Steel suspension box hoisting system with integral hoisting function and hoisting method of steel suspension box hoisting system

An overall hoisting and steel hanging box technology, which is applied in caissons, water conservancy projects, artificial islands, etc., can solve the problems of narrow operating space for steel casings, unguaranteed welding quality, and inability to turn around and utilize them, and achieve higher installation accuracy Easy to control, reduce construction difficulty, simple and fast erection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The following non-limiting examples illustrate the invention.

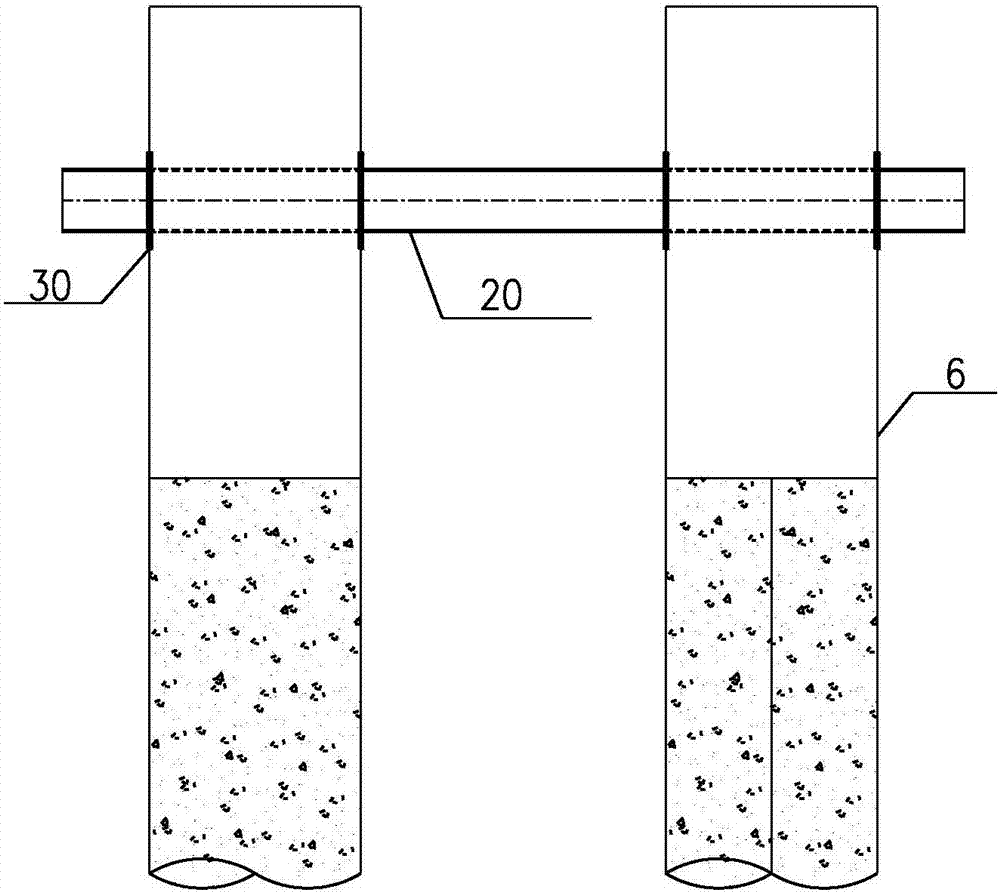

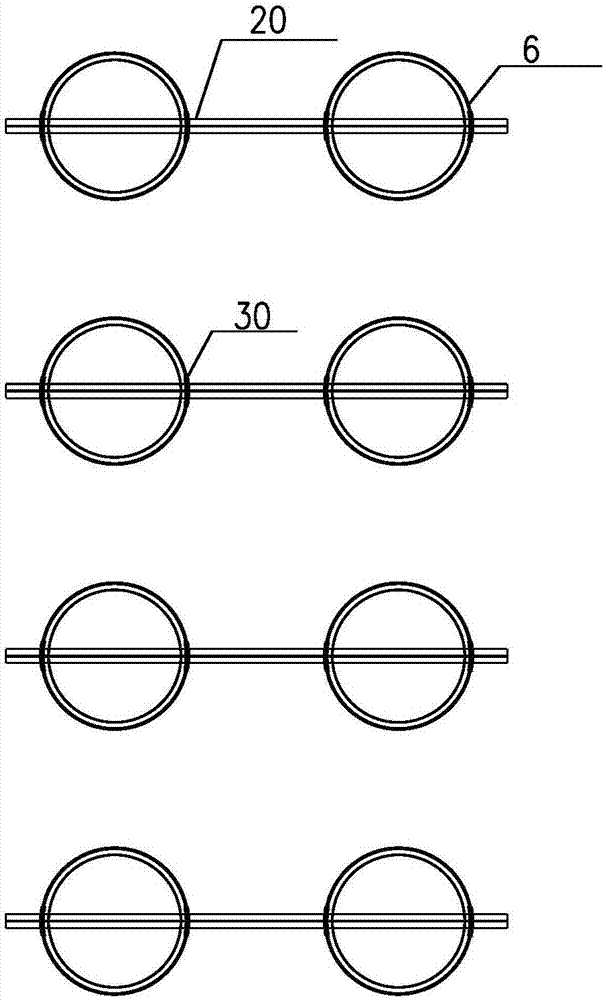

[0069] refer to Figures 1 to 3 , 8, 9, and 12 show a steel hanging box hoisting system for integral hoisting, including a steel hanging box and an assembled platform thereof.

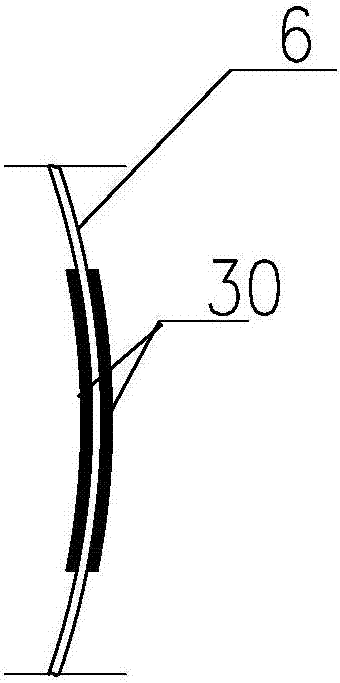

[0070] The assembled platform includes several steel casings 6 and several platform beams 20. The casing walls of each steel casing 6 are prefabricated with through openings, and each platform beam 20 is movable through the openings on each steel casing 6. A whole row of steel casings 6, and the two ends of the platform beam 20 are exposed outside the steel casings 6 at the two ends of the row. As an option, the openings on each steel casing 6 are provided with a positioning guide mechanism. As shown in the accompanying drawings of this embodiment, the positioning guide mechanism is a positioning guide frame, and the positioning guide frame is formed by the outer steel casing 6 near the lower end of the opening position. Consists ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com