field of steel rail manufacturing and particularly relates to an internal-damage-resistant pearlite steel rail and a manufacturing method thereof. For the problems that the performance of an on-line heat treatment pearlitic steel rail head prepared in the prior art is low in uniformity and poor in internal-damage-resistant performance. The invention providesthe manufacturing method of the internal-damage-resistant pearlitic steel rail. The manufacturing method comprises the following steps: a, conducting hot rolling on a steel billet to form a steel rail; b, when the center temperature of the top surface of the steel rail is air-cooled to 750-800 DEG C, utilizing final rolling waste heat to cool both sides of the rail head until the center temperature of the top surface is 700 DEG C; c, cooling the top surface of the rail head, the two side surfaces of the rail head and the lower jaws of the two sides of the rail head until the temperature of thesurface layer of the rail head is 520 -550 DEG C, then cooling the top surface of the rail head and the two sides of the rail head until the temperature is 400 -450 DEG C, and carrying out air cooling to the room temperature. The steel with better performance is prepared by controlling steel components and three-section accelerated cooling mode. The internal-damage-resistant pearlite steel rail and the manufacturing method are suitable for a large-transport-capacity railway with high requirements on the anti-fatigue performance of the steel rail.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

Lead-free easily cut and deformed SnZnBi aluminum alloy

The invention discloses a lead-free easily cut and deformed SnZnBi aluminum alloy. The alloy consists of the following components in percentage by weight: 8 to 12 percent of aluminum (Al), 0.8 to 1.5 percent of copper (Cu), 0.05 to 0.2 percent of bismuth (Bi), 0.05 to 0.15 percent of stannum (Sn) and the balance of Zn and inevitable impurities, wherein the content of the impurities is less than or equal to 0.05 percent. The alloy of the invention has excellent cutting property, good mechanical property and good machining and molding property, is easy to realize extrusion molding, can be prepared into rods and wires, and is particularly suitable for the machining and production fields having relatively high requirements on cutting, machining and molding; the raw materials are cheap and readily available; and the alloy contains no lead, is environment-friendly, is the lead-free easily cut and deformed SnZnBi aluminum alloy capable of substituting lead brass and has good application prospect.

