Manufacturing method of high-strength, toughness and layered tear-resistant steel plate with a thickness of 50-80 mm

A technology of anti-lamellar tearing and manufacturing method, which is applied in the field of plate rolling and post-rolling cooling process in the metallurgical industry, can solve problems such as uneven rolling deformation, poor anti-lamellar tearing performance, and uneven cooling, and achieve Fine grain and structure, good resistance to lamellar tearing, and the effect of reducing core defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

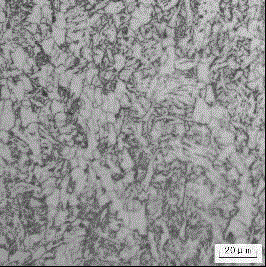

Embodiment 1

[0025] A high-strength, toughness-resistant lamellar tearing steel of this embodiment is composed of the following weight percentages: C 0.12%, Mn 1.43%, Si 0.15%, Als 0.023%, Ni 0.21%, Nb 0.03%, Ti 0.013% , Cu 0.15%, P 0.011%, S0.002%, the rest is iron Fe and unavoidable impurities, and the grain size is 10.5. The thickness of the steel plate is 50mm.

[0026] The billet size is 300mm×1870mm×2400mm, the billet is heated to 1250°C, and the heating time is controlled at 1.1min / mm.

[0027] The parameters of recrystallization rolling (rough rolling) are shown in Table 1.

[0028] Table 1.

[0029] .

[0030] The parameters of non-recrystallized rolling (finish rolling) are shown in Table 2.

[0031] Table 2.

[0032] .

[0033] The process parameters of the ACC cooling system are shown in Table 3.

[0034] table 3.

[0035] .

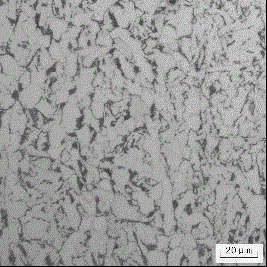

Embodiment 2

[0037] A high-strength, toughness-resistant lamellar tearing steel of this embodiment is composed of the following weight percentages: C 0.12%, Mn 1.43%, Si 0.15%, Als 0.023%, Ni 0.21%, Nb 0.03%, Ti 0.013% , Cu 0.15%, P 0.011%, S0.002%, the rest is iron Fe and unavoidable impurities, and the grain size is 11. The thickness of the steel plate is 60mm.

[0038] The billet size is 300mm×1870mm×2400mm, the billet is heated to 1230°C, and the heating time is controlled at 1.2min / mm.

[0039] The rough rolling parameters are shown in Table 4.

[0040] Table 4.

[0041] .

[0042] The finishing rolling parameters are shown in Table 5.

[0043] table 5.

[0044] .

[0045] The process parameters of ACC cooling system are shown in Table 6.

[0046] Table 6.

[0047] .

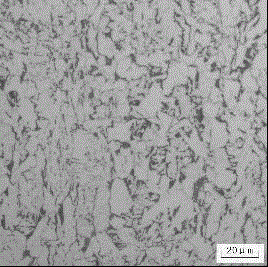

Embodiment 3

[0049] A high-strength, toughness-resistant layered tearing steel of this embodiment is composed of the following weight percentages: C 0.09%, Mn 1.45%, Si 0.15%, Als 0.039%, Ni 0.21%, Nb 0.03%, Ti 0.011% , Cu 0.17%, P 0.012%, S0.002%, the rest is iron Fe and unavoidable impurities, the grain size is 12 grades. The thickness of the steel plate is 70mm.

[0050] The billet size is 360mm×1870mm×5300mm, the billet is heated to 1240°C, and the heating time is controlled at 1.2min / mm.

[0051] The rough rolling parameters are shown in Table 7.

[0052] Table 7.

[0053] .

[0054] The finishing rolling parameters are shown in Table 8.

[0055] Table 8.

[0056] .

[0057] The process parameters of the ACC cooling system are shown in Table 9.

[0058] Table 9.

[0059] .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com