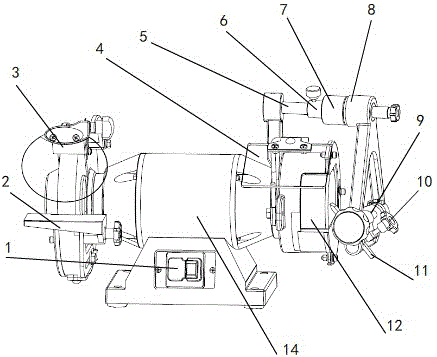

Motor double-shaft-extension cutter sharpener

A knife sharpener and motor dual technology, applied in the direction of grinder, grinding workpiece support, grinding/polishing equipment, etc., can solve the problems of low speed and single function, achieve simple transmission mechanism, beautiful appearance and reduce transmission failure. source effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

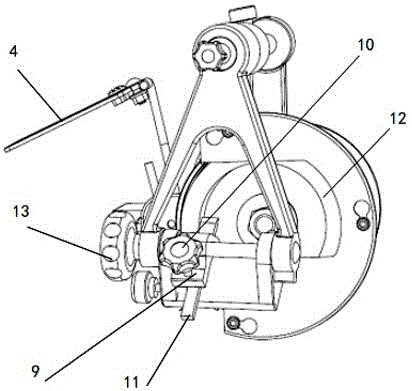

[0010] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing, as figure 1 , 2 As shown, the present invention provides a kind of motor double shaft extension knife sharpening machine, comprises motor 14, and motor 14 has two ends shaft extensions, and wherein one end installs common knife grinding wheel machine, to cutter rough grinding, and the other end of motor 14 installs pendulum grinder Knife device, pendulum knife sharpening device includes grinding cup type grinding wheel 12, hanging shaft 5, adjusting seat 6, adjusting nut 7, swinging seat 8, knife pressing plate 9, knife clamping handle 10 and M8 locking handle 13, knife sharpening cup The molded grinding wheel 12 is installed on the main shaft of the motor 14, driven by the motor 14 to rotate, the suspension shaft 5 is located on the top of the motor 14, and is fixed on the shell of the motor 14, and the suspension shaft 5 is sequentially inserted t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com