Owner:CENT SOUTH UNIV

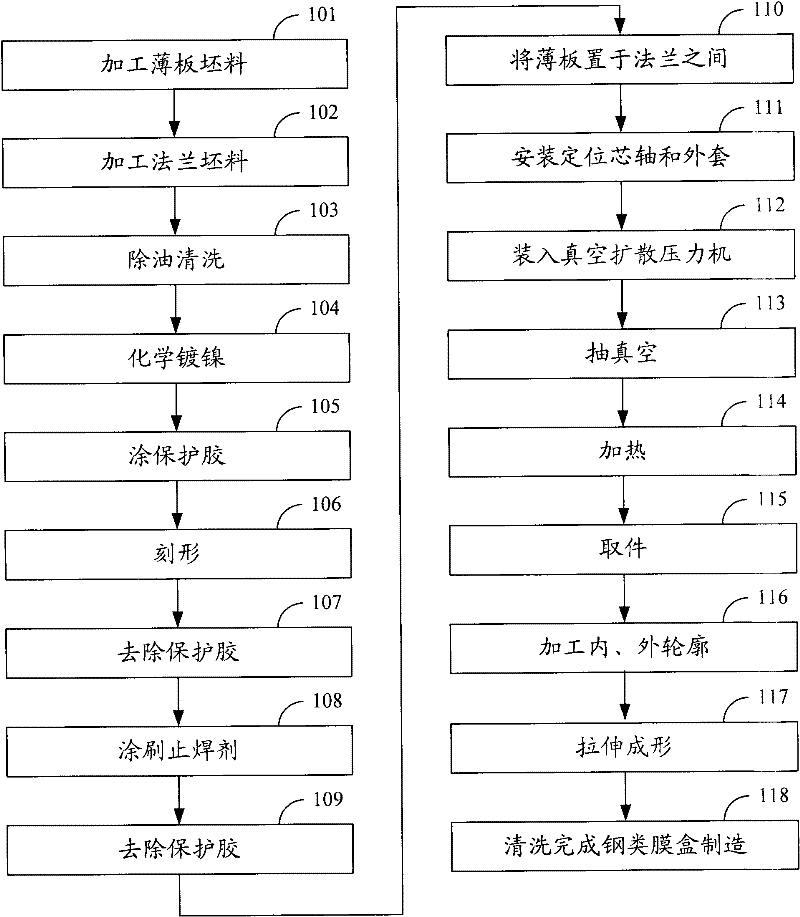

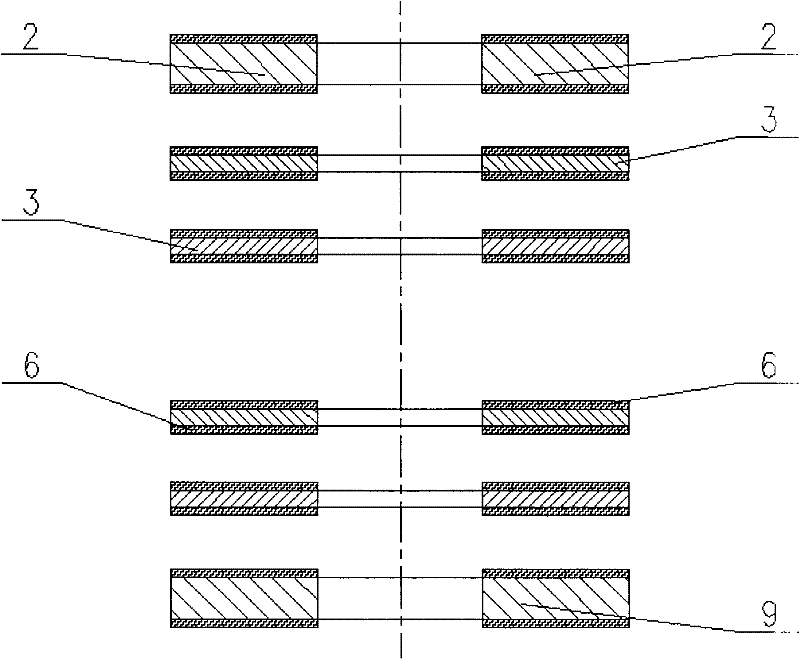

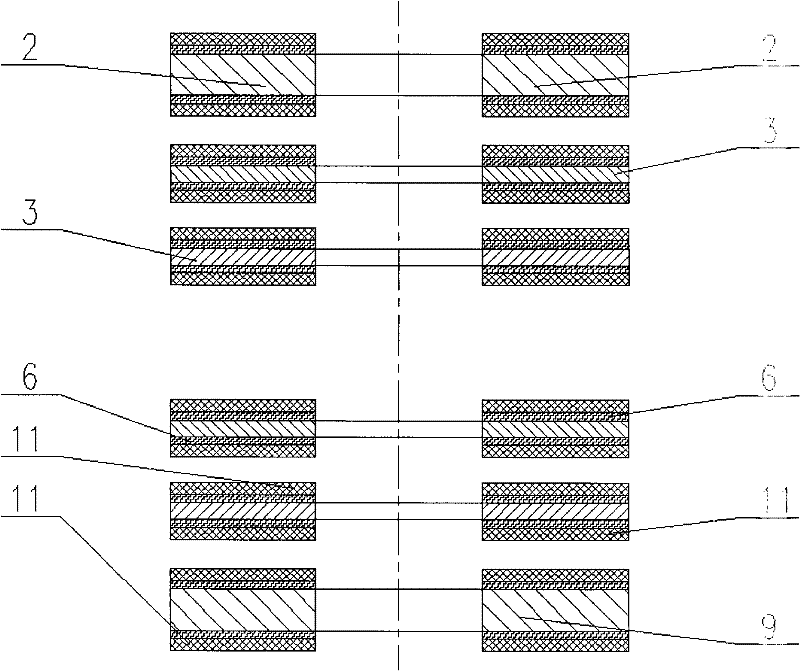

Diffusion welding method and weldment

InactiveCN102441732AHigh elongationImprove plastic indexNon-electric welding apparatusThrust chamberEngineering

The invention relates to the technical field of press welding in mechanical engineering, in particular to a diffusion welding method and a weldment, which are used for solving the problem of high temperature required by diffusion welding in the prior art, providing a novel solution for researching and developing regenerative cooling body parts of space rockets, missile engine diaphragm capsules and rocket thrust chambers, prolonging the fatigue life of the regenerative cooling body parts of the engine diaphragm capsules and the thrust chambers, and enhancing the strength and reliability of the regenerative cooling body parts. The surface of the weldment is plated with a nickel coating which contains nickel and phosphorus. The diffusion welding method provided by the invention comprises the following steps of: tightly jointing the nickel coatings on the surfaces of two weldments; and performing diffusion welding on the two jointed weldments. In the scheme, the nickel coatings containing nickel and phosphorus are added, so that the temperature needed by diffusion welding is lowered.

