Medium-strength packaging steel strip and production method thereof

A production method and packaging technology, which is applied in the production field of medium-strength packaging steel strips and medium-strength packaging steel strips, and can solve the problems of high elongation after breaking and unstable tensile strength greater than 800MPa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

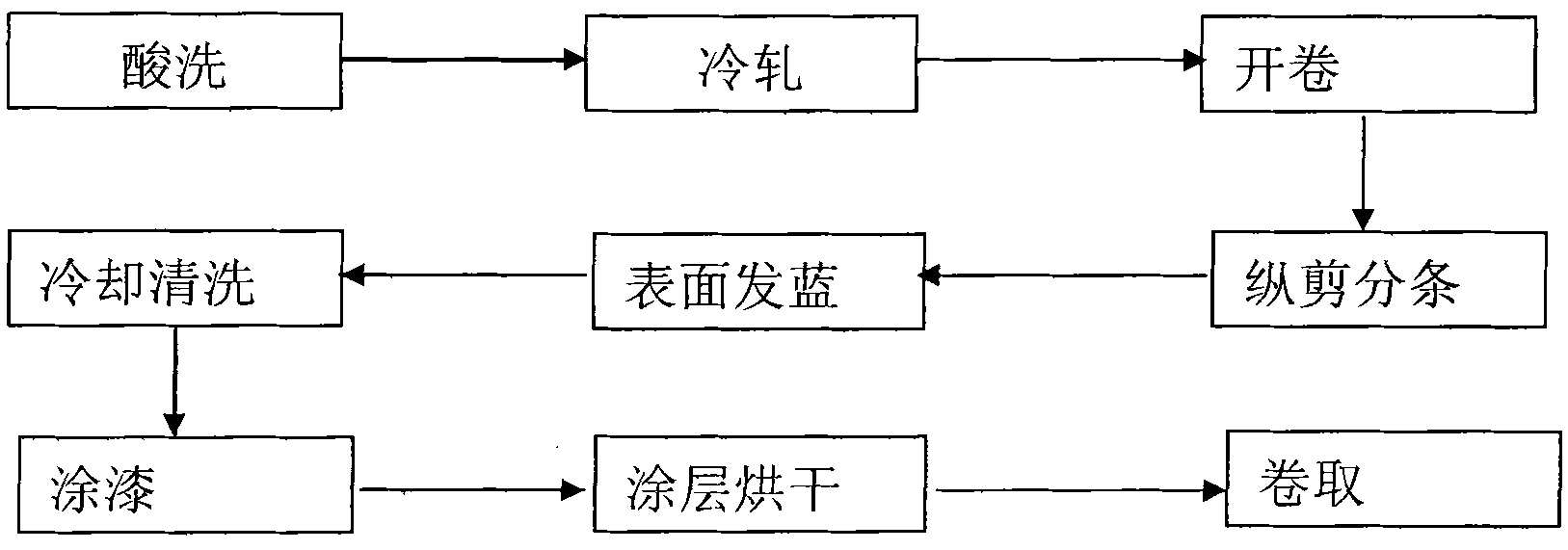

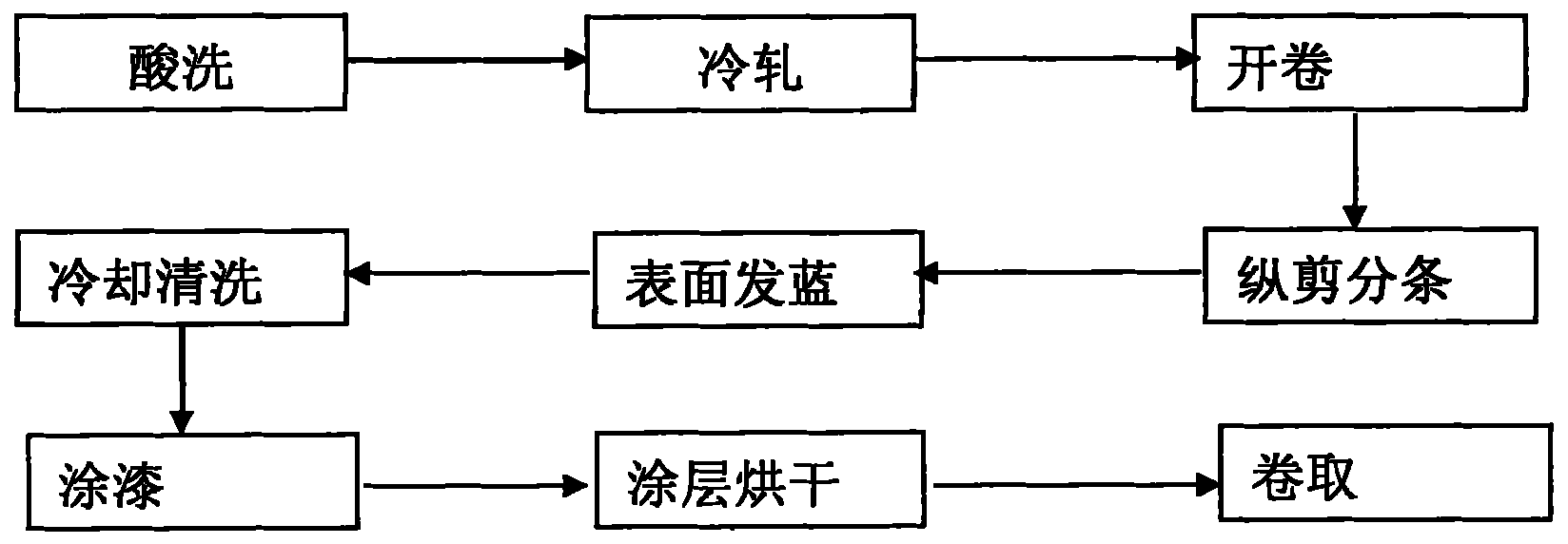

Image

Examples

Embodiment 1

[0042] Select a carbon steel with the following components: C: 0.07%, Si: 0.10%, Mn: 1.27%, P: 0.008%, S: 0.001%, the balance is Fe, and the percentages are weight percentages.

[0043] The above-mentioned carbon steel hot-rolled plate is selected as a raw material, and is pickled and cold-rolled into a steel strip of 0.9×389mm. The mechanical properties after cold-rolling are: tensile strength is 875MPa, and elongation is 6%. Then enter the production line that realizes the production method of the present invention, produce by the process method of the present invention, the whole production process steel strip running speed is 40m / min, and the blueing temperature is 440 ℃, and the heat preservation time is about 20s, after 30 After cooling in water at ℃, the paint is dried, and the finished product is put into storage after being coiled by a coiler.

[0044] The mechanical properties of the obtained finished product are: tensile strength 830Mpa, elongation 7%.

Embodiment 2

[0046]Select a carbon steel with the following components: C: 0.08%, Si: 0.15%, Mn: 1.27%, P: 0.008%, S: 0.001%, and the balance is Fe, and the percentages are weight percentages.

