Production technology of helix rib steel wire

A spiral rib steel wire and production process technology, applied in the field of double tensioner + spiral forming stabilized heat treatment to produce spiral rib steel wire, can solve the problem of the decrease of linearity and relaxation performance of steel wire, the decrease of plasticity index such as elongation, and the surface processing of steel wire Hardening and other problems, to achieve the effect of reducing loss, reducing compression, good plasticity index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

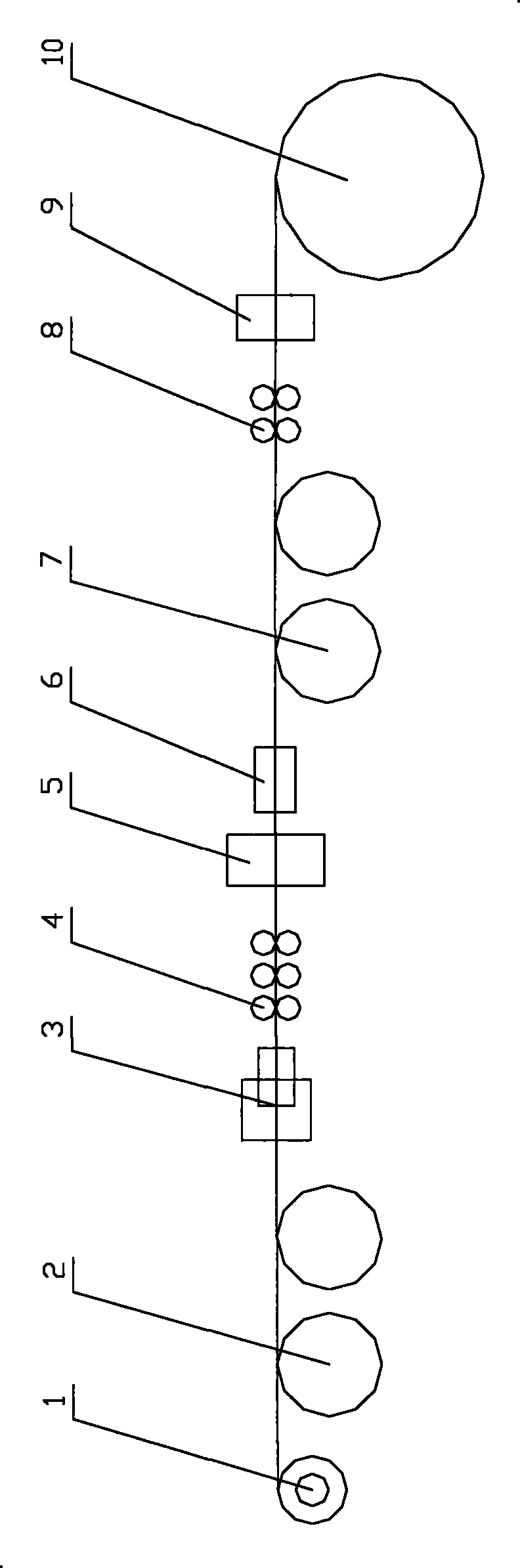

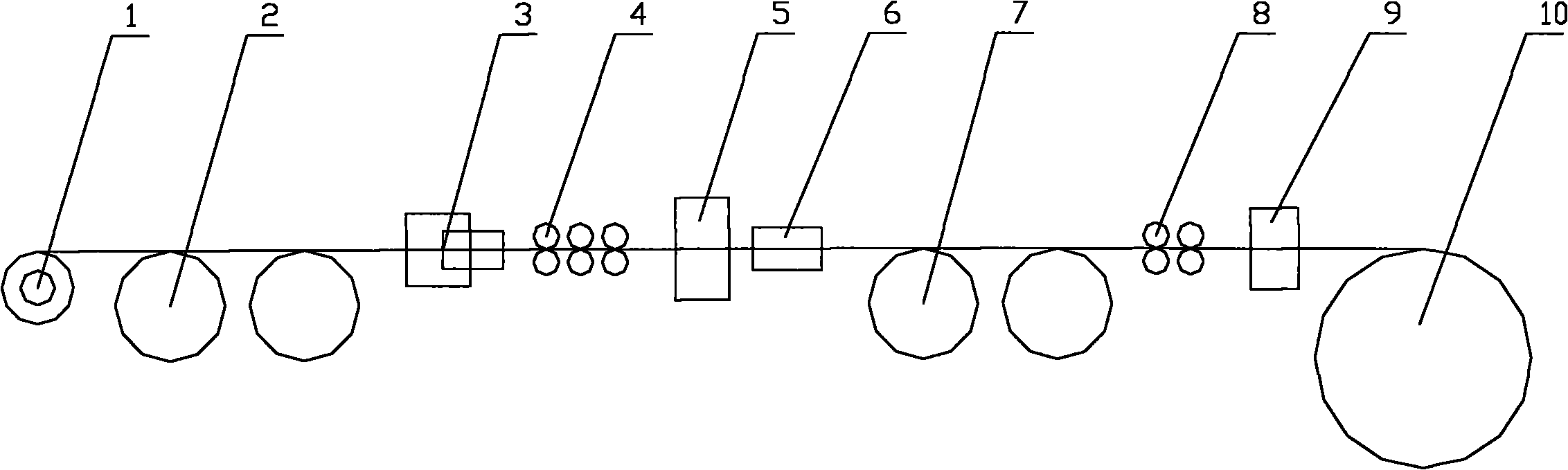

[0012] The embodiment, as shown in the figure, includes that the steel wire is unwound through the pay-off machine 1, passes through the first tensioning wheel set 2, enters the spiral body 3 for spiral forming, and after being straightened by the straightener 4, enters the intermediate frequency 5 for Tempering, then cooling 6, passing through the second tensioning wheel set 7, the steel wire enters the shearing machine 9 through traction 8, cuts and divides the disc, and finally takes up the wire 10 into a coil.

[0013] This invention uses double tensioning wheels + spiral forming for stable production. The tension is formed by the torque difference between the two sets of tensioning wheels, which can be adjusted at will and is not restricted by the compression amount of the spiral mold. Much smaller, the geometric size of the steel wire helix will not be changed by the influence of mold drawing, the meter weight of the steel wire will naturally not exceed the standard range...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com