Owner:北京智创联合科技股份有限公司

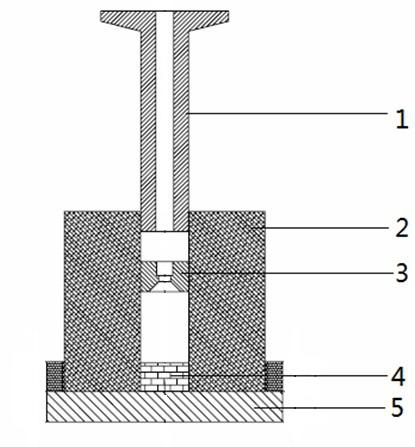

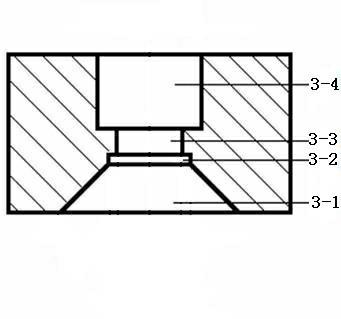

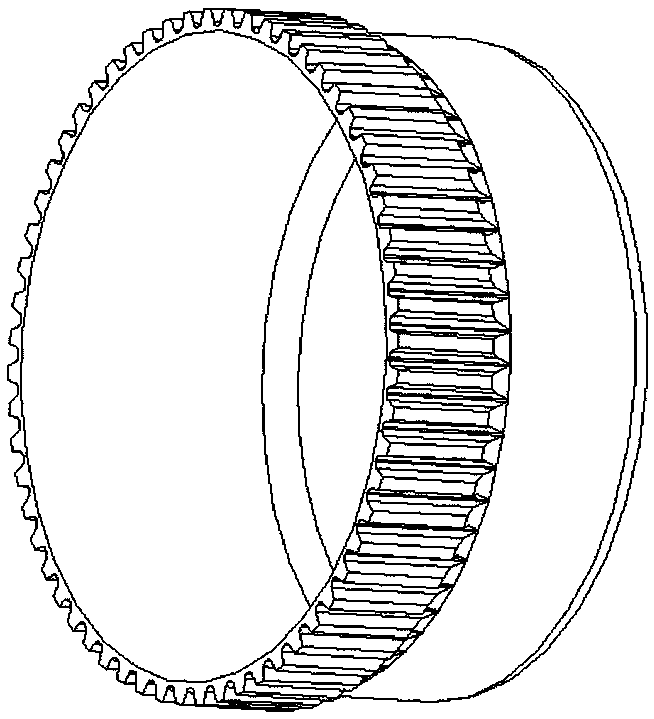

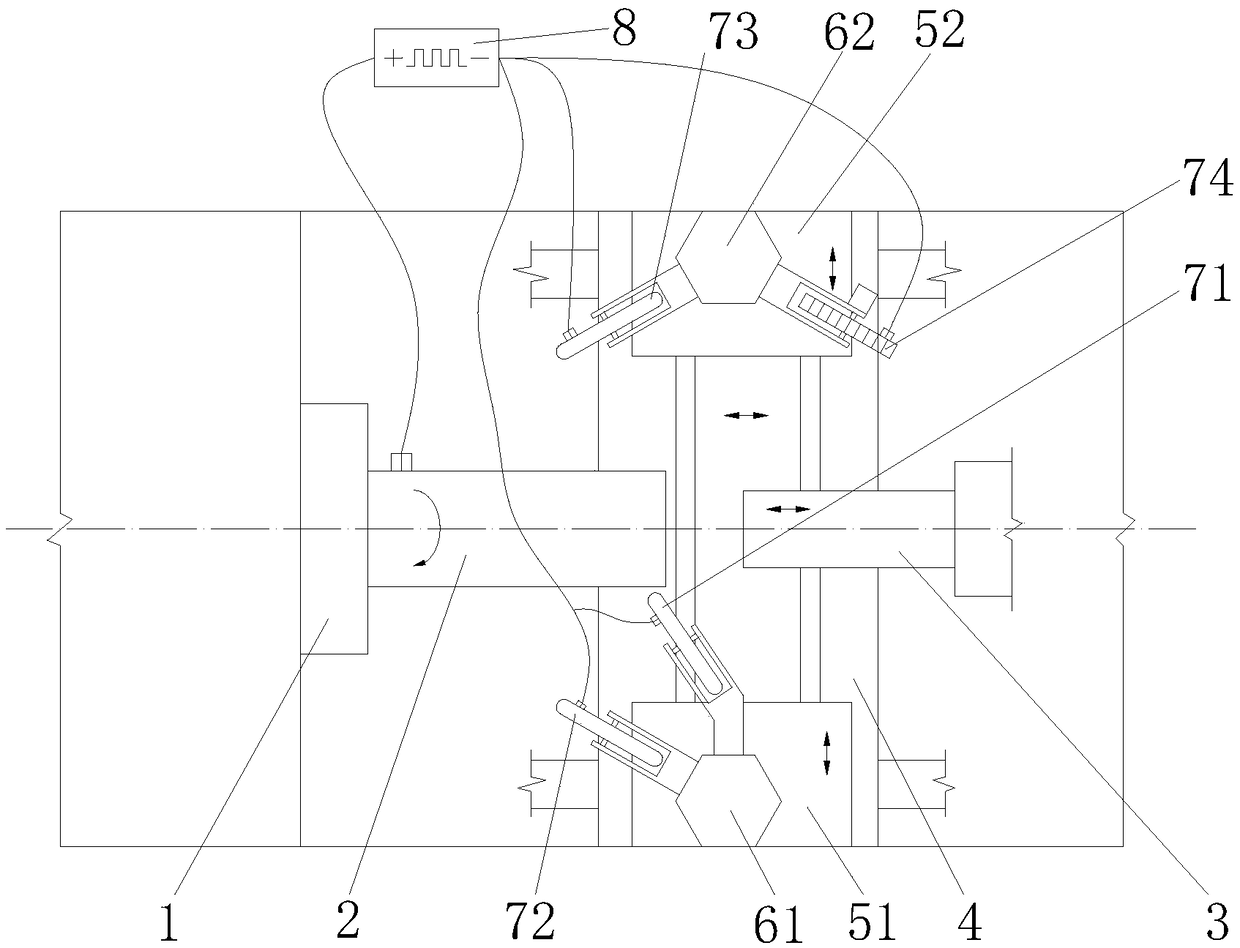

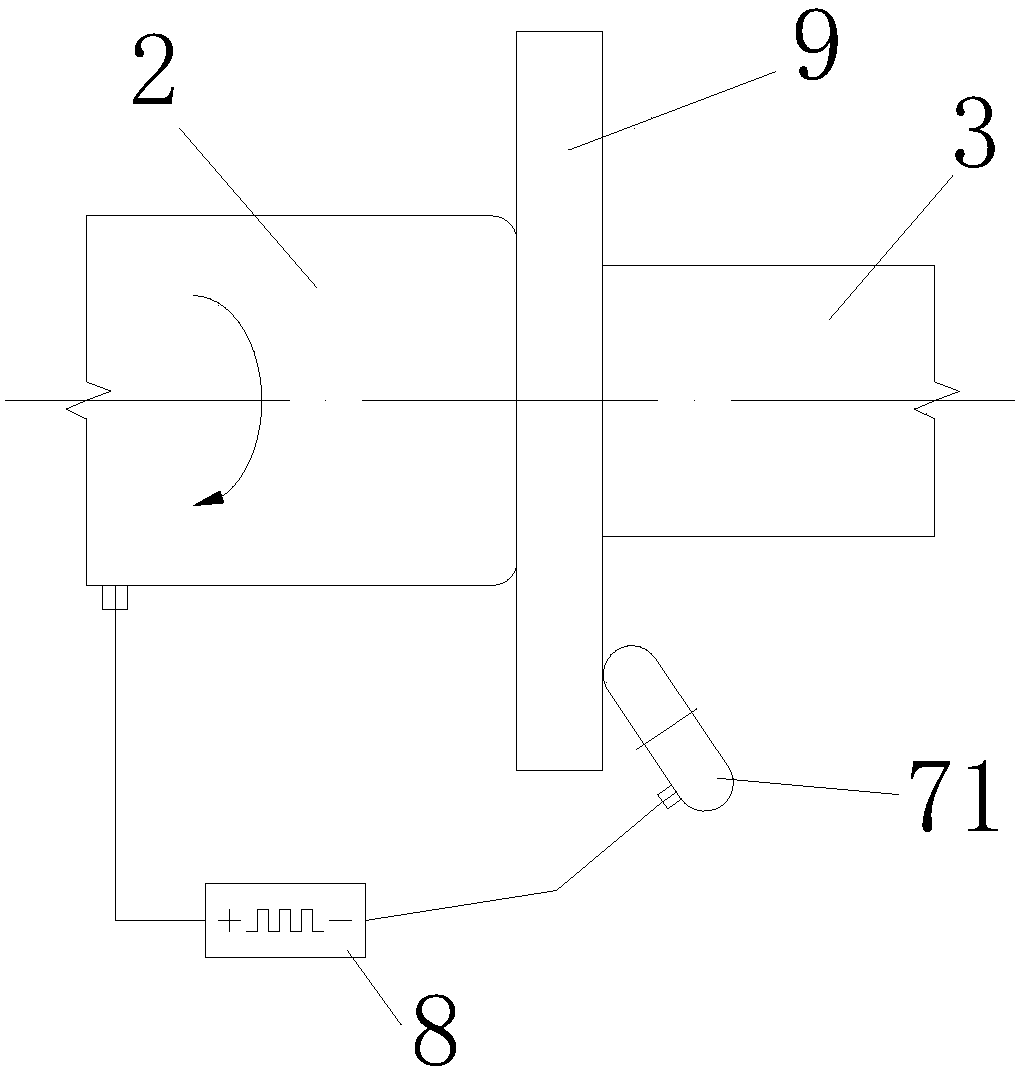

Preparation method of cup-shaped flexible wheel and device thereof

ActiveCN109351836AReduce intensityReduced fatigue lifeShaping toolsEngineeringMechanical engineering

The invention discloses a preparation method of a cup-shaped flexible wheel and a device thereof. A circular slab is tightened at the end of a core die by a tail top. A positive wire of a pulse powersupply is connected with the core die, and a negative wire is directly connected with each rotary wheel of a rotary wheel assembly. The circular slab is first spun and deformed into a cup-shaped workpiece with both inner and outer walls being straight walls by one rotary wheel. Then the cup-shaped workpiece is spun and deformed into two thickened cup-shaped workpieces with different straight wallthickness by another two rotary wheels, and a thicker smooth section is used as a tooth profile reserved section. Finally, the tooth profile reserved section is spun by one toothed rotary wheel to form a circle tooth profile around the outer circumference. At last, a small amount of cutting process is carried out to complete the processing process from the circular slab to the cup-shaped flexiblewheel workpiece. According to the cup - shaped flexible wheel manufacturing process based on plastic forming, streamline formed in the process of deformation can be completely retained, and the service life of parts is prolonged advantageously. The advantage of the method is more obvious for flexible wheels with an extremely small thickness.