[0047] The above-mentioned carbon steel hot-rolled plate is selected as a raw material, and is pickled and cold-rolled into a steel strip of 0.9×389mm. The mechanical properties after cold-rolling are: the tensile strength is 870MPa, and the elongation is 6%. Then enter the production line that realizes the production method of the present invention, produce by the process method of the present invention, the whole production process steel strip running speed is 40m / min, and the blueing temperature is 440 ℃, and the heat preservation time is about 20s, after 30 After cooling in water at ℃, the paint is dried, and the finished product is put into storage after being coiled by a coiler.

[0048] The mechanical properties of the obtained finished product are: tensile strength 840Mpa, elongation 8%.

Embodiment 3

[0050] Select a carbon steel with the following components: C: 0.05%, Si: 0.12%, Mn: 1.22%, P: 0.009%, S: 0.002%, and the balance is Fe, and the percentages are weight percentages.

[0051] The above-mentioned carbon steel hot-rolled plate is selected as a raw material, and is pickled and cold-rolled into a steel strip of 0.9×389 mm. The mechanical properties after cold rolling are: tensile strength is 860 MPa, and elongation is 5%. Then enter the production line that realizes the production method of the present invention, produce by the process method of the present invention, the whole production process steel strip running speed is 40m / min, and the blueing temperature is 420 ℃, and the heat preservation time is about 20s, after 30 After cooling in water at ℃, the paint is dried, and the finished product is put into storage after being coiled by a coiler.

[0052] The mechanical properties of the obtained finished product are: tensile strength 810Mpa, elongation 9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com