Pendulum tool grinding machine

A knife sharpener and pendulum technology, applied in the field of pendulum knife sharpeners, can solve problems such as low rotational speed, achieve the effects of simple transmission mechanism, reduction of transmission failure sources, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

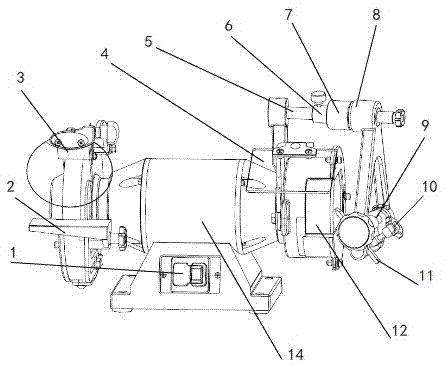

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

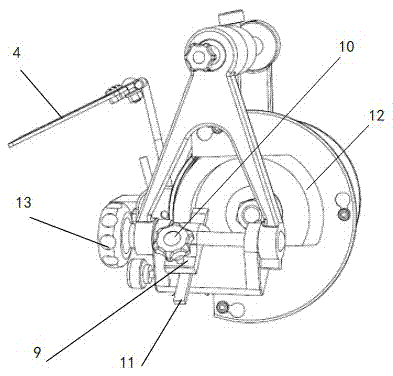

[0013] The motor 14 of the present invention has two ends of shaft extensions, one end drives the common 7-inch emery wheel to run for coarse grinding of cutters, and the other end drives the cup-shaped emery wheel 12 to rotate, and combines the pendulum sharpening mechanism to sharpen the blade. When the grinding wheel on the left side is rough grinding, hold the tool with your hand, and use the bracket to grind the tool. When the right side is finely grinding, use the pressure knife plate 9 and the handle 10 to clamp and fix the knife together, and manually swing the knife sharpening attachment to swing back and forth. The working process moves back and forth like a pendulum, so it is called a pendulum knife sharpener.

[0014] When the tool is clamped, the knife pressing plate 9 is pressed against the tool, and the handle 10 at the rear of the knife pressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com