Owner:SOUTH CHINA UNIV OF TECH

Method for manufacturing blade forging of heavy type combustion engine

InactiveCN101062515AImprove plastic indexMetal-working apparatusFurnace typesCombustionTreatment system

The forging for heavy combustion vane uses ze pi 479 steel, with technical conditions being C 0.12%-0.18%, Cr 15%-16.5%, Ni 2.0%-2.5%, Mo 0.9%-1.3%, N 0.03%-0.10%. The final forging temperature is controlled within 1040deg.C-1160deg.C, with deformation ratio bigger than 25%. It determines the deformation temperature and heat treatment system to meet the production requirement for heavy combustion steel vanes.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

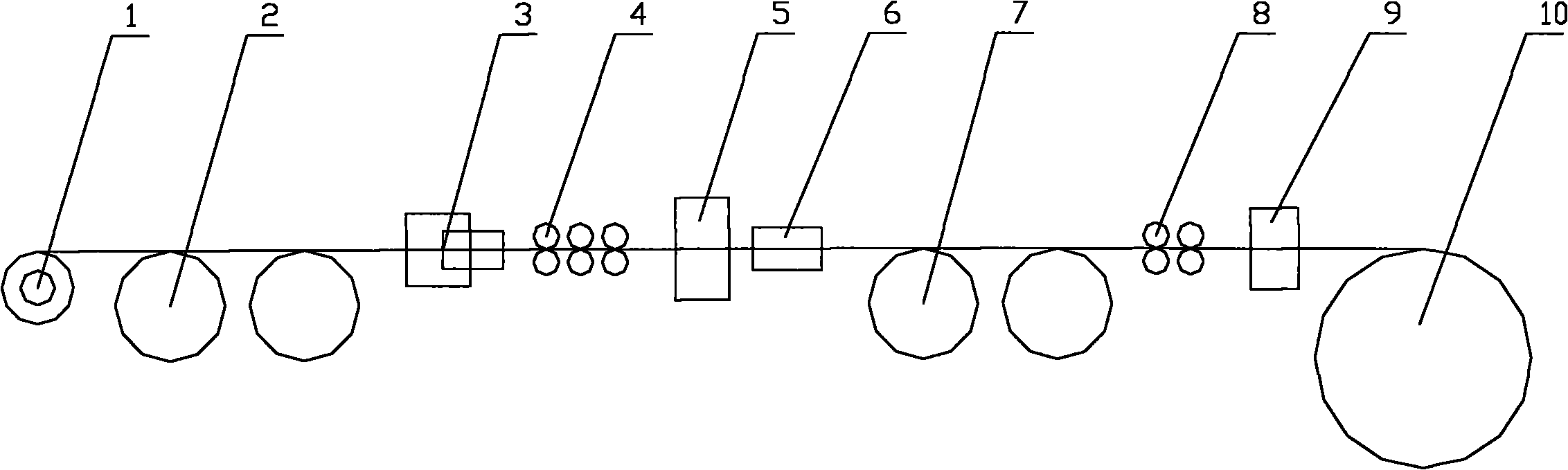

Production technology of helix rib steel wire

The invention relates to a production technology of a helix rib steel wire, which comprises the following steps: paying off a steel wire by a paying-off machine; passing through a first group of tension pulleys; entering a helicoid to form helix; tempering in an intermediate frequency after being straightened by a straightener; cooling down; passing through a second group of tension pulleys; entering shears by traction; cutting and dividing into trays in the shears; and finally collecting wires into trays. Therefore, each performance index of the helix rib steel wire is improved, and the steel wire is provided with good linearity. Furthermore, the compression amount of helix forming is reduced; the accuracy of helix size is guaranteed; the weight per meter of steel wire meets normative requirement; and the loss of a helix model is greatly reduced.

Owner:奥盛(九江)新材料有限公司

Anti-contact fatigue pearlite steel rail and manufacturing method thereof

ActiveCN107675080AExtended service lifeHigh strengthTemperature control deviceFurnace typesSurface layerRoom temperature

The invention belongs to the technical field of steel rail manufacturing, and particularly relates to an anti-contact fatigue pearlite steel rail and a manufacturing method thereof. The method of theanti-contact fatigue pearlite steel rail is provided to solve the problems that the obtained pearlite steel rail is poor in performance and low in anti-contact fatigue resistance due to the fact thatperformance of a fracture surface of a rail head of the pearlite steel rail is not uniform in the prior art. The manufacturing method of the anti-contact fatigue pearlite steel rail comprises the following steps of a, a steel billet is hot-rolled into a steel rail, and final rolling temperature is 900-1000 DEG C; b, when the center temperature of the top surface of the steel rail is air-cooled to750-800 DEG C, cooling mediums are sprayed to the top surface of the rail head and two side surfaces of the rail head, and the center temperature is cooled to 650 DEG C; and c, the cooling mediums aresprayed to the top surface of the rail head, the two side faces of the rail head and the lower jaws on the two sides of the rail head, and the temperature of the surface layer of the rail head is cooled to 520 DEG C, and then is air-cooled to the room temperature. According to the anti-contact fatigue pearlite steel rail and the manufacturing method thereof, the steel rail with better performanceis prepared by modes of controlling the steel component and accelerated cooling two sections, and the method has the advantages of being simple in operation, low in equipment requirement and suitablefor popularization and application.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

Low-cost X80 straight seam welded pipe and manufacturing method thereof

ActiveCN105779904AWork hardening effect is obviousReduce manufacturing costLaminar coolingLower grade

