High-carbon high-strength tough pearlitic steel rail and production method thereof

A pearlitic rail, high-strength and toughness technology, applied in the direction of manufacturing tools, metal rolling, temperature control, etc., can solve the problems of poor performance of pearlitic rails, achieve low equipment requirements, simple operation, and improve the comprehensive performance of strength and toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

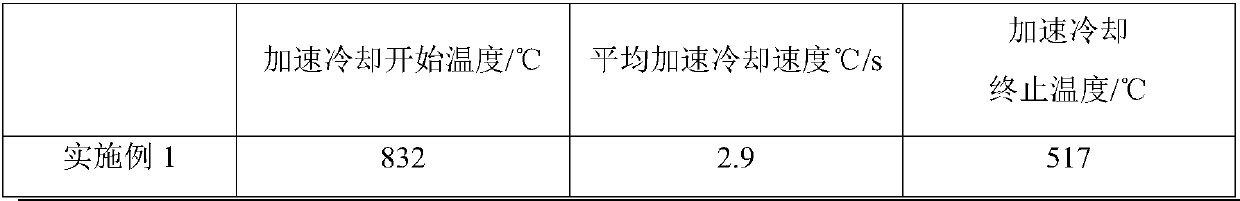

[0038] Embodiments 1-6 use the method of the present invention to manufacture pearlitic steel rails

[0039] The chemical composition of the pearlitic rail billets used in Examples 1 to 6 is shown in Table 1 below:

[0040] The chemical composition list (%) of pearlitic rail billet of table 1

[0041]

C

Si

mn

P

S

Cr

V / Ti / Nb

Example 1

0.96

0.37

0.59

0.011

0.005

0.37

0.008Ti

Example 2

0.91

0.43

0.90

0.008

0.004

0.20

0.09V

Example 3

1.05

0.34

0.50

0.012

0.006

0.40

0.04Nb

Example 4

0.94

0.50

0.72

0.009

0.004

0.32

0.07Nb

Example 5

0.86

0.29

0.76

0.010

0.003

0.28

0.026Ti

Example 6

0.98

0.20

0.84

0.010

0.005

0.25

0.03V

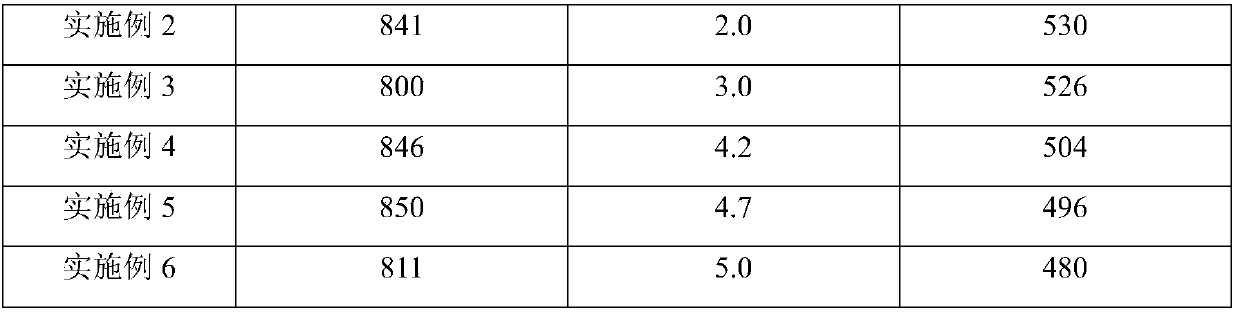

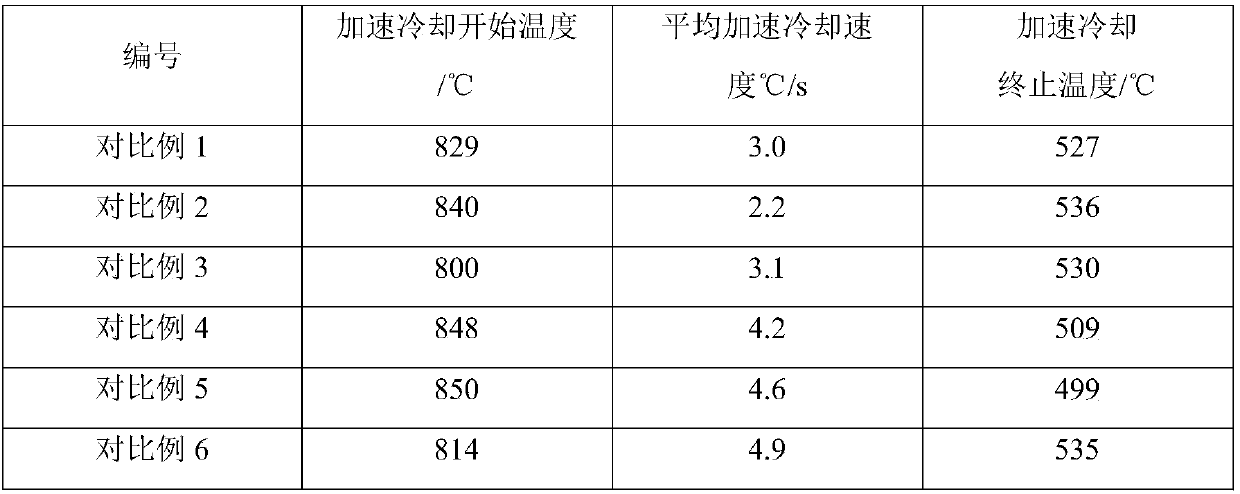

[0042] Roll the billets shown in the above table into 60kg / m rails, and cool them in the following way:

[0043] a. Rail rolling

[0044] Hot rolling the bil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com