Precise installation method for expansion joint of concrete roadway type steel

A concrete road, precise installation technology, applied in the directions of roads, roads, bridge parts, etc., can solve the problems of inability to adjust again, a large number of human resources, and the difficulty of section steel expansion joints, so as to achieve easy control of installation accuracy and large promotion and application space. , The effect of easy guarantee of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

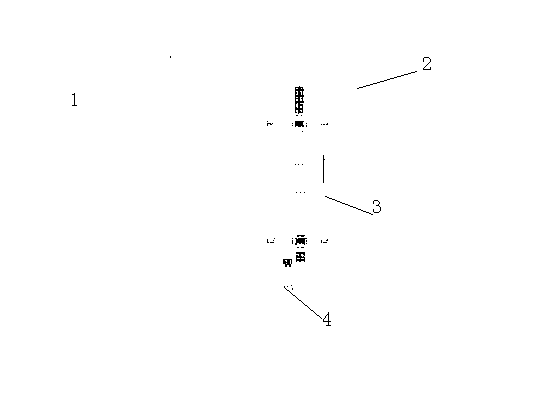

[0038] Such as figure 1 Shown: a method for precise installation of concrete road steel expansion joints, which includes the following steps:

[0039] Step 1, pre-buried expansion joint distribution reinforcement in advance;

[0040] Step 2: Clean up the bottom of the reserved tank, spread the plastic sheet, fill the yellow sand to the bottom elevation of the asphalt surface layer, spread the asphalt and roll it;

[0041] Step 3: Set out the wires according to the design requirements, cut out the reserved expansion joint positions, and clean them up;

[0042] Step 4, using ordinary nuts and bolts, welded into a section steel adjusting device 3,

[0043] Step five, embedding expansion bolts 4 in the reinforced concrete 1, and fixing the section steel adjusting device 3;

[0044] Step 6, install profile steel 2, initially fix the steel expansion joints, check whether the steel expansion joints are flush with the pavement structure with a gauge and a feeler gauge, after meetin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com