The invention discloses a low-cost X80 straight seam welded pipe and a manufacturing method thereof. Chemical components of the low-cost X80 straight seam welded pipe include, by weight percent, 0.039%-0.079% of C, 0.16%-0.26% of Si, 1.33%-1.83% of Mn, smaller than or equal to 0.017% of P, smaller than or equal to 0.0046% of S, 0.14%-0.24% of Cr, 0.019%-0.059% of Nb, 0.019%-0.039% of V, 0.0051-0.028% of Ti, 0.011%-0.057% of Al, 0.13%-0.28% of Ni and the balance Fe and a trace of inevitable impurities. According to technological characteristics, the soaking temperature ranges from 1120 DEG C to 1220 DEG C, two-stage control rolling is adopted, and the rolling temperature in a recrystallization area ranges from 950 DEG C to 1200 DEG C; second-stage rolling is conducted in a non-recrystallization area, and the air cooling ending temperature ranges from 650 DEG C to 750 DEG C; and the laminar cooling speed ranges from 5 DEG C / s to 25 DEG C / s, JCO or UO is adopted for pipe manufacturing, the expanding rage e is larger than or equal to t / D, and the maximum value of the expanding rate is 2.5%. The low-cost X80 straight seam welded pipe and the manufacturing method thereof have the beneficial effects that a low-grade steel plate is used for manufacturing the high-grade X80 straight seam submerged arc welding pipe, strength and plasticity indexes are good, and the production cost is reduced.

Owner:ANGANG STEEL CO LTD

Strong and tough pearlitic steel rail and its manufacturing method

ActiveCN107675083BExtended service lifeHigh strengthTemperature control deviceFurnace typesManufacturing technologyRoom temperature

The invention belongs to the technical field of steel rail manufacturing and particularly relates to a tough pearlitic steel rail and a manufacturing method thereof. The invention provides the manufacturing method of the tough pearlitic steel rail for solving the problems that the property of the fracture surface of a pearlitic steel rail head prepared through the prior art is uneven, and the property of the obtained pearlitic steel rail is poor. The manufacturing method comprises the following steps that a, a steel billet is hot-rolled into the steel rail, and the finish rolling temperature is 900-1000 DEG C; b, when the steel rail top surface center temperature is air-cooled to 850 DEG C, cooling media are sprayed to the top surface of the rail head, the two side surfaces of the rail head, and the mandibles of the two sides of the rail head, and cooling is conducted till the top surface center temperature is 630-650 DEG C; and c, cooling media are sprayed continuously, cooling is conducted till the rail head surface layer temperature is 480-500 DEG C, and air cooling is conducted to be the room temperature. According to the tough pearlitic steel rail and the manufacturing methodthereof, through the modes of steel component controlling and two segment accelerated cooling, the steel rail with the more excellent toughness is prepared, and the tough pearlitic steel rail and themanufacturing method thereof are suitable for application of heavy loads and passenger and freight mixed transporting railways.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

High-pressure-resisting and low-carbon alloy steel material

Owner:SJ PETROLEUM MACHINERY CO LTD SINOPEC

Method for improving performance of steel plate by adjusting manganese titanium boron content

Owner:JIGANG GRP

Steel wire rod for aluminum-containing steel fibers and used for deep drawing, and rolling method thereof

InactiveCN111485175AImprove flowUniform tissueHeat treatment process controlWire rodSmelting process

The invention belongs to the field of metal materials, and specifically discloses a steel wire rod for aluminum-containing steel fibers and used for deep drawing, and a rolling method thereof. A continuous casting billet comprising specific components is obtained according to an aluminum-containing pure steel smelting process, reasonable heating temperature and heating time of the continuous casting billet are controlled in a heating furnace, and the process parameters of the wire rod in a rolling process and the cooling process parameters of the wire rod on a Stelmor cooling line are optimized, so that the produced wire rod for the steel fibers is high in universality, uniform in structure, small in crystal grain, excellent in mechanical property, and good in plasticity index, and an ironoxide sheet has a thickness of 10-20[mu]m, and is suitable for mechanical shelling and low in wire fracture; and the wire rod produced by the method has tensile strength Rm of 350-390MPa, percentageelongation A of not less than 40% after fracture, area reduction Z of not less than 80%, and ferrite grain size of 7-8, the wire fracture in a drawing process of a user can be controlled to be less than 0.25 times per ton, and the technical requirement of a wire rod for high-grade steel fibers is completely met.

Owner:ZENITH STEEL GROUP CORP +1

635MPa-grade high-strength anti-seismic steel bar and preparation method thereof

The invention belongs to the technical field of hot-rolled ribbed steel bars for reinforced concrete structures, and particularly relates to a 635MPa-grade high-strength anti-seismic steel bar and a preparation method thereof. Steel in a steel bar comprises the following chemical components in percentage by weight: 0.24-0.29 percent of C, 0.70-0.80 percent of Si, 1.50-1.60 percent of Mn, less thanor equal to 0.035 percent of P, less than or equal to 0.035 percent of S, 0.100-0.160 percent of V, 0.010-0.030 percent of Nb and the balance of Fe and inevitable impurity elements. The 635MPa-gradehigh-strength anti-seismic steel bar with high strength and high plasticity is produced by adopting a high-C, Si and Mn component design and a V and Nb combined microalloying manner under the condition of existing process equipment of a production plant and combining steelmaking and steel rolling processes, is stable in performance and good in comprehensive mechanical property, and has yield strength greater than or equal to 635MPa, tensile strength greater than or equal to 795MPa, percentage elongation after fracture greater than or equal to 15%, total elongation under maximal force greater than or equal to 9.0%, the strength-to-yield ratio greater than or equal to 1.25 and the yield-to-yield ratiogreater than or equal to 1.30, good anti-seismic performance is achieved, and the requirements of high-rise and large-span anti-seismic structures are met.

