High-strength and toughness hypereutectoid steel rail and manufacturing method thereof

A manufacturing method and hypereutectoid technology, applied in the field of rail manufacturing, can solve problems such as poor performance of pearlitic rails and difficulty in uniform cooling, and achieve the effects of low equipment requirements, excellent strength, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0051] Embodiments 1-6 use the method of the present invention to manufacture hypereutectoid rails

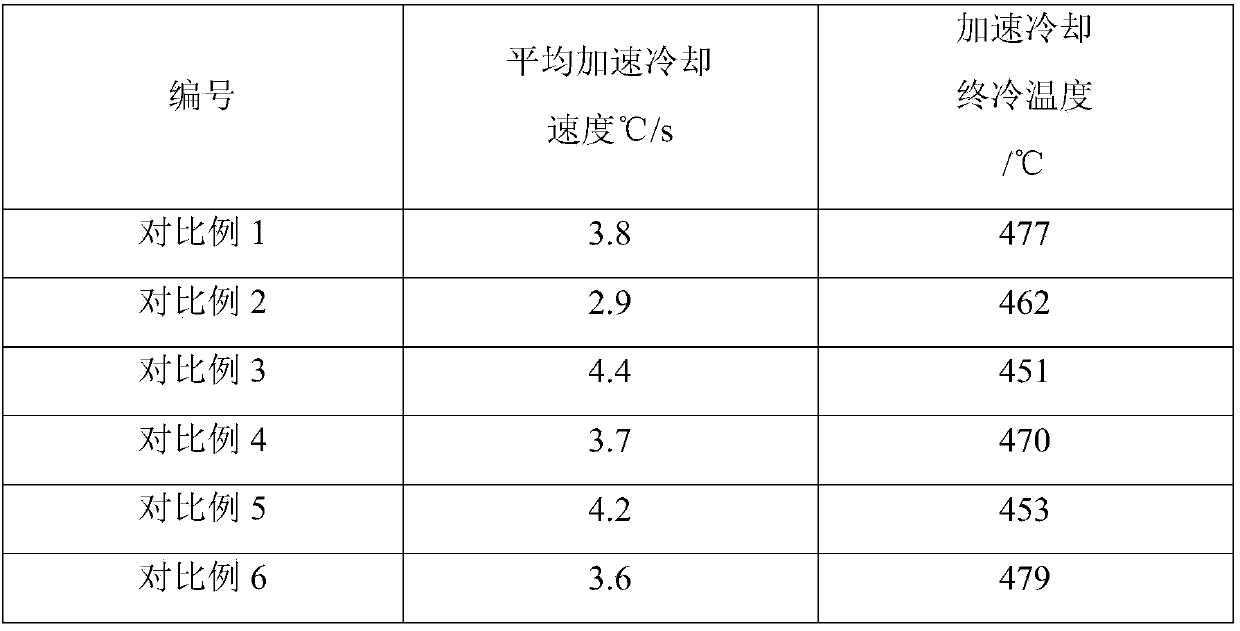

[0052] The chemical composition of the hypereutectoid rail billets used in Examples 1 to 6 is shown in Table 1 below:

[0053] The chemical composition table (%) of table 1 rail billet

[0054]

C

Si

mn

P

S

Cr

V / Ti / Nb

Example 1

1.02

0.31

0.79

0.011

0.003

0.57

0.02V

Example 2

0.99

0.20

0.90

0.010

0.004

0.51

0.06Nb

Example 3

0.90

0.37

0.85

0.011

0.004

0.44

0.018Ti

Example 4

0.97

0.42

0.92

0.009

0.005

0.38

0.08V

Example 5

0.92

0.50

0.95

0.010

0.003

0.30

0.030Ti

Example 6

1.05

0.25

0.70

0.012

0.004

0.60

0.02Nb

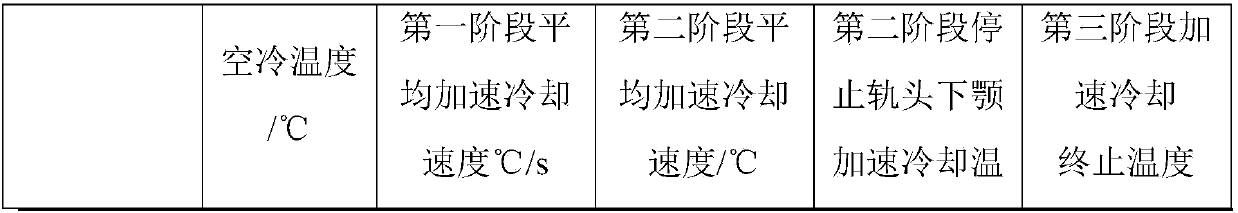

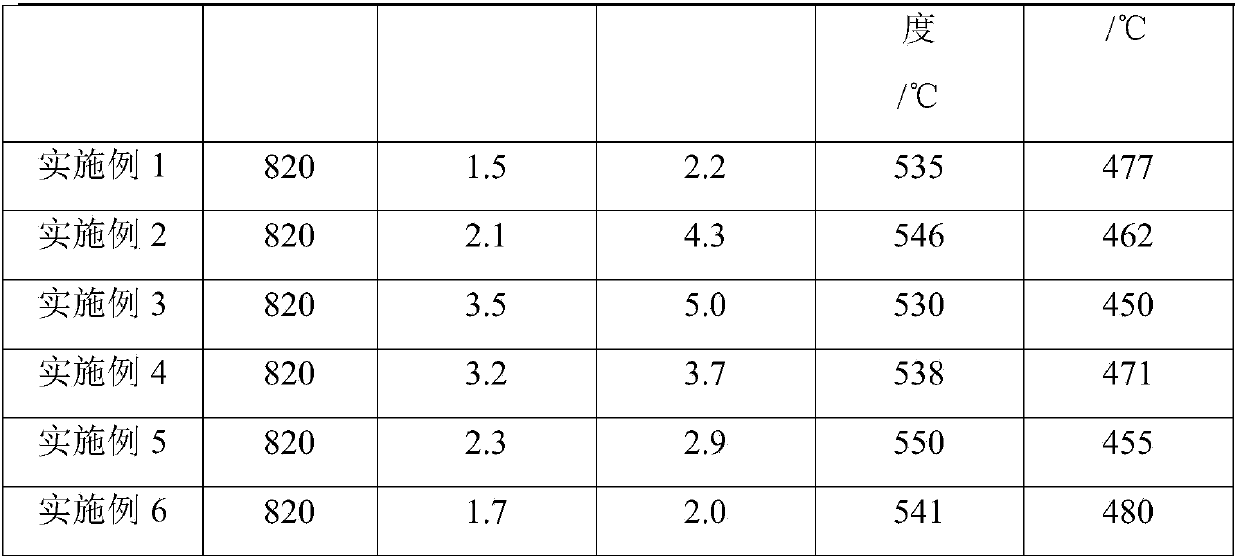

[0055] Roll the slabs shown in the above table into 75kg / m rails, and cool them in the following way:

[0056] b. The first stage of cooling

[0057] Utilizing the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com