Low-cost X80 straight seam welded pipe and manufacturing method thereof

A straight seam welded pipe, a low-cost technology, applied in the field of pipeline steel, can solve the problems of waste, insufficient product potential exploration, complex preparation process, etc., and achieve the effect of reducing production cost and obvious work hardening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

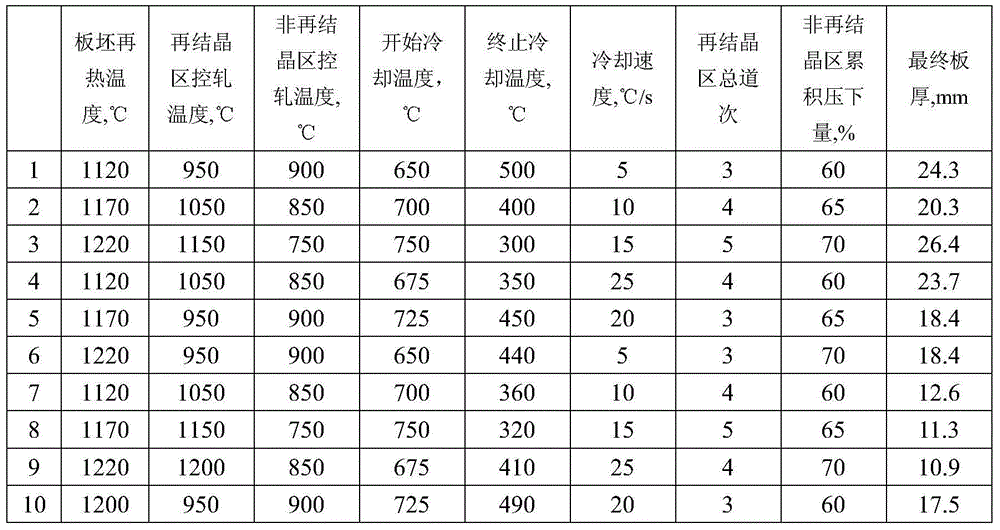

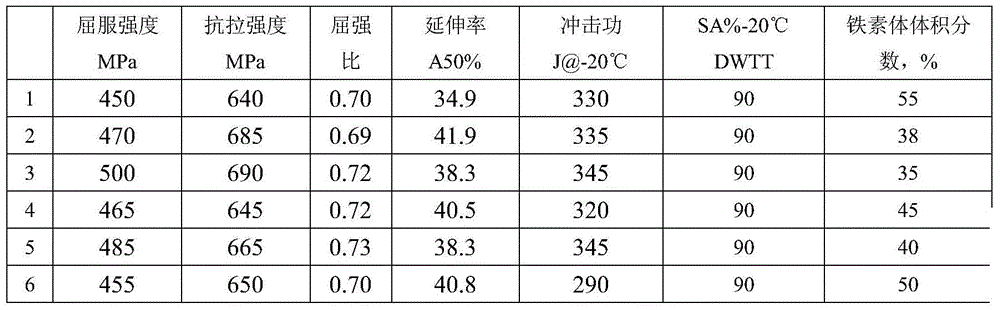

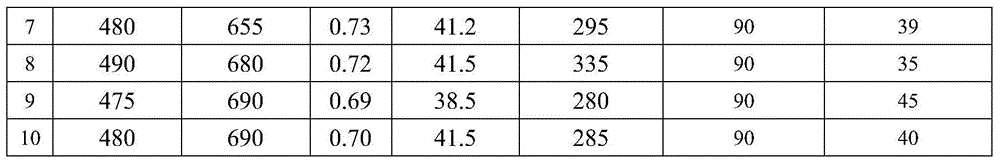

[0051] Below in conjunction with specific embodiment the present invention is further described:

[0052] The content range of each component in the steel pipe designed in the present invention is by weight percentage: C0.039%-0.079%, Si0.16%-0.26%, Mn1.33%-1.83%, P≤0.017%, S≤0.0046% , Cr0.14%-0.24%, Nb0.019%-0.059%, V0.019%-0.039%, Ti0.0051%-0.028%, Al0.011%-0.057%, Ni0.13%-0.28%, I The amount is Fe and traces of unavoidable impurities.

[0053] The process route adopted in the present invention is: material preparation→converter or electric furnace smelting→external refining→continuous casting→slab reheating→controlled rolling and controlled cooling→steel plate performance inspection and sizing→JCOE or UOE pipe making.

[0054] The specific steps are:

[0055] a) Perform soaking treatment after cleaning the as-cast billet within the set composition control range, and control the temperature within the range of 1120-1220°C;

[0056] b) Carry out high-pressure water descali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com