Owner:安徽吾兴新材料有限公司

Steel rail for passenger and freight mixed transportation railway and manufacturing method of steel rail

InactiveCN107674960AExtended service lifeHigh strengthRailsFurnace typesManufacturing technologyRoom temperature

The invention belongs to the technical field of steel rail manufacturing, and particularly relates to a steel rail for a passenger and freight mixed transportation railway and a manufacturing method of the steel rail. The manufacturing method of the steel rail for the passenger and freight mixed transportation railway aims to solve the problem that the toughness comprehensive performance of the pearlite steel rail prepared by the prior art is low, and comprises the following steps that a, a steel slab is subjected to hot rolling to be the steel rail, and the finish rolling temperature is 900-1000 DEG C; and b, when the temperature of the center of the top face of the steel rail is air-cooled to be 800-850 DEG C, jetting of cooling media is conducted on the top face of a railhead, the two side faces of the railhead and lower jaws on the two sides of the railhead correspondingly, cooling is conducted till the temperature of the center of the top face is 520-550 DEG C, and air cooling isconducted till the temperature of the center of the top face reaches the room temperature. According to the steel rail for the passenger and freight mixed transportation railway and the manufacturingmethod of the steel rail, the steel rail with the performance being more excellent is prepared and obtained through a mode that steel components are controlled, and accelerated cooling is conducted onthe two sections, and the steel rail is suitable for the passenger and freight mixed transportation railway.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

