Porous metal material and preparation method thereof

A porous metal, metal technology, applied in ceramic products, manufacturing tools, additive processing and other directions, can solve the problems of difficult removal, low heat resistance of materials, large pollution, etc., to achieve a wide range of applications, low preparation costs, and processing costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

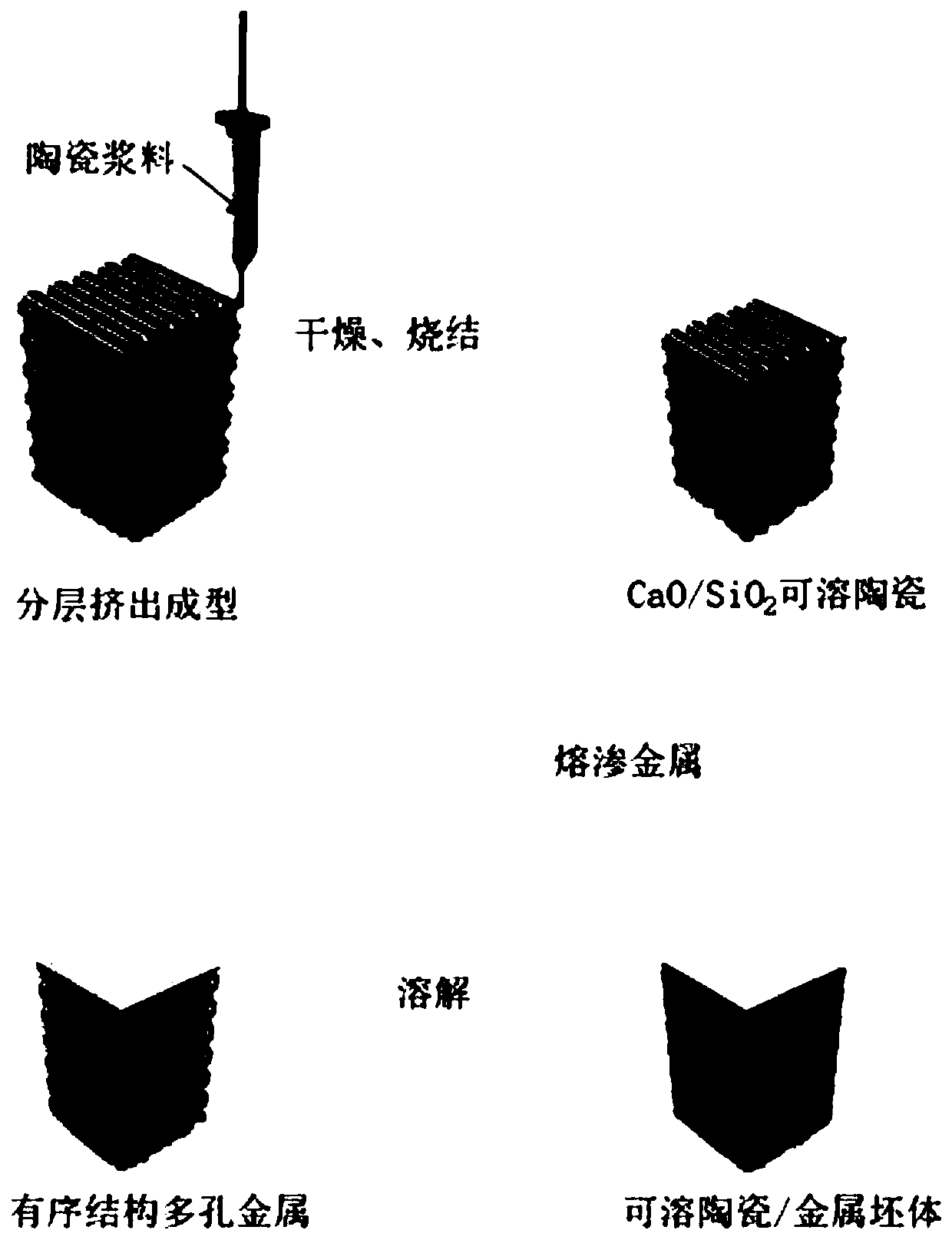

[0032] The preparation method of the described porous metal material mainly comprises the following steps:

[0033] In step 1, a porous ceramic body corresponding to the porous metal material to be prepared is prepared by using a 3D printing extrusion molding process, and the porous ceramic body is dried and sintered to form a soluble porous ceramic.

[0034]Specifically, the sintering process used is: first sintering at 180°C-250°C for 1-3 hours; then sintering at 700-900°C for 2h-3h; The heating rate is 5-20°C / min. Step one specifically includes the following steps:

[0035] (1) Use 2000-5000 mesh Al 2 o 3 , ZrO 2 , SiO 2 , MgO, SiC, Si 3 N 4 One or more of them are combined with 1000-3000 mesh CaCO 3 The mixture obtained by mixing in any proportion is used as one of the raw materials to prepare a uniform slurry, and the prepared slurry is put into the needle tube of the 3D printer.

[0036] (2) The bottom plate of the 3D printer is preheated at a preheating tempera...

Embodiment 1

[0042] The preparation method of the porous metal material provided by Example 1 of the present invention mainly includes the following steps:

[0043] S1, firstly, 2000 mesh CaCO 3 powder, 5000 mesh SiO 2 The powder is stirred and mixed with the binder polyethylene glycol and silica sol, then the defoamer octanol is added, and the ball mill is used to mix evenly to obtain a slurry, and the mixed slurry is put into the needle tube of the 3D printer; then, 50 Preheat the bottom plate of the 3D printer at a preheating temperature of ℃, and start printing to obtain a porous ceramic body. Wherein, the nozzle diameter of the 3D printer is 0.3mm, the printing layer height is 0.25mm, and the printing speed is 20mm / s.

[0044] S2, drying the porous ceramic body at 45°C, and putting the dried porous ceramic body into a high-temperature sintering furnace for sintering at 200°C for 1.5h, sintering at 800°C for 2h, and sintering at 1100°C for 2h, Sintering was carried out with a heatin...

Embodiment 2

[0048] The preparation method of the porous metal material provided by Example 2 of the present invention mainly includes the following steps:

[0049] S1, firstly, 3000 mesh CaCO 3 Powder, 5000-mesh SiC powder, binder polyethylene glycol, and silica sol are stirred and mixed, then the defoamer octanol is added, and the ball mill is used to mix evenly to obtain a slurry, and the mixed slurry is put into the needle tube of the 3D printer ; Next, preheat the bottom plate of the 3D printer with a preheating temperature of 45° C., and start printing to obtain a porous ceramic body. Wherein, the nozzle diameter of the 3D printer is 0.2mm, the printing layer height is 0.15mm, and the printing speed is 30mm / s.

[0050] S2, drying the porous ceramic body at 50°C, and putting the dried porous ceramic body into a high-temperature sintering furnace for sintering at 200°C for 2h; sintering at 750°C for 1.5h; and sintering at 1200°C for 2h, Sintering was carried out with a heating rate o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com