Enhanced golf club performance via friction stir processing

a golf club and stir processing technology, applied in the field of golf club fabrication, can solve problems such as reducing momentum transfer efficiency, and achieve the effects of enhancing the hardness of at least a portion of the golf club face, improving the performance of the golf club, and enhancing the hardness of the fa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

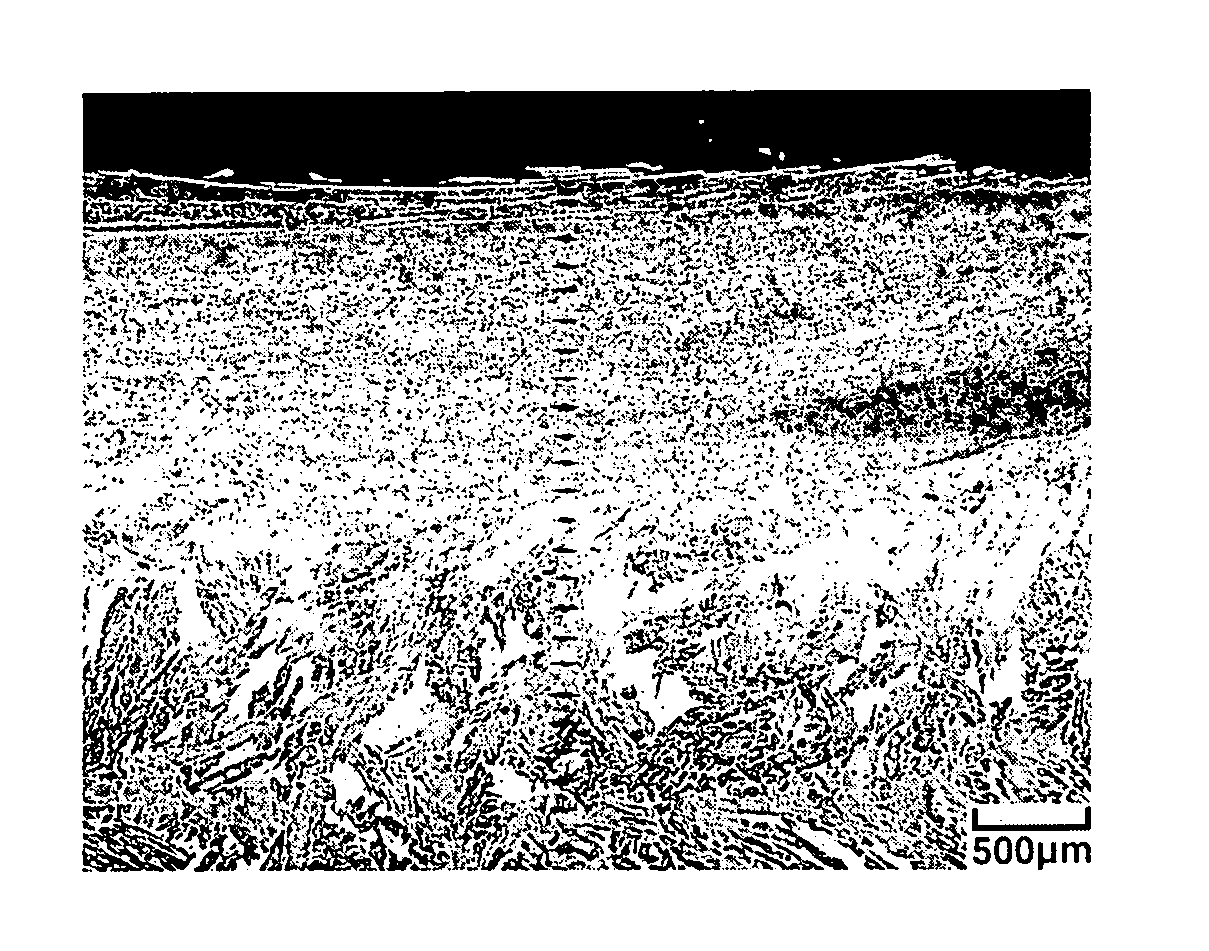

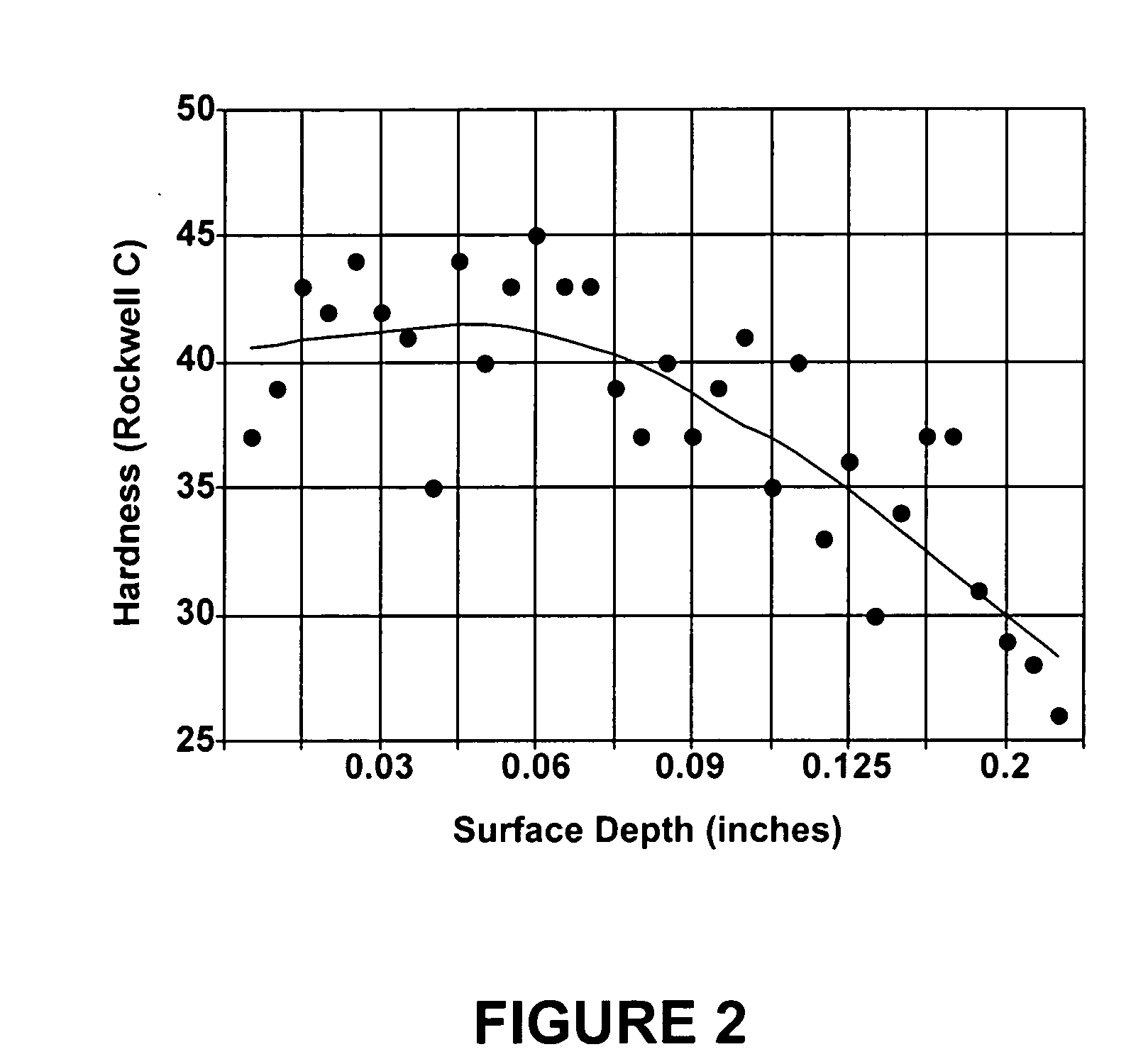

[0023] One of the friction stir processed club heads was cross-section for microscopic examination and hardness testing. FIG. 1 shows an optical micrograph of the cross-section, which illustrates the fine-grained microstructure produced in the surface region by the FSP treatment. FIG. 2 shows the Rockwell “C” hardness values measured at various distances from the surface (hardness indents shown in FIG. 1) using a Knoop hardness tester with a 500 g load. The FSP treatment increased the hardness from about 26 for the bulk material to more than 40 at the face surface.

example 2

[0024] The intact friction stir processed (FSP) six iron was compared to a stock (unprocessed) six iron of the same type by an objective evaluator, who is a professional golf club fitter and expert golfer. This evaluator reported that balls hit with the FSP iron tended to attain higher loft and somewhat greater distance compared to those hit with the stock six iron. The evaluator also reported that the FSP six iron hit balls with a more solid feel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thick | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com