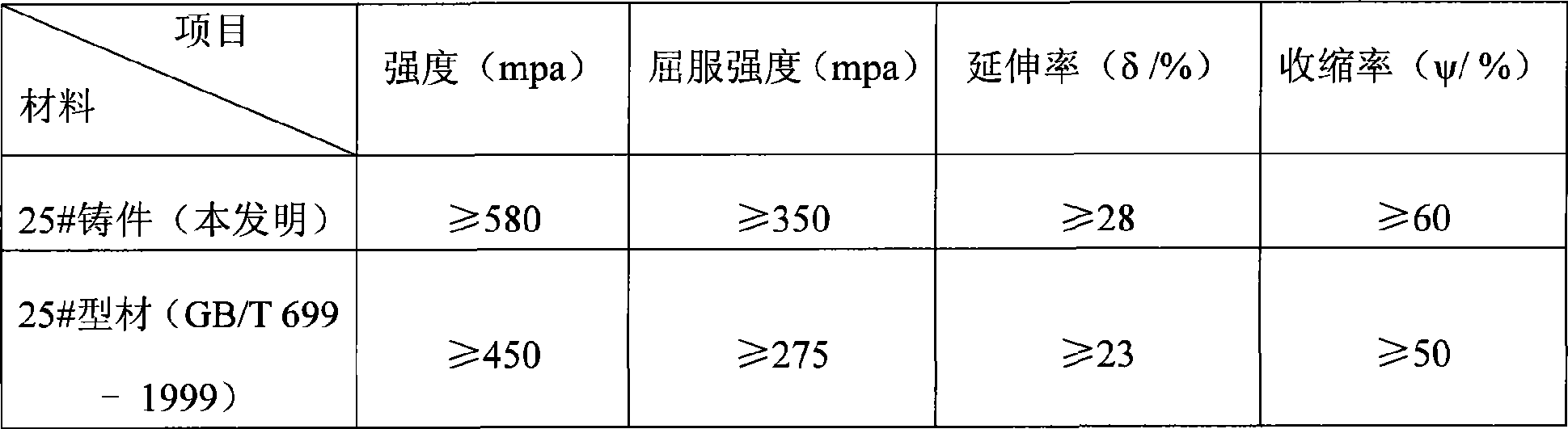

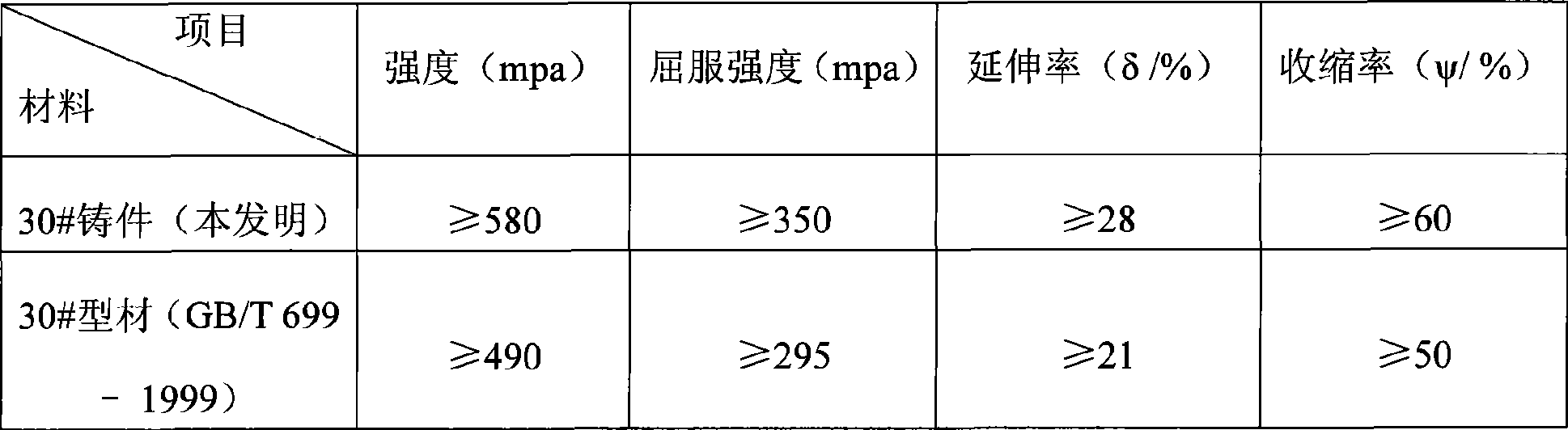

Heat treatment quenching and tempering method

A heat treatment quenching and tempering method is disclosed, comprising the following steps of: (1) putting a cast in a heating furnace to be heated up to over AC3, followed by heat preservation; (2) after the heat preservation, taking out and putting the cast in a cooling medium for being cooled; (3) putting the cooled cast in the heating furnace once again to be heated up to the temperature between AC1 and AC3, followed by the heat preservation; (4) after the heat preservation, taking out and putting the cast in the cooling medium for being cooled; (5) putting the cooled cast back in the heating furnace to be heated up to the temperature between 500 DEG C and AC1, followed by the heat preservation; (6) after the heat preservation, taking out and putting the cast in the air for being cooled. Compared with the prior art, the invention has the advantages of low apparatus requirement, simple technological process, low technological cost, realizable batch operation, ideal resultant plastic index and high rate of finished products.

Owner:NINGBO TONGDA PRECISION CASTING

High-strength and toughness hypereutectoid steel rail and manufacturing method thereof

ActiveCN107739805AExtended service lifeHigh strengthFurnace typesHeat treatment furnacesThree stageToughness

The invention belongs to the technical field of steel rail manufacturing and particularly relates to a high-strength and toughness hypereutectoid steel rail and a manufacturing method thereof in orderto solve the problems that the fracture surfaces of the rail heads of a hypereutectoid steel rail prepared in the prior art is not uniform in performance, and the obtained hypereutectoid steel rail is poor in performance. The manufacturing method of the high-strength and toughness hypereutectoid steel rail, provided by the invention, comprises the following steps of a, hot-rolling a steel billetinto a steel rail; b, cooling the top surface of the rail heads and the two side faces of the rail heads until the temperature of the center of the top surface reaches 700 DEG C when the temperature of the center of the top surface of the steel rail is air-cooled to 820 DEG C; and c, cooling the top surface, the two side faces and the lower jaws of the two sides of the rail heads until the surfacetemperature of the rail heads reaches 530-550 DEG C, cooling the top surfaces and the two side faces of the rail heads to 450-480 DEG C and air-cooling the rail heads to the indoor temperature. The steel rail with more excellent performance is prepared through control over steel ingredients in a three-stage accelerated cooling method and is suitable for heavy haul railways.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

Steel wire rod for annealing-free solder wire and production process thereof

ActiveCN102513725BChemically stableImprove plastic indexWelding/cutting media/materialsSoldering mediaWire rodMechanical property

The invention belongs to the metallurgy field and relates to a production process of a steel wire rod, particularly the steel wire rod for an annealing-free solder wire and a production process of the steel wire rod, wherein the steel wire rod comprises elements in weight percentage as follows: 0.07-0.1% of C, 1.25-1.4% of Mn, 0.4-0.6% of Si, less than or equal to 0.02% of P, less than or equal to 0.02% of S, 0.2-0.55% of Mo, 0.5-1.0% of Ni, less than or equal to 0.2% of Cu, less than or equal to 0.2% of Ti and less than or equal to 0.1% of Al with the balance of Fe. The process comprises steps of detecting a blank, heating the steel blank, descaling by high-pressure water, roughly and intermediately rolling, pre-finishing rolling, cooling in a first section by water, finishing rolling bya unit, cooling in a second section by water, diameter reducing and sizing rolling, cooling in a third section by water, spinning, cooling by wind, finishing and delivering to a warehouse. The methodof the invention employs a rolling-controlled and cooling-controlled process to execute process control of the steel wire rod of the solder wire to obtain an F+P tissue appropriate to draw, and has advantages as follows: good comprehensive mechanical property is realized, a solder wire factory can avoid annealing and perform multi-pass drawing without wire breakage, the production efficiency is greatly increased and the production cost is reduced at the same time.

Owner:NANJING IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com