Built-in stand type cast-in-place reinforced concrete pillar and construction method

A reinforced concrete and support type technology, which is applied in the direction of pillars, columns, pier columns, etc., can solve the problems of high technical level of carpentry, difficult quality control, complicated operation procedures, etc., and it is easy to control the installation accuracy and improve the construction quality , The effect of facilitating construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

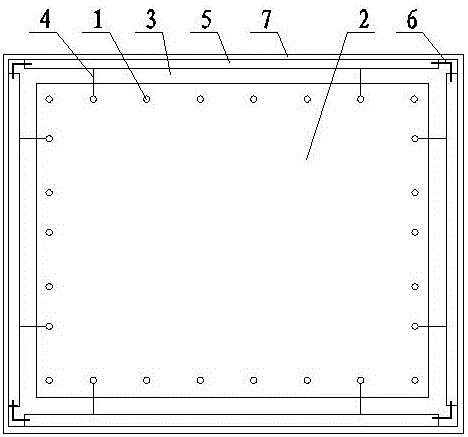

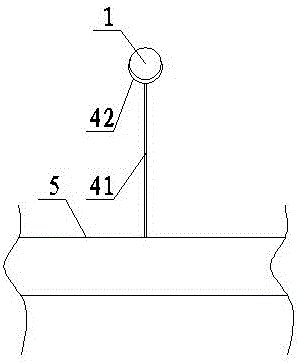

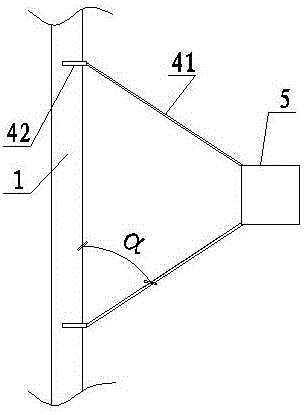

[0025] Such as figure 1 , figure 2 , image 3 The shown built-in bracket type cast-in-place reinforced concrete column includes a concrete column body 2 and a main bar 1 arranged in the concrete column body 2, and built-in brackets are arranged at intervals along the height direction around the concrete column body 2, and the built-in brackets It includes a support rod 4 connected to the main reinforcement 1 and four support rods 5 connected to the other end of the support rod 4. The support rods 5 are parallel to the side of the corresponding concrete column 2, and the adjacent support rods 5 pass through the "L" shape The corner connectors 6 are connected to each other, and the corner connectors 6 are fixedly connected to the support rod 5 by electric welding or rivets. Each side of the concrete column 2 is provided with at least two support rods 4 correspondingly, and the distance between adjacent support rods 4 is not greater than 300mm. The bracket rod 4 and the corne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com