High-pressure-resisting and low-carbon alloy steel material

A low-carbon alloy steel, high-pressure technology, applied in the field of ferrous metals, can solve the problems of insufficient hardenability of raw materials, insufficient impact toughness, insufficient strength, etc., to prevent early burst failure, improve surface wear resistance, prevent Effect of temper brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

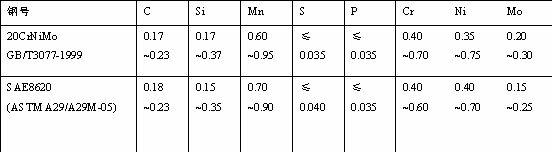

Method used

Image

Examples

Embodiment 1

[0032] Using the smelting process of electric furnace + vacuum refining degassing + electroslag remelting, the mass percentages of components other than Fe in the molten alloy steel are: C: 0.15%, Si: 0.15%, Mn: 0.7%, S: 0.001%, P: 0.001%, Cr: 0.45%, Ni: 0.7%, Mo: 0.45%, Al: 0.02%, V: 0.003%, Nb: 0.02%.

Embodiment 2

[0034] Using the smelting process of electric furnace + vacuum refining degassing + electroslag remelting, the mass percentages of components other than Fe in the molten alloy steel are: C: 0.16%, Si: 0.16%, Mn: 0.72%, S: 0.0011%, P: 0.0011%, Cr: 0.5%, Ni: 0.75%, Mo: 0.5%, Al: 0.025%, V: 0.004%, Nb: 0.025%.

Embodiment 3

[0036] Using the smelting process of electric furnace + vacuum refining degassing + electroslag remelting, the mass percentages of other components except Fe in the molten alloy steel are: C: 0.17%, Si: 0.17%, Mn: 0.75%, S: 0.0012%, P: 0.0012%, Cr: 0.55%, Ni: 0.8%, Mo: 0.5%, Al: 0.03%, V: 0.005%, Nb: 0.03%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com