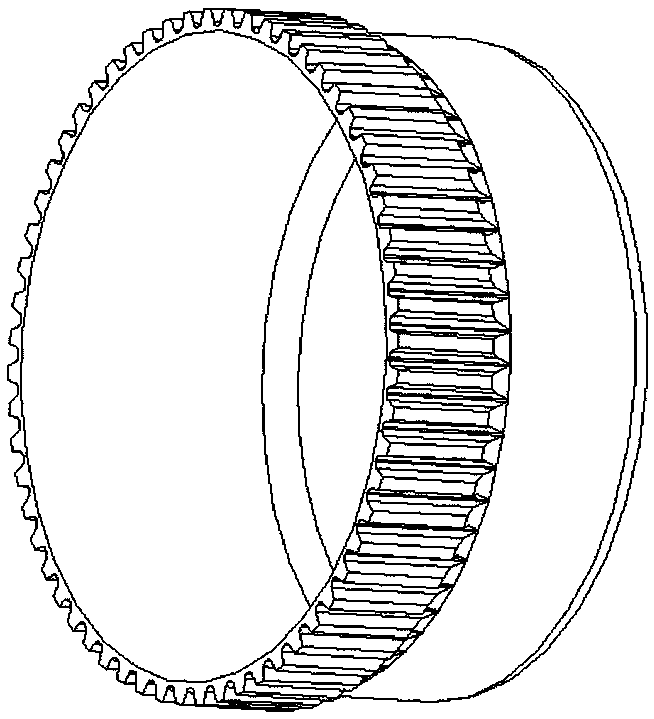

Preparation method of cup-shaped flexible wheel and device thereof

A flexible wheel and cup-shaped technology, which is applied in the field of cup-shaped flexible wheel preparation, can solve the problems of high processing cost, shortened wheel life, reduced workpiece strength and fatigue life, etc., to ensure wall thickness uniformity and dimensional accuracy, The effect of stabilizing the plastic deformation process and improving the current utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

