Steel rail for passenger and freight mixed transportation railway and manufacturing method of steel rail

A technology of mixed transportation of passengers and cargo, and a manufacturing method, which is applied in the field of rails, can solve problems such as poor performance of pearlitic rails, and achieve the effect of low equipment requirements, simple operation, and improved comprehensive performance of strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

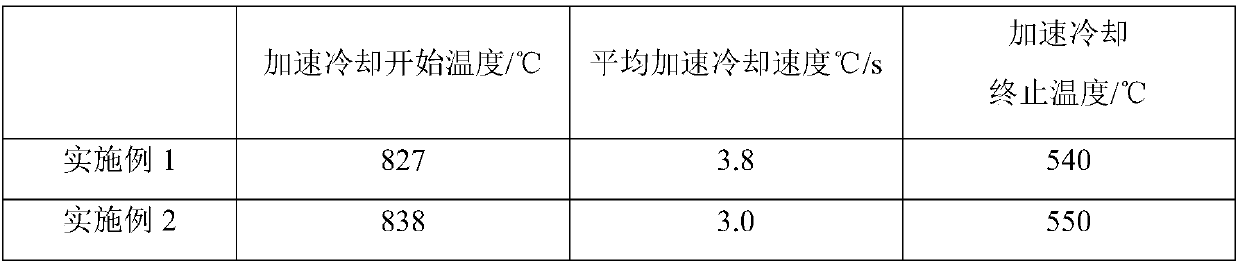

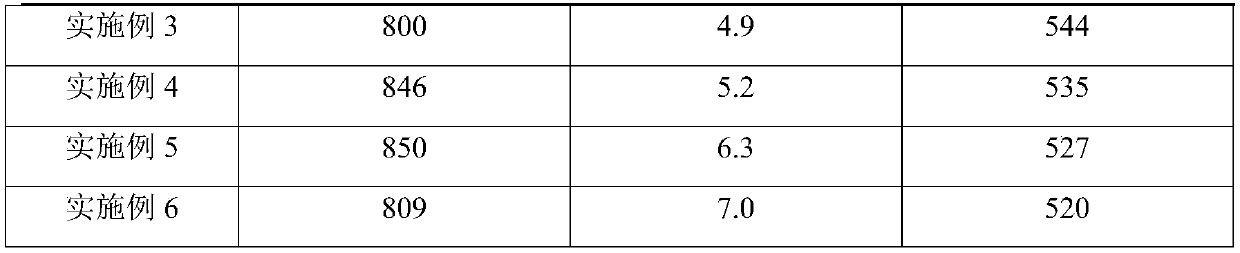

[0038] Embodiment 1~6 uses the inventive method to manufacture the pearlitic steel rail for passenger-cargo mixed railway

[0039] The chemical composition of the pearlitic rail billets used in Examples 1 to 6 is shown in Table 1 below:

[0040] The chemical composition list (%) of pearlitic rail billet of table 1

[0041]

C

Si

mn

P

S

Cr

V / Ti / Nb

Example 1

0.82

0.37

0.70

0.011

0.007

0.44

0.03V

Example 2

0.85

0.19

0.88

0.012

0.005

0.15

0.04Nb

Example 3

0.70

0.60

1.05

0.013

0.006

0.27

0.019Ti

Example 4

0.77

0.52

0.94

0.010

0.006

0.38

0.07Nb

Example 5

0.80

0.15

0.77

0.015

0.008

0.50

0.10V

Example 6

0.74

0.44

0.98

0.011

0.007

0.22

0.009Nb

[0042] Roll the billets shown in the above table into 60kg / m rails, and cool them in the following way:

[0043] a. Rail rolling

[0044...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com