Hot-rolled steel for automobile wheel rim and its production process

A production process and technology of hot-rolled steel, applied in the field of hot-rolled steel, can solve the problems of affecting the quality and appearance of the car body, increasing energy consumption of process equipment, and low material utilization rate, so as to save heating furnace equipment and reduce energy consumption Total consumption, the effect of reducing billet cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

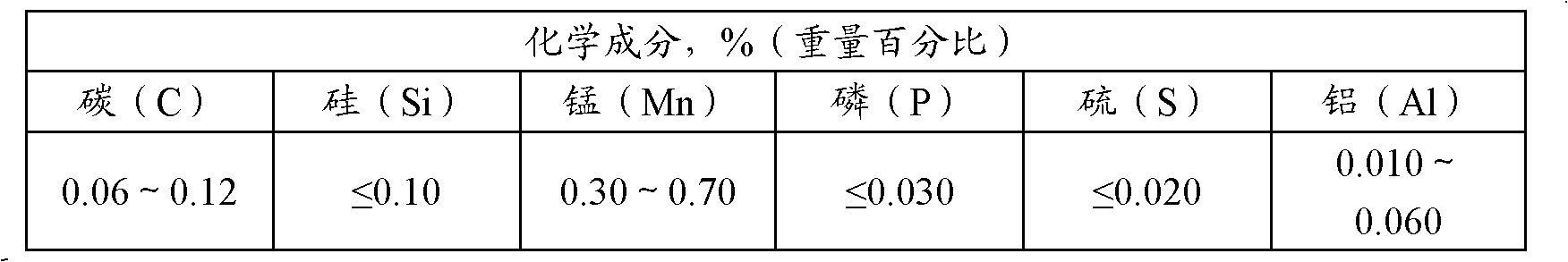

[0015] Table 1 lists the chemical composition by weight percentage contained in the hot-rolled steel sheet and steel strip of the present invention; Table 2 lists the mechanical properties achieved by the hot-rolled steel sheet and steel strip of the present invention.

[0016] As shown in Table 1, the present invention provides a kind of hot-rolled steel plate and steel strip for automobile wheel rim, and its chemical composition comprises by weight percentage: C: 0.06~0.12%, Si:≤0.10%, Mn: 0.30~ 0.70%, P: ≤0.030%, S: ≤0.020%, Al: 0.010-0.060%.

[0017]

[0018] Table 1

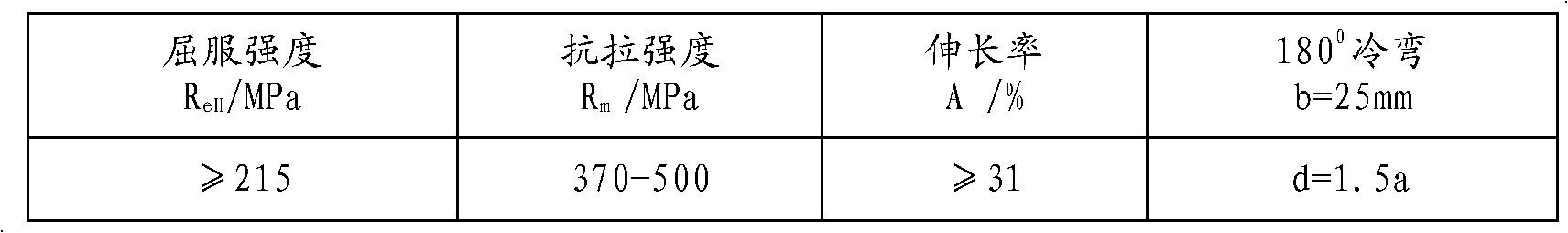

[0019] As shown in Table 2, the mechanical properties of the hot-rolled steel plate and steel strip of the present invention are designed to meet the following conditions, that is, yield strength: ≥ 215MPa; tensile strength: 370~500MPa elongation: ≥ 31%; 1800 cold bending, b=25mm:d=1.5a.

[0020]

[0021] Table 2

[0022] On the other hand, the present invention also provides a production process of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com