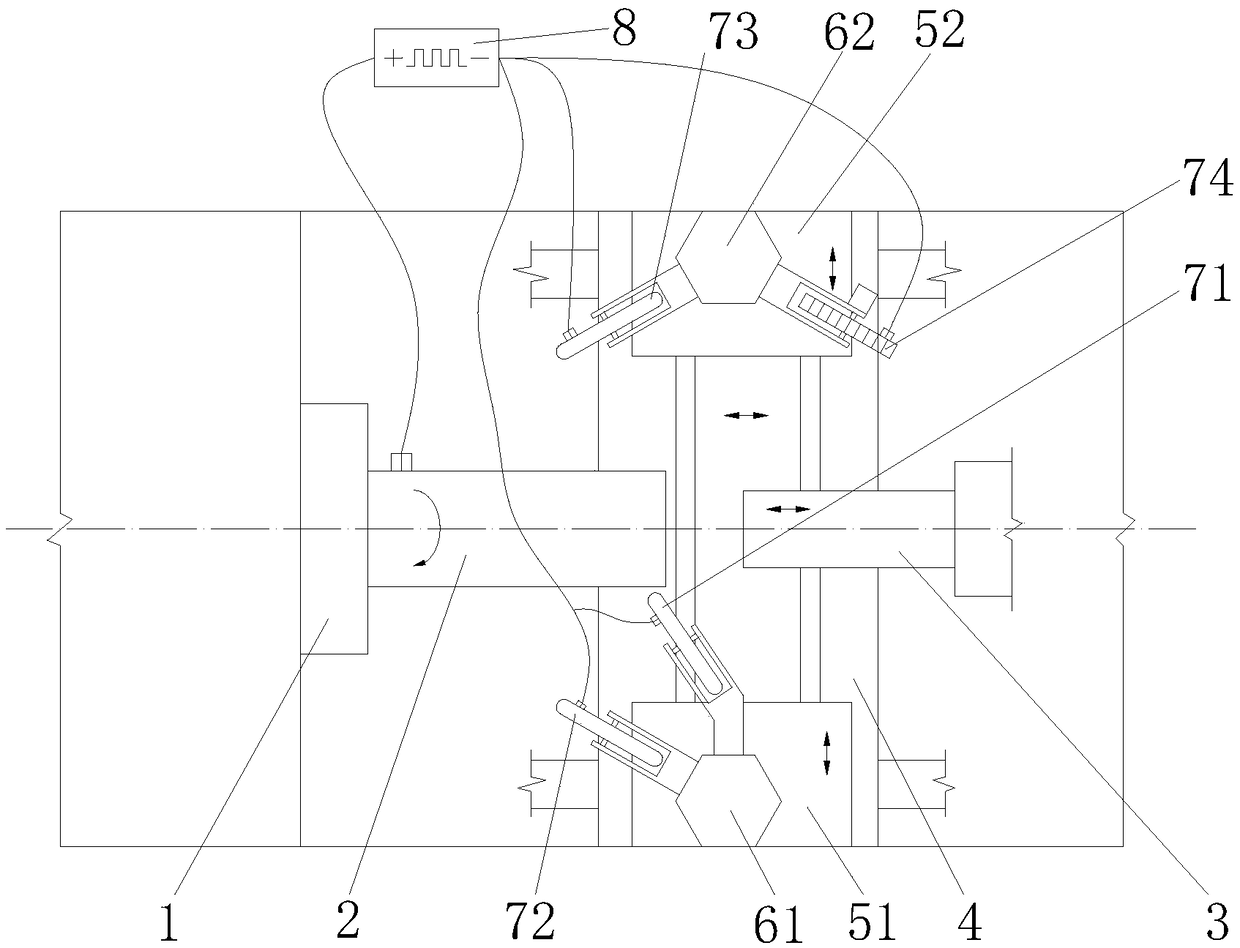

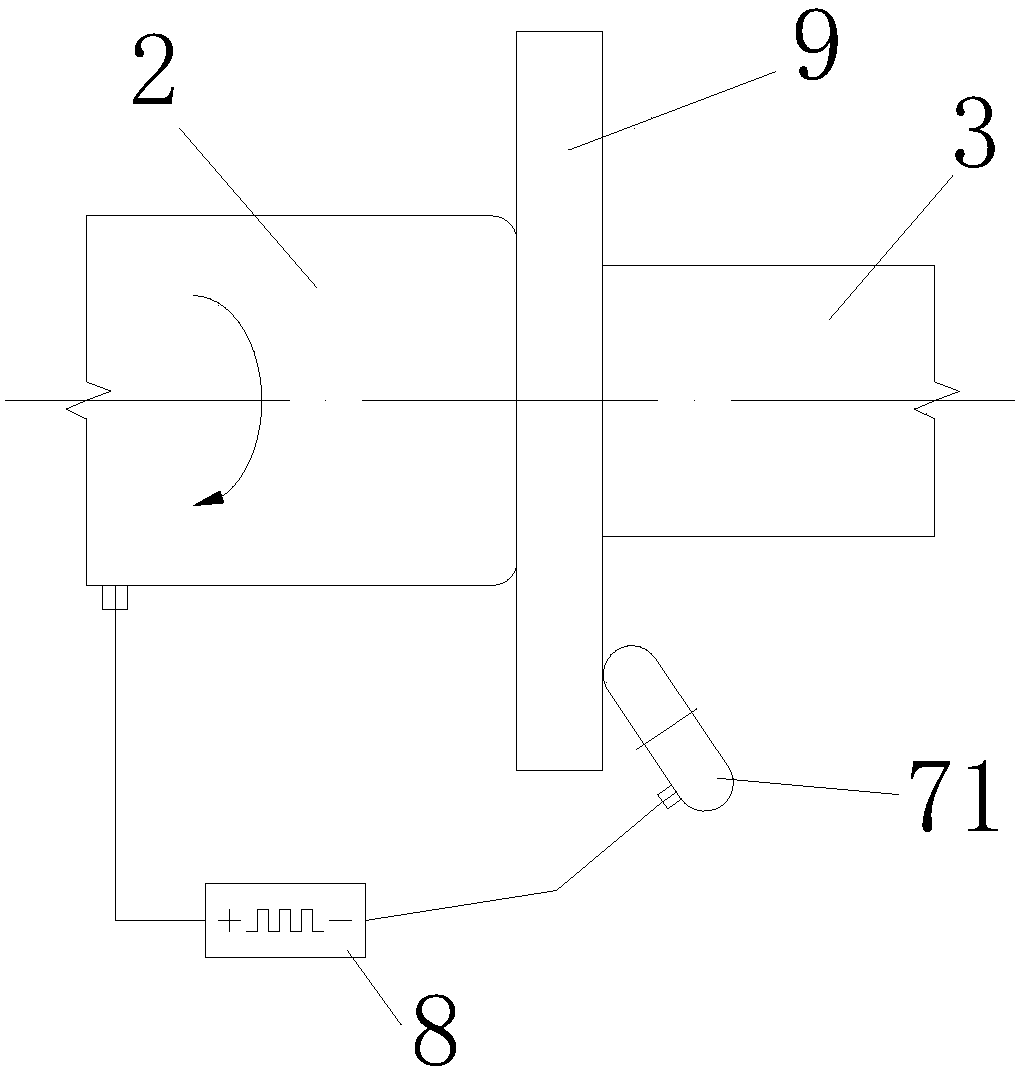

[0034] Such as Figure 1-9 shown. The invention discloses a spinning machine tool device used in a method for preparing a cup-shaped flexible spline. The spinning machine tool device includes a machine tool spindle 1, a mandrel 2, a tail top 3, a mobile platform for longitudinal and lateral movement, and is installed on the mobile platform. Rotary wheel assembly on the platform;

[0035] The mobile platform includes a vertical mobile platform 4 positioned below the station area, and two horizontal mobile platforms 51, 52 with the same structure carried by the vertical mobile platform 4; the two horizontal mobile platforms 51, 52 take the mandrel 2 as the center symmetrical arrangement and symmetrical movement;

[0036] The rotary wheel assembly includes (multi-station) first rotary wheel base 61 and second rotary wheel base 62, as well as first rotary wheel 71, second rotary wheel 72, third rotary wheel 73, and fourth rotary wheel 74;

[0037] Wherein, the machine tool main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com